A properly installed and adjusted heating system provides maximum comfort in a private home. The quality of its operation depends not only on how accurately the wiring is designed and the equipment is selected. Much depends on whether the preliminary calculations are correct, for example, the volume and flow rate of coolant in the heating system. If everything is calculated accurately, the results can be used in the future, for example, in the modernization of engineering communications. How to calculate the flow rate of coolant and calculate the required volume of antifreeze for pouring into the pipes, according to what formulas you need to do the calculation – you will learn about this below from our article.

Makalenin içeriği

Basic definitions

The calculated flow rate of the coolant is necessary to know at what speed the working fluid should circulate in the pipes and radiators of heating. This allows you to select a circulation pump with optimal performance characteristics. If the pump is underpowered, the rooms will not warm up properly, if the pump is overpowered, the energy consumption will increase.

To prevent this from happening, a preliminary calculation of the coolant flow rate according to the heat load is required. For this purpose, the difference between the temperature of the medium at the inlet of the heating system and at the outlet of the heating system is determined. The value will be needed for subsequent calculations.

What is the flow rate of the heat transfer medium according to the heat load?

This is its mass quantity, measured in kg/s (kilograms per second), which is necessary to transfer the required amount of heat into the room. The calculation is made by dividing the heat demand in watts by the heat output of the medium in J/kg.

If very precise results are not required, an approximate formula for the fluid flow rate can be used.

For the calculation, it is assumed that 15 liters of thermal fluid are needed to transfer 1 kW of heat.

For example, if a 10 kW heating boiler is installed in the building, approximately 150 liters of medium will be required for its correct operation.

What is the heat load

Heat load is a parameter that is defined as a temperature difference (temperature difference) between two points: at the entrance to the heating system (direct mains) and at the exit from it (return). If the approximate mass flow rate of the heating medium can be used, it is often done without measurements. For this purpose, an average value of 15-20 °C is taken for a standard autonomous heating system.

After obtaining preliminary data go to the main calculations.

Calculation of the volume of coolant for autonomous systems

In multi-storey residential buildings, the heat distribution is made according to standard designs and there is no need to calculate anything. In private houses, the calculation of the coolant flow rate and its required amount for pouring is carried out individually.

Please note: calculate these parameters should be after the project is developed heating distribution, known size, type and characteristics of all components – pipes, batteries, heating boiler, etc..

The calculations of the following characteristics are carried out.

The power of the heating boiler

It is selected for the layout, the total area of the premises and the floor of the house. If the boiler will be less powerful, the rooms will become poorly heated. With too much power will increase unproductive energy costs.

Professionals use engineering formulas for accurate calculation. If high accuracy is not essential, you can calculate the power based on the approximate ratio: 10 m² = 1 kW.

Thus, for a house with a total area of 250 m² will need a boiler model for 25 kW.

It is recommended to increase this result by 10-15% to avoid problems with sudden thermal overloads. The final calculation shows that you will need a 27.5-28.75 kW boiler. From the available model range, choose the nearest larger value. This calculation is suitable for houses with rooms of normal height (up to 3 meters) and located in places with moderate climatic conditions.

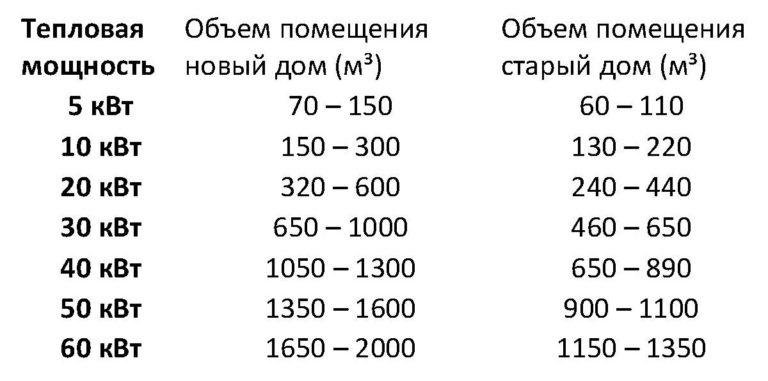

If the house is located in a warm or cold region and/or has higher ceilings, correction factors are introduced. It is also possible to use special tables in which the heat output is specified taking into account the type of building and the total volume. To calculate the latter, the total floor area should be multiplied by the ceiling height.

