When installing gas boilers, the regulations must be strictly observed. Also strictly according to the norms must be mounted chimney for gas boiler. Although the temperature of flue gases is low and has no coloring, the damage is not less, but great – because leaks are poorly defined. Therefore, it is necessary to do everything diligently, paying special attention to the tightness of the joints.

Contents of the article

Requirements for chimneys for gas boilers

All requirements for flue channels are prescribed in the normative documents – SNiP 2.04.05-91 and DBN V.2.5-20-2001. Their fulfillment is mandatory. If you generalize, then everything can be reduced to a few points:

These are the basic requirements. It is obligatory to fulfill them. They provide the required degree of safety. After all, the fact that the gas boiler exhaust has no color does not mean that it is harmless. Therefore, all moments of safety must be given maximum attention.

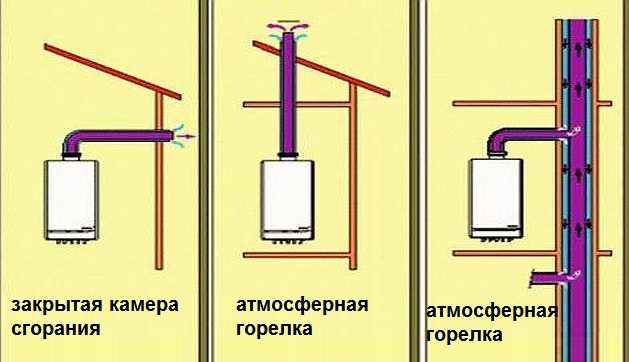

Boiler designs and ways of arranging chimneys

There are two types of burners for gas boilers:

It is clear that the choice of the type of chimney depends primarily on the type of combustion chamber. In one case it should be a coaxial pipe, in another – a conventional one. But in addition to this, there are many more nuances on the structural design.

From what material

Chimney for a gas boiler in a private house can be made of different materials. The main requirement is resistance to chemically aggressive substances, inability to pass gases. Traditionally, several materials are used. On the advantages and disadvantages, peculiarities of the assembly of each of them we will talk in detail.

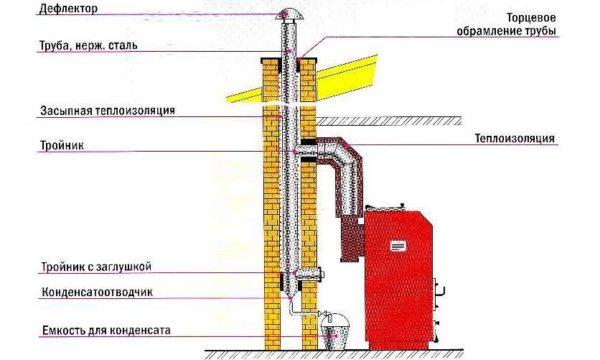

Brick chimney

Today it is no longer the most popular type of chimney. It turns out to be heavy, with a large height requires a foundation. In addition, laying a brick chimney takes a lot of time.

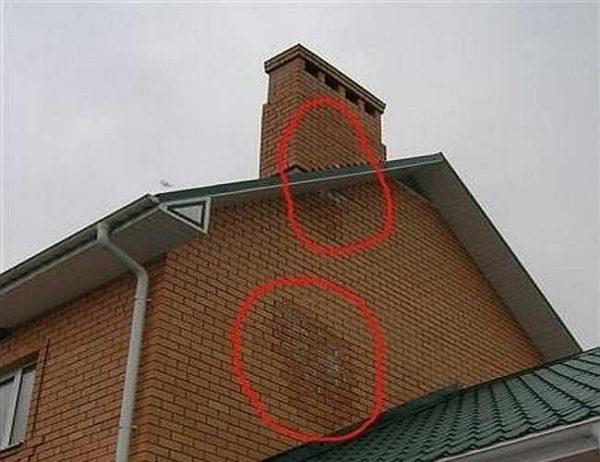

At the same time, this type of chimney has a number of negative qualities. First –its inner walls are not smooth, which contributes to the accumulation of soot, worsens the draught. Second – brick ishygroscopic. Therefore, the condensate flowing down the walls is absorbed, which contributes to rapid destruction.

