Constant pressure in the water supply system of a private house is usually created by means of a pumping station. It is clear that it is better if it works without problems, but breakdowns periodically occur. To restore water supply faster and save on services, you can repair the pumping station with your own hands. Most of the breakdowns can be eliminated independently – nothing super complicated to do.

Innehåll i artikeln

The composition of the pumping station and the purpose of the parts

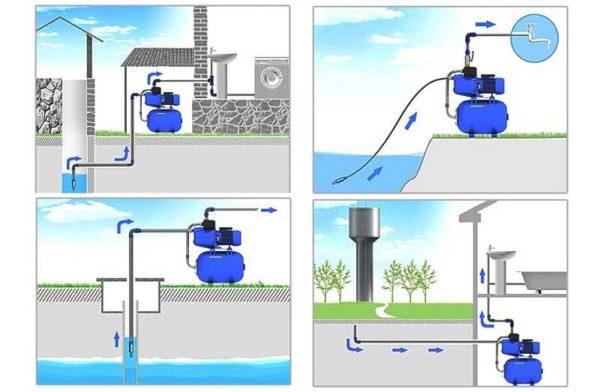

Pumping station – a set of individual devices connected to each other. To understand how to repair the pumping station, you need to know what it consists of, how each of the parts works. Then it is easier to eliminate malfunctions. The composition of the pumping station:

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of different devices.

Principle of operation of the pumping station

Now let’s take a look at how all these devices work. At the first start of the system, the pump pumps water into the hydraulic accumulator until the pressure in it (and in the system) is equal to the upper threshold set on the pressure switch. As long as there is no water flow, the pressure is stable and the pump is switched off.

Somewhere a faucet is opened, water is drained, etc. For a while, water flows from the accumulator. When its quantity decreases so much that the pressure in the accumulator falls below the threshold, the pressure switch triggers and switches on the pump, which pumps water again. It is switched off again by the pressure switch when the upper threshold – the cut-off threshold – is reached.

If there is a constant flow of water (bathing, watering the garden), the pump works for a long time: until the required pressure is created in the accumulator. This periodically happens even when all taps are open, because the pump supplies less water than is flowing out of all points of discharge. After the flow rate has stopped, the station works for some time to create the required reserve in the gyroaccumulator, then switches off and switches on after the flow rate appears again.

Problems and faults of pumping stations and their correction

All pumping stations consist of the same parts and their failures are mostly typical. It makes no difference whether the equipment is Grundfos, Jumbo, Alco or any other company. The diseases and their treatment are the same. The difference is in how often these faults occur, but their list and causes are usually identical.

The pump station does not shut down (does not build up pressure)

Sometimes you notice that the pump has been running for a long time and won’t shut off. If you look at the pressure gauge, you can see that the pump station is not gaining pressure. In this case, the repair of the pumping station is a lengthy affair – you will have to go through a large number of reasons:

- There is no water in the well or borehole. If this is true, this situation is called “dry running” and threatens that the motor will burn out. The water the pump pumps is used to cool the motor. If there is no water, it overheats and burns out. To protect against this situation, special protection is needed: water level sensors (float and electric).

- High resistance of the suction line (long length with small pipe diameter) or air inflow (leaky connection).

- Clogged filter on the pipe or check valve. They are removed, cleaned, checked for function, put back in place and test run.

- Another possible reason for the pump not shutting off is a faulty pressure switch or incorrectly set pump shut-off limit:

- The pressure limit at which the pump should shut off is too high, the pump is simply not able to build up the required pressure. Then adjust the pressure switch (lower the cut-off limit).

- Check the contacts of the pressureswitch – clean them from scale (dark scale) with very fine grit sandpaper (you can use a nail file).

- Troubleshoot the pressure switch by cleaning it(remove salts on the adjustment springs and clean the inlet and outlet port). Be careful, the inlet diaphragm must not be damaged. If this does not help, replacement is required.

