In a private house and at the dacha, there is a constant need to weld something. In order not to turn to the pros for small things (and not to pay them), you can buy an inexpensive welding machine and learn yourself. To acquire these skills, it is recommended to buy DC welding machines, and in particular, welding inverters. They have small dimensions, weigh little, with their help you can get a high-quality weld even without having a lot of experience.

Obsah článku

What is a welding inverter and how it works

This device is called an inverter because it converts the alternating current of the 220 V network with a frequency of 50 Hz into high-frequency oscillations, and then – into direct current. At the same time, the device has a high efficiency: about 85-90%, and even with fairly heavy loads, the meter “winds” a little. In any case, you will not have to pay crazy bills. Consumption will be slightly higher than without welding, but not much.

Most inverter welding machines work from a household network of 220 V (there are also machines from 380 V). And this is one of their advantages. Moreover, they practically do not affect it in any way, ie do not “sit” voltage. About the neighbors be calm: they will not know that you are engaged in welding. The second important plus is that they can work more or less normally at low voltage. It is necessary, of course, to look in the characteristics, but at 170 V most of them still allows you to work with a 3 mm electrode. This is very important especially in rural areas where low voltage is the norm rather than the exception.

What else is good for beginners – that the arc at inverter welding and get and hold easier. And in general, according to many people cooks from “softer” and the arc is “easier”. So you want to learn to weld – try inverter welding first.

Read about the choice of welding inverters for home and cottage here.

Basics of welding with an inverter

To begin with, let’s understand the design of the welding inverter. “The stuffing” we will not consider, let’s examine what is on top and what we will have to use.

This machine is a small metal box that weighs from 3 kg to 6-7 kg depending on the power. The case is usually metal, some manufacturers make ventilation holes in it – for better cooling of the “stuffing” (mostly transformer). There is a strap for carrying, sometimes there is also a handle: the strap is put on the shoulder, if the work requires movement.

On one of the panels there is a key or toggle switch to turn on the power. In the front part there are indicators of power and overheating. There are also knobs for setting the voltage and welding current. Also on the front panel there are two outputs – “+” and “-” to which work cables are connected. One cable ends with a clothespin clamp, which is attached to the workpiece, the second – the electrode holder. The power cable connector is usually located at the back. That’s pretty much it.

When buying an inverter, pay attention to the fact that the cables were long enough and flexible: it is more convenient to work this way. It is on the insufficiently long and rigid working cables most of all complaints from users of the popular brand of inverter welding machines “Resanta”.

The general principles of working with an inverter welding machine are described in this video.

Inverter welding for beginners

As with any electric welding, the melting of metal occurs due to the heat of the electric arc. It arises between the welding electrode and the metal being welded. To create an arc, they are connected to opposite poles: one is fed with “+”, the other with “-“.

When the electrode is connected to the “minus” and the workpiece to the “plus”, the connection is called “direct”. If “plus” is applied to the electrode, the connection is reversed. Both options are used in welding, but only for metals of different thickness: reverse – for welding thin metals; direct – for welding thick metals (thickness more than 3 mm). But this is not an immutable rule, sometimes it is the other way around.

What is the practical reason for this division? The physics of the process. Electrodes at the onset of the arc move from minus to plus. And transfer at the same time to the positively charged surface also its energy, increasing its temperature. Therefore, the element that is connected to the positive output is heated more. When welding metals of sufficient thickness, they need to be well heated so that they fused and the seam was quality. Therefore, they are supplied with “+”. Thin metal, on the contrary, from overheating can burn through and to it cling “minus”, more heated electrode, from which in the seam comes more molten metal.

Properly weld metal inverter can only be if the electrode is well controlled by you. To do this, you need to take the holder correctly. How to do this, see in the video.