If the height is different for different rooms, the calculation is done separately and the results are added up.

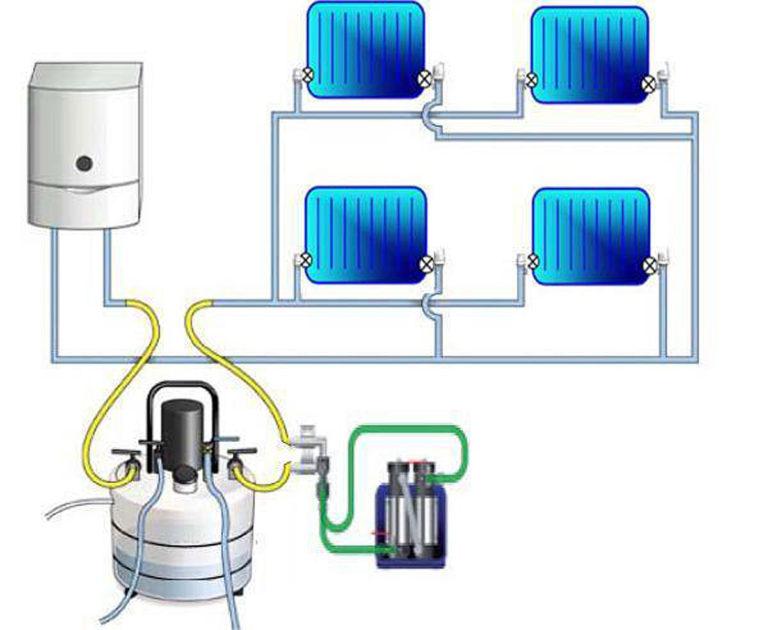

Calculation of the volume of the heating medium

This is necessary to know how much water or antifreeze will be needed to fill the system. The total volume is calculated using the formula:

V of soğutma sıvısı = V of boiler + V of radiators + V of pipes

To calculate the total amount, the calculation of each component should be made.

- Heating boiler. All its characteristics, including volume, are indicated in the technical documentation for each model. Calculation is not required. For floor boilers, it is 25 liters or more, for wall boilers – about 3-7 liters.

- Batteries. From their volume depends on the flow rate of coolant through the radiator. Data are also indicated in the technical documentation. If it is lost, the volume of the battery is calculated from the approximate capacity of a separate section. For cast iron, aluminum and bimetallic volume is about 1.5, 0.4 and 0.3 liters, respectively. For a ten-section battery will be 15, 4 and 3 liters.

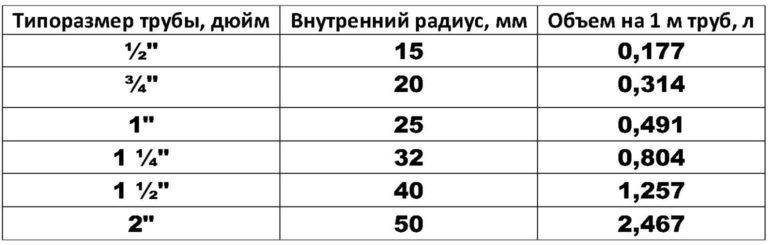

- Pipes. Their volume and the flow rate of the coolant depend on the internal diameter. Reference tables are used for calculation. They indicate the volume of one linear meter for each size. If pipes of different diameters are installed in the heating system, the calculation is carried out separately, and the results are added up.

