The work of connecting the cable from the power line pole to the inlet junction box on the house should be carried out by a specialized organization: it is too demanding an area. Nevertheless, you need to decide on the method of entry – overhead or underground – as well as the type of cable and its cross-section. So you will have to deal with how you can connect electricity from the pole to the house and choose your option.

Bringing electricity through the air

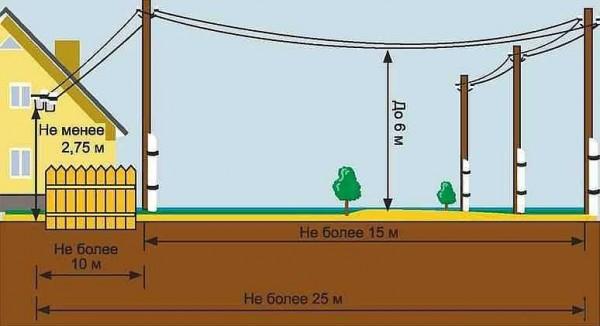

The air method of supplying electricity is attractive because it does not require a lot of time and money. But the regulations set requirements that not all houses meet:

Although copper wires require a smaller diameter, they cost considerably more than aluminum. Therefore, the introduction of electricity into the house from the pole is most often made of cables with aluminum cores. There are two ways:

- Between the poles to stretch a torso or wire, to it on special clamps to attach a current-carrying cable.

- Use self-supporting wires, for which the support is not necessary: CIP (self-supporting insulated wire). It is connected with the help of:

- insulators (glass, polymer, porcelain);

- special fittings.

Special fittings appeared not so long ago, but are becoming increasingly popular. It has a certain safety margin. If it is exceeded (falling trees, mass snowfall, etc.), the armature is destroyed, but the cable remains intact, the power supply is not disturbed.

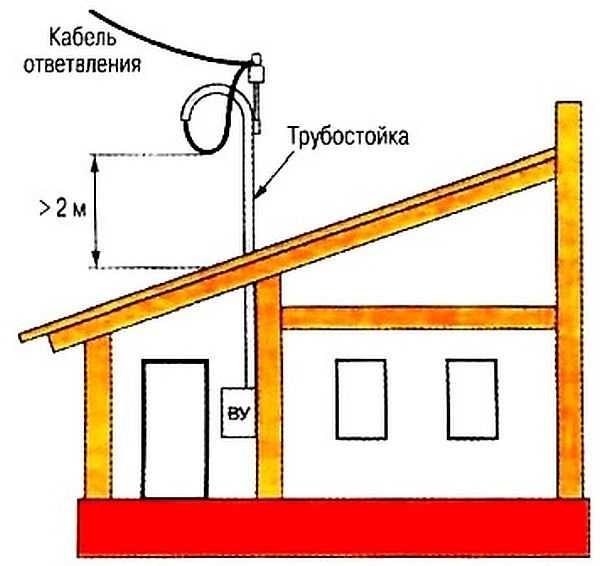

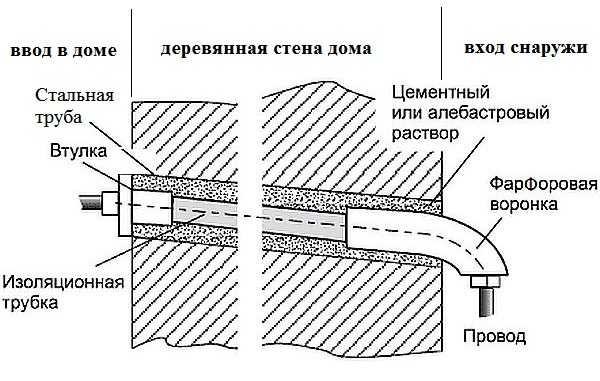

From the place where the cable touches the wooden wall of the house to the place where the switchboard is installed, the cable should be laid in a steel pipe

The air entry of electricity into the house has disadvantages:

- The wiring is exposed, which can cause damage to the wiring.

