Cable and conductor products are quite diverse. But how to make sense of this variety, how to understand what is encoded in the name? For easier identification was developed a whole system – cable marking. These are letter designations, which encrypts the basic information about the material of the cores, sheaths and the field of application of this particular product.

Contenuto dell'articolo

General principles of cable product labeling

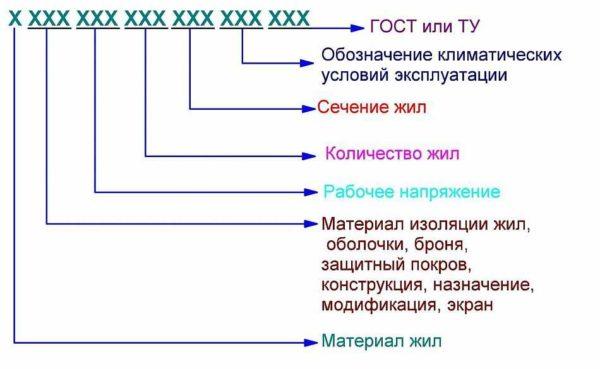

In order to identify the cable, its characteristics and area of application was easier, a system of designation or cable marking was developed. Data are written in a certain order, each letter or number has its own meaning.

What each position means and what letters can stand there, see the table below. There is nothing much to add here:

| The arrangement of letters or numbers | What stands for | Used letters and their decoding |

|---|---|---|

| 1st letter | Core material | – no letter – copper |

| A – aluminum | ||

| 2nd letter | Degree of flexibility | D – flexible, multicore |

| nothing – single core | ||

| 3rd letter | Insulation material | B – polyvinyl chloride (PVC) |

| P – polyethylene | ||

| R – rubber | ||

| HP – non-combustible | ||

| F – fluoroplastic | ||

| C – film insulation (for assembly wires) | ||

| 4th letter | Sheath material or armor type | BbG – armor made of steel profiled tape |

| Bn – armor made of steel bands with a protective cover that does not support combustion | ||

| B – PVC | ||

| D – double wire braiding | ||

| K – armor made of round steel wires enclosed in a steel covering | ||

| SB – lead armor | ||

| 5th letter | Type of protective cover, purpose of the outer layer, designation of the core construction | B – PVC (if it is at the end it means paper insulation) |

| G – anti-corrosion protective layer. If “G” – no protection from mechanical damage | ||

| O – insulated wires are united by a common braid | ||

| Cp – protective layer – extruded PVC hose | ||

| Shp – protective layer – extruded polyethylene hose | ||

| Shps – the same, but self-extinguishing polyethylene | ||

| E – shielded | ||

| T – wire for laying in pipes |

Also, the cable marking consists of several digits. There may be a working voltage (for power cables), then necessarily goes the number of cores and through the sign “x” indicates the cross-section of these cores. And the last may be applied to the designation of the standard, according to which this type of cable and wiring products are manufactured.

Examples of deciphering the marking of cables

Cable VVG – 2×1,5. Decoded as follows: power cable in a sheath made of polyvinyl chloride (PVC). The sheath is covered with an anti-corrosion layer. It consists of two copper conductors with a cross-sectional area of 1.5 mm2.

Its subspecies – VVGp – also, only in flat version. VVGng – cable wrapping does not support burning.

Cable VBbshvng. The deciphering of this abbreviation is as follows: the cores are copper (no letter A). Insulation of PVC cores, armor Bb – of two steel bands, without protective cushion. Protective cover of cable – Shvng – disembodied hose made of PVC of reduced flammability.

Cable KG. Decoding of the letter designation is as follows. The cores are copper, the cable is flexible. That’s it. Wires without insulation, if there is still the letter “n” – KGn – cable sheath made of non-combustible oil-resistant rubber.

How to decipher APvPu2g? Cable with aluminum conductors (letter A first), wire insulation made of cross-linked polyethylene (Pv), cable jacket made of reinforced polyethylene (Pu), double waterproofing (2g). In this case, aluminopolymer tape is used in combination with longitudinal waterproof tapes.

