In the household it is often necessary to sand something, scrape off old paintwork. Most of all work with wood. Few manufacturers sell perfect products. Unless the carpenter. And if there are perfectly processed boards, the price of them is such that willy-nilly you want to sand them yourself. Even though the work is tedious and uninteresting. Therefore, a wood sander is one of the tools that should be in the home arsenal.

Conținutul articolului

Types, purpose, features of work

There are different types of sanders that perform one type of work, but with different results. There are tools for coarse (preliminary), medium (intermediate) and fine (finish) grinding. Part of the tool can even perform polishing.

To choose a wood sander, first of all, you need to determine for what type of work you need it. For coarse grinding – leveling irregularities, height differences – one type is suitable, under the finish sanding – bringing to perfection – another type. And both tasks can be solved with the use of equipment of different types.

UShM – angle grinder

The well-known bolgarka can also be used for sanding wood. With the function of rough grinding, it copes quite well. Of all possible tools, this one is the most productive. If you need to quickly level large areas of wooden surfaces – floor, wall, log cabin sanding – this is the work for the UShM. Minus – the surface turns out to be very uneven, it takes a long time to level all the holes and humps. If on the log it will still “pass”, then for any carpentry work the result is unsatisfactory. If only there is an opportunity to buy another tool, it is not worth it to use an UShM for sanding wood.

For a Bulgarian drill there are special attachments for grinding wood. The best option – petal or plate circles with sandpaper of different grits. When they are installed, the working plane is below the protective casing, it is safe to work, you can move in any direction. Carefully handle places with protruding nail heads and self-tapping screws. The tool is lowered from above and carefully moved. A sharp movement can easily tear the grinding wheel, so be careful.

Changing the grain size of the used grinding wheels, you can carry out rough and medium (intermediate) grinding. The work will take less time than if any other wood sander is used. But on bringing to a smooth surface may take more time, because, if there is a lack of experience, there will be more missteps.

When sanding wood, the sandpaper gets clogged and the speed of work is reduced. In addition to a decrease in speed, there is another sign – the smell of burning wood. Immediately change the disk is not necessary, you can restore its performance. To do this, grind the metal for a few seconds. All the adhered – resin, wood fibers, dust – burns, the surface is cleaned, the processing speed increases again. This trick, by the way, can be used with other grinders.

If you have to clean and change the circles often, on the bolgarka install an attachment with Velcro. Changing the sandpaper is much easier and faster – detached/attached – a matter of seconds. But working with the nozzle is more dangerous. Due to its height, the sanding area is above the level of the protective cover, it does not fulfill its functions. During the start, it happens that the insecurely fixed wheel or even the nozzle itself flies off. They have a small weight, injuries are not serious, but they are still injuries. Reduce the risks helps UШМ with a soft start, but, all the same, you need to work in gloves, protective clothing with tightly buttoned sleeves, boots that cover the feet, safety glasses.

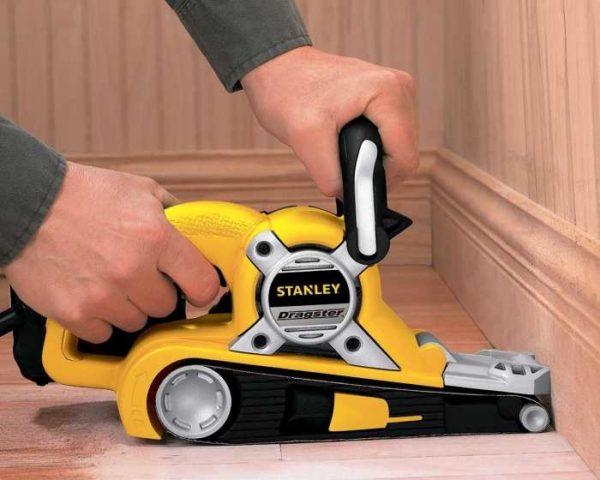

Belt sander

It is called so because of the fact that the sandpaper is in the form of a belt, continuously moving with the help of rollers. Therefore, such a wood sander is also called “endless”.

