For a novice welder, choosing an electrode can be a challenge. There are more than two hundred brands with different properties, purpose and characteristics. And about 100 brands are suitable for manual electric arc welding with inverter machines. It is impossible to tell about all of them, and it is not necessary to begin with. Just briefly characterize the main types and what electrodes for inverter welding are more suitable for beginners.

Obsah článku

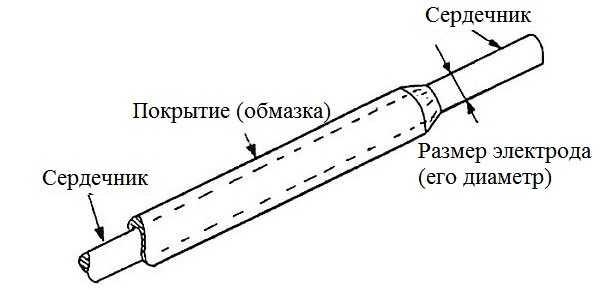

What is an electrode and what is the cladding for

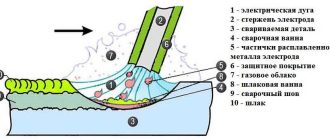

An electrode is a piece of metal wire with a special coating – cladding. During welding, the core melts from the arc temperature. At the same time, the cladding burns and melts, creating a protective gas cloud around the welding area – the weld pool. It cuts off the oxygen contained in the air. In the process of burning the cladding, part of it becomes liquid and covers the molten metal in a thin layer, also protecting it from interaction with oxygen. So the cladding ensures good weld quality.

Any electrode is inspected before welding: the coating should not have chips. Otherwise, you will not achieve homogeneous heating and a high-quality weld. Also pay attention to the tip of the electrode: the thickness of the coating should be the same on all sides. Then the arc will come out in the center. Otherwise, it will be displaced. For welders with experience this is not terrible, but for beginners it can create tangible problems.

It is necessary to monitor the moisture content of the cladding. Some of them at high humidity ignite very poorly (for example, UONI). Due to this “capriciousness” of the grease, they should be stored in a dry place, providing if possible hermetic packaging. You can put the box in a bag, and also put a few bags of salt, which are in shoe boxes.

It is not worth buying wet electrodes: they can, of course, be dried, but their characteristics will be reduced. If it still happens that the electrodes have become damp, they can be dried in an ordinary household oven at low temperatures (they are usually indicated on the package). The second method is to put them for a long period of time in a dry, well-ventilated room.

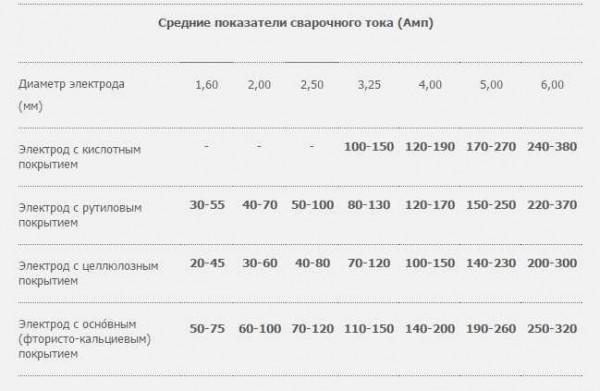

Types of coating and their characteristics

There are only four types of coatings:

- Basic.

- Rutile.

- Acidic.

- Cellulose.

Basic (UONI) and cellulose coatings are suitable only for direct current welding. They can be used on responsible seams: they create a strong, elastic weld, resistant to shock loads.

The other two (rutile and sour) – can work for both AC and DC welding. But the acid coating is very toxic: it can only work indoors if the workplace is equipped with forced exhaust.

Rutile cladding has a greenish or blue tint, electrodes are characterized by easy ignition. They are well ignited even if the inverter has a low idle voltage (a good volt-ampere characteristic is required for confident ignition of the main coating, how to choose an inverter welding machine, read here.). When welding with rutile electrodes (MP-3), the metal is almost no spatter, but there is a lot of slag and it is not easy to get away: you have to work with a hammer.

Perhaps you will be interested in how to weld a gazebo from a metal pipe or how to make a shed on a frame from a pipe.

