To make a balcony or loggia a cozy place is not so difficult. Most often decide to cover the balcony with wagon. There is a lot of work, but it is not difficult and everything can be handled with your own hands.

Conținutul articolului

What kind of wagon to use

Basically, when they talk about wagoning, they mean products made of wood. Much less often this term is also called PVC panels, adding the word “plastic”. Probably, it’s all about a very similar principle of connecting the slats with each other and the way they are mounted, as well as the fact that externally it looks like long boards with a spike on one side and a groove on the other. Choosing which wagon to use for the balcony, usually proceed from the cost, aesthetic or practical considerations.

In some regions, wooden wagon – a cheap material, in some – expensive. So you have to compare the price of plastic and wood yourself. Often wood is favored because it is natural. This is true, but to maintain its attractiveness, it is impregnated with protective compositions, and this is chemistry. Then it is painted or varnished. Compositions, as you understand, are not natural either.

If we proceed from practical considerations, then ahead is definitely the paneling PVC: it is easy to wash, does not require additional care or processing, for many years retains the same appearance. Except that on the sunny side it will fade, so it is better to take light colors: on them the loss of color is almost imperceptible.

Wooden wagon is more capricious in operation: before installation, it must be covered with protective impregnations. If you are only going to give it some shade, you can pick up such an impregnation, which will immediately give you the desired color. Then this is the end of its processing. If you decide to paint or varnish the finish, then it should be done after installation (but before installation still impregnate with antiseptics). During operation, you will periodically need to remove the old coating, and cover everything anew: lacquer or paint can crack, balcony trim will lose its attractiveness. Here is such a fuss.

Despite all this deciding what wagon is better for the balcony, give preference to wood. Tastes, of course, everyone has different, but the general consensus is that the room covered with wood is much cozier. As a result, the desire for beauty outweighs practical considerations.

What to cover the wagon on the balcony to keep it attractive for a long time read in the article “What to cover the wagon indoors”

Which one is better

We will talk about wooden products. First let’s talk about the species. The cheapest wagon is made of pine and spruce. Despite the relatively low cost, it is durable: the wood of coniferous species contains a large amount of resins, which are antiseptics and preservatives. In regions with hot summers, this can lead to the fact that on the sunny side in places of intense heat, resin will be released in places. Another disadvantage is soft wood. If you knock on it (decently, for example, with a hammer), there will be a dent. If this does not scare you – you can cover the balcony with pine or spruce wagon: these are all the disadvantages of this type of wood.

There are still expensive varieties of conifers: larch and cedar. They have a very more dense wood, more durable, well resist atmospheric phenomena. But these are their qualities for paneling the balcony inside is absolutely unnecessary. A more compelling argument can serve as a beautiful color and structure of wood, as well as a smaller amount of resins. Cladding with wagons made of such wood – it is beautiful and long-lasting.

Hardwood is pleasant to the eye. Here choose to your taste: linden has a slightly pinkish shade, aspen becomes silver-gray, alder has a beautiful pattern, oak for decorativeness and reliability – generally out of competition, but also at a price too.

Profiles and appearance

Now about technical characteristics. Let’s start with the profiles. In the sale there is just wagoning, and there is eurowagoning. The main difference is that on the back side of the “euro” version there are one or more longitudinal grooves. They provide air circulation, which prolongs the “life” of the finish. Also, according to the idea, lumber with the prefix “euro” has standard dimensions and should be produced from high quality wood. In practice, everything is different: the dimensions “float” and the quality is not always good.

There are a couple dozen profiles. Different chamfers, “waves” of different sizes and other shaped surfaces allow you to get different in appearance walls. In the photo above – the most common, produced usually in large batches.

There are a few more types that can be made to order. Such a “custom” batch will cost much more: you will have to reconfigure the equipment.

Grades and moisture content

The grade of wagons depends on the number of knots, cracks and color changes that have fallen on the board. Grade A or “Elite” should not have them at all, or in very small quantities. Grade “B” – no more than 4 knots of brown color and color changes of small area, grade “C” can have many knots.

The presence of knots does not indicate that the wood is bad. The main thing is that they were brown, not black in color and had no signs of destruction. And in general, knotted wood sometimes looks great. All this is a matter of taste and preference.