- Hanging wires limit the possibilities when approaching large equipment (cranes, aerial trucks, etc.).

Underground (trench) electricity entry

Another way to make an electricity supply to a wooden house is underground, through a trench.

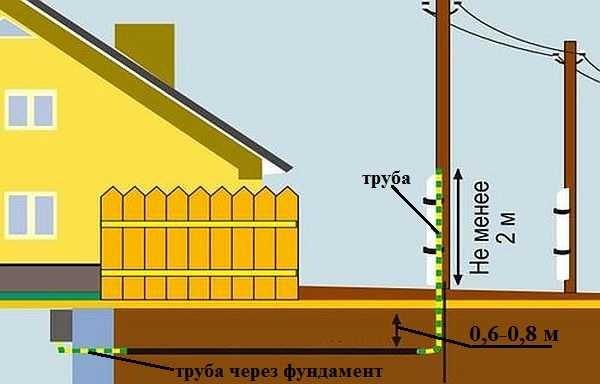

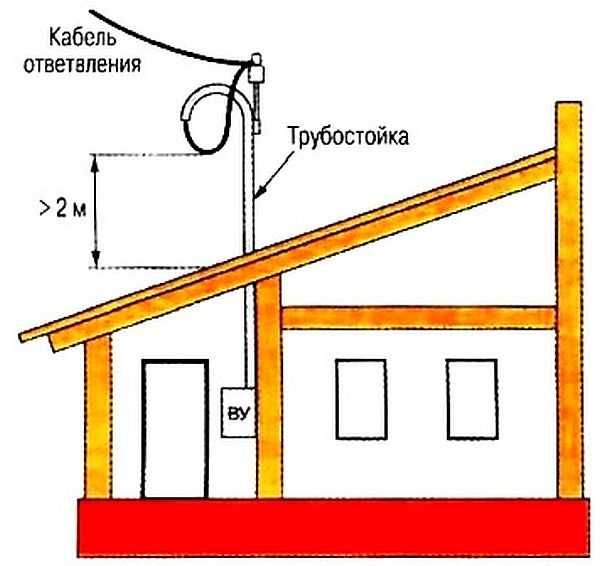

In this case, the cable on the post is lowered inside the steel pipe, its height should be at least 2 m from ground level. Then, from the pole to the place of entrance to the house, a trench is dug. Its depth:

- 0.7 meters, when laying the cable in a plastic or asbestos pipe or under the protection of a brick (concrete) slab

- 1 meter – without protection.

The power cable enters the house also in a metal pipe. It can be run through the foundation (strip), but not under it. The second option is to raise the pipe along the wall by at least 2 meters, and at this height to conduct it through the wall, also in a metal pipe.

When connecting underground to the pole, it is recommended to use a power cable with copper conductors in reinforced insulation, better – armored. With a power consumption of less than 15 kW restrictions on the cross-section of copper conductors is not, but most often use a cable VBbshv with a core of 10 square millimeters.

All these works – up to the connection of power to the electric meter and its sealing – must be carried out by a special organization. Independent connection is forbidden, and even threatens with fines: it requires an agreed project and a certain level of tolerance. But choose the type of connection, and then all other work on the installation of electrical wiring in the house – you can do with your own hands.

How to assemble the electrical panel read here. It will be useful to read about the rules of connecting wires in junction boxes.

Cable entry through the wooden wall of the house or foundation

If from the pole to the wooden house is laid CIP or other conductor with aluminum conductors, according to the PUE to enter it into the house is not allowed: “it is not allowed to lay cables with aluminum conductors on combustible structures. It is necessary to switch to copper. Most often for this purpose is used cable VVGng – in non-combustible insulation.

It should be remembered that to connect these two conductors use terminal boxes, the usual twisting is inadmissible. United directly copper and aluminum enter into an active chemical reaction, quickly and strongly oxidized, which worsens the contact. As a result, even with minor loads in the place of connection appears a spark, and this – a direct path to fire. Therefore, the use of terminal boxes is mandatory. They are in a sealed case, there are open. For use on the street, of course, it is better sealed, in the house you can put and open.

