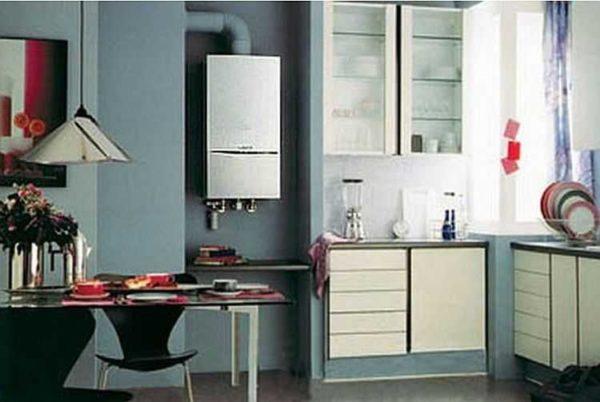

A gas heater is a flowing water heater that runs on natural gas. If you have no hot water supply, but gas is available, this equipment will increase the comfort of your life. You just open the faucet, hot water flows out of it, and its temperature is regulated by you. Even if you have a centralized supply of hot water in your house or apartment, but you are not satisfied with the price you have to pay for heating, or perhaps not satisfied with the temperature, the installation of a gas heater will also solve these problems. Heated water costs much less than it is provided centrally – that’s a significant saving on your utility bills. To understand which gas column is better, you will have to study the structure of the equipment and its types. Then the choice for you will be simple and informed.

Inhoud van het artikel

Structure of a gas heater

Gas flow water heaters consist of three main units:

- gas burner and exhaust system;

- heat exchanger;

- ignition and control module.

All these units have several modifications and their layout gives different models with different characteristics. All this allows you to choose a unit for your own requirements, because to say what gas heater is better, you can only be tied to a specific situation.

Type of ignition

In order for the column to start its work, it is necessary to ignite the gas. Old models were ignited manually, bringing a burning match to the igniter. Today, such units are no longer on sale, they are a thing of the past. They have been replaced by others that work in automatic or semi-automatic mode.

Piezo ignition

In gas columns with a piezo element, ignition occurs in a semi-automatic mode. There are two burners – the main burner and the pilot burner. The pilot burner is a small wick that burns constantly, regardless of whether there is a flow of hot water or not. The main burner is only on when the faucet is opened. All other times it is off.

The procedure for starting the gas column with piezorozhig is simple: you press the button on the front panel, a spark appears on the candles, which ignites the pilot burner. When the hot water tap is opened, gas is supplied to the main burner, ignition is from the pilot burner. As long as the water is flowing, both burners are lit. When the tap is closed, the gas supply to the main burner stops, only the pilot burner is lit again.

What are the advantages of gas columns with piezo elements? These are the cheapest models, usually have mechanical control – regulator, which allows you to change the height of the flame, thus regulating the temperature of hot water. These models are energy-independent, which can be important for dacha.

There are more disadvantages and they are more serious. The wick burns (must burn) constantly while you use the column, and this is a gas consumption. Let it be small, but constant, as a result for a month runs up quite a decent amount. So this is far from the most economical way to heat water. The second disadvantage is also associated with the burning of the wick. If it goes out, you will not be able to light the column. The wick goes out because it does not have enough oxygen to burn, or because there is a periodic back draft in the chimney, which blows out the flame. Since there is a flame controller, it is not terrible – the gas is shut off automatically, but the need to re-light the pilot burner is unpleasant.

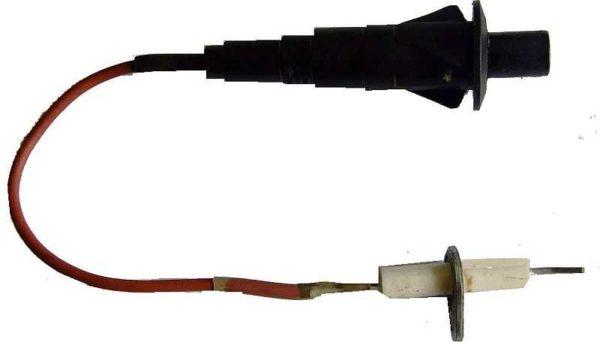

Electric ignition

Automatic gas columns have an eletro-ignition. This is an electric spark generator that is activated when the tap is opened. All the rest of the time the gas does not burn, which significantly saves fuel. There is an electric ignition, working from batteries, there is – from the 220 V network. What gas column is better on this parameter, you have to choose according to the circumstances.

