To supply water to the house or irrigate the site, a well is often used. If earlier they could do with a gate and a bucket even in a private house, but today even at the dacha this option is no longer satisfactory. After all, you can get the conveniences of the modern level by installing a pump for the well. To make the system work properly, you need to pick up the equipment correctly.

Contents of the article

Types of pumps and their use for wells

According to the method of installation, pumps are surface and submersible, according to the principle of operation – centrifugal and vibrating. And in the submersible and surface there are models of both types. So it turns out four varieties of equipment. To choose the right pump for the well, you need to understand the weaknesses and strengths of each type of this equipment.

Surface

The surface pump is attractive due to the simplicity of installation and mobility. The equipment itself is on the surface, and only the hose is lowered into the well. Another point – a small cost, which is explained by the fact that there is no need to make the housing hermetic.

The surface pump for a well is very easy to connect

Despite all the advantages, surface models can be used for a shallow well. The maximum depth is 8 meters, but preferably less. This is the main limitation and their main disadvantage. The second negative point is the low efficiency – no more than 25%. This is the lowest indicator among all pumps.

Why do not make more powerful equipment of this type? Because due to the peculiarities of the working cycle, the liquid that is lifted from a great depth is saturated with air bubbles (the phenomenon is called cavitation). If water with a large number of air bubbles gets into the working organ, it will burn out.

The problem can be circumvented with an ejector, which is built into the pipeline lowered into the well. The depth from which surface installations with an ejector can pump water is much greater – up to 15 meters, but the efficiency is even less – in the region of 15%, which means that electricity bills will be large.

Submersible

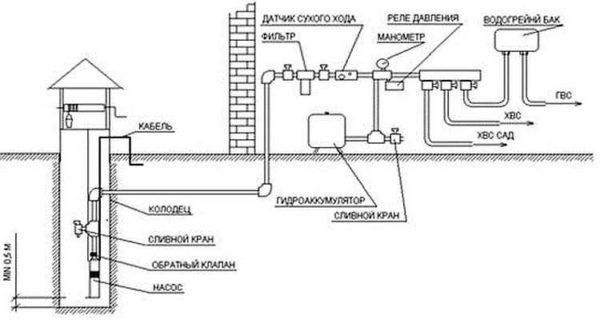

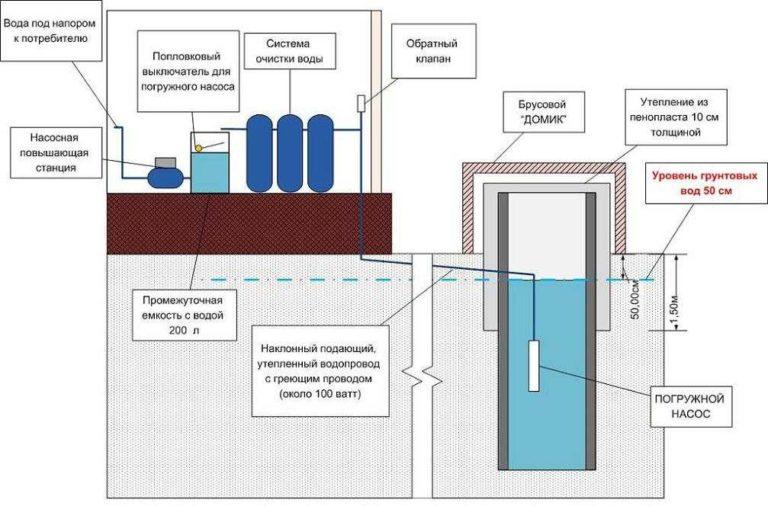

Submersible pumps for the well in the best case have an efficiency of about 45%, on average – about 35%. From the name it is clear that they are in the water column. This is the main difficulty – it must be well fixed, and then through the wall of the well to lead the main line to the house.

Fix a submersible pump for a well usually with the help of a chain or a strong cable (optimally – made of stainless steel). They are attached to a special lug in the upper part of the body, the free end is wound on a gate, such as the one that used to lift buckets. With the help of this device, if necessary, lift the equipment to the surface.

Read more about water supply from the well (with schemes and description of installation) here.