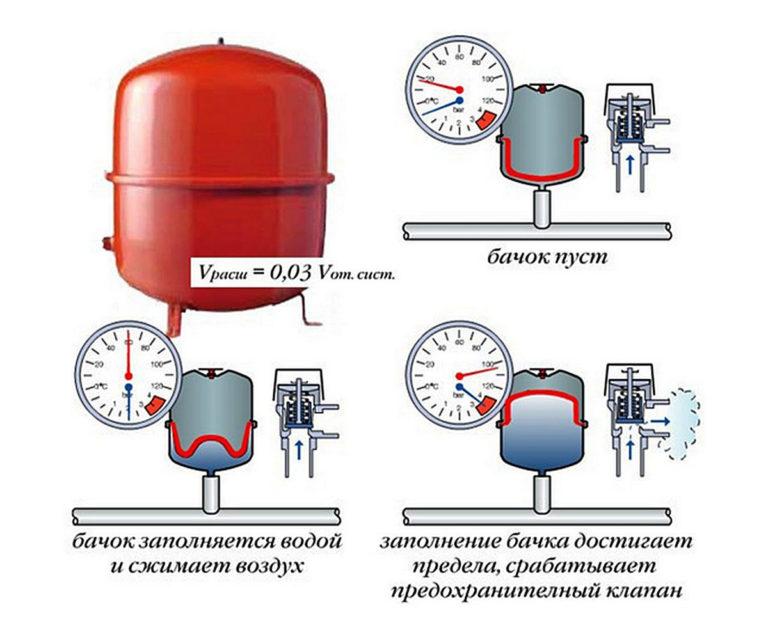

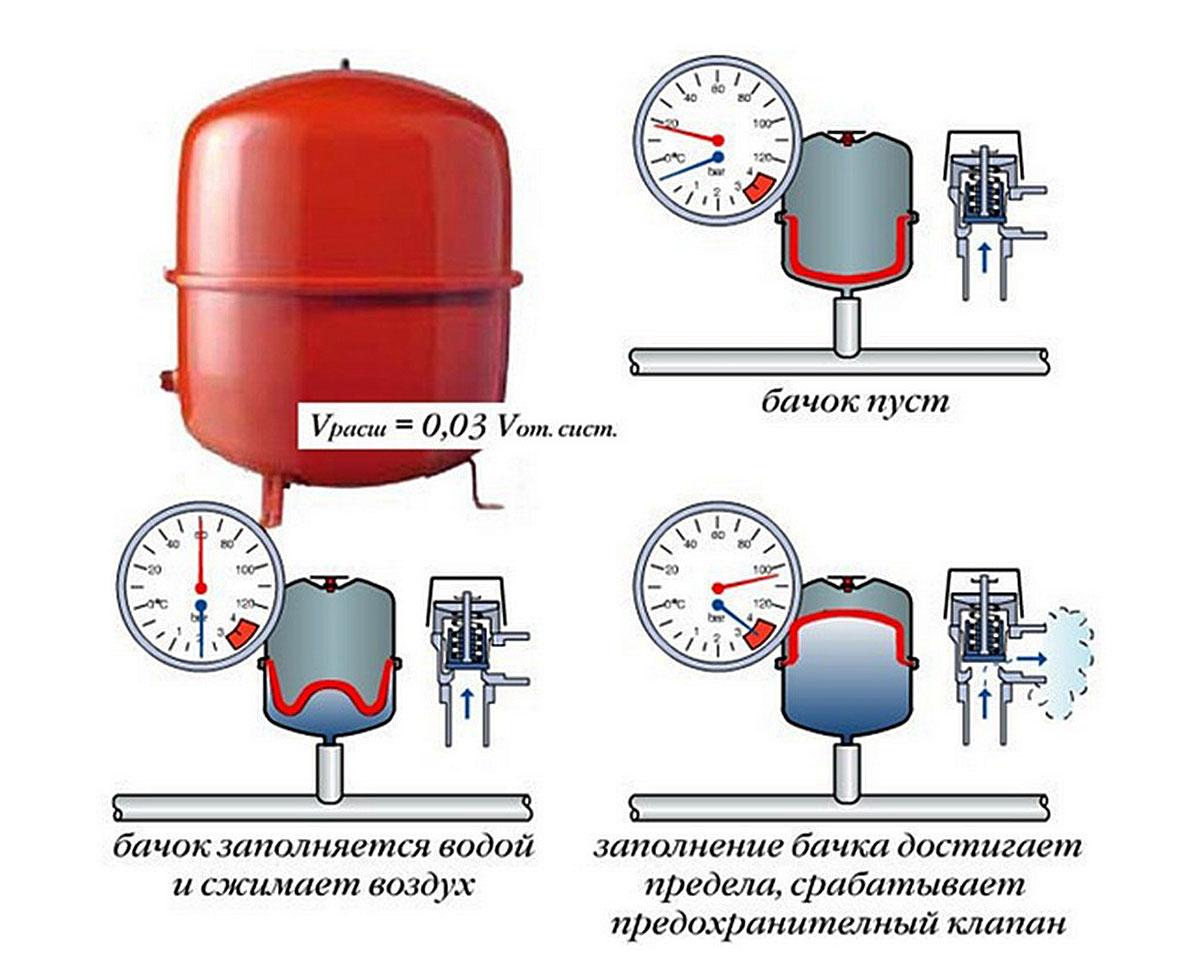

Volume of the expansion tank

Since all coolants expand when heated, the flow rate of hot coolant will be slightly higher than that of cold coolant, and the pressure in the heating system will increase. To compensate for this phenomenon, expansion tanks are installed. Their volume is calculated according to the formula:

V = (VS x E)/d

Where:

- VS – total volume of the heating system;

- E – coefficient of thermal expansion;

- d – coefficient of efficiency.

For water the expansion coefficient is assumed to be 4%, Thermagent is assumed to be 4.4%. The standard value of d for private houses is taken as 0.57 (based on the maximum working pressure of 2.5 bar and tank charging at 0.5 bar).

Filling the heat transfer medium into the pipes

After all the necessary calculations have been made, the heating system can be filled. The correct filling of the circuit involves the consecutive fulfillment of several steps.

№ 1. Pressure test

This procedure is carried out to check the tightness of the heating system. For this purpose, two pressure gauges are installed in the circuit. The upper point is at the expansion tank in an open system or at the upper floor radiator in a closed system. Lower – on the return line at the heating boiler. If the house has one floor, the upper point is installed on the supply main. On the furthest radiators from the boiler, manometers are also mounted. Before starting work, they should show 0,3-0,4 atmosphere.

Opressovka allows you to check whether the calculation of the system, its wiring and installation was done correctly. The work is carried out in this sequence:

- a hose from the pressure pump is connected to the heating system through a drain cock or other point;

- if the pressure test is carried out in an open system, it is necessary to close the valve on the expansion tank beforehand;

- the pump is switched on and starts pumping water into the heating pipes from the pressure tester tank;

- pumping is carried out until the pressure in the pipes reaches the working level of 0.7-1.5 atm;