To solve these problems inside the brick chimney insert a smooth pipe of suitable diameter. Usually it is a pipe made of stainless steel or asbestos. When building such a combined chimney, attention must be paid to the following things:

- The joints of the insert pipe must be made airtight. If it is a conventional or sandwich pipes made of stainless steel, everything happens standard – the chimney is collected by condensate. If the liner is made of asbestos-cement pipes, will have to take care of the tightness of the joints. And to put cement on the joint is not an option. Such a joint is not airtight in any way – condensate will be absorbed. We will have to invent airtight clamps, use hydrophobic (water repellent) compositions. And they must also be chemically resistant. As an option, you can consider lubricating the joints with heat-resistant sealants with an operating temperature of about 200°C.

- In order for condensate to form as little as possible, it is better to insulate the pipes (even inside the brick casing). For this purpose, it is desirable to use insulation material that is not afraid of getting wet.

- A condensate collector must be attached to the liner pipe at the bottom. Access to it should be free.

If you make a chimney for a gas boiler according to these rules, then even with abundant condensate release, it will be easy to cope with it.

Stainless steel – single-wall pipes and sandwich

Modern gas boilers are arranged in such a way that the flue gas temperature at the outlet is not very high. Therefore, condensate is always formed. With a good draught most of it flies into the pipe, with good insulation the remaining part evaporates. So it turns out that the liquid is not always present in the condensate collector. But the condensate itself is formed during the operation of the gas boiler all the time. Sometime in larger quantities, sometimes in smaller quantities. In this regard, the requirements for stainless steel for the chimney are high: it must withstand prolonged contact with caustic substances. These requirements meet mainly food grade stainless steel. Yes, it costs a lot, but only it will serve for years.

Now about whether to make a chimney for a gas boiler from a single-wall pipe or from a sandwich pipe. In order to condensate formed in minimal quantities, it is desirable that the chimney does not cool down. That is, it must be insulated. And although the sandwich chimney has a lining of insulation, when laying outside (on the street) it is also better to insulate it – it will last longer, the draft will be better. But in this option will require less insulation – one layer, while the usual pipe may have to wrap two or even three layers. So the cost of installing a chimney from a single-wall stainless steel pipe and sandwiches will be comparable. Just in the first case will have to use more insulation, in the second less.

If we talk about reliability, then sandwich chimneys are more reliable, if only because they consist of two layers of metal. By the way, if you will insulate the chimney, the outer pipes can be made of galvanized steel – with condensate they do not contact, temperatures are low, and appearance is unimportant, as everything will be wrapped with insulation.

Ceramic chimneys

Ceramic chimneys are good for everything: they are durable, reliable, well tolerate contact with aggressive substances. But have two significant disadvantages. First – they are expensive. The second – have a lot of weight, so that the device high chimney requires a foundation. And this – additional costs to the already considerable amount. But the service life of such a chimney is counted in decades.

Asbo-cement pipes

Once it was the most popular type of material in the construction of chimneys for a gas boiler in a private house. The material, of course, porous, has rough walls, and its cross-section is not ideal (not round, but rather, oval). But this is probably the cheapest option.

When using asbestos-cement pipes for the chimney of the gas boiler is necessary:

- Make it as straight as possible, trying to make the joints even.

- Seal the joints. As already mentioned, just putty with cement is not an option. It is necessary to seal the joint. Several solutions to the problem – the use of hydrophobic additives in the mortar, coating the dried cement mortar sealant, the use of airtight clamps.

- To reduce the amount of condensate pipe to make high, well insulated.

In general, nothing new, all the same rules as for the materials described above, but added fuss with joints. So, as a result, the price of the chimney from asbestos pipes is almost the same as stainless steel.

For boilers with an open combustion chamber

For gas boilers with an atmospheric burner requires a smoke channel that provides a good draught – the removal of combustion products occurs due to the movement of air through the pipe. Therefore, it is made as straight as possible, preferably – with smooth walls. There are two variants of execution:

Which of the options is better? Easier to realize the external chimney – with the output through the wall. It is important only to pass through the wall correctly (to observe the fire clearance, if the walls are combustible). But for this option requires good insulation, quality fastening to the walls. And even under these conditions, condensation is usually a lot. Therefore, the installation at the outlet of the tee and condensate collector is mandatory.