If you often turn off the light, it makes sense to choose a model that works from batteries. As you understand, in this case, you have to make sure that they do not “sit down”. If there are no problems with electricity or there is a backup power source, it is better to choose a gas column operating from the 220 V network. Once plugged the cord into the socket and forgot about it. Electricity consumption is minuscule, so that on the bills and they have almost no effect.

Automatic gas columns have electronic control. A board with a microprocessor is installed in the body, the desired temperature is set from a small control panel (push-button or touch). There is also often put a small LCD screen, which displays the current state of the equipment, water temperature, if there is heating. This kind of gas column is the best, if you appreciate the convenience of handling.

The disadvantages are a higher price and demanding power supply. Electronics needs a stable voltage of 220 V with small deviations of about 2*3 V. Such parameters are not maintained in our country, so that the automatic gas column worked for a long time, requires a stabilizer, and it is better not relay, but electronic. It not only stabilizes the voltage, but also equalizes the shape of pulses, which is also very important for imported water-heating columns.

Burner, combustion chamber, smoke outlet

The heating of water in a gas heater takes place due to the heat released during the combustion of gas. The combustion itself takes place in the burner, and it is “packed” in the combustion chamber. Unburned gases that remain in the chamber are discharged through the chimney. Let’s consider all these devices in more detail.

Burner

The source of heat in the gas column is a gas burner. There are three types: one-stage, two-stage, modulated. The first two types in recent times are almost not found – they do not allow you to maintain a given temperature, so there is no point in considering them – all columns have a modulating burner.

Modulating burners can be controlled manually – by a special knob installed on the body – or through a microprocessor, which maintains the set temperature of water. Burners are mainly made of galvanized steel, as this material is optimal for the task. It is inexpensive, durable, has a high melting point, normally tolerates frequent heating.

Types of combustion chamber and chimney

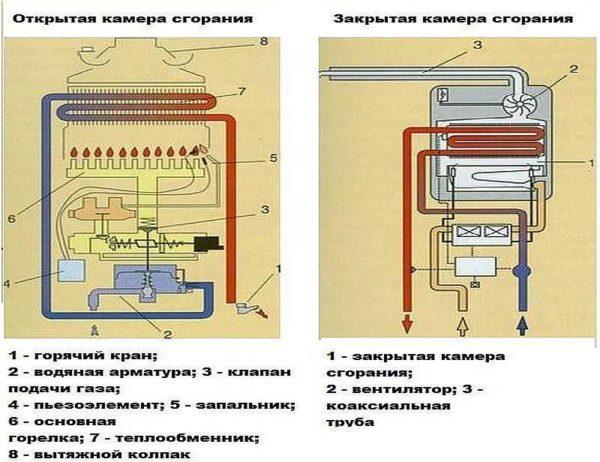

Combustion chambers in gas columns are of two types – open and closed. Their name reflects the essence:

- closed (turbo, fan) is a metal box in which the burner is inserted with a socket at the top for installing a chimney;

- open (atmospheric) – it is actually the entire body of the column, as there is no isolated space, just in a certain place is installed burner, on top there is a cover with a socket, to which the chimney is connected.

Different types of combustion chamber require different chimney. In an open chamber, the air intake is from the room, so you need an effective ventilation system, a normal air supply and an atmospheric chimney going into the vent channel. Closed chamber is equipped with a coaxial chimney (two pipes of different diameters, inserted one into the other), which is led through the wall to the street. In this case, the products of combustion are removed forcibly, with the help of a fan through the inner pipe, and oxygen goes directly to the burner through the outer pipe.

