在我国,冬天没有暖气几乎是不可能生存的,因此,暖气设备需要花费大量的时间、精力和金钱。我国最常见的供暖方式是水(液体)供暖。其组成部分是冷却剂。如何为供暖系统选择冷却剂,如何泵送冷却剂 - 将在文章中介绍。

文章内容

什么是冷却剂?

液体供暖系统中的冷却剂是将热量从锅炉传递到散热器的物质。在我们的系统中,水或特殊的不冻液体(防冻剂)被用作冷却剂。选择时应遵循以下几个标准:

考虑到这些要求,最适合用于加热系统的液体是水。它安全、无害、热容量大,而且运行时间不受限制。但在冬季极有可能停机的供暖系统中,水的作用就不好说了。如果结冰,就会导致管道和/或散热器破裂。这就是此类系统使用防冻剂的原因。在零度以下的温度下,它们会失去流动性,但设备不会损坏。因此,从这个角度来看,为供暖系统选择冷却剂是很容易的:如果系统始终处于监控和可运行状态,则可以使用水。如果是临时住所(别墅)或可能长时间无人看管(出差、寒假),如果该地区可能经常停电和/或长时间停电,则最好向系统中注入防冻剂。

用水作为传热介质的特殊性

从热传导效率的角度来看,水是一种理想的热载体。它具有很高的热容量和流动性,因此可以按照所需的体积向散热器输送热量。我应该使用哪种水?如果系统是封闭式的,可以直接从水龙头倒水。

是的,自来水的成分并不理想,它含有盐分和一些机械杂质。是的,它们会沉淀在加热系统的元件上。但这种情况只会发生一次:在一个封闭的系统中,冷却剂会循环数年,很少需要少量的补充。因此,少量沉淀物不会造成任何实际损害。

如果是开放式加热,则对作为传热介质的水的质量要求要高得多。在这种情况下,水会逐渐蒸发,并定期得到补充 - 水被重新注入。这意味着液体中的盐浓度一直在增加。这意味着元件上的沉淀物也会不断累积。这就是为什么在开放式供暖系统(在阁楼上有一个开放式膨胀水箱)中要注入纯净水或蒸馏水的原因。

在这种情况下,最好使用蒸馏水,但要获得所需的蒸馏水可能会有问题,而且价格昂贵。然后可以倒入经过过滤器过滤的纯净水。最关键的是水中是否含有大量的铁和硬度盐。机械杂质也不在话下,但最容易处理的是几种不同大小的网眼过滤器,它们可以过滤掉大部分杂质。

为了避免购买纯净水或蒸馏水,您可以自己准备。首先,将水倒入并静置,使大部分铁沉淀下来。将静置的水小心倒入大容器中煮沸(不要盖上盖子)。这样可以去除硬度盐(钾和镁)。原则上,这些水已经准备就绪,可以倒入系统中。然后再注入蒸馏水或纯净饮用水。这样做不会像初次注水那样对口袋造成负担。

供暖用防冻剂

除水以外,供暖系统中还会注入特殊的不冻液体--防冻剂。通常是多原子醇的水溶液。不久前,市场上出现了以甘油为基础的防冻剂。因此,现在有三种用于供暖系统的不冻液。

不冻液体的种类及其特性

防冻剂基于两种物质:乙二醇和丙二醇。前者更便宜,冻结温度更低,但毒性很强。不仅喝了会中毒,即使只是浸泡双手或吸入蒸汽也会中毒。第二种不结冰的供暖系统冷却剂以丙二醇为基础。有时它甚至被用作食品添加剂。它的缺点(除了价格)是在温度高于丙二醇时会失去流动性。

尽管乙二醇冷却剂的毒性很高,但购买的人还是比较多。这很可能是因为价格--丙二醇的价格是丙烯的两倍。但是,纯乙二醇防冻剂也具有化学活性,会产生泡沫,流动性更强。泡沫和活性是通过添加剂来消除的,而流动性的增加却不会以任何方式得到纠正。如果再加上毒性,这将是一个危险的组合。只要有一丝可能,这种防冻剂就会泄漏。由于其蒸汽是有毒的,因此不会带来任何好处。因此,如果可能的话,请使用丙二醇。

