Zszywacz może być używany do przybijania listew, folii lub paroizolacji do listew, tapicerki lub płyt wiórowych do mebli. Urządzenie to nazywane jest również pistoletem na zszywki, zszywaczem, gwoździarką, pistoletem na zszywki i takerem.

Treść artykułu

Rodzaje zszywaczy

Pierwszą rzeczą, którą należy zrobić, jest podjęcie decyzji o rodzaju zszywacza. W zależności od rodzaju siły napędowej, zszywacze budowlane są:

- Mechaniczne. Napędzane siłą rąk, mają niską wydajność, niewielką liczbę zszywek, które można w nie "wsunąć". Z takim sprzętem dość trudno jest pracować z twardymi materiałami - trzeba włożyć w to sporo wysiłku. Ale zszywacze mechaniczne mają niewielkie wymiary, niewiele ważą, co pozwala na pracę w niewygodnych pozycjach. Przyciąga również ich niska cena, chociaż istnieją modele o dość dużej cenie.

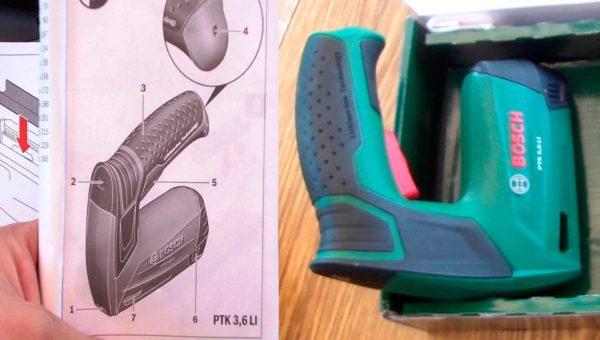

- Elektryczny. Zszywka wylatuje po naciśnięciu spustu, ale mechanizm spustowy jest zasilany energią elektryczną. Są modele działające z sieci, są - na baterie. Oczywiście wydajność jest wyższa niż w przypadku zszywaczy ręcznych, ale ceny są znacznie wyższe, zwłaszcza w przypadku zszywaczy akumulatorowych. Jest też więcej wymiarów. A modele pracujące z sieci przeszkadzają i ograniczają ruchy przewodu, a bezprzewodowe mają niewygodną wagę i nieporęczny uchwyt - bateria jest zwykle przymocowana do niego od dołu. Ale wysiłek fizyczny jest minimalny.

- Pneumatyczne. Siłą napędową jest sprężone powietrze, pod wpływem którego zszywki lub gwoździe wylatują z magazynka. Mają również wysoką wydajność i duży magazynek, który mieści dużą liczbę zszywek lub gwoździ. Jednak wąż od kompresora (i hałas z niego) przeszkadza jeszcze bardziej niż w modelach elektrycznych. Przemieszczanie się z takim urządzeniem jest problematyczne. Dlatego ten typ zszywacza jest bardziej odpowiedni do profesjonalnego użytku w określonym miejscu.

Jeśli potrzebujesz zszywacza budowlanego do jednorazowej pracy - tylko na czas budowy lub dekoracji domu, mieszkania, wybierz mechaniczny lub elektryczny. Mechaniczny działa w każdych warunkach, elektryczny tylko tam, gdzie jest prąd. Nawet modele bezprzewodowe wymagają okresowego ładowania. Tak, można do nich dokupić drugi zestaw akumulatorów i gdy jeden działa, drugi się ładuje. Ale ładowanie również wymaga prądu.

Zszywacze pneumatyczne są kupowane głównie w warsztatach do użytku profesjonalnego. Do jednorazowych prac jest to zbyt drogi i bardzo hałaśliwy sprzęt.

Profesjonalne lub domowe

Podobnie jak wszystkie inne narzędzia, zszywacze budowlane są warunkowo podzielone na profesjonalne i domowe. Różnica w cenie w tym przypadku jest bardzo znacząca - w czasach. I jest to uzasadnione. Chodzi o funkcjonalność, liczbę ustawień, tryby pracy i zasoby robocze. Modele domowe mają niewielki zasób roboczy, ponieważ są wykonane głównie z tworzywa sztucznego.

Modele profesjonalne wykonane są ze stali, często ze stali nierdzewnej. Posiadają elementy plastikowe, ale są to nakładki na rękojeść wykonane z metalu, aby złagodzić odrzut. Oczywiste jest, że będą pracować dłużej i zazwyczaj łatwiej się z nimi pracuje - łatwiej wchodzą zszywki, rzadziej się gniotą itp.