Belt sander on wood is designed for rough and intermediate leveling of the surface. By installing sandpaper with a finer grain, you can achieve a medium clean finish. This is sufficient for carpentry products that do not go for painting. To bring to a perfect state, you need a different type of wood sander. And to eliminate longitudinal scratches will have to conduct step grinding, changing the grain size several times – scratches remain deep.

What is a good belt sander on wood? It has a good performance. The belt on it is installed in such a way that one side gets to grind close to the wall. What are its disadvantages? Because of the design, not all points can be “reached”. For example, corners, shaped notches, grooves and other small details. It is not always possible to “fit” between two parts (when processing a railing, for example). Another disadvantage – most belt sanders have a solid mass, it is difficult to work them on weight, sanding vertical surfaces. But on the horizontal plane – they are the most productive.

The following disadvantages – high noise level, not the largest spot of grinding. It is so noisy that it is extremely uncomfortable to work without headphones. Why a small grinding spot, because by the look of it it is quite large? Even with a large belt width, it grinds only in the center – the part in front and behind is not used because it is raised for feeding the rollers.

There are peculiarities in the work of the belt sander on wood. To reduce the depth of the furrows it leaves, it must be driven along the fibers. Then the finish sanding takes less time. And another thing – if in the process of work to gape and leave the machine in one place for a long time, a solid “hole” is formed. Despite this – this is the most productive wood sander, which is often used.

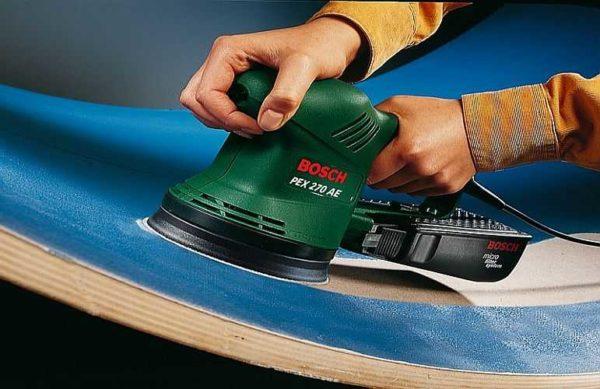

Orbital (eccentric)

Orbital sander on wood has a round sole with velcro, on which disks of sandpaper are attached. The disks are the same as those used for a power drill, so they are interchangeable. There are dust extraction holes in the sole of the machine. Dust is collected in a bag, a cassette-type container, almost all models allow you to connect a construction vacuum cleaner.

The work of the eccentric wood sander is based on simultaneous rotation and forward-backward movement (reciprocating motion). This achieves a sufficiently good speed for intermediate and finishing work on wood. When working with this type of sander, the platform moves in a spiral or orbital motion. Therefore, they call this tool also orbital sanders.

Eccentric grinders are good for processing curved or profiled surfaces – the machine is small in weight, makes little noise, it is easy to control, the angle of the disk can get to notches, cutouts, etc. At the same time, it also processes large planes at a good pace. When fitted with coarse grit sandpaper, it can also be used for coarse and intermediate sanding. The speed is less than that of the belt, but it is also quite acceptable. There are such machines with a different radius of motion (eccentricity) – from 3 to 8 mm. Selecting this parameter and determine the main purpose (about this below).

The disadvantages of this type of machine – the impossibility of processing in the corners. The round platform simply does not fit there. More – at the edges there is a zone of uncertain grinding – close to the wall or vertical surface to grind off will not work.

Vibrating

The soleplate of the vibrating sander can be rectangular or triangular. When working, it makes circular movements with a small amplitude – vibrates, which gave the name to this type of equipment. This wood sander is used for finishing – under varnishing or painting, but is characterized by low productivity.

Vibrating wood sander with a rectangular surface allows you to process large areas, but with its help it is not possible to grind wood near vertical planes and walls – it begins to beat about the barrier. Triangular in this regard is more suitable for working in corners and hard-to-reach places, but it is still tight to the wall will not let you down.