More stable under normal conditions works gas column with a closed combustion chamber, but it has disadvantages. The chimney in winter can frost, because of which the column goes out (it is extinguished by automation, controlling the removal of combustion products). The second point – with a strong side wind, the air flow can blow out the flame. The gas supply is cut off by the same automation, but the situation is unpleasant. The third circumstance is that not all city authorities allow you to hole the walls in the houses and introduce pipes.

So in this case, too, it is difficult to say exactly which gas column is better – it depends on many factors.

Heat exchanger

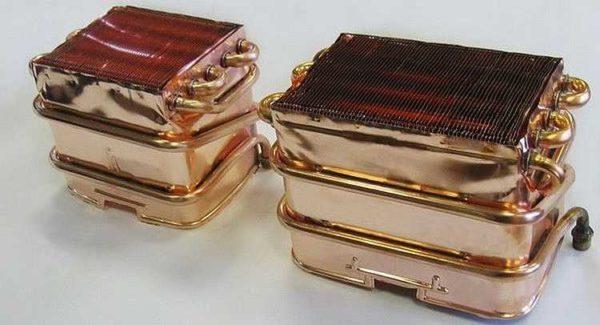

Water heating occurs while it flows through the heat exchanger. It is a metal pipe installed above the burner. The shape of the heat exchanger in the gas column is special – in the lower part is laid snake pipe with fins, then around the installed sheet of metal, on top of which the pipe is spirally wound. The water flowing through this long path is heated by the heated metal.

Make heat exchangers from galvanized steel (the most budgetary option), stainless steel and copper. The best in terms of effective heat transfer copper. They are also the most economical, but also expensive. The most durable – stainless steel, but they are much worse in terms of heat transfer. Which gas column is better in this case – it is up to you. You choose the quality that is more important to you.

If you decide to buy a gas column with a copper heat exchanger, do not try to find a cheap model. In order to reduce the price, manufacturers use low-quality copper, and even tubes are made with thin walls. Such a heat exchanger will serve the warranty period, and then problems will start – leaks will appear.

If you remove the casing, you will see fistulas in the tubes, through which water drips. They are mostly located on the outside of the pipe, just in the place where condensation forms. If the tube is of normal thickness, it is not terrible, but thin walls are quickly corroded. Such a leaky heat exchanger does not have to be replaced (it costs about 1/3 of the total price), it can be soldered. You will need refractory solder with melting point of about 200°C, a powerful soldering iron and soldering flux. The technology of work is usual – clean the damaged place to a clean metal, degrease, tin, solder.

How to determine the power

First of all, it is necessary to determine the power or performance of the gas column. These are two interrelated characteristics, simply reflecting the different characteristics of the unit. Productivity is how many liters of water per minute can heat the column, and power – what amount of heat it can extract. Some manufacturers specify power, others specify capacity, so you need to understand exactly what you need.

Let’s first understand what kind of performance you need a gas heater. This depends on the number of consumers that you need to provide warm water. There are norms of consumption for equipment of different types:

If you have a kitchen sink, shower and washbasin connected to hot water, so that all three points work simultaneously and the water temperature does not fall, you need a capacity of 4 + 4 + 10 = 18 l/min. That’s a lot, the price tag will be solid. If you think about it, you will realize that all three devices are almost never turned on at the same time. There are situations when the shower and one of the taps work together. To provide them with hot water, the capacity should be 14 liters per minute. This is a little more modest, but quite enough for comfortable living. Look for the value found in the technical specifications, it should not be less.

Now let’s deal with the power. Gas columns can allocate to heating water from 6 kW to 40 kW of heat. Here the division is as follows:

- for heating water for one point of water intake is suitable gas column with a capacity of up to 19 kW;

- for two points the power should be from 20 kW to 28 kW;

- three points require more than 29 kW.

Now, you will be able to tell exactly which gas heater is better in terms of power in relation to your needs.