Istnieje również klasa pośrednia - półprofesjonalna. Znajdują się one pomiędzy tymi dwiema kategoriami pod względem ceny i jakości. Często to właśnie w tej grupie należy szukać sprzętu do użytku domowego. Działa on normalnie i nie kosztuje zbyt wiele.

Jak wybrać zszywacz mechaniczny

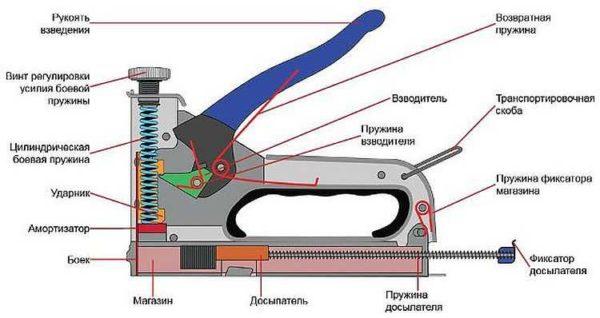

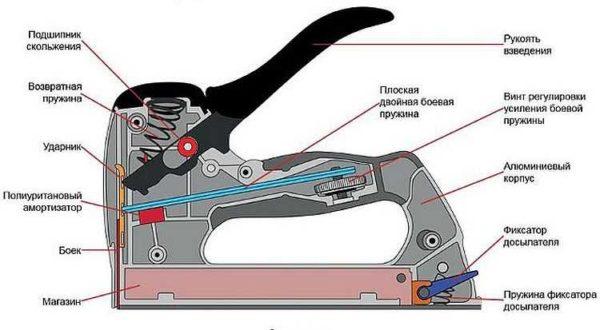

Zszywacz mechaniczny - jedno z najpopularniejszych narzędzi. Kosztuje niewiele, a jest używany w wielu pracach i operacjach. Ze względu na budowę, zszywacze mechaniczne są dwojakiego rodzaju: ze sprężyną spiralną i sprężyną (płytką).

Zszywacze ze zwijaną sprężyną to najtańsze modele. Takie narzędzie należy do kategorii narzędzi domowych. Są proste, ale podczas pracy wymagany jest znaczny wysiłek, aby ponownie przymocować mechanizm. Ponadto z czasem takie sprężyny tracą część swojej elastyczności i zaczynają działać gorzej. Kolejny nieprzyjemny moment - duża siła odrzutu. Takie modele nadają się do krótkotrwałego użytkowania - obciążenie jest zbyt duże.

Profesjonalne mechaniczne zszywacze budowlane są wykonane z wykorzystaniem płaskich sprężyn talerzowych. Zapewniają one płynniejszą pracę, mniejszy odrzut, mają większe zasoby, ale są droższe.

Jeśli planujesz pracować przez kilka godzin, weź tego typu narzędzie. Usprawiedliwi się, a zastosowanie zostanie znalezione - za pomocą takiego urządzenia można wykonać wiele różnych operacji. Jest to szczególnie przydatne dla tych, którzy starają się dużo robić własnymi rękami. Podczas budowy jest używany bardzo często, a następnie przyda się w gospodarstwie domowym.

Ważne punkty

Wybierając dowolny zszywacz mechaniczny, należy zachować ostrożność:

- Korpus powinien być składany - na śrubach. Wówczas istnieje możliwość jego demontażu w razie potrzeby, wyczyszczenia i nasmarowania.

- Jak daleko od ciała znajduje się uchwyt. Im bliżej ciała, tym łatwiejsza obsługa.

- O możliwości regulacji mechanizmu przebijania. Podczas pracy z miękkimi materiałami (na przykład sosna) ustawiana jest wartość minimalna. Dzięki temu zszywka wchodzi, ale materiał nie jest gnieciony. Podczas pracy z twardym drewnem, sklejką, płytą wiórową itp. trzeba będzie włożyć więcej wysiłku, w przeciwnym razie zszywki nie wejdą w materiał, a zdobycie ich młotkiem - nie jest najprzyjemniejszym zajęciem.

- Obecność funkcji podwójnego uderzenia. Służy ona do pracy z twardymi materiałami. Taki tryb pracy pozwala wielokrotnie uderzać w nie w pełni wbity wspornik. Nowy w tym przypadku nie jest podawany.

Również w celu bezpiecznego transportu i przechowywania pożądane jest posiadanie funkcji "bezwstrząsowego zejścia" lub możliwości zablokowania mechanizmu - często jest to po prostu metalowa pętla, która jest przerzucana przez uchwyt.