| 名称 | 物质 | 重量 | 工作温度范围 | 开始结晶 | 热分解温度 | 使用寿命 | 水稀释的可能性 | 价格 |

|---|---|---|---|---|---|---|---|---|

| 迪克西 65 | 一甘醇 | 10 千克 | -65°C ~ +95°C | -66°С | + 111°C | 10 年 | 是 | 850 卢布 |

| 温暖之家--生态 | 丙二醇 | 10 千克 | -30°C至+106°C | -30°C | +170°С | 5 年 | 是 | 1050 卢布 |

| Dixis TOP -30 | 丙二醇 | 10 千克 | -30°C 至 +100°C | - 31°C | +106°С | 3 年 | 是 | 960 卢布 |

| 以甘油为基础的防霜冻剂 | 甘油 | 10 千克 | -30°C 至 +105°C | 4 年 | 没有 | 700 卢布 | ||

| 以丙二醇为基础的 PRIMOCLIMA 防霜剂 | 丙二醇 | 10 千克 | -30°C至+106°C | -30°C | +120°С | 5 年 | 是 | 762 卢布 |

| 热敏剂 30 | 乙二醇 | 10 千克 | -20°C至+90°C | -30°C | +170°С | 10 年 | 没有 | 650 卢布 |

| Teplocom(甘油) | 甘油 | 10 千克 | - 30°C 至 +105°C | 8年 | 没有 | 780 卢布 |

另一个重要的缺点是乙二醇的过热反应非常严重,而且过热发生的温度很低。在 +70°C 时就会形成大量沉淀物,沉淀在加热系统的元件上。沉积物会降低热量输出,再次导致过热。因此,在使用固体燃料锅炉的系统中不使用此类防冻剂。

相反,丙二醇的化学性质几乎是中性的。与所有冷却剂相比,它与其他物质的反应较少,过热发生的温度较高,导致的后果较轻。

上世纪末,人们开发出了一种用于加热系统的甘油基防冻剂。它介于乙烯和丙烯冷却剂之间。它对人体安全,但对垫片的影响不大,对过热的反应也很严重。就价格和温度特性而言,它与丙烯冷却剂大致相同(见表)。

使用防冻剂作为传热介质的系统的特点

在设计加热系统时,首先必须考虑冷却剂。这是因为不冻液体的热容量较低,而且还有其他特性。如果所有设备都是为水设计的,而将防冻剂倒入其中,可能会出现以下问题:

正如您所意识到的,供暖系统的最佳冷却剂是水。它的特性更好,价格也便宜很多倍。如果暖气受到除霜的威胁,则必须浇注防冻剂,但不是汽车防冻剂,而是专门用于暖气的防冻剂。在这种情况下,如果资金充足,最好使用丙二醇。乙烯防冻剂是一种极端情况。它们适用于封闭系统,其中安装了特殊的垫圈和自动锅炉,不会出现过热现象。

为了使买家更容易浏览,冷却剂添加着色剂。在乙烯中为红色或粉红色,在丙烯中为绿色,在甘油中为蓝色。一段时间后,颜色可能会变淡或完全消失。发生这种情况是由于染料的热破坏,但对防冻剂本身的属性不会产生影响。

如何泵送冷却液

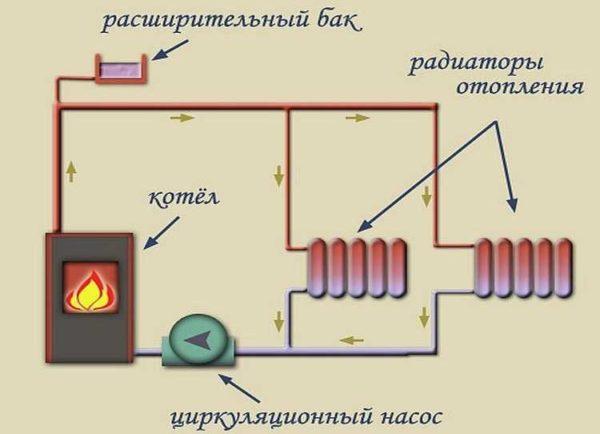

通常只有封闭式系统才会出现问题,因为开放式系统是通过膨胀水箱进行注水的。加热系统的冷却剂只需倒入其中即可。在重力作用下,冷却液会在系统中扩散。加注系统时,必须打开所有通风口。