What else to pay attention to when choosing

In the technical characteristics of gas columns there are a few more lines to pay attention to. First, look at the minimum pressure of water and gas, with which the model can work. Imported gas columns of European manufacturers in this respect are more capricious – they are designed for a stable pressure, poorly tolerate drops. But under normal conditions, they work stably and without breakdowns.

Some manufacturers to adapt their equipment to our conditions put reducers that compensate for surges. If the model you like does not have such a device, and you have water pressure and / or gas pressure jumps, you can install a reducer in front of the entrance to the column. This device is simply placed in the pipe break, the installation is standard. At the same time other consumers will be protected.

It is also useful to study the list of service programs and protection levels. From them depends on the safety and comfort of the equipment. It is very desirable to have the following functionality:

- Gas control. Tracks the presence of a flame on the burner, if it goes out, cuts off the gas supply.

- Traction control. Controls the presence of draught in the chimney. If the combustion products are not draining, the gas supply is cut off.

- Flow control or hydraulic valve. Shuts off the heater if the water pressure is too low or nonexistent.

- Overheating protection. Thermosensor monitors the temperature of water in the heat exchanger, when approaching the critical mark (boiling) it switches off the column. This prolongs the life of the equipment (when boiling, the heat exchanger can burst, as well as the pipes).

These features are necessary for the safe operation of the gas heater. This is almost a standard set, which is in all good gas water heaters. All the others are optional. They, as a rule, are no longer so critical (for example, remote control).

Dimensions of gas columns and prices

The overall dimensions of gas water heaters are small – they are commensurate with a small hinged kitchen cabinet. The average height is 550-650 mm, width 300-400 mm, depth 200-300 mm. But if desired, you can find models wide and flat, or vice versa, narrow and deep. Which gas column is better in this parameter can be said only by referring to the place of installation, so there is no unambiguous answer here.

Prices for gas columns vary widely. Simple models with piezorozhig and galvanized burner cost from 110$. Equipment with electric ignition and a bunch of service functions – up to 450$. So there is room to spread out.

| Naam | Country-manufacturer | Stroom | Productiviteit | Max water temperature | Min water pressure | Combustion chamber | Burner | Body exchanger | Ignition | Dimensions (H*W*H) | Prijs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Neva 4511 (Neva) | Rusland | 21 kW | 11 l/mmin | 90°C | 0.3 bar | closed | electronic/battery | 565*290*220 mm | 175$ | ||

| Electrolux GWH 265 ERN NanoPlus | Sweden/China | 20 kW | 10 l/min | open | copper | electronic/battery | 665*390*245 mm | 110$ | |||

| Bosch W 10 KB | Germany/Portugal | 17.4 kW | 10 l/min | 0.15 bar | open | roestvrij staal | copper | electronic/battery | 638*341*242 mm | 145$ | |

| Bosch WR 10 – 2P (GWH 10-2 CO P) | Germany/Portugal | 17,4 kW | 10 l/min | 60°C | 0.1 bar | open | roestvrij staal | piezo | 638*341*242 mm | 167$ | |

| WERT 10EG RED GLASS | Russia/China | 20 kW | 10 l/min | 0.2 bar | open | copper alloy | electronic/battery | 550*330*188 mm | 92$ | ||

| Ariston FAST EVO 11 B | Italy/China | 19 k/W | 11 l/min | 65°C | open | copper | electronic/battery | 640*370*240 mm | 164$ | ||

| Vaillant MAG OE 11-0/0XZ C | Duitsland | 19.2 kW | 11 l/min | 55°C | open | piezo | 177$ | ||||

| Bosch WR 13 – 2P (GWH 13-2 CO P) | Germany/Hungary | 22,6 kW | 13 l/min | 60°C | 0.1 atm | open | roestvrij staal | copper | piezo | 720*385*242 mm | 210$ |

| Neva Lux 6014 | Rusland | 28 kW | 14 l/min | 0,1 bar | open | elektronisch | 650*350*240 mm | 210$ | |||

| Ariston FAST 14 CF E G20 | Italy/China | 24,3 kW | 13-14 l/min | 60°C | 0,2 bar | open | copper | piezo | 580*374*223 mm | 115$ |