In order for modern household appliances to work and for the faucet and shower to have a normal pressure, it is necessary to create a certain level of pressure in the water supply system. One of the components that is responsible for this is a check valve for water. What is this device, how it works, where to put it. About this and much more we read further.

文章内容

What is a check valve on water, its purpose and scope of application

Check valve – one of the types of shut-off valves. The essence of its work is to block the flow in the opposite direction. Its second task is to prevent a drop in pressure.

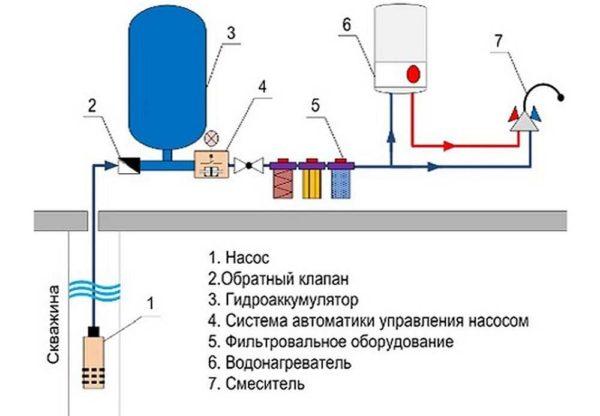

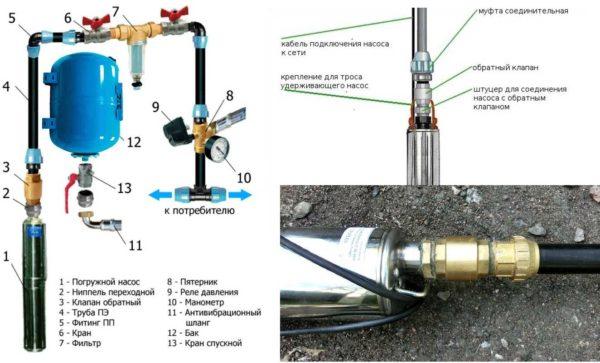

In the case of water supply, it blocks the reverse movement of water. In private water supply systems (from wells or boreholes), the check valve is placed in such a way that it keeps the water in the suction pipe after the pump is switched off. If the system is made on the basis of a pumping station, then, most likely, there is a check valve in its composition. But it is necessary to look in the passport. Is it necessary or not in this case a second one? Depends on the length of the supply line, the cross-section of the pipeline, the pump capacity and several other factors. But more often it is installed.

In apartments or with centralized water supply in the house, it is put before the meter. But here its task is different – to prevent the possibility of “reeling off” readings. The presence or absence of a check valve in this case does not affect the performance. But its installation is a mandatory condition of the operating organization. The seal is placed in such a way as not to exclude unauthorized discharges of water.

Where else may need a check valve for water? In the heating system. Not centralized, but private. There may be circuits in which, under certain conditions, a reverse flow may occur. These circuits are also equipped with a check valve. In the boiler piping, if there is a hygienic shower. These devices can also give a reverse flow. So a check valve is needed.

Types of check valves, its device and principle of operation

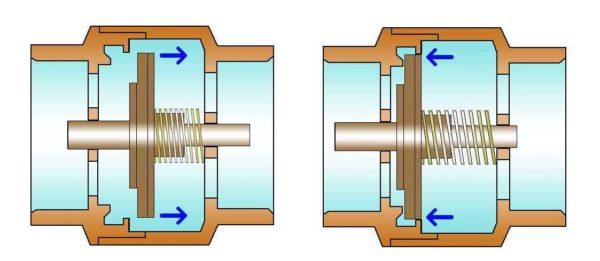

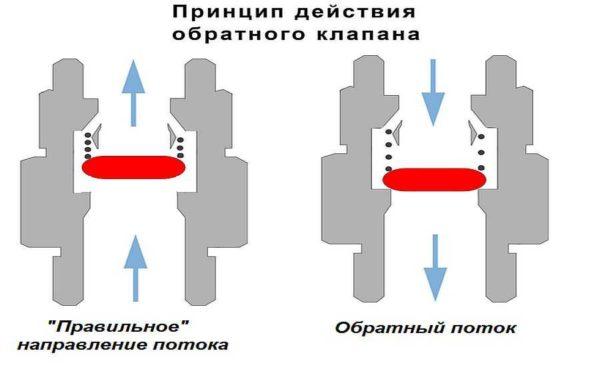

The device of the check valve is simple. There is a seat with some narrowing and a shutoff element. With the “correct” flow, the shutoff element is pushed away from the bottleneck. As soon as the direction changes, it pushes against the seat, blocking the passage. On the body, by the way, there should be an arrow that indicates the “correct” direction of water flow.

