In an effort to reduce energy costs, we are replacing incandescent bulbs with more economical ones. LEDs are considered the best, as they give bright light at low current consumption. And the manufacturer states that they should work at least 30 years, but in fact after six months of operation simply do not light up. Given the high cost of LED lamps, this is not fun at all. The good news is that repairing an LED light bulb is not too difficult a task. The problem can be solved with a minimal set of tools. In some cases, you can even do without a soldering iron.

Innehåll i artikeln

Device LED light bulb for 220 V

Self-repair of the LED bulb is possible only if you have an idea of what parts it consists of and how it all works. This will allow yourself to look for malfunctions. The device of the LED bulb is not too complicated. If you look from the outside, you can distinguish three parts:

- plastic or glass light diffuser,

- a metal, plastic or ceramic heat sink for heat dissipation,

- the base of one of the standards.

To repair the LED bulb with your own hands, it will be necessary to get to the insides – all the problems are concentrated here.

If you disassemble the LED lamp, inside we will find the electrical part, where we will look for damage. These are:

- Voltage converter/stabilizer or driver. It is located half in the base, half in the heat sink.

- The board with the LEDs.

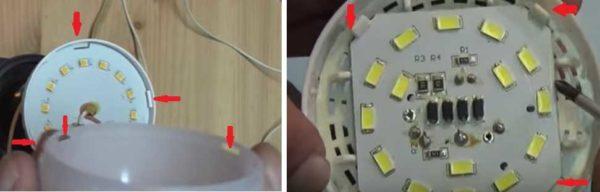

As you can see, not too complicated, although there are a lot of variations. For example, in some models, the driver is soldered on the same board where the LEDs are attached. This is an “economy” solution and is usually found in cheap bulbs. In others, the LED is one. These are, on the contrary, expensive models, as one large and powerful LED costs much more than a bunch of small ones with the same (or greater) luminescence power.

LED light bulb schematics

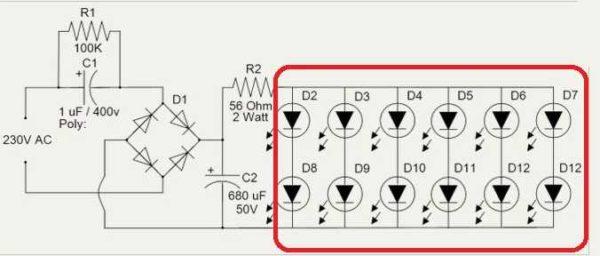

LEDs are powered by low voltage – about 3 V, consume very little current – from 20 to 50 μA, connect them to the 220 V network can only through a converter. It can be seen in the lower part of the lamp. The scheme of the LED bulb for 220 V is also not complicated, but it is easy to identify possible problems.

The picture above shows a circuit with a diode bridge. It converts and stabilizes the voltage. This is one of the most common options, since such lamps are not very expensive. As you can see, in this variant, the diodes are connected in parallel, but this is a rare option. More often they are connected in series – one after the other.

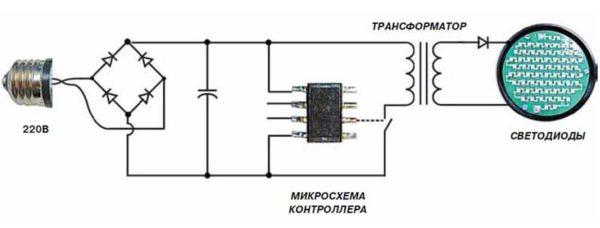

There are other LED bulbs. In them there is a microcircuit. Such lamps are more expensive, but usually more durable, since the parameters of operation are controlled by a microcontroller, which gives a more stable power supply. And poor-quality power supply equals a rapid decrease in the brightness of the glow. Sharp voltage spikes in general lead to breakdown of the LED. Since they are connected in series – one after the other – failure of one LED means failure of the entire lamp. It simply does not light up. Although not working, say, one LED out of 80.

How to disassemble

Repair of the LED bulb begins with the fact that it must be disassembled. There is no vacuum in it, so it is possible. The light diffuser and the base are usually separated without problems. They are connected using notches on the various parts.

There are two options. The easier to disassemble and the more complex. In the simple one, the parts of the lamp are connected only by mechanical latches. In the more complex, in addition to the latches there is also silicone, which ensures the water resistance of the lamp. Such copies can be operated in high humidity. Disassemble the LED lamp should be so:

- Clamp the base in your hands and turn counterclockwise the radiator. The light diffuser is removed in the same way.

- In some LED bulbs, the connections are filled with silicone. In this case, turn, do not turn, nothing moves. If you look closely, you can see the sealant. In this case, you need a solvent. It is dialed into a syringe (without a needle or with a thick needle), carefully introduce the liquid around the perimeter. You need to hold it for 5-10 minutes, and then try again. From the first time it is usually not possible to disassemble the LED bulb, but three or four runs help.

The boards inside the bulb are either inserted into the grooves, or are also held on the latches. It is easier to push them off with a flat screwdriver, while pushing the board upwards. The force should not be excessive, as the latches are plastic and may break.