How to choose electrodes for inverter welding

First of all, the composition of the core is selected: it should be similar to the type of metal being welded. In the household, structural steel is most often used. Here from the same wire and should be electrodes. Sometimes it is still necessary to weld stainless steel. Then the core should also be made of stainless steel, and for high-alloy and heat-resistant make of metal with the same characteristics.

Perform all work at home or on the construction site can be done with the use of only a few brands of electrodes:

- MR-3

- UONI 13/55

- ANO 21

- OK 63.34

They are recognized by many as the best electrodes for beginners who work with inverter welding machines: it is easier to work with them, at the same time, they allow you to cook high-quality welds even in the absence of significant experience. Below are the characteristics and general application of those consumables that many specialists consider good electrodes for inverter. In any case, they are often recommended to novice welders to gain experience.

Electrodes with rutile coating MP 3

Most often beginners are advised to start mastering welds with MR-3 electrodes. They are easily ignited, even with not very good volt-ampere characteristics of the welding machine, give good protection of the weld pool, allow you to control its position quite easily. If the electrode is not ignited, calcine it at a temperature of 150-180 ° for 40 minutes.

They are used in machines with alternating (welding transformers) and direct current (welding rectifiers and inverters). Inverters are usually connected in reverse polarity (+ on the electrode). They are suitable for any type of weld except vertical top-down.

Read about the types of welding machines here.

MR 3 electrodes are not capricious to the quality of welded surfaces. They can be used even on untreated, rust-covered and wet parts. Welding is carried out with medium (2-3 mm) or short arc.

The feature of MP 3 is very important for novice welders: they “hold” the arc well, it is easy to work with them. For this, not all professionals like this brand: they call them Bengal lights. They weld too softly: slow movements are necessary for good heating. Which is not to the taste of the pros, for beginners it’s just what they need. Try to start your welding training just with MP3. You should be fine.

| Electrode diameter LEZ MP-3, mm | Dĺžka, mm | Recommended welding current, A | Pack weight, kg | Price, rub |

|---|---|---|---|---|

| 2,0 | 250 | 40-60 А | 1,0 | 146 |

| 2,5 | 300 | 60-100 А | 1,0 | 120 |

| 3 | 350 | 70-100 А | 1,0 | 95 |

| 4 | 450 | 80-170 А | 1,0 | 91 |

| 5 | 450 | 130-210 А | 1,0 | 91 |

UONI 13/55 with basic coating

These are probably the most widespread and popular electrodes with basic coating. They are recommended for welding carbon and low-alloy steels. They are suitable for joints of critical structures. Seams are obtained strong to shock loads and plastic, well tolerate the effects of low temperatures.

Nevýhoda týchto elektród: dobre sa zapaľujú len pri dostatočne veľkej hodnote voľnobežných otáčok pri meniči (nad 70 V). Druhá významná nevýhoda: vysoké nároky na čistenie a spracovanie zváraných kovov. Ak na okraji zostane hrdza, prach, olej alebo iné nečistoty, spoj bude porézny.

Práca s UONI 13/55 je možná len na zváracích strojoch na jednosmerný prúd vrátane invertorov, s opačnou polaritou (na elektródu sa privádza +) a krátkym oblúkom (hrot elektródy držte bližšie k zváranému povrchu). Minimálne napätie naprázdno je 65 V.

| Priemer elektródy UONI 13/55 (výrobca Mezhgosmetiz) | Dĺžka elektródy, mm | Recommended welding current, A | Maloobchodná cena balenia, ruble |

|---|---|---|---|

| 2,0 | 250 | 30-60 А | |

| 2,5 | 300 | 40-70 А | 127 rub |

| 3 | 350 | 80-100 А | 116 rubľov |

| 4 | 450 | 130-160 А | 111 rubľov |

| 5 | 450 | 180-210 А | 110 rubľov |

ANO 21

Tento typ elektród s rutilovým povlakom je určený na prácu s uhlíkovými oceľami s malou hrúbkou. (O zváraní tenkých kovov si prečítajte tu.) Pri ich použití sa oblúk ľahko zapaľuje (vrátane opätovného zapaľovania), zvar je jemne odlupovaný (z vlniek malých rozmerov), troska sa ľahko oddeľuje. Elektródy ANO 21 možno použiť na zváranie vodovodných alebo plynových potrubí.