Jak uzupełniać

Zszywacz budowlany może mieć dwa rodzaje magazynków. Wygodniejsze w użyciu jest otwieranie magazynka. Wówczas napełnianie zszywacza budowlanego jest równie proste jak zszywacza biurowego: wyciąga się sprężynę, wkłada blok zszywek, zwalnia sprężynę. To wszystko, można pracować. Podczas pracy można w każdej chwili usunąć zablokowaną zszywkę, poprawić blok zszywek itp.

Jeśli magazynek jest wysuwany, łatwo jest również włożyć zszywki do zszywacza: po zwolnieniu mechanizmu blokującego należy wyciągnąć sprężynę, włożyć blok zszywek, przywrócić sprężynę na swoje miejsce, mocując ją w prowadnicy.

W przypadku tej konstrukcji usunięcie zakleszczonej zszywki może być problematyczne. Konieczne będzie wykucie jej z zaczepu, a to może być niebezpieczne - nie należy zapominać o zablokowaniu mechanizmu zwalniającego.

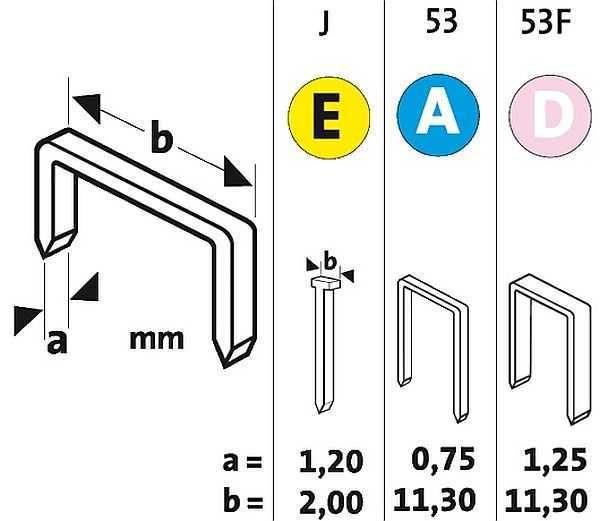

Jakie elementy mocujące mogą działać

Istnieją trzy rodzaje zszywek, z którymi współpracują zszywacze mechaniczne: zszywki w kształcie litery P i U oraz szpilki (w kształcie litery T). Oczywiście lepiej jest, jeśli urządzenie może pracować ze wszystkimi typami, ale zazwyczaj nie są to tanie modele. Tak, zszywki w kształcie litery P i U są potrzebne głównie przy układaniu kabli, a to, trzeba się zgodzić, specyficzna praca, a w kształcie litery T są używane rzadko, ponieważ nie zapewniają stabilnego mocowania, ale są niezbędne, jeśli chcesz, aby elementy złączne były jak najmniej zauważalne.

Niemniej jednak najczęściej potrzebne są zszywki w kształcie litery U. Są one prawie uniwersalne, mają różną grubość grzbietu i wysokość nogi, są dobierane do rodzaju pracy. W charakterystyce zszywacza zwykle wskazuje się maksymalną długość nóżek, z którą to urządzenie może sobie poradzić. Średnio jest to 10-15 mm. Według tego wskaźnika można ocenić siłę uderzenia - im dłuższe zszywki można zszywać, tym mocniej i łatwiej jest poradzić sobie z pracą.

Elektryczny zszywacz budowlany

Zszywacz elektryczny jest niezbędny do częstej i długiej pracy, a także w przypadkach, gdy trzeba użyć dużych zszywek - moc tych urządzeń jest znacznie wyższa. Średnie wartości - długość nogi wynosi 20-25 mm, a maksymalna w niektórych profesjonalnych modelach do 50 mm. Niektóre modele mogą pracować z gwoździami, ale takiej funkcji należy szukać.

Podstawowe parametry

Pierwszym wskaźnikiem, na który należy zwrócić uwagę, jest liczba "strzałów" na minutę. Średnia liczba to 20-30 sztuk, wysoka - około 50. Jeśli brakuje czasu, taka powolność jest denerwująca, ale w tym przypadku należy używać zszywaczy pneumatycznych. Są one najbardziej szybkie.

Jeśli mówimy o mocy elektrycznej, jest ona stosunkowo niewielka - nie więcej niż 1,5 kW, a prawie wszystkie modele pracują z napięciem 220 V. Jeśli zamierzasz kupić zszywacz elektryczny pracujący z sieci, zwróć uwagę na długość przewodu - im dłuższy, tym wygodniejsza jest praca.

