Building a house or renovating it often requires welding work. It takes a long time to ask for help from professionals each time. And most of the work does not require high qualifications. If you are planning construction or repair, you have a large dacha or house, it will be cheaper for you to do all (or almost all) welding work yourself. And we will tell you how to choose a welding machine for home and dacha.

文章内容

Electric welding machine for home and dacha, types, advantages and disadvantages

Both at home and in production, electric welders are most often used. For the most part, household models operate from the 220 V network, but you can find machines that are powered by a three-phase network of 380 V. Some of them weld on direct current, some – on alternating current.

Transformer welding machines

Give an output of alternating current welding transformers. Their design is simple and reliable: two step-down transformers with the possibility of adjusting the output current. Adjustment is not very accurate, and its range is small. And this is one of the disadvantages. This unit rarely breaks, but it weighs a lot: even a household, not the most powerful model, will drag on a couple of tens of kilograms. Industrial models can weigh a hundred kilograms and even more.

About two decades ago, electric welding was only on “transoms”. Today, this is far from the case: DC welding current sources are more widespread. And all because of the shortcomings of the transformer welding machine. The current it produces is alternating, its polarity is constantly changing. When welding, this is expressed in the fact that the arc “jumps”, which causes a large number of sparks. The arc is difficult to control, obtaining a quality weld is possible only with a highly skilled welder. But even under this condition, they are used only for welding ferrous metal: the possibility of adjustment is limited, fine-tuning is almost impossible, which limits the scope of their use.

Another significant disadvantage: when working, especially when igniting the arc, the voltage in the network drops significantly. Such surges do not like modern electronics, which we have more than enough in the house and at the cottage. Therefore, for home use transformer welding machines are bought very rarely. Even though they are reliable and inexpensive. If someone has them, they stand in the garage or shed as a backup “just in case”.

Rectifiers for welding

In essence, these are the same welding transformers, but they have a rectifier unit at the output. They are sometimes referred to as DC welding transformers. They produce a constant current, because of which the arc is more stable, it is easier to work, but experience is still needed, albeit to a lesser extent than on transformers. Their disadvantage: power losses at the rectifier, but the constant arc is compensated for.

The design is reliable, there is nothing to break: a step-down transformer, rectifier unit and regulation. These are all components of the welding rectifier. The price is a little higher than for transformers. But also this type of welder is not popular today. The disadvantages are almost the same: a large mass, voltage surges when working. Connecting the welder to the household network and working with it will cause voltage fluctuations and, consequently, dissatisfaction of neighbors.

Welding inverters

As soon as they appeared on the market, were an expensive treat. With the development of technology and the emergence of a new element base (IGBT transistors), their characteristics have become better, the weight is less, and the price is lower. Modern household welding inverters can weigh from 3 kg and produce a current of 160-180 amperes, which is enough to work with an electrode 3-4 mm. Their cost is about 3-6 thousand rubles. Not very much, given the rates for the services of welders.

They give out a stable arc, it is easy to control it. Get a good seam can be a non-professional, and even with a little practice. The design is such that it allows you to adjust the welding current and voltage in a wide range. This allows you to use the same machine for welding different metals, different thicknesses.

Another important advantage – inverter welding does not “sit” the network. Almost does not affect it in any way. The only condition: the socket for the welding machine must be grounded. Protection class of these units IP21, which means that they are grounded through the power grid. Therefore, the connection of the inverter welding machine to the household network only through a grounded socket.

If you need a mobile, light welding machine for home and dacha, choose it from welding inverters. Learning to weld with it is simple. Super-welder will not become soon, but almost all the work at home or on the construction site can do themselves after a short period of time.

Welding machine for home and cottage: transformer or inverter?

Questions about what welding machine is better – inverter or transformer – does not arise almost no one. Even at the enterprise, where there are good transformers, when inverters appear, they stand idle. But for home and no questions: inverters are definitely better. And here’s why:

The only spoon of tar adds prices: it is higher than for transformers. But there are good brands that cost a little. For example, inverters Resanta. For professional use, they are suitable with difficulty, but as a welding machine for home or for the dacha – very even well proved themselves. Prices for household modifications (140-160 Ampere) 110-130$.