Another disadvantage of vibratsionok – the so-called “lambs”. If a grain of sand or other hard fragment gets under the surface, it leaves small circles on the wood – “lambs”. It is difficult to remove these marks. You have to use sandpaper of increasingly small grit, gradually removing scratches. But if in the process something gets under the sole again, the process is repeated again. For this reason, the surface is thoroughly cleaned before work and a plasterer is usually connected – for quick and timely removal of foreign fragments.

Oscillation

Strictly speaking, this is not a grinder, but it can be sanded. And those places that are inaccessible for other types of machines – corners (even sharp), places directly at the vertical walls. For grinding on the tool is set a special-shaped triangular platform, on which the sandpaper on a self-adhesive base is fixed.

When working, the platform moves in the horizontal plane with a very small amplitude – the tops of the triangle are deflected by about 1.7 ° (this is an average of 2.5 mm). This small movement is the reason for the sanding process. This machine can be used to grind in corners and close to vertical surfaces. Not only wood, but also smeared and dried glue can be removed. In general, the oscillating machine is used for finish sanding in hard-to-reach places – because of the low productivity and sanding spot, it is unrealistically long to process more or less large surfaces.

What type of grinder to choose

Summarizing, we can say that for work on the house and construction ideally need two grinders – for rough and finishing. Most often a pair is used – belt + eccentric. If you plan to engage in the manufacture of furniture, then without oscillation you can not do without.

If you do not like the result of belt sanding, you can buy two orbital with different eccentricity. For coarse grinding, a tool with an eccentricity of 6-8 mm is suitable, for finish sanding and even polishing – 2-4 mm. The only disadvantage of this solution is that good eccentric grinders are expensive.

If the budget is limited, and in the household there is a Bulgarian Bulgarian machine (UShM), rough grinding can be done with its help, and for intermediate or finishing use orbital or vibratory. Just keep in mind that vibratory – the most unproductive, although the cheapest. If possible, buy an orbital – it is more versatile and gives better results.

Technical selection criteria

Any tool is divided into classes, which differ in working resource (and price). So and a wood sander can be household or professional. Domestic are designed for short continuous work with breaks. Basically, it is recommended to work no more than 3 hours a day, periodically taking breaks of 15 minutes.

Professional models are designed to work for 8-12 hours, breaks are needed rarely or not at all. The working life of such a tool is many times longer. For this purpose, durable and reliable (read – expensive) materials are used. In addition, the productivity of such equipment is much higher, as a rule, there is a greater number of adjustments.

When choosing, the first thing to decide is what class your machine should be. It should be said that some manufacturers and household class is not bad, and some also have semi-professional lines. This is an intermediate class, as a rule, for private use, it is optimal in terms of price/quality combination. Some models are used even by professionals.

General selection parameters

Although wood grinders are different, there are also general points that you need to pay attention to when choosing. Here they are:

These are the general points to pay attention to. Now on to what is important for different types of sanders.

Belt

When choosing a belt sander, you need to look at these parameters:

- Length and width of the belt. The width of the belt – from 6 mm to 100 mm. Narrow web can be processed small parts, wide increases productivity. The length of the belt depends on the model. Clearly, the longer the belt, the longer it works without replacement. When buying a second belt-type grinder, try to find a model with the same length – less consumables will be needed.

- Power consumption – from 500 W to 1200 W. The higher the power, the higher the productivity and endurance of the tool, the longer the period of work.

- Belt centering mechanism. It can be manual (in household models) and automatic (in professional models). It keeps the belt in the right place. Automatic is more reliable.

- Additional handle. The tool is heavy, it is not always convenient to hold it with one hand. An additional handle (removable or stationary) allows you to control it better and work in non-standard positions (on verticals, inclined planes, on the ceiling).

- Adjustable belt speed, minimum and maximum values. The belt speed determines the sanding speed. At high speeds, however, the finish is very coarse. By changing the grit of the sandpaper it makes sense to change the belt speed. Also the speed selection is influenced by the hardness of the wood. That is why it is convenient to have an adjustment of the belt speed, as you can select the desired mode of operation.