给封闭式供热系统加注冷却剂有几种方法。有一种不使用技术的填充方式--重力,还有一种使用潜水泵(如 "宝贝 "或特殊泵)的方式,借助这种泵可以对系统进行压力测试。

重力灌装

这种为供暖系统泵送冷却液的方法虽然不需要设备,但却需要大量时间。挤出空气需要很长时间,获得必要的压力也需要很长时间。顺便说一下,他是用汽车泵抽水的。所以你还是需要设备。

我们要找到最高点。通常是其中一个排气口(已拆除)。加注时,我们打开水龙头排出冷却液(最低点)。当有水流过时,系统就加满了。

使用这种方法,您可以从供水处连接一根软管,将准备好的水倒入一个桶中,将其升至入口上方,然后将其倒入系统中。防冻剂也可以倒入,但在使用乙二醇时,需要使用呼吸器、橡胶防护手套和防护服。如果物质沾到织物或其他材料上,也会变成有毒物质,必须销毁。

系统注满水后(从水龙头排出自来水),取一根长约 1.5 米的橡胶管,将其连接到系统入口处。选择入口,使压力表清晰可见。此时我们安装一个止回阀和一个球阀。在软管的自由端安装一个易于拆卸的适配器,用于连接汽车泵。取下适配器后,将冷却液倒入软管(保持软管向上)。注满软管后,使用适配器连接泵,打开球阀并将液体泵入系统。必须确保没有空气泵入。当软管中的水几乎全部泵完后,关闭阀门,重复上述操作。在小型系统中,要获得 1.5 巴的压力,需要重复操作 5-7 次,而在大型系统中,则需要更长时间。

用潜水泵浇注

为了产生工作压力,可以使用马利什(Malysh)型低功率潜水泵抽取供暖系统的冷却液。该泵连接到最低点(而不是系统的排水点)。泵通过一个球阀和止回阀连接,在系统的排水口处安装一个球阀。

将冷却剂倒入容器中,放下泵并打开。在运行过程中,不断添加冷却剂 - 泵不应推动空气。

在此过程中,请留意压力表。一旦压力表的箭头离开零刻度线,系统就已注满。在此之前,散热器上的手动排气口可以打开 - 空气会从排气口排出。系统注满后,应立即关闭。

然后开始升压--继续为加热系统泵送冷却液。当压力达到要求时,停止泵并关闭球阀。打开所有通风口(散热器上也要打开)。空气排出,压力下降。重新打开泵,泵送一些冷却剂,直到压力达到设计值。再次释放空气。重复此过程,直到排气口不再排出空气。

然后可以启动循环泵,再次排出空气。如果压力保持在正常范围内,则泵送供暖系统的冷却液。可以投入运行。

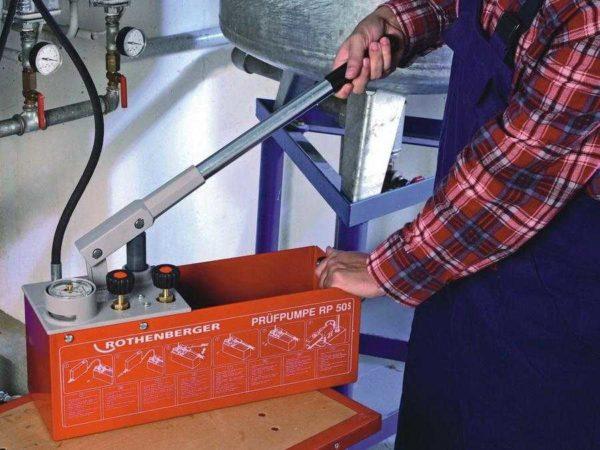

使用泵进行压力测试

系统的填充方式与上述情况相同。在这种情况下,需要使用特殊的泵。它通常是手动的,带有一个容器,用于倒入供暖系统的冷却液。液体从容器中通过软管泵入系统。可以从销售管道的公司租用。原则上,购买是合理的,因为如果使用防冻剂,就必须定期更换,也就是说,有必要再次注入系统。

在给系统充气时,杠杆或多或少都会比较容易操作,而当压力升高时,杠杆就已经比较难操作了。泵上和系统中都有压力表。可以在更方便的地方对其进行监控。然后,顺序与上述相同:泵送到所需压力,排出空气,再次重复。直到系统中没有空气为止。之后 - 同样启动循环器约五分钟(或整个系统,如果泵在锅炉内),然后排出空气。同样重复几次。