Welding automatic machines (semi-automatic)

These are more complex and much more productive devices. The basis is one of the above-described sources of welding current, plus a device for feeding the welding wire, torch and control unit. Welding on such devices is carried out in the environment of shielding gases, metals are joined using a special soldering wire. This allows you to easily connect parts of thin metal, as well as weld non-ferrous metals. For home, such equipment is unlikely to be in demand, but in automobile workshops for body repair they are often used.

Semiautomatic welding machines can work in two modes MIG/MAG. MIG – welding with inert gas supply. It is used when joining stainless steel to preserve the alloying metals in the steel. MAG mode – when active gases are fed into the fusion zone, protecting the metal from interaction with air oxygen. Some models can also work in the MMA mode of welding – manual arc welding. This mode in semiautomatic machines is convenient when joining thin metals. When welding thick parts, this equipment shows low productivity, so for these cases it is more profitable to take machines for manual electric arc welding.

Working with them is not difficult: there is an automation unit that controls the process. The seam turns out beautiful and even, there are no problems with the occurrence of the arc at all. Even if they weld very thin sheets of metal (0.5-0.8 mm), they do not “lead” and the seam does not pull. For these purposes, they are ideal.

How to choose a machine for electric welding

If you have decided on the type of welding machine (transformer, rectifier, inverter, automatic machine or generator), you need to choose a model. There are several key parameters that will facilitate this process:

- Supply voltage: 220 V or 380 V. For households usually take welding machines that work from 220 V. All types of welding machines except inverters are quite demanding to its characteristics. It is only inverters without problems can work in the range of 180-250 V. At the others, when increasing, the protection is triggered (they are disconnected), and when decreasing, the parameters fall strongly. Three-phase devices for 380 V, as a rule, more powerful and reliable, but also cost more expensive (minimally – about 20-30 thousand rubles). They are more often purchased for production, large service stations. For welding “for yourself” with your own hands, the power of these units is excessive.

- Output current. If you choose a welding machine for home and cottage, you will use it periodically, for most works is enough current 160-180 Ampere (inverters at this current you can work with electrodes 3-4 mm without problems). If you expect to weld thick metal, more than 190-250 Ampere you do not need. Industrial models can deliver up to 500 amps.

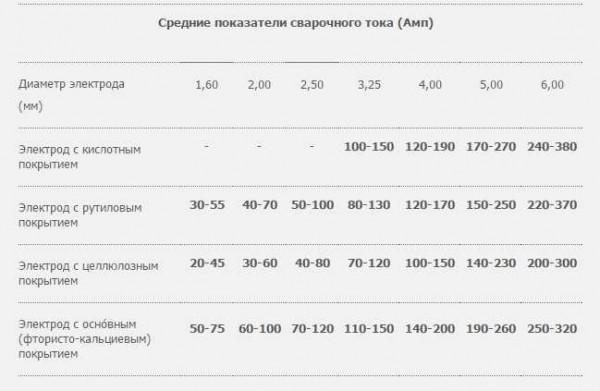

- No-load voltage. It is measured on the apparatus without load. It can be from 45 V to 80-95 V. From this parameter depends on the ease of ignition of the arc. The higher the idle voltage, the easier it is to start welding. Also, higher characteristics guarantee a more stable arc, which facilitates welding. This parameter is taken into account when selecting the type of electrodes: for some, a low voltage is sufficient for ignition (riutyl coating), while others need higher values (basic coating).

| Metal thickness, mm | Electrode diameter, mm |

|---|---|

| 1.2 – 2.0 mm | 1,5 mm |

| 1.5 – 3.0 mm | 2,0 mm |

| 1,5 – 5,0 mm | 2,5 mm |

| 2,0 – 12,0 mm | 3,0 mm |

| 4,0 – 20, mm | 4,0 mm |

| 10 – 40 mm | 5,0 mm |

- Maximum diameter of electrodes with which the machine can work. This indicator, in addition to the selection of electrodes, also affects the thickness of metal with which the machine can work.