How a weld is formed during welding

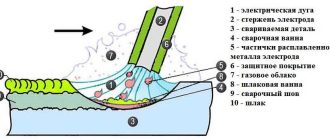

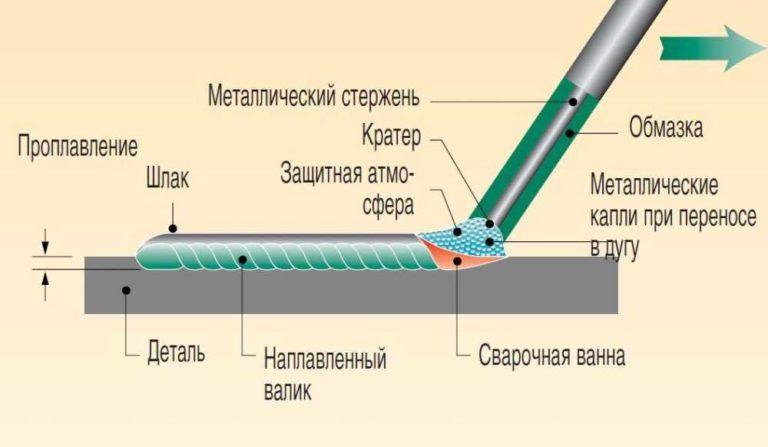

To the basics of welding with an inverter were clearer, let’s consider what happens when a seam is formed. To begin with, let’s clarify that the welding electrode for welding metals consists of a metal core and cladding – a special coating that covers the welding area from contact with oxygen in the air. Read more about electrodes for inverters here.

Now actually about the welding process. An electric arc is formed by contact between the electrode core and metal (see below for more information on how to ignite an arc). At the same time the cladding starts to burn. It partially melts, turning into a liquid state, and partially turns into gases. These gases surround the welding zone – the weld pool. They do not allow oxygen from the air to “break through” to the molten metal. The part of the cladding that has changed to a liquid state covers the molten metal, creating a second layer of protection. After cooling down, it turns into slag, which crusts the weld. And at this stage, the slag protects the still hot metal from oxygen.

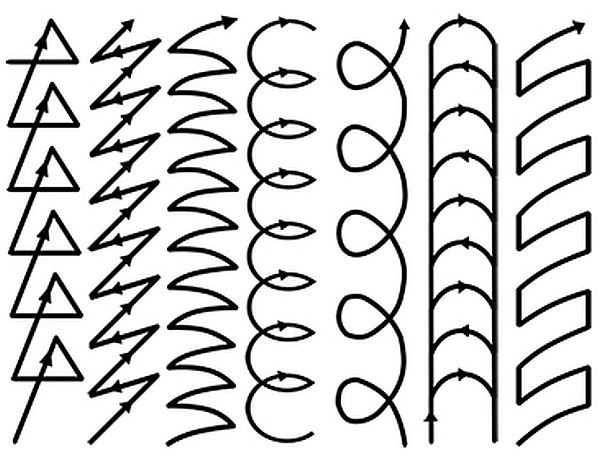

But slag and protection is not the only process that occurs, which must be controlled. When welding, you need to make sure that the place where the two pieces of metal are joined is heated evenly and sufficiently. Both pieces should melt the same distance from the edge. In order for the heating to be even, you need to keep the same distance from the tip of the electrode to the part. It is not very easy to do this: the electrode melts during welding and particles of its molten metal are carried by the arc into the weld. This is why you have to gradually move the electrode holder closer to the workpiece. But this is not the end of the technique of welding with an electrode. It is necessary to “write out” some figures with its tip – zigzags, circles, herringbones, etc. They allow you to make the seam wider and fuse two parts together. The most common electrode movements are shown in the photo below.

That is, you need to move the electrode from side to side to the width of the weld along one of these trajectories, while keeping an eye on the state of the weld pool, and lower the electrode as it burns, keeping the distance to the part constant. This is such a difficult task for someone who wants to learn how to weld metal. It’s easier with an inverter – the arc is constant and doesn’t jump around, but you may not succeed at first.

This video shows in very slow motion the process of transferring metal particles from the electrode to the weld pool and how it is formed.

How to learn how to weld metal with an inverter

Begin the training with the ignition of the arc. To do this, you will need, in addition to the machine, metal (5-6 mm thick) and electrode mask and crags (thick leather gloves) welder, as well as dense clothing and boots made of thick leather – to protect against sparks and scale.

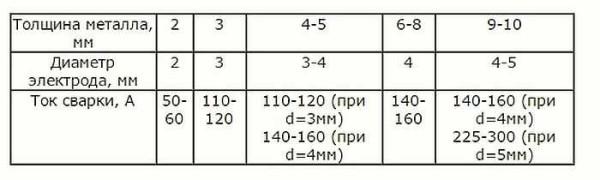

The work starts with connecting the welding cables. Then in the holder insert the selected electrode (for starters, take MP 3 with a diameter of 3 mm – they easily ignite and weld well). After turning on the power supply, set the welding current (see the table). For a 3 mm diameter electrode set the current 90-120 A. The current in the process of welding can be adjusted. If you see that you do not get a roll, but just some unconnected strips, increase it. If, on the contrary, the metal is very liquid and it is difficult to move the weld pool, decrease it. The settings depend very much on the machine and the chosen electrode. So try, change. Having set the current put on a welder’s mask (beginners will be easier to work in a chameleon mask), you can work.