Here with humidity is a much more serious matter. To buy for interior decoration wagon from raw wood, may be much cheaper, but also much more troublesome. If you nail the trim boards with high humidity, it will gradually dry out, reducing in size. Gaps will appear between the boards, some of them will twist or bend. You will have to remove everything, reassemble and reassemble. Moreover, it may be twice: it is difficult to predict when shrinkage will end. Therefore, for interior finishing of the balcony wagon is better to take lumber chamber drying. Humidity then is not higher than 7-10%, it is no longer “will not behave” and will not bend: these materials rejected after drying. That is why the prices are higher.

About the thickness and width of the slats. For interior decoration of premises you can take a thin board: atmospheric conditions are stable. But the balcony – not quite an interior room, temperature and humidity fluctuations are more serious. Even with good insulation of the balcony. Therefore, the thickness is suitable average – 14-16 mm, but you can also use 12 mm.

The width of the board can be from 60 mm to 150 mm. Nail narrow longer, with a wide work less, but in a small room wide strips “eat” the volume. So, for balcony cladding, the optimal width of the wagon is medium, about 90-120 mm.

How to cover the balcony with wagon with your own hands

First of all, you need to decide whether you will insulate the balcony or not, if you will, then what parts of it and what material. From this depends on the structure of the purlin and the thickness of the bars used. The order of works will change slightly – there will be no installation of insulation. All other stages and their sequence will be similar.

The order of works – step-by-step instructions

First, all the old finish is dismantled, plaster, paint, tiles that do not hold well. Everything that holds firmly, you can not touch. For greater reliability, before you cover the balcony with wagon, it is worth priming the walls, floor and ceiling with an antifungal composition. This is especially true if it was previously open. After drying the composition begins work on the installation itself:

- On the walls and ceiling is nabbed purlins. It is usually made of wooden planks. If the balcony or loggia will be insulated, the step of the installation of strips is consistent with the width of the insulation.

- The insulation is installed and fixed.

- Floor joists are installed.

- The insulation is laid between them.

- Moisture-resistant plywood with a thickness of at least 10-12 cm is laid on top, it is fixed in the lags with self-tapping screws.

- Wagon is mounted on the walls.

- The ceiling lining is mounted.

- Floor and ceiling skirting boards, corners, slopes are installed.

Further about some stages and materials in detail.

What to insulate

Before you cover the balcony with wagoning, you need to lay insulation. Any of the insulation materials available on the market will do:

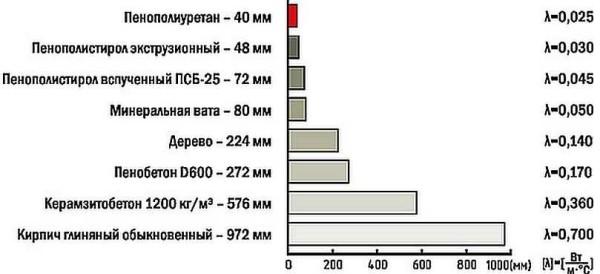

- The cheapest is foam plastic (PSB). Produced in the form of plates. It has a good thermal conductivity (see the graph). Its main disadvantage: it does not tolerate loads – crumples, but under the wagon this disadvantage is unimportant. The second point, which many people do not like, is that it is not natural and can emit harmful substances. With unnaturalness can not argue, and the second statement is only partially true. Under normal conditions of use foam is chemically neutral and harmless. It emits harmful substances only when burning. Another negative quality: it has low vapor permeability (does not remove vapors). But this is the downside of insulation. With an overabundance of moisture today are coped with the help of a ventilation system.

- Mineral wool. They are made from melted rocks, slag or fiberglass. So this insulator is natural. But in production, phenol-formaldehyde resins are used as a binder, which is not happy. There are basalt quilted mats, in the production of which binders are not used – they can be used even in children’s institutions. Positive qualities of mineral wool – not bad thermal insulation properties, ease of work (only not with fiberglass). The disadvantage of this material – hygroscopicity, because of which it should be closed from all sides from moisture. The price range is average.

- Extruded (extruded) polystyrene foam (EPS). It has very good thermal insulation characteristics and high density, well resists mechanical loads. At the same time with thermal insulation is good dampens sounds. Of the relatively inexpensive insulation, it is the most effective. Sold in slabs, has a system of locks, which eliminates the formation of gaps between which cold air penetrates. It is this material is advised most often. If you have the material opportunity, under the finish of the wagon put it. From the disadvantages – does not conduct steam and is not cheap.