选择电焊机的几个一般技巧。要决定哪种电焊机更适合家用,应从您需要解决的任务出发。对于焊接黑色金属,变压器就足够了。如果需要焊接结构钢或低合金钢,则需要逆变器。对于薄金属或有色金属的焊接--半自动。

尺寸往往是决定性因素。 如果您需要一台便携式紧凑型电焊机,那么它就是一台由 220 V 电网供电的逆变器。它的体积和重量都非常小。即使只是扛在肩上、挂在腰带上也很方便。同时,它适用于多种材料,可以获得良好的焊缝。

如果您的电源不理想,那么您也可以选择逆变焊机:它们不怕电压波动,即使电压降到 180 V 也能工作。

我们还建议焊接新手使用这些机器:其中一些机器具有一些有用的功能,使焊接新手的工作更加轻松:

- 热启动模式--"热启动"--有利于电弧点火。在焊接开始时,会发出一个额外的电流脉冲,以促进点火;

- 防粘。初学者在开始工作时很难正确选择焊接参数。因此,电极会 "粘 "在工件上。在使用变压器和整流器时,很难将其撕下。而在变频器中,电流会自动减小,因此可以毫不费力地将电极撕下。

- 电弧力 - 增加功率。当电极快速接近时,电流增大,防止电极粘连。

如果您是焊接新手,想知道逆变器和变压器哪个更好,选择很简单:逆变器(如何选择逆变焊机,请阅读此处)。它只有一个缺点:学会逆变器后,如果不重新培训,就无法使用变压器。其他缺点:它不喜欢灰尘,尤其是金属灰尘。因此,在它附近最好不要清理金属,也不要用螺栓卡或磨床工作。此外,和其他电气设备一样,变压器也不喜欢潮湿,害怕结露。

Welding generators

这是一种相当复杂的设备,由发电机(汽油或柴油)和焊接电流源组合而成。焊接可以使用直流电和交流电。设备已经相当昂贵,但对于那些还没有电或电很不稳定的定居点或建筑工地来说,这是最好的选择。如果您的定居点还没有通电,您就需要这样的设备。

传统的电焊机可以用发电机供电吗?可以,但如果同时使用家用电器或电网中的其他电器供电,则在工作期间必须关闭这些电器:电压会 "跳变",因此可能会造成故障。还有一点:电焊机所需的发电机设计较为简单(对电源特性的要求不高)。因此,其方案要简单得多。因此,焊接发电机的成本要低于一对电焊机+发电机。

如果您没有电,或者电力供应严重中断,那么购买的不是家用和/或别墅用电焊机,而是电焊发电机,这样会更有利可图。

首先要选择发电机的类型:汽油或柴油。然后选择焊接电流源的类型:变压器、整流器或逆变器。然后是上述电焊的常规参数。

Welding machine for aluminum

铝焊接的特点是熔点低,而且通常金属厚度较小。因此,传统的手工焊接不太适用:需要经验,但不是每个人都有经验。您需要使用气体保护焊(MIG 模式的半自动机器)或氩弧焊机(TIG 焊接)。使用氩弧焊焊接铝的过程请参见视频。

还有通用的多功能焊接机。一台这样的设备可以进行三到五种类型的焊接。但这种通用设备的价格已经高达数十万。对于家庭来说,它们完全没有用武之地。这些已经是专业焊接机了,而且适用范围很广。例如,"Multiplaz 4000 "可用于以下模式:

- 手工电极焊接 (MMA);

- 使用非熔化电极的氩弧焊(TIG)。

这两种模式都可以在屏蔽气体环境中以交流(AC)、直流(DC)或脉冲(PULSE)电流模式进行。它的调节功能不仅多,而且非常多,参数范围非常广。除了可以焊接所有 "标准 "类型的钢材外,还可以焊接铝,甚至是未经预处理的薄不锈钢、钛。焊缝质量非常高。但是,您是否需要在家里或别墅里安装这样的设备,这是一个问题。除非您打算开一家生产厂或靠焊接赚钱。