- after that all connections are carefully inspected: pipe joints, radiator fittings, seals, etc..;

- in parallel, open the Maevsky valves on the radiators to bleed off the air trapped with the coolant;

- then increase the pressure by a quarter or half of the nominal pressure, hold for 30 minutes for polymer pipes, 10 minutes – for metal pipes;

- re-inspect the joints and record the pressure.

If pressure calculations show that the pressure has decreased by no more than 0.1-0.2 atm, the system is considered leakproof.

№ 2. Flushing

After pressure test, the system should be prepared for heating – flushed with water or a special solution with additives. The flushing liquid poured into the tank is pumped out by a pump and fed through a hose into the heating pipes through a special fitting or another convenient pumping point. In an open system, the water or solution can be supplied through an expansion tank. Flushing is carried out until the liquid coming out of the drain hole is clean – free of debris and dirt particles. When the work is completed, the flushing solution is completely removed from the system.

№ 3. Filling

After calculations, pressure testing and flushing, the system is filled with a properly selected heating medium. The filling procedure will be different for open and closed circuits. Before filling, the coolant is properly prepared: water is softened and concentrated antifreeze is diluted in the specified proportion. Certain coolants, such as Thermagent ECO, are available ready for filling.

How to fill a closed system

The coolant is pumped into the pipes by a pump through a hose connected to the make-up connection. Two workers will be required for correct pumping: one will monitor and control the equipment, the second – to bleed air from the radiators through the Maevsky valves. This will allow timely removal of air jams formed in the system. Filling takes place in several stages.

First. Before starting work, the heating circuit is prepared for filling. Close the cocks Maevsky and those installed on the heating boiler (cutting off). Open all other shut-off valves and the expansion tank valve.