Jeśli decydujemy się na model akumulatorowy, wybierzmy ten o większej pojemności baterii lub z drugim akumulatorem w zestawie. Dobrze jest też znać czas ładowania - im krótszy, tym lepiej. I jeszcze jedno: jeśli masz już jakieś narzędzia akumulatorowe, warto kupić zszywacz budowlany tej samej marki lub z podobnymi akumulatorami - będą one wymienne.

Podsumowując część elektryczną: sprawdź, jak długo zszywacz elektryczny może pracować bez przerwy. To znaczy, ile czasu upłynie przy aktywnym użytkowaniu, aż silnik się nagrzeje. W przypadku przegrzania moc jest znacznie zmniejszona, zszywki są gorzej zatkane. Jeśli taka sytuacja wystąpi - zrób sobie przerwę.

Ale przy tym wszystkim należy wziąć pod uwagę, że elektryczny zszywacz budowlany waży od 1,5 do 2 kg, co jest dość dużo, jeśli trzeba pracować na pionowych powierzchniach. Owszem, wysiłek związany z naciśnięciem spustu jest minimalny, ale trudno jest utrzymać ciężar podczas długotrwałego użytkowania. Dlatego przy wyborze zwracamy uwagę na wagę.

Więcej o wyglądzie: obudowa jest wykonana z odpornego na uderzenia tworzywa sztucznego, ale lepiej, gdyby platforma (dolna część) była w całości wykonana z metalu.

Dodatkowe funkcje

Aby dostosować tryb pracy w określonych warunkach, wygodnie jest, jeśli istnieje płynna regulacja siły uderzenia. Istnieją również przełączniki, które mają kilka pozycji roboczych, co również nie jest złe.

Pomoże to zapobiec usterkom związanym z arbitralnym wyzwalaniem. Jeśli elektryczny zszywacz budowlany ma taką funkcję, "wydaje" zszywki tylko wtedy, gdy część robocza zetknie się z jakąś powierzchnią.

Zszywacze pneumatyczne

Ten typ narzędzia jest używany głównie w produkcji średniej i dużej pojemności. Charakteryzuje się wysoką produktywnością: prędkość 50-60 zszywek na minutę jest normą. Pneumatyczny zszywacz budowlany różni się budową: nie ma sprężyny, uderzenie następuje dzięki energii sprężonego powietrza. Zasilanie powietrzem jest dostarczane przez sprężarkę, a moment zasilania jest określany przez naciśnięcie spustu. W modelach stacjonarnych może to być pedał nożny, a w modelach ręcznych może to być zwykły spust lub przycisk.

Przy wyborze warto również zwrócić uwagę na to, jakie elementy złączne mogą współpracować z tym urządzeniem. Nawiasem mówiąc, mogą one wbijać nawet dłuższe zszywki i gwoździe - średnio 50-80 mm, ale można też znaleźć takie, które współpracują z gwoździami 100 mm.

W przypadku tego sprzętu najważniejszym parametrem jest ciśnienie robocze. Minimalnie wynosi ono 4 bary, średnio 5-6 barów. W związku z tym sprężarka musi gwarantować wymagane ciśnienie.

Z pozytywnych punktów - niska waga pistoletu - tylko około 1 kg. I to pomimo faktu, że są one wykonane głównie ze stali.

Zszywki do zszywacza: rodzaje i wybór

Jak już wspomniano, każdy zszywacz współpracuje z określonym łącznikiem. Idąc do sklepu po nowe zszywki, musisz znać ich typ lub przynajmniej wymiary. Informacje o typie zszywek znajdują się w paszporcie produktu lub na tabliczce znamionowej (metalowej płytce) z informacjami przymocowanymi do korpusu.

Zszywki do zszywaczy są wykonane z różnych metali:

Oprócz materiału i wymiarów (długość nóżek i szerokość grzbietu), należy również zwrócić uwagę na to, czy nóżki są zaostrzone, czy nie. Nie ma to znaczenia w przypadku miękkich materiałów, ale podczas pracy z twardymi materiałami może mieć decydujące znaczenie: zaostrzone zszywki znacznie łatwiej wbijają się w najgęstsze deski lub tworzywa sztuczne.

Pamiętam, jak kiedyś używałem zszywacza pneumatycznego przy dużym zleceniu. Przeszedł przez materiały jak po maśle! Na początku byłem sceptyczny, ale naprawdę zaoszczędziłem czas. Zszywacze mechaniczne też są solidne przy małych projektach, ale te elektryczne są idealne do codziennych zadań. Super przydatne narzędzia!