For a novice welder, choosing an electrode can be a challenge. There are more than two hundred brands with different properties, purpose and characteristics. And about 100 brands are suitable for manual electric arc welding with inverter machines. It is impossible to tell about all of them, and it is not necessary to begin with. Just briefly characterize the main types and what electrodes for inverter welding are more suitable for beginners.

Isi artikel

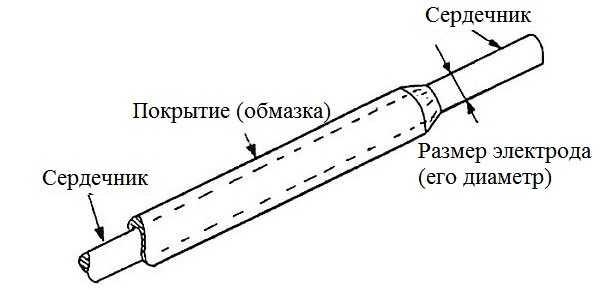

What is an electrode and what is the cladding for

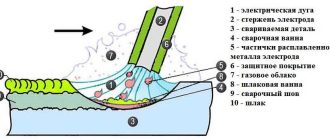

An electrode is a piece of metal wire with a special coating – cladding. During welding, the core melts from the arc temperature. At the same time, the cladding burns and melts, creating a protective gas cloud around the welding area – the weld pool. It cuts off the oxygen contained in the air. In the process of burning the cladding, part of it becomes liquid and covers the molten metal in a thin layer, also protecting it from interaction with oxygen. So the cladding ensures good weld quality.

Any electrode is inspected before welding: the coating should not have chips. Otherwise, you will not achieve homogeneous heating and a high-quality weld. Also pay attention to the tip of the electrode: the thickness of the coating should be the same on all sides. Then the arc will come out in the center. Otherwise, it will be displaced. For welders with experience this is not terrible, but for beginners it can create tangible problems.

It is necessary to monitor the moisture content of the cladding. Some of them at high humidity ignite very poorly (for example, UONI). Due to this “capriciousness” of the grease, they should be stored in a dry place, providing if possible hermetic packaging. You can put the box in a bag, and also put a few bags of salt, which are in shoe boxes.

It is not worth buying wet electrodes: they can, of course, be dried, but their characteristics will be reduced. If it still happens that the electrodes have become damp, they can be dried in an ordinary household oven at low temperatures (they are usually indicated on the package). The second method is to put them for a long period of time in a dry, well-ventilated room.

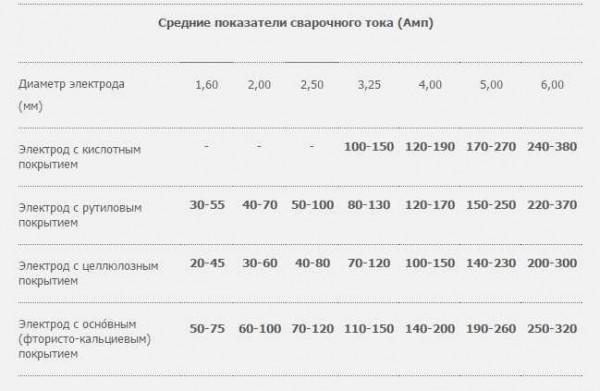

Types of coating and their characteristics

There are only four types of coatings:

- Basic.

- Rutile.

- Acidic.

- Cellulose.

Basic (UONI) and cellulose coatings are suitable only for direct current welding. They can be used on responsible seams: they create a strong, elastic weld, resistant to shock loads.

The other two (rutile and sour) – can work for both AC and DC welding. But the acid coating is very toxic: it can only work indoors if the workplace is equipped with forced exhaust.

Rutile cladding has a greenish or blue tint, electrodes are characterized by easy ignition. They are well ignited even if the inverter has a low idle voltage (a good volt-ampere characteristic is required for confident ignition of the main coating, how to choose an inverter welding machine, read here.). When welding with rutile electrodes (MP-3), the metal is almost no spatter, but there is a lot of slag and it is not easy to get away: you have to work with a hammer.

Perhaps you will be interested in how to weld a gazebo from a metal pipe or how to make a shed on a frame from a pipe.

How to choose electrodes for inverter welding

First of all, the composition of the core is selected: it should be similar to the type of metal being welded. In the household, structural steel is most often used. Here from the same wire and should be electrodes. Sometimes it is still necessary to weld stainless steel. Then the core should also be made of stainless steel, and for high-alloy and heat-resistant make of metal with the same characteristics.