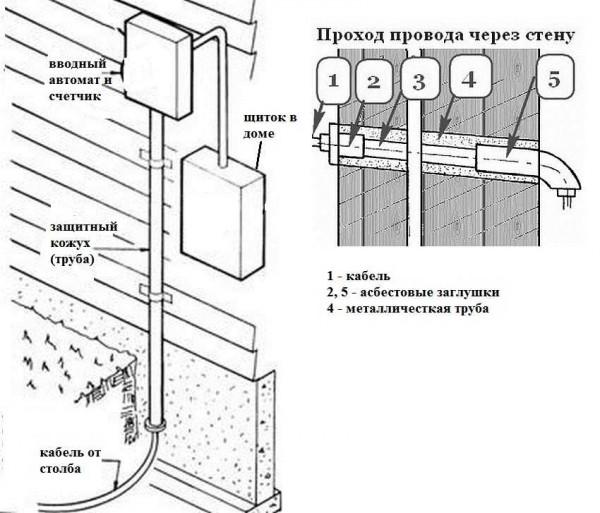

But this is not all. Through the wooden wall, you can conduct the power cable only through a steel pipe with a thick wall. The diameter of the pipe must be at least 4 times the outer diameter of the wire. The wall thickness is standardized (SP 31-110-2003) and must be no less than:

- 2.8 mm for cables with core cross section of 4 sq. mm

- 3.2 mm for cables with conductors 6-10 sq. mm.

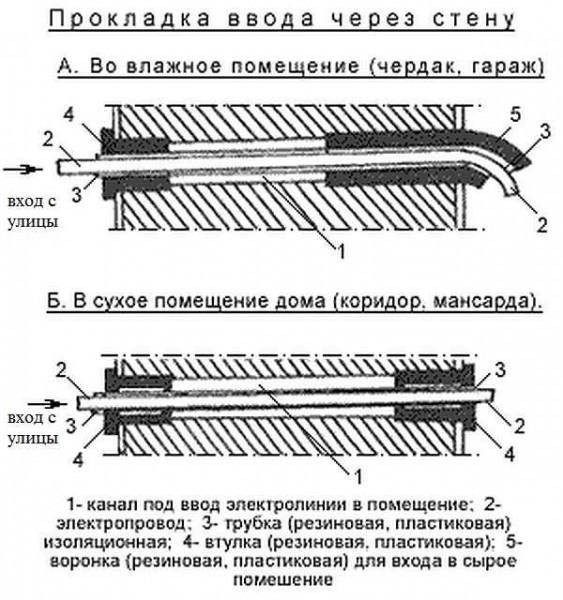

It is desirable to locate the inlet with a reverse slope so that water does not flow inside. To seal the entry and exit points, as well as to ensure electrical safety, you can use asbestos, rubber or plastic plugs. The edges of the pipe will need to be carefully trimmed and sanded until completely smooth so that the cable does not fray and its sheath is not damaged.

For reassurance and to increase reliability, the section that will be inside the pipe can be wrapped with asbestos thread or other insulating material. It can also fill the space inside the pipe so that insects do not settle there. Another option is to fill the pipe with cement or alabaster mortar.

On how to make wiring in a wooden house, read here.

When entering through the foundation, the situation is slightly different: the structure is no longer considered combustible, so you can use plastic tabs. They are installed at the stage of manufacture of the strip foundation. In this case, the cable entry differs depending on whether the cable enters a wet or dry room.

Parts necessary to organize a safe entry of electricity into the house, cost not very much, but significantly increase the reliability, electrical and fire safety of your home. The structures are not complicated at all, you can cope with their arrangement with your own hands.

Hey! I once helped my neighbor wire his shed. We ran the main line from the pole and made sure to use proper insulation and grounding. It was tricky, but with some teamwork and the right tools, we got it done safely. Always check local codes before starting!