- Foil polyethylene foam. This is an effective vapor barrier, which does not allow moisture to penetrate into the insulation. When using mineral wool, it should be rolled from the top, nailed to the battens with staples, and the joints should be glued with foil tape. You can use just construction foil, but it is more difficult to work with it, and a layer of polyethylene is an additional heat insulator. This material can be used alone only in the southern regions, in the rest of the territory it is only an addition that improves thermal insulation.

- For those who want to have an environmentally friendly housing, there is a natural insulator with excellent characteristics: foamed glass (foam glass). It does not burn, does not emit anything, light, strong, frost-resistant (working temperature range from -260°C to +230°C). Thermal conductivity of cellular glass is 0,04-0,08 W/(m-K). It can be cut with a hacksaw, mounted on foam. The disadvantage is high price. There is a foam glass of Chinese manufacturers at reasonable prices, but the quality is below average, there is Belarusian – average and in price and characteristics, the best – European, but it is expensive.

- Often for insulation of balconies use foam blocks. For normal efficiency, their thickness should be about 27 cm. To take away such an area from a small-sized room, no one will not, so on top of the foam concrete still put a layer of some of the above-described thermal insulation materials.

Any of these insulators can be used on the ceiling, floor or walls. For the floor there is a natural and inexpensive option – expanded clay, but it is not as effective as the materials presented above: the average thermal conductivity of 0.1 W/(m-K) (twice as high as minwat).

How to properly cover the balcony with wagon

Balcony cladding is technologically little different from the finishing of other rooms: first, a frame is assembled, to it then nailed cladding board. It is necessary to horizontally and vertically align the purlin, and then correctly set the first on the wall or ceiling plank, as the installation of all the rest is conducted from it. Then the first board is nailed to the second, then the third and so on, up to the corner. On the next wall everything is repeated again.

Making the battens

Covering with wagon begins with the creation of a frame – purlins. It is most often made of a bar. The section is chosen depending on the thickness of the insulation (if there is one). The bar should be of such a size that over the surface of the insulation remained a gap of 1,5-2 cm. This gap will maintain the normal humidity of the insulation and wood, which will prevent the appearance of fungi and mold.

If the timber of the required size is too expensive, you can save money. Under the purlin take a bar of the same thickness as the insulation (or a little more). It is mounted between the rails, and on top, perpendicularly, nail the counter-batten. It is made of strips 1.5-2 cm thick. They will give the required gap. Only in this case, it is necessary not to get confused with the direction of fastening the wagon.

Cladding wagon can be vertical or horizontal. Planks of the purlin under it are installed perpendicularly. If the trim will be attached vertically, then the purlins under it should be located horizontally.

If there is a counter-batten, the rules change: the primary purlins are also nabbed (vertically), and the counter-batten – horizontally. With this system, the battens will be mounted vertically.

More often the cladding wagon on the balcony is done vertically. Accordingly, the installation of purlins can begin with the bar under the window unit. It is set horizontally, checking the level in two planes. If the wall is uneven, in the right places install wooden or plywood pads of the required thickness. Fix the purlins with dowels.

Planks are necessarily nailed around the perimeter of the walls and ceiling, away from the corners 30-40 mm. Also be sure to nail along the perimeter of window and door openings. Then intermediate bars are fixed: one bar from the other should be at a distance of 40-50 cm. A framework is obtained on the walls and ceiling, to which the wagon is then attached.

Boards of wagon are cut a little shorter than the required length (0,5-1 cm). This is to compensate for dimensional changes at high temperature and/or humidity.

Instructions for installing the lagging boards

Fasten them with self-tapping screws or nails to the battens. If you will use nails, take with a small cap – finish, self-tapping screws – on wood (better – light-colored, not black). There is also a variant of fastening – staples from the construction stapler. This is the fastest way and quite reliable. Only take staples with a long sharpened foot, T-shaped staples are also suitable.

The first bar is installed in the most difficult to work in the corner. It is exposed with a spike in the corner, check the correctness of installation with a construction level. Nailed into the plate (in the face), indenting from the edge of 1-2 cm. To prevent the wood from splitting, a thin drill is pre-drilled with a hole. Then screw in a self-tapping screw or hammer a nail.

On the opposite side (where the groove is located), the wagon is fastened with nails, self-tapping screws, staples. They are hammered at an angle of 45° into the stud. It turns out to be a hidden fastening – it is closed by the next board.