You should also pay attention to how convenient it is to change the belt. There are also models that allow you to quickly change brushes. Sometimes spare brushes even come in a set.

Popular models of belt sanders

| Producător | Model | Putere | Belt size (width/length) | Belt Speed | Weight | Preț |

|---|---|---|---|---|---|---|

| Interskol | LSHM-76/900 | 900 W | 76 mm / 533 mm | 250 m/min | 3.2 kg | 55-90 $ |

| Makita | 9911 | 650 W | 76 mm / 457 mm | 270 m/min | 2.6 kg | 100-150$ |

| Bosch | PBS 75 AE | 750 W | 75 mm / 533 mm | 350 m/min | 3.5 kg | 120-160$ |

| Interskol | LSHM-100/1200E | 1200 W | 100 mm / 610 mm | 400 m/min | 5.6 kg | 100-150$ |

| Makita | 9404 | 1010 W | 100 mm / 610 mm | 440 m/min | 4.7 kg | 200-270$ |

Eccentric (orbital)

In addition to all the described general parameters, in the choice of an eccentric machine for sanding wood there are its own nuances:

The selected model still in the store should be tested. To do this, place a disk of sandpaper on the platform and turn on the tool. Vibration should not be felt at all. This means that it is well balanced and will work comfortably.

Popular models of eccentric sanders

| Producător | Model | Putere | Disk speed | Platform oscillation frequency | Disk size | Platform stroke (eccentricity) | Preț |

|---|---|---|---|---|---|---|---|

| Makita | BO5031 | 300 W | 12000 rpm | 24000 rpm | 125 mm | 2,8 mm | 90-120 $ |

| Makita | BO5041 | 300 W | 12000 rpm | 24000 rpm | 125 mm | 3 mm | 100-200$ |

| Metabo | SXE 450 TurboTec | 350 W | 13100 rpm | 8500 rpm | 150 mm | 6.2 mm | 185-220$ |

| Bosch | GEX 150 AC | 340 W | 12000 rpm | 24000 rpm | 150 mm | 4 mm | 175-220$ |

| Bosch | GEX 125-1 AE Box | 250 W | 12000 rpm | 24000 rpm | 125 mm | 2.5 mm | 70-90$ |

Vibrating

First of all, you need to choose the shape of the soleplate. It can be rectangular (most often), square or iron. The system of fastening sandpaper here is clamped, just a piece of sandpaper of the desired size is stretched and fixed with clamps. For normal operation of dust extraction in the stretched paper in the right places (holes in the platform) need to make holes. It is best to connect a vacuum cleaner for dust removal, since the presence of dust under the platform leads to the appearance of a large number of scratches. That is, instead of grinding, we get a spoiled part. This is an important point.

What to pay attention to:

Vibratory sander is used only for finish sanding and is characterized by low productivity. Only paper with fine grain can be put on it. Coarse finishing should be done with another tool.

Popular models of vibrating sanders

| Producător | Model | Putere | Platform oscillation frequency | Belt (soleplate) size | Platform stroke | Preț |

|---|---|---|---|---|---|---|

| Interskol | PSHM-115/300E | 300 W | 10500 col/min | 230×115 mm | 35-50$ | |

| Makita | BO3711 | 190 W | 22000 coll/min | 228×93 mm | 2 mm | 60-75$ |

| Makita | BO3700 | 180 W | 20000 col/min | 230×93 mm | 2 mm | 50-60$ |

| Bosch | PSS 200 AC | 200 W | 24000 col/min | 230×93 mm | 2 mm | 50-70$ |

| Hitachi | SV12V | 300 W | 20000 col/min | 228×114 mm | 2,4 mm | 100-130$ |

Choosing a wood sander can feel a bit tricky, but it’s all about knowing what you need. I once picked one for a DIY project, and it made sanding so smooth—literally! Got the job done in no time and my woodwork looked fabulous. Happy sanding, everyone!