In the case of a chimney outlet through the roof there are at least two difficult moments – the passage through the ceiling of the first floor and through the roof. In these places, special passage units are installed. They ensure a proper degree of fire safety.

Read more about how to conduct sandwich pipes through the wall or ceiling here.

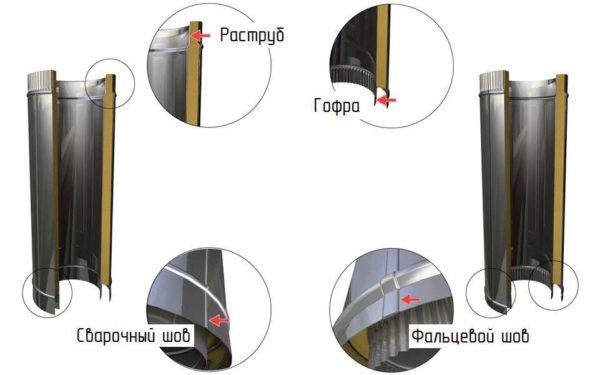

Features of the assembly of metal pipes

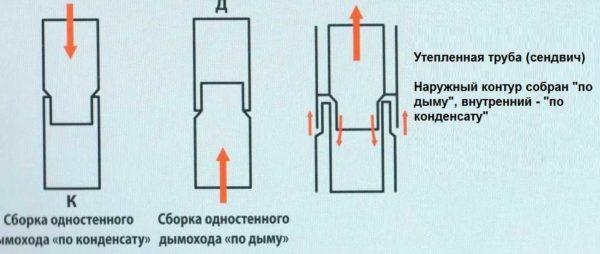

If they collect use sandwich pipes or single-walled metal, then the external chimney for a gas boiler is assembled “by condensate”. That is, inserting the upper pipe inside the lower one. This is possible due to the presence of a corrugated edge on one side.

When assembling the chimney inside the building, the construction is assembled “by smoke”. In this case, it is more important that the gases do not get into the room. Therefore, turn the pipes so that the upper element is put on the already installed.

There is a third option – to assemble two circuits differently: the outer on the smoke, the inner – on the condensate. Dya such an assembly must be used sandwich, as only they have two circuits. This is the best option, as the protection is complete, but the assembly is complicated.

Chimneys in a shaft (box)

To communications do not spoil the interior, they are often “packed” in a shaft – a specially built box. Inside there are, as a rule, a chimney (or chimneys, if the devices work several), ventilation ducts, there may be risers of water supply, heating, sewerage. In any case, it is better to close the chimney pipe with thermal insulation. If in the heated room insulation can still not be used, then in the attic (especially if it is cold), insulation must be mandatory. Use basalt wool with an operating temperature of at least 300°C.

Insulation will positively affect the temperature inside the chimney, which will give an increase in the draught and reduce the amount of condensation. But do not forget that we are talking about gas boilers, and they have a low temperature of combustion products.

For closed combustion chambers

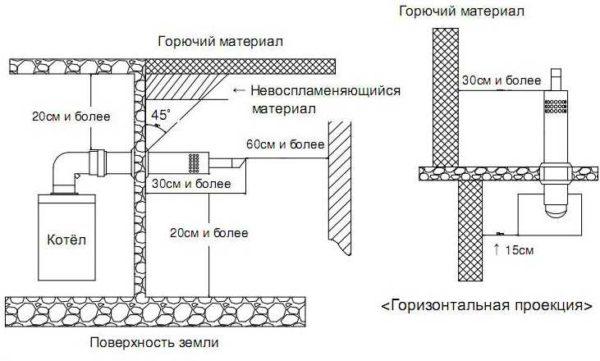

Coaxial chimney looks like a pipe in a pipe. The design comes ready-made, assembled quickly and without problems. You only need to know the diameter of the outlet pipe and parameters – height, length.

The device of the coaxial chimney is the simplest. The pipe rises above the boiler and turns 90 °. From it to the ceiling should be at least 20 cm. Then it is carried through a hole in the wall, outside it should end at least 30 cm from the wall.

The height relative to the ground level – the outlet of the pipe must be at least 20 cm above the ground, and the distance to the nearest wall – from the end of the pipe to the wall must be at least 60 cm.