Second. To control the pressure in the system install a pressure gauge. The employee controlling the pump, monitors the pressure. When the manometer shows 1,4-1,5 bar, the assistant begins to bleed the air from the radiators, starting from the lowest and moving to the top. As the pressure drops slightly, the main worker pumps the coolant into the pipes. He makes sure that the pressure gauge shows at least 1.0 bar. After all the air has been vented, the coolant is pumped up to 1.5 bar. When this value is reached, open the taps on the heating boiler: first the return tap, then the direct tap. Then again carry out pumping, bringing the pressure to the calculated operating level.

Third. At the end of the filling of the coolant and complete filling of radiators from the circulation pump to release the air accumulated there. To check the correctness of pumping is carried out test run of heating. To do this:

- the boiler and circulation pump are switched on;

- the pipes are heated with coolant;

- on each radiator open the Maevsky cocks;

- check if the air is completely out of them and close them again.

If the calculation of the coolant flow rate and the start of the system is done correctly and there are no leaks, the pressure reaches the working level (no more than 1.8 bar) and stabilizes.

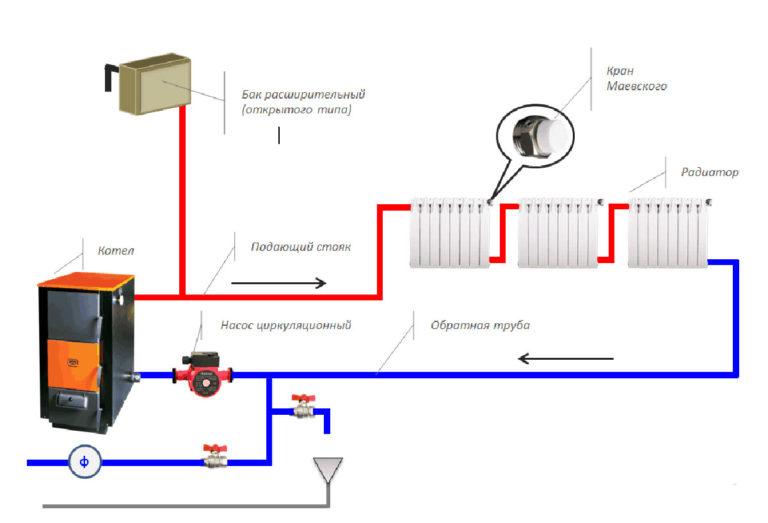

How to fill an open system

In contrast to closed circuits, where the use of antifreeze based on ethylene glycol is permissible, only the safe coolant “Thermagent ECO” on propylene glycol can be used in open circuits. This is due to the fact that in such heating the working fluid is in contact with air. As in the previous case, two people will be needed for the work.

Features of pouring into an open system

Most often the filling is carried out directly through the expansion tank, from which the cover is removed. On all radiators, the Maevsky taps are preliminarily opened. One of the workers pours the coolant into the expansion tank, the second monitors the radiators. As soon as the air is completely out and water or antifreeze starts to flow from the taps, they are shut off. The coolant is poured in so that its level is about half the height of the tank. This will ensure the necessary replenishment of the fluid flow rate in the heating pipes. Filling can also be carried out through the make-up connection. In this case, you will need a pump. Mayevsky valves are closed in the same order: from the lowest to the top.

What to pay attention to. Before starting work, close all stop and control valves with the expectation that after pouring the system will be started and warmed up. Then the Maevsky cocks are opened again to release the air. If the flow rate of the coolant increases and its level in the tank decreases, it is refilled again.

Which coolant to choose

The optimal working medium for both open and closed heating systems can be considered Thermagent products made with modern OAT (Organic Acid Technology) metal technology. The carboxylate additive package acts selectively, forming a thin protective film only on the corrosion center. Thanks to this, their consumption is minimized.

Calculations show that thermal agents can be successfully used in heating systems for 10 years without requiring drainage and replacement. Additional pluses include:

- no foaming during circulation;

- low viscosity at low temperatures;

- stable properties at temperature fluctuations.

Thermagents are universal, can be used both in heating of private homes and large industrial facilities.

Hey, I recently tackled calculating flow rate for my heating system, and it was a game-changer! Just a few simple steps, and it made such a difference in efficiency. Props to whoever put this info together; it really helped me out!