Basically, check valves are distinguished by the type of shutoff element. It can be:

- ball type (ball type);

- disc;

- 磁盘

- petal or bivalve.

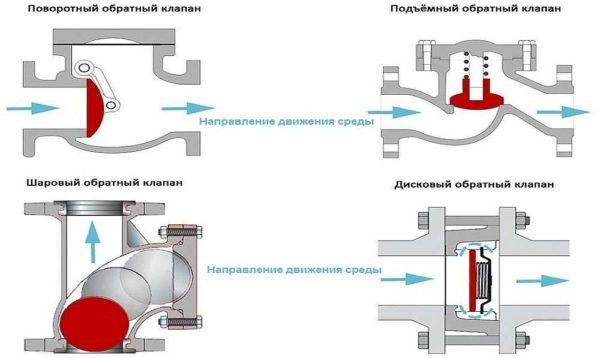

In a ball valve, the ball is “free floating”. He is not attached to anything, carried by water. Quite a reliable system. Except that it does not always cover the seat tightly enough, so it is used quite rarely.

The discs can be lifted or rotary. Rotary, as well as ball valves, open and close under the influence of the water flow. Lifting ones have a spring loaded stem. In the “normal position” the passage is closed; when water pressure appears, it pushes the spring back, pushing the shutoff element upward.

The most common in home water supply systems is the disk check valve. It differs in that the valves of this type can have small dimensions. And the design is simple and reliable. The shutoff disk is placed across the flow, the spring presses it against the seat. The water pushes the spring away, freeing the way.

There is also a double-leaf valve for water. Its shut-off element consists of two halves of the disk (petals), which are fixed on the axis. Hence another name for this model – petal. They are held closed by springs. Water flowing into the water supply pushes them back, folding and pressing them against each other. This type has the least hydraulic resistance. In some cases (with long suction line lengths) this can be important.

Materials, markings, dimensions

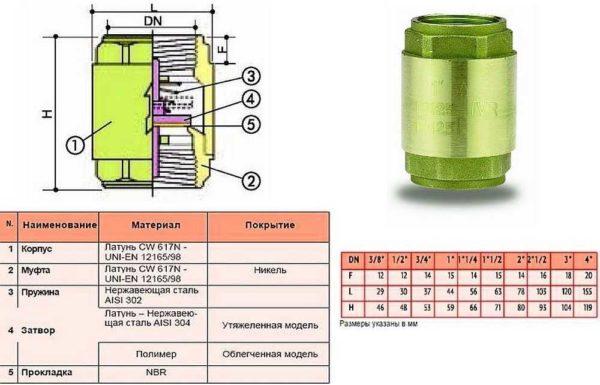

Check valve for water is made of stainless steel, brass, large sizes of cast iron. For household networks usually take brass – not too expensive and durable. Stainless steel is undoubtedly better, but it is usually not the body that fails, but the shut-off element. It is worth choosing it carefully.

For plastic plumbing systems, check valves are made of the same material. They are polypropylene, plastic (for HDPE and LDPE). The latter can be under welding/gluing or threaded. You can, of course, solder adapters to brass, put a brass valve, then again an adapter from brass to HDPE or plastic. But such an assembly is more expensive. And the more connection points, the lower the reliability of the system.

The material of the shutoff element – brass, stainless steel or plastic. Here, by the way, it is hard to say what is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to work. Plastic wears out faster, but it does not jam. In this respect it is more reliable. Not for nothing some manufacturers of pumping stations put check valves with plastic disks. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to “waste” and it is replaced.

What is indicated in the marking

A few words about the marking of the check valve. It specifies:

The nominal passage is designated as DN or DN. When choosing this parameter, it is necessary to be guided by other valves or the diameter of the pipeline. They must coincide. For example, you will put a water check valve after the submersible pump, and to it a filter. All three components must have the same nominal bore. For example, on all of them should be written DU 32 or DN 32.

A few words about the nominal pressure. This is the pressure in the system, at which the shut-off valves remain functional. It should be taken exactly not less than your working pressure. In the case of apartments – not less than the test pressure. It exceeds the standard working pressure by 50%, but in real conditions it can be much higher. The pressure for your house can be found out in the management company or plumbers.

What else to pay attention to

With each product should come a passport or description. It specifies the temperature of the working medium. Not all valves can work with hot water or in the heating system. In addition, it is indicated in what position they can work. Some should stand only horizontally, others only vertically. There are also universal ones, such as disk valves. That is why they are popular.