If the cut-off limit of the pressure switch is well below the maximum pressure the pump can produce and it has been working normally for some time and then stopped, the cause is different. The pump may have a blown impeller. Immediately after purchase it was coping, but in the process of operation, the impeller wore off and “the force is now not enough”. The pump station repair in this case is to replace the pump impeller or buy a new unit.

Another possible cause is low mains voltage. Maybe the pump is still running at this voltage, but the pressure switch is no longer working. The solution is a voltage stabilizer. These are the main reasons why the pumping station does not shut down or build up pressure. There are quite a lot of them so that the repair of the pumping station can take a long time.

Repair of the pumping station: frequently turns on

Frequent switching on of the pump and short intervals of its operation lead to rapid wear of the equipment, which is very undesirable. Therefore, the pumping station should be repaired as soon as a “symptom” is detected. This situation occurs for the following reasons:

- Denhydraulic accumulator is too small in volume. When choosing a pumping station for home and cottage often take a hydroaccumulator of small volume – 24 liters or 32 liters. This is very small, as the water reserve in such tanks is only 30-50% of its total volume, that is, in a tank of 24 liters to pump only 7-12 liters of water. Naturally, such a volume of water is consumed very quickly, from which the pump is turned on frequently. The method of treatment – installation of an additional hydroaccumulator (it is connected in parallel to the already installed).

- Incorrectly set limits of the pressure switch. To avoid this situation you can increase the delta (the difference between the pressure for switching off and switching on the pump) and due to this make the threshold of switching on the pump lower (optimally – 1-1,5 atm). One important point: the pressure at which the pump switches on must be 0.2 atm lower than the pressure in the accumulator. The pumping station may frequently start just because the pressure in the accumulator är lower than the set threshold. Cause:

- A clogged check valve. If the valve does not shut off the water, it leaves the system, the pressure drops, and the pump turns on. Frequency of switching on – about 10-20 minutes. The way out – check and clean the check valve, if necessary, replace it.

- Also the cause may be damage to the diaphragm of the hydroaccumulator. In this case, in addition to the frequent activation of the pump, the water is also supplied jerkily: when the station is working with a high head, when disconnected, the pressure immediately drops. In this case, there are two options – the diaphragm itself has ruptured or the rebate, which fastens it to the body. In both cases, it will be necessary to disconnect the hydroaccumulator and replace the faulty part.

- Its one cause of frequent pump operation and water supply surges – a broken spool in the upper part of the hydroaccumulator. To replace it, you will have to remove the accumulator, remove the diaphragm and replace the nipple.

Now you know why the pumping station often turns on and what to do about it. By the way, there is another possible reason – leaky piping or some kind of connection, so if all of the above does not apply to your case – check if the joint is not leaking somewhere.

Air in the water

A small amount of air in the water is always present, but when the faucet begins to “spit”, it means that something is not working properly. There can be several reasons for this, too:

The pumping station does not turn on

The first thing to check is the voltage. Pumps are very demanding to voltage, with a low voltage simply do not work. If everything is normal with voltage, the matter is worse – most likely the motor is defective. In this case, the station is carried to a service center or put a new pump.

From other reasons – faulty plug/socket, frayed cord, burned/oxidized contacts in the place where the electric cable is attached to the motor. This is something you can check and fix on your own. More serious repair of the electrical part of the pumping station is carried out by specialists.