It is no less important to choose the position of the submersible pump in the well. It is necessary to make it so that there is at least a meter to the bottom (otherwise sand and silt can get in). At the same time it is necessary that there is a sufficient water layer above the casing (see the instructions, different models have different requirements). If the height of the water column in the well is small, this can be a problem. Although there are models that allow horizontal installation in the well (eg, Aquario ASP).

| Name | Type | Pressure | Capacity | Power | Manufacturer | Price | Notes |

|---|---|---|---|---|---|---|---|

| Grundfos SB 3-35 M | centrifugal, submersible | 33 м | 6,6 m3/h | 800 W | Italy | 250$ | Overheating protection |

| Grundfos SB 3-35 AW | centrifugal, submersible | 33 м | 6.6 m3/h | 800 W | Italy | 330$ | Float switch |

| Grundfos SB 3-45 A | centrifugal, submersible | 43 м | 6,4 m3/h | 1000 W | Italy | 280$ | Float switch + overheating protection |

| Baby 10 m/ 16 m /25 m /40 m | vibrating, submersible | 40 м | 0.43 m3/h | 250 W | г. Livny | 24$ – 34$ (depending on cord length) | Lower water intake, diameter not less than 100 mm |

| Malysh-M-L 10 m/ 16 m /25 m /40 m | vibrating, submersible | 40 м | 0.95 m3/h | 240 W | г. Livny | 23$ – 33$ | Upper water intake |

| Malysh-K 10 m/ 16 m /25 m /40 m | vibrating, submersible | 40 м | 0.95 m3/h | 240 W | г. Livny | 25$ – 34$ | Lower water intake + thermal protection |

| Malysh-3 10 m/ 16 m /25 m /40 m | vibrating, submersible | 40 м | 0,43 m3/h | 160 W | г. Livny | 25$ – 34$ | Lower water intake, diameter not less than 76 mm |

| Jileks VODOMET PROF 40/50 A | centrifugal, submersible | 50 м | 2,4 m3/h | 520 W | Russia | 160$ | Float + presence of solids 2 kg/m3 |

| Jileks VODOMET PROF 40/75 A | centrifugal, submersible | 75 м | 2.4 m3/h | 670 W | Russia | 205$ | Float + presence of solids 2 kg/m3 |

| Jileks VODOMET PROF 55/35 A | centrifugal, submersible | 35 м | 3.3 m3/h | 460 W | Russia | 135$ | Float + presence of solids 2 kg/m3 |

| Jileks VODOMET 55/35 M | centrifugal, submersible | 35 м | 3.3 m3/h | 460 W | Russia | 135$ | Presence of solid particles 2 kg/m3 |

| Vodolei BCPE 0,32-25 U to 140 U | centrifugal, submersible | from 25 m to 140 m | 1.2 m3/h | 440 W to 2500 W | Promelectro | 132$ – 290$ | Protection from overheating |

| Vodolei BCPE 0,5 (from 16 W to 100 W) | centrifugal, submersible | from 16 m to 100 m | 1,8 m3/h | from 400 W to 2050 W | Promelectro | 115$ – 255$ | Protection against overheating |

| Vodolei BCPE 1,2 (from 12 W to 80 W) | centrifugal, submersible | from 12 m to 80 m | 4.3 m3/h | from 500 W to 2820 W | Promelectro | 140$ – 280$ | Protection from overheating |

| Vodolei BCPEU 0,5 (from 16 U to 63 U) | centrifugal, submersible | from 16 m to 63 m | 1.8 m3/h | from 400 W to 1270 W | Promelectro | 125$ – 220$ | Overheating protection, smaller diameter |

Some explanations to the table. There are many more models with different characteristics than presented in the table. Here and presented only some, so you can see the approximate range of prices and characteristics. In the description to the pumps for wells Vodolei is in parentheses the index of models, indicating the height of lift for equal performance. At pumps “Baby” in the index is the length of the cord with other equal characteristics.