Characteristic breakdowns

Since you decided to repair the LED bulb with your own hands, it is assumed that you have a tester or multimeter and you know how to carry out elementary measurements. You will also need a soldering iron, but with a thin stinger and low-power. You can do without it, but you will have to look for a replacement. Soldering with a soldering iron, too, you should know how to solder at least a little. You should also have tweezers, wire cutters and utiks. Utiki or duckbill is a hand tool, similar to miniature pliers with long grips – they are convenient to hold small parts, but you can do with tweezers. And then there are the spare parts. They will have to be purchased as the malfunction is detected. It is good if there is a second non-working lamp. It can be used as a donor – to take from there the necessary parts.

LED breakdown

As already mentioned, in the LED bulb crystals are connected in series. From the output of one wire goes to the input of another and so bypasses all the elements. The scheme is very simple. But if at least one crystal is not working, the bulb will not burn. And crystals often fail, so the first thing we do is to check them. Moreover, they are easy to find in any model. You do not need a circuit for checking.

First of all, carefully examine all the crystals. Those that are normal “feel” have a light even color. You should be alerted to dark spots. If there are dark, almost black dots on the crystals, these LEDs are most likely punctured. They are changed unequivocally. If the surface is a little darker, the crystals are still shining, but already “on the last breath” and will soon burn out, they are also better to replace now.

To make sure of the serviceability or malfunction of LEDs, you can use a multimeter. It is switched to the dial test mode, the probes are applied to the contacts of the LED. If the current to operate the LED needs a small, serviceable LEDs light up. The second option to check – a battery at 3-4 volts, to the contacts of which are soldered wires. These wires (with observance of polarity) apply to the crystals. The serviceable ones light up, and the defective ones remain dark.

How to unsolder damaged LEDs

Up to this point, everything is simple and clear, the repair of the LED bulb difficulties, so far, does not present difficulties. Now you need to decide how to solder small LEDs. The whole thing is that they are soldered to a substrate that conducts heat well. That is, heating the contact of one LED you, at the same time, warming the entire board. If you act with a low-power soldering iron will take too much time. Powerful – also not an option, as overheating is very easy. The maximum temperature that crystals can tolerate without consequences is 80°C. With further heating quickly goes to destruction, so when repairing the LED bulb, the main task – as little damage as possible to the other elements.

Spot heating will still not work, but you can try to cause minimal damage to neighboring crystals. To do this, we first bite out/break out the crystal plate, and heat the remaining metal legs with a low-power (20W) soldering iron and remove them.

If you do not have a low-power soldering iron, you can use an iron. It should be rigidly fixed (for example, with a clamp) and set to medium mode. To minimize the “heating field” it is better to use the spout of the iron. In this case we will heat the whole board. Or rather, we will heat the edge where the damaged LED is located, but the whole board will be heated. And this is the disadvantage of this method – from overheating crystals become cloudy and quickly fail. So the whole trick is to quickly remove the damaged crystal as soon as possible.

Before we begin, we color all the faulty crystals with a marker. We turn the board so that the place with the burned-out elements is on the iron platform. Continuously pull the damaged element upwards, clamping it with pliers. As soon as it comes off, try the damaged ones next to it. If they come off, great. If not, turn the board so that the damaged element is heated more. Then immediately remove the board and leave it to cool down. No special means for quick cooling! Just put it down, let it cool itself.

How to solder new LEDs

In place of the soldered LEDs remain contact pads. On them we apply a drop of flux for soldering, on top of them lay out serviceable (with observance of polarity) and warm up again, but this time we press on the crystal. When its legs “enter” the solder, the board is removed or turned over. If there is no LED, you can solder a piece of wire instead. The lamp will shine a little dimmer, but it will work. Yes! This trick works only if there are ten or more crystals on the board.

The video presents another method of replacement. You need to find a similar LED on the tape, cut it out and solder it together with the substrate in place of the removed one.

Another method of soldering small LEDs. He seems to be the most realistic without the use of special equipment. You can solder out the diodes using a small gas torch.

Damage in the driver

If visually all the LEDs are normal or they have already been changed, repair the LED bulb continue by looking at the driver. Some damage is easy to establish visually. Blackened or cracked resistors, bloated capacitance. If you look closely, it is all noticeable. If visually nothing is determined, take a tester, check the integrity of components.

It also happens that all the elements are absolutely normal, but the LED bulb still does not light up. Most likely, this is a bad assembly. It is necessary to check all soldering points. If you do not sufficiently heat the place of soldering, after a while from the constant temperature changes, the contact will deteriorate or disappear altogether. In the first case, the light bulb is on or off. In the second case, it simply stops working. Bring all soldering points to the light and look carefully. If we find a crack in the solder – this is it. Cold soldering. Next, just warm the place well with a soldering iron.

Very rarely fail diode bridges, so they are checked last. If the diode is broken, it is unsoldered, it is soldered, rechecked (in idea, they should be checked only unsoldered), if the damage is confirmed, put a similar one. Do not confuse the connection, otherwise nothing will work. In general, the repair of the LED bulb is not too difficult a task. It will cost much less than a new bulb. And you, along the way, you can improve the design. As a result, burn out LED bulbs will be less often. In any case, you lose nothing (almost).

Man, I had to fix a 220V LED bulb last week! It was a total game changer! Just popped it open, checked the wires, and bam! It was glowing again. I felt like a DIY superhero! Can’t believe I didn’t try this sooner!