The opening pressure characterizes the “sensitivity” of the fitting. For private networks, it is rarely important. Unless on supply lines close to the critical length.

Also pay attention to the connection thread – it can be internal or external. Choose based on the convenience of installation. Do not forget about the arrow, which indicates the direction of water flow.

Dimensions of water check valves

The size of the check valve for water is considered by the nominal passage and produce them under all – even the smallest or largest diameters of pipelines. The smallest DU 10 (10 mm nominal passage), the largest – DU 400. There are the same sizes as all other shut-off valves: taps, valves, valves, bends, etc. More to the “sizes” can be attributed to the conditional pressure. The lowest – 0.25 MPa, the highest – 250 MPa.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Further are the main ones, and they are usually purchased by enterprises. You will not find them in the retail network.

Also, note that different companies have the same nominal passage, the external dimensions of the device may differ. In terms of length – it is clear. Here the chamber, in which the shut-off plate is located, can be larger or smaller. The diameters of the chambers also differ. But the difference in the area of the connecting thread can only be due to the thickness of the walls. For private houses, this is not so terrible. Here the maximum working pressure is 4-6 Atm. But for multi-storey buildings it can be critical.

How to check

The easiest way to check the check valve is to blow into it in the direction that locks it. Air should not pass through. At all. Not at all. Also, try pressing down on the plate. The stem should move smoothly. No clicking, no friction, no misalignment.

Also inspect the seat and disk. Especially where they fit together. Everything should be smooth/smooth. The tightness of this type of valve depends on the exact fit. In more expensive models, a rubber/polymer/plastic sealing ring is installed on the plate. Needless to say, it should lie flat, without waves, there should be no scratches or burrs.

Where to put the check valve

To begin with a couple of words about how the check valve on water is marked on the schematics. For him there is a special icon. This is two triangles, turned vertices to each other. One of the triangles is colored, one is not. The direction of flow of the working medium is indicated by an arrow. In the opposite direction, the flow is closed.

In general, there is no clear indication of where exactly to put the check valve. It is important that it fulfills its functions, and the place of its installation is a secondary matter. It is necessary for the water supply or heating system to work correctly. And its specific place is determined by the parameters of the system and the convenience of maintenance. Exception – the water inlet in the apartment. Here you will be clearly told, the check valve is put before the counter and no other way.

For example, in the boiler piping on the supply pipe there should be a check (shut-off) valve. It prevents the entry of hot water into the system, which can occur when the water is heated and this will create increased pressure, which can “transfer” the plumbing. In such a case, it is better to put the backflow preventer closer to the source of hot water, so as not to expose the thermal load of other elements of piping and cold water pipes, which are not always today of metal.

On a well or in a well with a submersible pump

If you look for information on where to put the check valve on the submersible pump, the information can be contradictory. Some advise to put it immediately at the pump outlet, others – at the entrance to the house or in the pit, if it is a well. Strangely enough, all three options work. Just for different cases.

Put the check valve in the house or in the pit above the well can be installed if the vertical section of the pipeline does not exceed 7 meters. The length of the horizontal section (if it is not inclined) does not play a role. With such a length of the pipeline, water will not flow back into the well or borehole.

If the water mirror is below seven meters (the pump pulls water from a depth of more than 7 meters), the check valve is placed after the pump. You can immediately (as in the photo above), or you can put a filter, then the check valve. It is allowed to install the valve a couple of meters above the water level. This does not play a big role. But this way of installation – at depth – is inconvenient for maintenance. Sooner or later the valve will either have to be cleaned or replaced. If it is in a well or in a well, it is necessary to take everything to the surface. The replacement itself takes a few minutes. It takes about five minutes to unscrew the threads, remove the old one, check/clean or put a new one on. But all the prep work is hard, wet and messy. So whenever possible, move the check valve into the house or a pit.

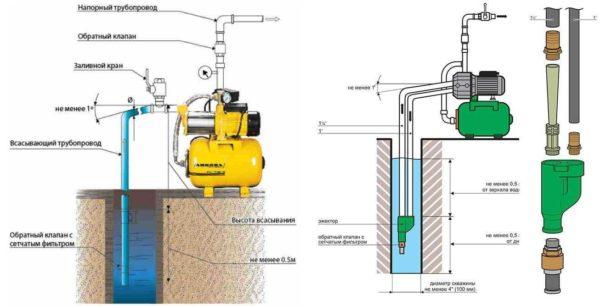

With a pumping station

As already said, some models of pumping stations have a check valve. Do I need to put a second one on the suction line? Again, if the water rises less than 7 meters, you can do without it or put it at the entrance to the house.