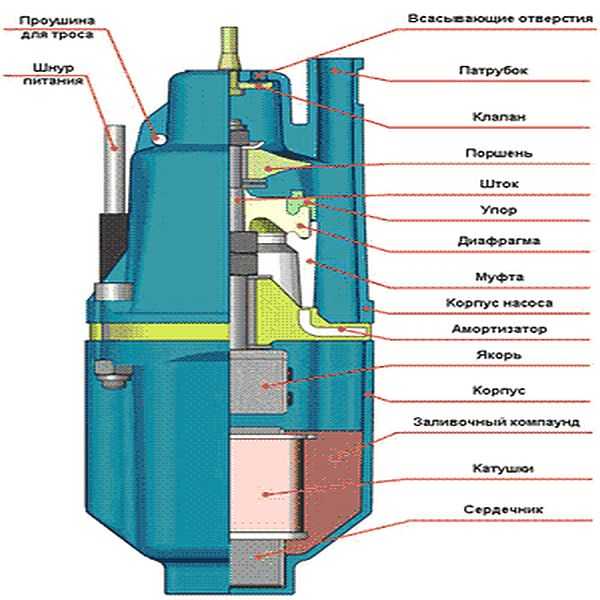

Vibrating

In a vibrating pump for a well, water pumping is carried out with the help of a diaphragm or a piston. They alternately, then create a rarefaction, due to which the water is sucked in, then pressurize, pushing it into the outlet. Such a working cycle creates quite a noticeable vibration, that’s why such devices are called vibration pumps. Vibrating pumps can be of the external or submersible type. Submersible vibro pumps work quieter – the water muffles the noise, outdoor ones are noisy devices.

Vibrating pump – the device is simple, inexpensive, has small dimensions and light weight, thanks to which it is very mobile (weight – a few kilograms) and can be used for pumping small volumes – at least in a barrel it can be lowered, just do not forget to turn off in time. All this is true, but there are many disadvantages:

- Vibration negatively affects durability, the service life is small.

- Demanding quality of power supply. When the voltage drops to 160 V, the performance falls by half, with an increase in power increases, but not so critically. Frequent fluctuations lead to accelerated wear, so in a pair to the vibrating pump for the well buy a stabilizer, you can the simplest, on the relay.

- Badly tolerates the presence of sand and other debris in the pumped water. The design is such that filters at the inlet will not put, and the presence of abrasive particles (grains of sand) quickly lead to failure of the piston or diaphragm. Therefore, such filters should not be used on sandy soils.

These are official data. And unofficial, from experience, say that such pumps have to be changed often – they quickly burn out. So this type is good as a temporary solution – for periodic use at the dacha. For a guaranteed water supply to a house with permanent residence, it is better to take centrifugal models.

| Name | Type | Suction depth | Lift height (head) | Capacity | Power | Price |

|---|---|---|---|---|---|---|

| DIOLD NP-0,4 | Surface vibe | 8 м | 32 м | 2100 l/h | 400 W | 50$ |

| DIOLD NPV-800 | Surface vibe | 8 м | 60 м | 3000 l/h | 800 W | 52$ |

| METABO HWA 3500 INOX | Surface vibe | 8 м | 45 м | 3500 l/h | 1100 W | 170$ (dry run and overheating protection) |

| METABO HWAI 4500 INOX | Surface vibe | 8 м | 48 м | 4500 l/h | 1300 W | 170$ (dry run and overheat protection) |

| PATRIOT R 900 | Surface garden | 8 м | 40 м | 3800 l/h | 850 W | 75$ (float, body stainless steel) |

| VIKHR PN-370 | Surface centrifugal | 9 м | 30 м | 2700 l/h | 370 W | 40$ (cast iron housing) |

| VIHR PN-1100CH | Surface centrifugal | 9 м | 50 м | 4200 l/h | 1100 W | 95$ (cast iron housing) |

| JAMBO 60/35 P | Surface centrifugal | 9 м | 35 м | 3600 l/h | 600 W | 85$ (polypropylene housing) |

| JAMBO 60/35 h | Surface centrifugal | 9 м | 35 м | 3600 l/h | 600 W | 95$ (cast iron body) |

| JAMBO 70/50 CH | Surface centrifugal | 9 м | 50 м | 4200 l/h | 1100 W | 120$ (cast iron body) |

| AL-KO Jet 3000 Inox | Surface centrifugal | 8 м | 35 м | 3100 l/h | 650 W | 100$ (stainless steel housing) |

Centrifugal

In these units, water pumping occurs due to the movement of impellers-blades mounted on the central shaft. These are located in the pump’s working chamber. This chamber is filled with water. As the vanes rotate, a lower pressure is created in the center and a higher pressure is created at the edges. This difference is what makes the water move.

It is the centrifugal well pump that is bought more often. It is less sensitive to the presence of sand in the water, its working depth is greater. From the negative – a higher price, but also the service life is much longer.