Welding with an inverter for beginners starts with learning how to ignite the arc. There are two methods: knock the tip of the electrode several times on the part or strike it like a match. Both methods work. Whichever is more convenient for you, use that method. But for the future, keep in mind that you should strike along the seam line so that no marks are left on the workpiece. You will have to practice for a while and burn a few electrodes to be able to start the arc steadily.

When the arc is ignited without problems, you can move on – to master the movements. Do this by laying on thick metal rollers. On the metal plate you draw a line with chalk, which will replace the seam for you. Then you light an arc. In the place where it hits, the metal melts and is covered with a film of liquid slag. This place is called the weld pool. This is what you have to move it along the drawn line. Do this with one of the movements shown in the figure above.

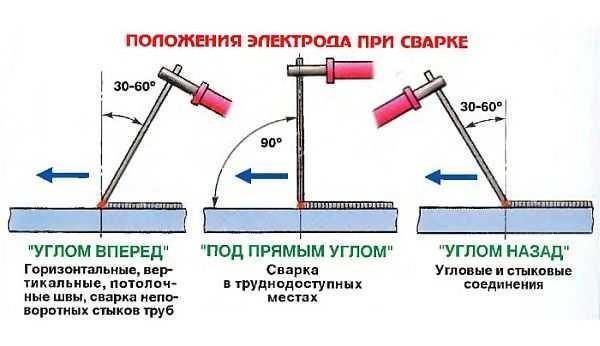

In order for the bath to move, the electrode should be tilted slightly, at an angle of about 50-45 °. Some people have a larger angle, some have a smaller one. In general, by tilting the electrode, you change the dimensions (width) of the weld pool. You can experiment: there are a lot of different techniques in welding and it is only important that the seam was high quality, and how you achieve this is your business, especially since you will be working for yourself and for yourself.

There are two main working positions of the electrode: forward angle and backward angle. When welding with a forward angle, we get less heat and the weld will be wider. This technique is used when welding thin metals. Thick metals are usually welded with a backward angle.

But the angle of inclination is not all the parameters that will have to be maintained. There is also the length of the arc. This is the distance from the tip of the electrode to the surface of the part. Medium arc – 2-3 mm, short – 1 mm or even close to it, long – 5 mm and more – until the breakaway. Practice begins with work on the average length of the arc. Keep to the metal 2-3 mm. Then the seam will be obtained more even and of higher quality: with too large a gap arc begins to jump, the heating of the metal is insufficient, the seam is obtained smeared, the connection is unreliable. With a short arc, another problem arises – the weld is too convex because the heating zone is too small. This is not good either, as it leaves undercuts – grooves along the seam on the workpiece – that reduce the strength of the joint.

After practicing for a while on laying rolls with different movements, you can try to weld seams after the rolls are of the same width and the cladding flakes are of approximately the same size. You can read about the types of welds and joints, as well as their preparation here, or you can watch another lesson “Welding for Dummies”.

The basics of inverter welding for beginners are all there. You are left with only practice: you need to use more than one electrode for training. Even, perhaps, not one kilogram. When the hand itself will make all the movements, everything will seem quite simple to you.

To consolidate the knowledge you have gained, try to train your hand a little without an electrode, practicing the movements with a pencil in your hand. This is also a good option, maybe you will find it more acceptable. In this video tutorial on inverter welding for beginners is very clear, simple and accessible all laid out. If there are any remaining ambiguities, review. Understand how to properly weld with inverter welding. For novice welders a lot of useful.

And lastly about some peculiarities of the operation of welding inverters. They are very afraid of dust, especially metal dust. Therefore, it is desirable near them not to use a bolgar and to conduct regular cleaning with a vacuum cleaner inside (after the warranty period is over). It is not recommended that they work in the rain or in wet rooms. This is especially true of inexpensive household models. Although they have protection against electric shock, but it is better still to be reinsured.

Choosing electrodes, pay attention to the area of their use: they must be suitable for working with a constant current. When welding at the highest current or voltage, the mode of operation is intermittent. It is specified for each machine in the passport.