Pracujú so striedavým aj jednosmerným prúdom s ľubovoľnou polaritou. Pred zváraním si vyžadujú tepelné spracovanie: kalcinujú sa pri teplote 120 °C počas 40 minút.

| Priemer, mm | Dolná poloha elektródy | Vertikálna poloha elektród | Poloha stropnej elektródy |

|---|---|---|---|

| 2 | sila prúdu 50-90 A | sila prúdu 50-70 A | sila prúdu 70-90 A |

| 2,5 | sila prúdu 60-110 A | sila prúdu 60-90 A | sila prúdu 80100 A |

| 3 | sila prúdu 90-140 A | sila prúdu 80-100 A | sila prúdu 100-130 A |

Stainless steel electrodes OK 63.34

Ak potrebujete zvárať nehrdzavejúcu oceľ, skúste OK 63.34. Možno ich použiť aj na zváranie konštrukčnej ocele. Vznikne tak šev s jemnou vlnou s hladkým prechodom na hlavný povrch kovu. Množstvo trosky je malé, ľahko sa vytĺka.

Táto elektróda je vhodná na zváranie zvislých zvarov a kovov s hrúbkou 6-8 mm, ktoré prechádzajú zhora nadol. Je vhodná na viacnásobné zváranie tupých a prekrývajúcich sa spojov. Pracuje s jednosmerným a striedavým prúdom akejkoľvek polarity, minimálne napätie naprázdno - 60 V.

Na zváranie budete stále potrebovať masku. Aby ste si uľahčili prácu, vezmite si zváraciu masku-chameleón.

How to choose the diameter of the electrode, how to connect it and how to set the current strength

Výber značky elektród pre menič nie je všetko. Aj keď ste sa rozhodli, zostávajú minimálne tri otázky:

- Aký priemer elektródy použiť pri zváraní;

- aký prúd nastaviť;

- ku ktorému výstupu "+" alebo "-" pripojiť elektródu.

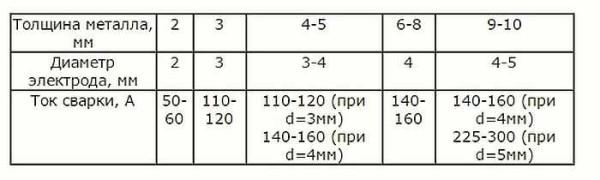

Poďme si o nich porozprávať postupne. Začnime tým, aký priemer elektródy je potrebný na zváranie. Vo všeobecnosti sa odporúča vychádzať z hrúbky zváraných kovov: pri malých hrúbkach sa berie elektróda s priemerom rovnakej veľkosti ako kov. Ak zvárate kov s hrúbkou 3 mm, potom sa elektródy berú s podobnou veľkosťou. Ak zvárate niečo hrubšie, resp. berte 4 mm. Pre začiatočníkov však bude ťažké pracovať s veľkými elektródami. Začnite ovládať zváranie s kovom s hrúbkou 3 - 4 mm. Na to použite elektródy 3 mm, alebo ako sa hovorí "trojité".

Ako pripojiť elektródy k akému výstupu. V technických špecifikáciách na balení je s najväčšou pravdepodobnosťou uvedené, pre akú polaritu je elektróda určená. Pri opačnej polarite sa elektróda pripája na kladný výstup, záporný výstup sa pripája na svorku, ktorá sa upína na diel. Pri priamej polarite je plus pripojený k obrobku a mínus k elektróde. Ako to vyzerá na zváracom invertore, je znázornené na fotografii.

Ako sa tieto dva typy pripojenia líšia? Tok elektrónov má iný smer. Ako viete, elektróny sa pohybujú z "mínusu" do "plusu". Preto sa pri zváraní ukáže, že prvok, ktorý je pripojený k "+", sa zahrieva viac. Zmenou spôsobov pripojenia môžete regulovať intenzitu zahrievania kovu.

Zvážme niekoľko situácií. Napríklad máte elektródu 3 mm, kov 2 mm. Ak použijete "+" na časť, môže sa prepáliť. Preto je v tomto prípade lepšie použiť opačnú polaritu, čím sa elektróda viac zahreje. Ak chcete zvárať 6 mm kov s rovnakou trojkou, je lepšie to robiť na priamu polaritu: tak bude ohrev kovu hlbší a šev bude odolnejší.

Ako si vybrať invertorový zvárací stroj si prečítajte tu. Možno vás bude zaujímať stavba plotu z vlnitej ocele.