Here is an example of a submersible centrifugal drainage pump – Vikhr DN 900. It can be used to pump out water from flooded cellars, small pits used for drainage, etc. In general, where the water is not very clean and can put other devices out of order.

To supply water from a well, you can use deep well pumps. They are mainly used for water intake from wells, but here they are also applicable. Here is a short video about these devices.

With or without a hydroaccumulator

When organizing water supply from the well, many water from the pump pumped into the hydroaccumulator (storage tank), and from there it is already fed to the water points – taps, appliances. They put such an accumulator in the attic. It is needed to solve two problems at once:

- Increase the service life of the pump. If the water supply system is built without a hydroaccumulator, the pump is turned on whenever the house opens a faucet, triggers household appliances that need water. Often such switches on – just for a second or two, and each start – a minus to the service life. If there is a storage tank, then a small flow rate comes from it. The water level is controlled by a float mechanism. It turns on the pump only after the water level in the tank reaches a critical level (set during installation).

- Increase the service life of the entire water supply system, including appliances connected to it. The fact is that each switching on of the pump is a water hammer. Since for a day the number of inclusions is counted in hundreds, the service life of the equipment in the system is significantly reduced. If there is a hydroaccumulator, all the hydraulic shocks from the internal wiring and household appliances are cut off – they are damped by the thickness of water in the accumulator.

So the storage tank in the water supply – a useful thing. What volume should be hydroaccumulator? Depends on the flow rate (how to count will tell below), put and 25 liters, and 150 liters, but the more reserve, the better – less often the pump will be turned on. As a bonus of installing a storage tank – some reserve of water in case of power failure.

How to purify water from the well read here.

Selection by technical characteristics

Determine what type of well pump you will put – this is the least part of the task. Then you need to choose the manufacturer, and then – to find a suitable model that can supply water in the right amount with the required head. These are the two main characteristics when choosing a well pump – capacity and head.

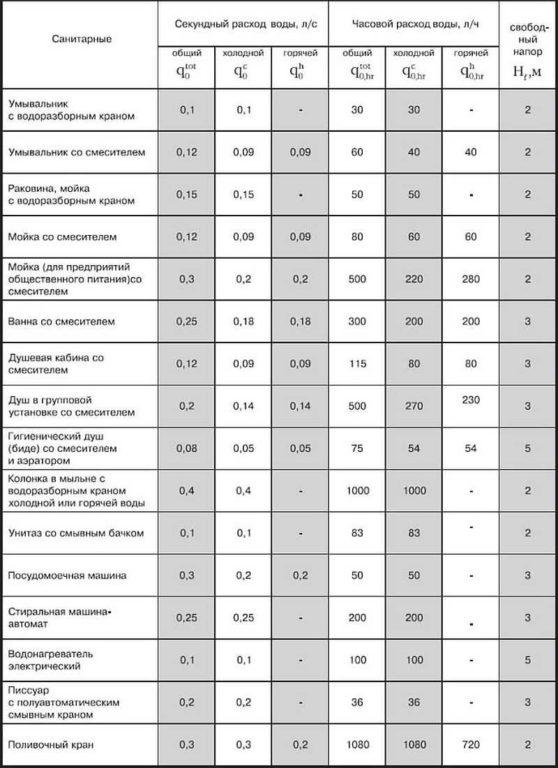

Capacity (flow rate)

The required capacity of the pump for the well (usually denoted Q, measured in l/s or l/h, less often in cubic meters/h) is calculated based on the composition of the system. It has some number of faucets, toilet, bidet, household appliances with water consumption. The water flow rate for all these consumers is calculated (usually in liters per second). The flow rate can be taken as an average of 0.2 liters per second for each point, or you can find it in the table.

It is not necessary to add a “just in case” reserve to this figure. The calculation already includes more than twice the reserve, and situations where all points of consumption are switched on at the same time are practically excluded. At most, you can simultaneously work half of the consumers, and even that for a few seconds, and in reality – even fewer points are simultaneously turned on. So the reserve is really large, and there is no need to increase it.

Head

The pressure of the pump (denoted by the letter H, measured in meters) – this is the value to which it will be able to raise water. When choosing a pump for a well, you need to know:

- The depth from which the water will be lifted (well depth).

- The rise to the highest point of consumption. If there is a hydraulic accumulator this is its height, if there is not – this is usually the highest shower in the house.

- The total elevation (Hgeo) is calculated as the sum of the depth of the well and the level at which the highest point of water consumption is located.