Perform all work at home or on the construction site can be done with the use of only a few brands of electrodes:

- MR-3

- UONI 13/55

- ANO 21

- OK 63.34

They are recognized by many as the best electrodes for beginners who work with inverter welding machines: it is easier to work with them, at the same time, they allow you to cook high-quality welds even in the absence of significant experience. Below are the characteristics and general application of those consumables that many specialists consider good electrodes for inverter. In any case, they are often recommended to novice welders to gain experience.

Electrodes with rutile coating MP 3

Most often beginners are advised to start mastering welds with MR-3 electrodes. They are easily ignited, even with not very good volt-ampere characteristics of the welding machine, give good protection of the weld pool, allow you to control its position quite easily. If the electrode is not ignited, calcine it at a temperature of 150-180 ° for 40 minutes.

They are used in machines with alternating (welding transformers) and direct current (welding rectifiers and inverters). Inverters are usually connected in reverse polarity (+ on the electrode). They are suitable for any type of weld except vertical top-down.

Read about the types of welding machines here.

MR 3 electrodes are not capricious to the quality of welded surfaces. They can be used even on untreated, rust-covered and wet parts. Welding is carried out with medium (2-3 mm) or short arc.

The feature of MP 3 is very important for novice welders: they “hold” the arc well, it is easy to work with them. For this, not all professionals like this brand: they call them Bengal lights. They weld too softly: slow movements are necessary for good heating. Which is not to the taste of the pros, for beginners it’s just what they need. Try to start your welding training just with MP3. You should be fine.

| Electrode diameter LEZ MP-3, mm | Length, mm | Recommended welding current, A | Pack weight, kg | Price, rub |

|---|---|---|---|---|

| 2,0 | 250 | 40-60 А | 1,0 | 146 |

| 2,5 | 300 | 60-100 А | 1,0 | 120 |

| 3 | 350 | 70-100 А | 1,0 | 95 |

| 4 | 450 | 80-170 А | 1,0 | 91 |

| 5 | 450 | 130-210 А | 1,0 | 91 |

UONI 13/55 with basic coating

Ini mungkin adalah elektroda yang paling luas dan populer dengan lapisan dasar. Elektroda ini direkomendasikan untuk mengelas baja karbon dan baja paduan rendah. Mereka cocok untuk sambungan struktur kritis. Jahitan diperoleh kuat untuk beban kejut dan plastik, mentolerir efek suhu rendah.

Kerugian dari elektroda ini: elektroda ini hanya dapat dinyalakan dengan baik pada nilai kecepatan idle yang cukup besar pada inverter (di atas 70 V). Kerugian signifikan kedua: persyaratan tinggi untuk pembersihan dan pemrosesan logam yang dilas. Jika karat, debu, minyak atau kontaminan lainnya tetap berada di tepi, jahitannya akan keropos.

Bekerja dengan UONI 13/55 hanya dapat dilakukan pada mesin las DC, termasuk inverter, dengan polaritas terbalik (+ diumpankan ke elektroda), dan busur pendek (jaga agar ujung elektroda tetap lebih dekat ke permukaan yang dilas). Tegangan idle minimum adalah 65 V.

| Diameter elektroda UONI 13/55 (pabrikan Mezhgosmetiz) | Panjang elektroda, mm | Recommended welding current, A | Harga eceran satu paket, rubel |

|---|---|---|---|

| 2,0 | 250 | 30-60 А | |

| 2,5 | 300 | 40-70 А | 127 gosok |

| 3 | 350 | 80-100 А | 116 rubel |

| 4 | 450 | 130-160 А | 111 rubel |

| 5 | 450 | 180-210 А | 110 rubel |

ANO 21

Jenis elektroda dengan lapisan rutil ini dirancang untuk bekerja dengan baja karbon dengan ketebalan kecil. (Baca tentang pengelasan logam tipis di sini.) Saat menggunakannya, busur mudah dinyalakan (termasuk penyalaan ulang), lasan terkelupas halus (dari gelombang berukuran kecil), terak mudah dipisahkan. Elektroda ANO 21 dapat digunakan untuk mengelas pipa air atau gas.

Mereka bekerja dengan arus bolak-balik dan arus searah dengan polaritas apa pun. Sebelum pengelasan, mereka memerlukan perlakuan panas: dikalsinasi pada suhu 120°C selama 40 menit.

| Diameter, mm | Posisi elektroda yang lebih rendah | Posisi elektroda vertikal | Posisi elektroda langit-langit |

|---|---|---|---|

| 2 | kekuatan saat ini 50-90 A | kekuatan saat ini 50-70 A | kekuatan saat ini 70-90 A |

| 2,5 | kekuatan arus 60-110 A | kekuatan saat ini 60-90 A | kekuatan saat ini 80100 A |

| 3 | kekuatan arus 90-140 A | kekuatan arus 80-100 A | kekuatan arus 100-130 A |

Stainless steel electrodes OK 63.34

Jika Anda perlu mengelas baja tahan karat, cobalah OK 63.34. Las ini juga dapat digunakan untuk mengelas baja struktural. Ini menghasilkan lapisan dengan gelombang halus dengan transisi yang mulus ke permukaan utama logam. Jumlah terak kecil, mudah dikalahkan.