Current strength when welding

Vo všeobecnosti sa pri inštalácii elektródy nastavuje sila zváracieho prúdu pre invertor v závislosti od priemeru použitej elektródy. Vo všeobecnosti má každé balenie odporúčania, ale môžete sa zaobísť aj bez nich: na každý milimeter priemeru berte 20-30 ampérov prúdu. Ukazuje sa, že ide o pomerne široký rozsah, ale potom ešte musíte vziať do úvahy, ako budete zvarovať: s odtrhom alebo bez neho. Pri zváraní bez odtrhnutia dajte nižšie prúdy, s odtrhnutím vyššie.

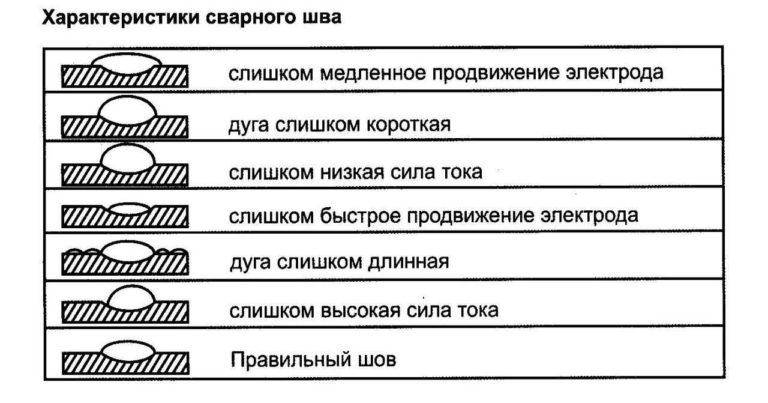

Napríklad pre elektródu s priemerom 3 mm je vypočítaný prúd od 60 A do 90 A. Skutočne pracujte v rozsahu od 30 Ampér do 140 Ampér. Pri zváraní bez prerušenia sa prúd nastavuje približne na 70 - 90 A, s prerušením na 90 - 120 A. Tieto parametre môžu "chodiť" v oboch smeroch: závisí to od rýchlosti pohybu hrotu elektródy, od značky a "tekutosti" zváranej ocele, od polohy zvaru (pri zvislom a vodorovnom zvare dajte o niečo menej, pri strope ešte menej).

Vo všeobecnosti platí, že ani prúdy odporúčané výrobcom nie sú ani zďaleka podmienkou. Začnite s nimi a potom si vyberte tak, aby sa vám s nimi pracovalo pohodlne a šev dopadol dobre. Mali by ste získať kvalitné spojenie a pomer prúdu a rýchlosti zvolíte experimentálne. Zároveň sa zamerajte na stav zvarového kúpeľa. Ona je vaším hlavným ukazovateľom kvality.

Informácie o správnom zváraní pomocou invertorového zvárania nájdete tu.

Now you know not only how to choose electrodes for inverter welding, but also how to connect them, what diameter you need them for this work, and how to pick up the current for each type of electrode and weld. Now let’s talk a little about electrode holders.

Electrode holders

On one of the welding cables, there is a holder (holder) in which the welding electrode is inserted. There are two types of holders:

- with a trigger key, in them the electrode is clamped automatically when the spring-loaded key is released by pressing it;

- threaded – the handle is screwed and unscrewed, releasing or clamping the inserted electrode core.

Which one is better? It’s up to you, but by accidentally pressing the key, you can drop the electrode during welding. Nothing terrible happens in this case, but it is unpleasant …

When choosing an electrode holder, the main thing to pay attention to the strength of the current for which it is designed. You choose the maximum parameter, which is available for your welding machine.

How to connect the cable to the welding electrode holder with a threaded clamp is shown in the video.

The disadvantage of the clothespin holder is that over time, the spring that clamps the electrode core weakens and the contact deteriorates. It is necessary to put a new one. How to do it on a clothespin holder, see in the video.

Connect the electrode holder for welding is not difficult. Only there is one nuance: with frequent work, the welding cable is rubbed by its edge. You can, of course, shorten the cable and redo it, but you do not always want to cut off even 10-20 cm. To prevent this from happening, find a hose whose inner diameter is the same or slightly smaller than the outer diameter of the welding cable. Cut a small piece of it – about 15 centimeters – and cut it lengthwise. This can now be slipped over the cable, pulled upwards and secured there.