KSPV cable. This stands for: cable (K), transmission systems (SP) in a vinyl sheath (V). That is, it is not a power cable, but is used for the transmission of various data (low-current). Conductors are copper – since there is no letter “A”.

Products AABL. Decoding is as follows: aluminum wires (A), sheath – aluminum (A), covered with armor of two steel bands (Bl), under the armor there is a protective cushion of plastic tapes.

APvPu – aluminum conductors (A), insulation of cross-linked polyethylene (Pv), reinforced sheath of polyethylene (Pu).

MKESH – installation cable (MK), shielded (E), in PVC protective hose.

Features of wire marking

In the range of cable-conductor products there are also wires. How do they differ from the cable? As a rule, they have a smaller cross-section, can be in insulation or without it. There are wires consisting of a single core, there are wires consisting of several cores.

To distinguish them from cables by name, in the name at the beginning of the marking put the letter “P”. It is in the first place, if the conductors are copper and their designation is simply not put (example 1), or in the second place, if the conductors are aluminum and denoted by the letter A (example 2).

- PBPPG – wire (P), domestic and industrial (BP), flat (P), flexible (G).

- APPV – aluminum conductors (A), wire flat (PP), in PVC sheath.

Wires can be of two cross-sections:

- round – in the marking it is not displayed in any way:

- flat, then the letter P is put.

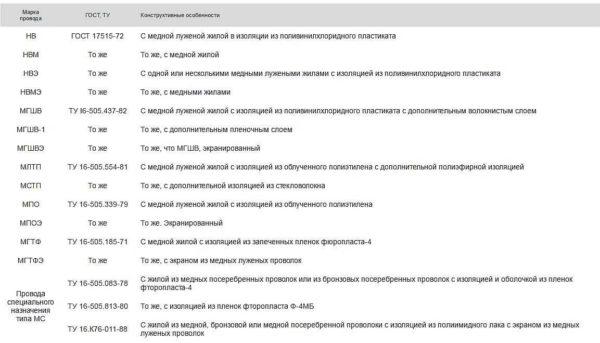

Mounting

If the wire has a specific purpose – mounting – instead of the letter “P” put “M”. For example, MGSHV. Decoded as mounting (M) multicore (G) wire in a sheath of polyamide silk and PVC.

The purpose of mounting wires – for connecting parts of devices, electronic and electrical equipment.

PVC insulated wires (marked with letter B) are designed for operation at temperatures not exceeding 70°C, cross-linked polyethylene (Cp) – up to 100°C. For operation in the environment heated up to 200°C wires of MC and MGTF types are used.

Self-supporting

Wires that are installed on power lines or used in the air method of connecting electricity from a pole to the house are called self-supporting – they do not need a support. They have enough rigidity to support their own weight.

There are not many products in this group, their deciphering can be memorized:

- CIP – self-supporting insulated wire in a sheath of cross-linked polyethylene. It is used in the air connection to the pole.

- A – wire twisted from several aluminum wires without insulation. Used to be quite widely used, now – less and less often.

- AC – aluminum conductors twisted around a steel core. Quite a specific product.

There is a separate group – heating cables. They have their own labeling. After the letter “P” is “H” as a representation of the purpose. For example, PNSV – wire (P), heating (H), single-wire steel core, PVC insulation.

I remember when I first learned about cable markings while working on a DIY project. It helped me avoid mixing up wires! Color coding shows voltage levels and uses, making it way easier to keep everything safe. Definitely a lifesaver for any electrical work!

Cable markings are super important! I remember when I was setting up my home office, and I almost mixed up my power cables and data cables. The markings helped me avoid a power surge disaster. Always check those labels to keep things safe and organized!

Totally get you! I once tangled my audio and power cables while jamming out. If I hadn’t checked those labels, I might’ve fried my speakers. It’s wild how something so small can save us from major headaches. Labeling is key for sure! Stay safe, friend!

Totally feel you! I did the same when I was wiring my gaming setup. I almost plugged my monitor into the wrong outlet. Those cable markings saved me from a total mess! Now, I double-check every time. Gotta keep it tidy and safe, right?