Elektroda ini bagus untuk mengelas las vertikal dan logam 6-8 mm, melintas dari atas ke bawah. Cocok untuk pengelasan multi-lintasan pada sambungan butt dan sambungan tumpang tindih. Bekerja dengan arus searah dan arus bolak-balik dengan polaritas apa pun, tegangan tanpa beban minimum - 60 V.

Untuk pengelasan, Anda masih memerlukan masker. Agar lebih mudah bekerja, ambillah bunglon topeng las.

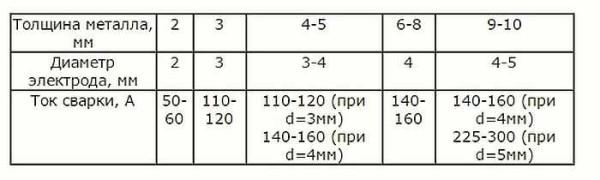

How to choose the diameter of the electrode, how to connect it and how to set the current strength

Memilih merek elektroda untuk inverter bukanlah segalanya. Bahkan jika Anda telah memutuskan, setidaknya masih ada tiga pertanyaan yang tersisa:

- Berapa diameter elektroda yang akan digunakan saat mengelas;

- arus apa yang akan ditetapkan;

- ke output "+" atau "-" untuk menyambungkan elektroda.

Mari kita bicarakan semuanya secara berurutan. Mari kita mulai dengan diameter elektroda yang diperlukan untuk pengelasan. Secara umum, disarankan untuk melanjutkan dari ketebalan logam yang dilas: untuk ketebalan kecil, elektroda diambil dengan diameter dengan ukuran yang sama dengan logam. Jika Anda mengelas logam setebal 3 mm, maka elektroda mengambil ukuran yang sama. Jika Anda mengelas sesuatu yang lebih tebal, masing-masing ambil 4 mm. Tetapi akan sulit bagi pemula untuk bekerja dengan elektroda besar. Mulailah menguasai pengelasan dengan ketebalan logam 3-4 mm. Untuk melakukan ini, gunakan elektroda 3 mm, atau seperti yang mereka katakan "tiga kali lipat".

Mengenai cara menghubungkan elektroda ke output apa. Dalam spesifikasi teknis pada kemasan, kemungkinan besar, diindikasikan untuk polaritas mana elektroda dimaksudkan. Dalam polaritas terbalik, elektroda dihubungkan ke output positif, output negatif dihubungkan ke penjepit, yang dijepit ke bagian tersebut. Dengan polaritas maju, plus dihubungkan ke benda kerja dan minus ke elektroda. Bagaimana tampilannya pada inverter pengelasan ditunjukkan pada foto.

Apa perbedaan kedua jenis koneksi ini? Aliran elektron memiliki arah yang berbeda. Seperti yang Anda ketahui, elektron bergerak dari "minus" ke "plus". Oleh karena itu, apabila melakukan pengelasan, ternyata elemen yang terhubung ke "+" lebih panas. Dengan mengubah mode koneksi, Anda dapat mengontrol intensitas pemanasan logam.

Mari kita pertimbangkan beberapa situasi. Contohnya, Anda memiliki elektroda 3 mm, logam 2 mm. Jika Anda menerapkan "+" ke bagian tersebut dapat terbakar. Oleh karena itu, dalam hal ini lebih baik menggunakan polaritas terbalik, yang akan menjadi elektroda yang lebih panas. Jika Anda ingin mengelas logam 6 mm dengan tiga yang sama, lebih baik melakukannya pada polaritas langsung: sehingga pemanasan logam akan lebih dalam dan jahitannya akan lebih tahan lama.

Bagaimana memilih mesin las inverter baca di sini. Anda mungkin tertarik untuk membangun pagar dari baja bergelombang.

Current strength when welding

Secara umum, saat memasang elektroda, kekuatan arus pengelasan untuk inverter diatur tergantung pada diameter elektroda yang digunakan. Secara umum, setiap paket memiliki rekomendasi, tetapi Anda dapat melakukannya tanpa mereka: untuk setiap milimeter diameter, ambil arus 20-30 ampere. Ternyata kisarannya cukup luas, tetapi kemudian Anda masih perlu memperhitungkan bagaimana Anda akan memasang lasan: dengan atau tanpa pelepasan. Untuk pengelasan tanpa sobekan, letakkan arus yang lebih rendah, dengan sobekan - lebih tinggi.