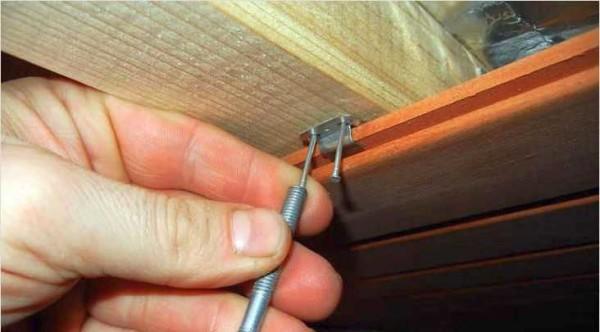

There is another option – paneling with wagons using special mounting plates – kleimers. They hold well, if the stud is long enough, and this is most often seen in eurowagging. Kleimers are installed in the stud (as if put on it). On the other side they have a mounting plate with holes for nails. One or two nails with a small cap are hammered into this plate.

The first board is fastened to each batten plate, all subsequent boards – through one in staggered order (alternating). The second board is inserted into the stud of the first board. If it enters loosely, it is padded with a small piece of wood attached to the board and a hammer. The hammer is tapped on the inserted piece of wood. This difficulty is necessary to avoid damaging the board. Having driven the stud into the groove, check whether the plank has become vertical. If necessary, correct, then nail. This is how the whole paneling is assembled. The last plank sometimes needs to be trimmed in width. It is fixed closer to the corner, as well as the first, in the plate.

The process of installing the battens and wooden wagons is shown in the video.

The entire process of cladding the balcony – from the installation of exterior trim and to the installation of slopes and platbands look in the video below. Only worked with PVC panels, but the stages of finishing are similar. The only difference is that the wooden wagon has no starter strips. All tops and bottoms are closed with skirting boards, and corners – corners.

How to treat the wagon

When cladding the balcony with wagoning, it is necessary to treat with antiseptics not only the finish, but also necessarily all the laths of the battens. The most popular protective impregnations and primers are listed below. Some of them can immediately give the wood a shade, not painting, but emphasizing the texture.

- Senezh Aquadecor is a tinting antiseptic. If you cover the wood with this composition, it immediately protects against mold, fungi, insects, while giving one of 16 shades. It does not need to use a finish coating.

- Akvateks “Primer antiseptic” – quality protection of the wood for subsequent finish coatings (e.g. varnish).

- TIKKURILA VALTTI-POHJUSTE is a priming antiseptic for wood, it protects against bio-damage, but does not protect against UV radiation. Therefore, it is recommended to paint as soon as possible.

- Impregnation Usadba “U-409”. Creates a thin polymer film on the wood, through which the vapor penetrates, but this film prevents the penetration of dirt into the wood, preserving the appearance of the finish. The composition includes additives that protect against fungi, mold and insects.

The package of each product has instructions for use and application. It describes the rules of application and consumption to ensure protection. Only if these rules are observed, you can be sure that the wagon and the frame under it will serve for a long time.

If we talk about stain, then most of the modern compositions simultaneously with the change in color of wood has and protective properties. For example, Akvateks stain (analog Senezh Aquadecor). It has a wide range of colors, contains a hard-to-wash antiseptic that protects the wood from damage by fungi or insects.

Processing of wagoning on the balcony can be done in different ways. It is most convenient to use tinting antiseptics for finishing the balcony. A single treatment will immediately protect, and color will give. But they only give shade, leaving the pores open. In these pores can be packed dirt. And getting it out is no easy task. If you need a protective film that will prevent the penetration of dirt, you can cover the wagon (tinted or not) with varnish or dirt-repellent impregnation such as Usadba “U-409”. The impregnation creates a polymer film on the surface that closes the pores, but does not give a shine.

Often there are problems on the sunny side: what to cover the wagon on the balcony so that it does not fade. The best solution is a light tinting, which slightly whitens the wood. Light-colored wall is less warm and fading it is not terrible. Looks such paneling waggonka wonderful.

If you want to have a shiny surface, you can use any varnish for interior work. On the types and types of varnishes, see the video. It will be easier for you to understand what varnish to cover the wagoning on the balcony.

Painting wagons on the balcony with ordinary paint is no longer relevant today. Why spend money on wood, and then paint over its texture? Then you can immediately put PVC. So choose: tinting, varnishing, or both.