If the vertical rise is greater, it should be placed at the inlet. Why? Because when the pump is off, the water will flow back. And when you turn on, pumping will be air, and only then water. And immediately say that not all stations normally tolerate this mode. Therefore, if you hear that the water after turning off the pump returns to the well or well, it is better to redo the system.

As you can see, in this scheme, the check valve is installed at the end of the pipe. Since it is sensitive to contaminants, it is better to purify the water beforehand. You can screw on standard filters, and you can put with a built-in mesh. Which option is better? Probably, after all, the first. First, you can collect in series as many filters as you need to supply relatively purified water. Secondly, it is cheaper to change one filter or one valve than a filter with a valve. There is more fiddling during installation, but not critical.

Why the valve does not work

A sign that the check valve is broken – the system can not hold the pressure built up. More precisely, a broken valve is only one of the reasons. The other is a leaky supply line. So you’ll have to check both options.

If you look carefully at the device of the check valve, you will realize that there is nothing to break. Possible breakdowns are a wedge on the stem and debris that prevents the disk from tightly pressing down. There may also be wear on the locking plate. The latter is incurable, we replace it immediately. Wear is also the grooves from the seat on the sealing ring. So the presence of a seal is an ambiguous advantage. The rubber is pressed through and the valve starts to “leak”.

If the stem is bent or jammed, in some cases you can correct it. As a rule, this does not last long, and again it will jam quite soon. If the locking plate has been clogged, it can usually be cleaned. And to prevent this situation from happening again, put a filter in front of the check valve. If it is already there and the water is still too dirty, there are several options:

- either put in a second, smaller filter;

- or raise the end of the pipe from the bottom;

- clean or deepen the well or borehole.

If we are talking about a submersible pump such as “Baby”, to reduce the amount of turbidity will help to dampen the vibrations that occur during its operation. Ways vary from using springs in the suspension, to rubberized suspension. This really helps. Another option is to put a wide-mouth barrel in the bottom of the well, and put a pump in it. Less silt and sand will rise.

The next remark. If after a long period of work without failures, check valves began to “fly” one after another, perhaps the water level has changed and you need to move the suction point. The second option – sand or silt clogged pipes and you need to rinse the pipeline elementary. Well, and check it for leaks. By the way, if the station does not gain pressure, then the matter is most likely not in the check valve, but in the pear, its mounting, nipple, etc.

I recently had a water check valve installed at home, and it’s been a game-changer! No more backflow issues, which used to be such a hassle. Super easy to maintain too. Really glad I made the switch—definitely worth it for peace of mind!

Totally get you! I had a similar setup at my place after dealing with some nasty leaks. Once I got the valve in, it was like a breath of fresh air! Maintenance became a breeze, and I felt way more chill about my plumbing. Solid investment, for sure!

Absolutely! I had this old leaky faucet that was driving me nuts. Once I replaced it, it was like night and day. Maintenance was so easy, and I didn’t stress about water damage anymore. Definitely worth it to tackle those projects!

Totally get you! I had a similar issue with a squeaky door. Once I oiled it up, it was like magic! So simple, but such a game changer. Now I can just glide in and out, no more annoying sounds. Definitely worth diving into those little fixes!

Имя Kieran относится к мужчине.

Комментарий:

“Привет всем! Я прочитал эту статью и хотел бы поделиться своим мнением. Мне кажется, что поднятые в ней вопросы действительно важны и требуют внимания. Особенно хочется отметить, как важно сохранять баланс между традициями и современными подходами. Я надеюсь, что общество будет двигаться в сторону более открытого и конструктивного диалога. Какие у вас мысли по этому поводу?”

Totally get you! I had a leaky showerhead that just wouldn’t quit. Once I switched it out, my stress disappeared. It felt amazing not worrying about water wastage. A little DIY can make such a difference–it’s like a mini victory! Cheers to tackling those home projects!

Totally feel you! I installed a water softener last year, and it’s been a lifesaver, too. No more scale buildup—my pipes and appliances are so much happier now. It’s like finally smoothing out those rough edges, you know? Peace of mind is priceless!

I totally get that! I installed a water softener too, and it’s like magic. No more scrubbing or worrying about my kettle; it’s all smooth sailing now. It really does take a load off, making day-to-day life feel way easier. Best decision ever!

Totally feel you! I had a similar game-changer moment when I installed a sump pump. No more worrying about flooding in my basement. It’s made life so much easier, just like your valve. Peace of mind is priceless, right? Cheers to home upgrades! 🛠️