Misalnya, untuk elektroda dengan diameter 3 mm, arus yang dihitung adalah dari 60 A hingga 90 A. Benar-benar bekerja dalam kisaran dari 30 Ampere hingga 140 Ampere. Saat pengelasan tanpa putus, arus diatur sekitar 70-90 A, dengan putus - 90-120 A. Parameter ini dapat "berjalan" di kedua arah: tergantung pada kecepatan pergerakan ujung elektroda, pada merek dan "fluiditas" baja yang dilas, pada posisi pengelasan (untuk pengelasan vertikal dan horizontal, letakkan sedikit lebih sedikit, untuk langit-langit - lebih sedikit lagi).

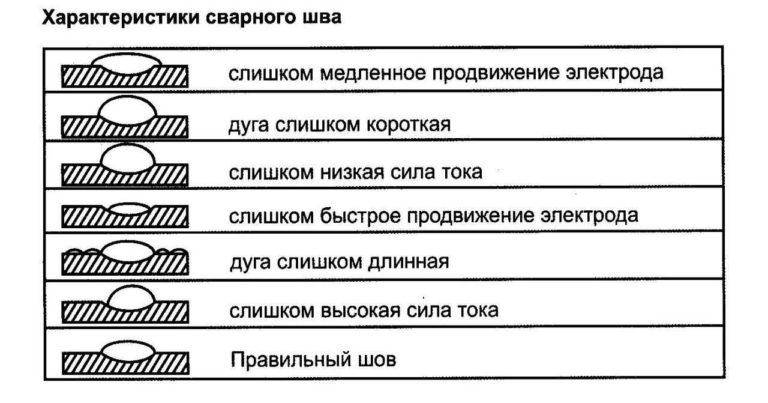

Secara umum, bahkan arus yang direkomendasikan oleh produsen pun jauh dari persyaratan. Mulailah dengan mereka, dan kemudian pilih agar Anda merasa nyaman bekerja dan jahitannya bagus. Anda harus mendapatkan koneksi berkualitas tinggi, dan rasio arus serta kecepatan yang akan Anda pilih secara eksperimental. Pada saat yang sama, fokuslah pada kondisi kolam las. Dia adalah indikator kualitas utama Anda.

Tentang cara mengelas dengan benar dengan pengelasan inverter, baca di sini.

Sekarang Anda tidak hanya tahu cara memilih elektroda untuk pengelasan inverter, tetapi juga cara menyambungkannya, diameter apa yang Anda butuhkan untuk pekerjaan ini, dan cara mengambil arus untuk setiap jenis elektroda dan pengelasan. Sekarang mari kita bicara sedikit tentang pemegang elektroda.

Electrode holders

Pada salah satu kabel las, terdapat penahan (holder) tempat elektroda las dimasukkan. Ada dua jenis pemegang:

- dengan kunci pemicu, di dalamnya elektroda dijepit secara otomatis ketika kunci pegas dilepaskan dengan menekannya;

- berulir - pegangannya disekrup dan dibuka, melepaskan atau menjepit inti elektroda yang dimasukkan.

Mana yang lebih baik? Terserah Anda, tetapi dengan menekan tombol secara tidak sengaja, Anda dapat menjatuhkan elektroda selama pengelasan. Tidak ada hal buruk yang terjadi dalam kasus ini, tetapi tidak menyenangkan ...

Ketika memilih pemegang elektroda, hal utama yang harus diperhatikan adalah kekuatan arus yang dirancang. Anda memilih parameter maksimum, yang tersedia untuk mesin las Anda.

Cara menyambungkan kabel ke dudukan elektroda las dengan penjepit berulir ditunjukkan dalam video.

Kerugian dari penahan jepitan adalah, bahwa seiring waktu, pegas yang menjepit inti elektroda akan melemah dan kontaknya memburuk. Anda perlu memasang yang baru. Cara melakukannya pada pemegang jepitan, lihat di video.

Menghubungkan dudukan elektroda untuk pengelasan tidaklah sulit. Hanya ada satu nuansa: dengan pekerjaan yang sering, kabel las digosok oleh ujungnya. Anda tentu saja dapat mempersingkat kabel dan mengulanginya, tetapi Anda tidak selalu ingin memotong bahkan 10-20 cm. Untuk mencegah hal ini terjadi, cari selang yang diameter dalamnya sama atau sedikit lebih kecil dari diameter luar kabel las. Potong sebagian kecil - sekitar 15 sentimeter - dan potong memanjang. Ini sekarang dapat diselipkan di atas kabel, ditarik ke atas dan diamankan di sana.