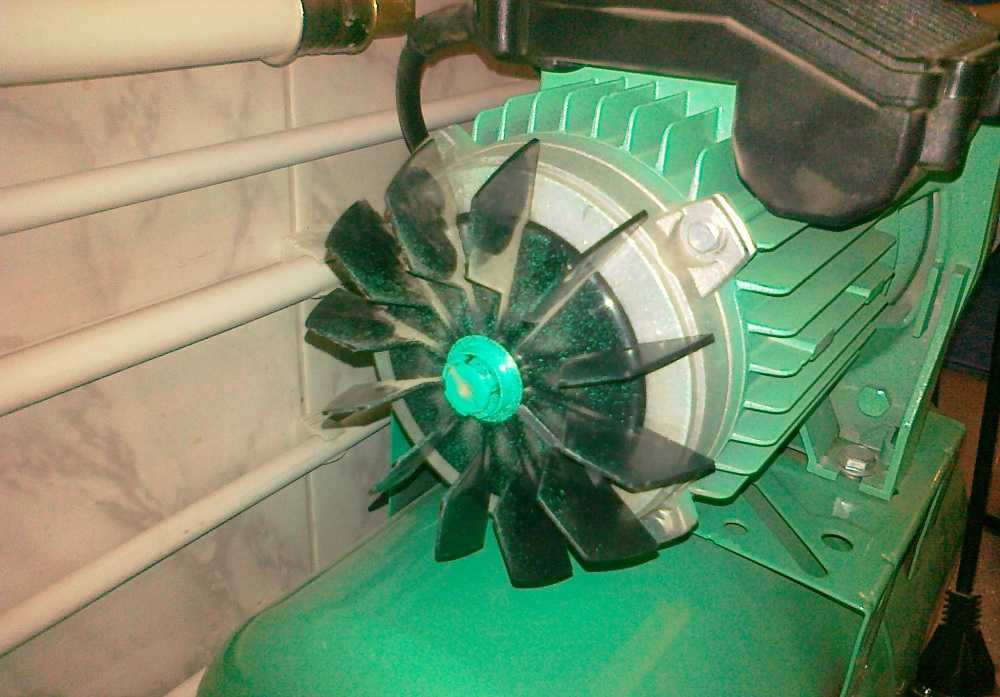

Motor hums but does not pump water (impeller does not rotate)

Such a malfunction can be caused by low voltage in the network. Check it, if everything is normal, go further. It is necessary to check whether the capacitor in the terminal block is not burned out. Take a tester, check it, change it if necessary. If this is not the cause, we move on to the mechanical part.

First you should check if there is water in the well or borehole. Next, check the filter and check the check valve. Maybe they are clogged or defective. Clean, check the function, lower the pipeline into place, start the pumping station again.

If this does not help, the impeller may be jammed. Then try manually turning the shaft. Sometimes after a long idle time it is “stuck” – overgrown with salts and can not move itself. If you cannot move the blades by hand, the impeller may be jammed. Then the repair of the pump station continue by removing the protective cover and unlock the impeller.

Some types of repair work

Some actions to repair the pump station with their own hands are intuitive. For example, it is not difficult to clean the check valve or filter, but replacing the membrane or pear in the hydroaccumulator can be difficult without training.

Replacing the “pear” of the hydroaccumulator

The first sign that the diaphragm is damaged is frequent and short-term activation of the pumping station, and the water is supplied jerkily: then a strong pressure, then weak. To be sure that it is the diaphragm, remove the plug on the nipple. If not air but water comes out of it, it means that the diaphragm has ruptured.

To start repairing the hydroaccumulator, disconnect the system from the power supply, release the pressure – open the faucets and wait for the water to drain. After that, it can be disconnected.

Next, the procedure is as follows:

- We loosen the fastening of the flange at the bottom of the tank. Wait until the water drains out.

- Unscrew all the bolts, remove the flange.

- If the tank is 100 liters or more, in the upper part of the tank unscrew the nut of the membrane holder.

- Remove the diaphragm through the hole in the bottom of the tank.

- Rinse the tank – there is usually a lot of rust-colored sediment in the tank.

- The new diaphragm should be exactly the same as the damaged one. Insert into it the connector, by which the upper part is attached to the body (screw it in).

- Install the diaphragm in the accumulator tank.

- If available, install the diaphragm holder nut in the upper part. If the tank is large, you will not be able to reach it by hand. You can tie the holder to a rope and so install the part in place by screwing the nut on.

- Tighten the neck and press the flange, install the bolts, successively screwing them up a few turns.

- Connect to the system and check the operation.

Replacement of the pump station diaphragm is finished. The matter is not complicated, but it is necessary to know the nuances.

As a maintenance tech, I once tackled a major pump failure. It was a real puzzle! After some teamwork and elbow grease, we got it back online. Nothing beats that feeling of fixing a big issue and keeping the water flowing smoothly. Teamwork makes the dream work!