- The distance the water must be transmitted (L) horizontally, including the elevation to the highest point.

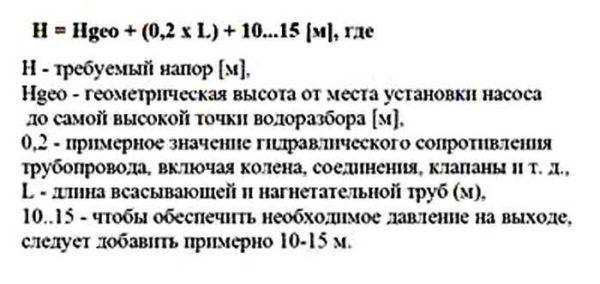

The formula for the exact calculation is complicated, so that when selecting a pump for a well, usually use a simplified version. One of them is on the photo.

According to the figure found and the head of the pump for the well is selected.

Choosing a model by graphic characteristics

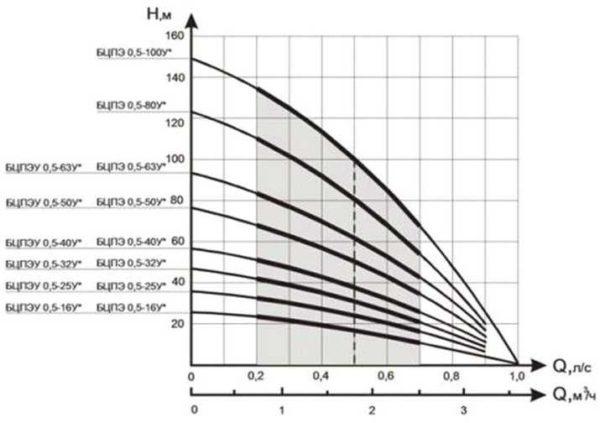

After you have determined the head and performance, it is necessary to choose a model. This is done according to the graphs showing the technical characteristics (on the photo below).

Similar graphs are in the technical specifications. You find on the coordinate axes those values that you have previously calculated, find the point of their intersection on the plane. It should be located in the middle part of the graph (in the figure, this field is colored gray), then the pump will work in normal mode, which guarantees its long service life. What to do if the point is outside the required zone? Look for another model, this one is not suitable for your case.

The point has been found, it is in the middle part of the operating characteristics. Then the graph closest to the point is, and this will be your pump model (they are signed). What if more than one model fits at the same time? This happens if the point is about midway between the graphs. Take the one whose characteristics are above the point.

How to make a house for a well is described here (with step-by-step photos).

What to pay attention to when choosing a pump for the well

In addition to the technical parameters and the type of pump, you will need to pay attention to a few additional parameters:

- Protection against idling is very desirable. This is a situation when the pump is working, but there is no water. Such moments often lead to breakdowns, sometimes just worsens the pressure, “sucked” air, etc. In such a case it is necessary to take the pump to a service center, perhaps it can be resuscitated.

- Availability or possibility of retrofitting with a float sensor (also called “frog”). This is a small sealed pear attached to the body with a piece of cable. The sensor floats in the water. When it drops below a certain level, the pump is switched off. It will turn on after the sensor goes up (if the taps are still open). This, by the way, is another advantage of the scheme with a hydroaccumulator – when the pump protection is triggered, you do not have to wait for it to turn on, you will use the water that is in the tank. Shutdown of the pump you will not even notice.

- Protection against overheating. When working continuously for a long time, the well pump can overheat. To prevent this from happening, and make this protection.

- Pay attention to the quality of assembly and fit of all parts of the housing. No backlash, no surface defects (cavities, burrs, etc.), no mismatch of parts in size. These are all signs of poor quality.

- Length of the supply cable (can be up to 40 meters). This parameter can also be important – not everyone has electricity to the well.

- Temperature mode. If you choose a pump for the well for a summer house seasonal visit, there is no special difference (if stored in a warm room). If the equipment will work all year round, it is necessary to choose models that can operate in a small plus temperature.

The choice of pump for the well on this can be considered complete. Not a simple matter, but it is necessary to track all these points. Then the equipment will work for a long time and without problems.

When I picked a well pump for my place, I just checked the flow rate and depth first. Got some good advice from a buddy who’d been through it. It made all the difference! Solid pump and good pressure now. Just make sure to read up a bit!