In order to heat a private house cheaper, some heating maintenance work owners prefer to do on their own. One of such operations is pumping coolant into the heating system. The process of filling the heating system can not be called complicated, but it is quite labor-intensive, so it is better to prepare in advance all the necessary equipment and tools.

Isi artikel

Choice of coolant

Two categories of working fluids are used in heating systems: water and antifreeze. Each option has its pros and cons.

Water. This is a completely harmless and practically free coolant, which, compared to antifreeze, can be considered an advantage. However, before you fill the heating system with water, it should be cleaned of hardness salts and mechanical impurities. The cost of purified (distilled) liquid is quite high. The main disadvantage of water as a coolant – a significant increase in volume when freezing. Therefore, for buildings with temporary residence should choose the second option – non-freezing liquids.

Antifreeze. These coolants are aqueous solutions of ethylene glycol and propylene glycol. Freezing point, depending on the concentration and type of dissolved substance, is within -30 … -60 °C. When choosing antifreeze for the heating system, it is necessary to take into account the peculiarities of a particular composition:

- ethylene glycol-based. Very toxic liquid. It is not allowed for use in open systems and private houses, especially in two-circuit heating schemes. The liquid has a bright crimson color.

- based on propylene glycol. The coolant will be the best option for heating systems in private homes. It is more expensive than the ethylene glycol analog, but this is compensated by its harmlessness to humans and the environment.

Antifreezes based on glycols can not be used with galvanized pipes, as the contact starts an active reaction and the coolant changes its composition.

How the heating system is filled

The method of pouring antifreeze into the heating system depends on whether it is open or closed. For each scheme, a different option is chosen. In most cases, the purchased antifreeze is a concentrate, which should be diluted before pumping it into the heating network. This should be done strictly according to the manufacturer’s instructions.

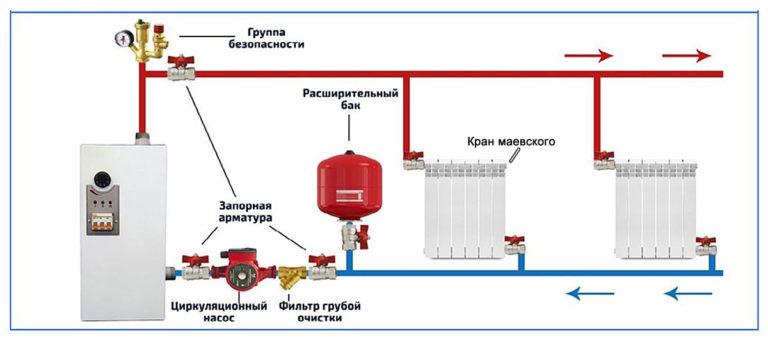

Filling a closed heating system

In this type of heating system, it is easiest to pump antifreeze into the heating system with the help of a pump, which is connected to the make-up connection. If there is no pump, the coolant should be poured through the highest point, having previously unscrewed the automatic air vent. A helper will be needed when filling. He will let the air out of the radiators while the coolant is being pumped. This will allow the timely elimination of formed air plugs.

Preparation for work. Before pouring antifreeze into the heating system, it is necessary to prepare. To do this, you should:

- close the Maevsky discharge cocks and those that cut off the boiler;

- open all stop valves and the expansion tank valve.

The purchased antifreeze should be diluted to the required concentration according to the manufacturer’s instructions.

Filling process. When pumping antifreeze, the pressure in the system is monitored with a manometer. After reaching the values of 1.4-1.5 bar, the assistant begins to gradually release air from the heating batteries in sequence from the lower to the upper. At the same time, the second worker monitors the pressure level in the system so that it does not fall below 1 bar. For this purpose, antifreeze is constantly pumped into the pipes. After all the air is out of the system, the pumping of coolant continues until the pressure in the system reaches 1.5 bar. Then open the boiler taps: first on the return line, then on the supply line. It is very important to open the second tap very slowly, so that the air has time to escape through the air vent. The pressure will start to drop again and the antifreeze should be pumped up again.

Completing the pumping. After the radiators are filled, the remaining air should be vented from the circulation pump. Then the pumping of the system without heating radiators is carried out. To do this, turn on the heat generator (boiler) and the circulation pump. After warming up the pipes on each radiator open the valves and check whether the air is completely out of them. If everything is done correctly, the pressure will reach the required level and stabilize.

What to look out for. The make-up line of a closed heating system must necessarily be equipped with a spring-type check valve. If it is absent, it will be very difficult to pump the coolant there. When starting the heating and reaching the operating temperature, the pressure in the pipes should not exceed 1.8 bar.

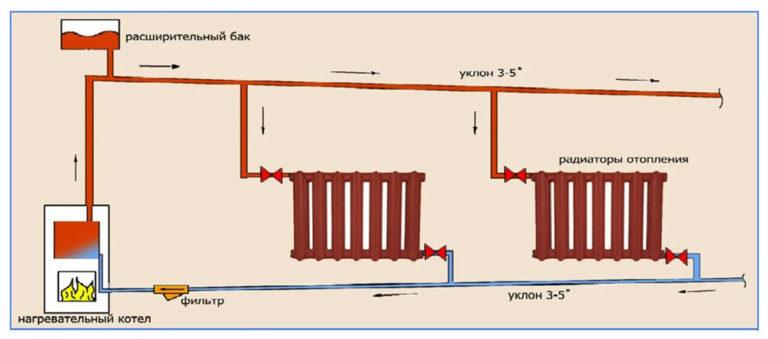

Filling an open heating system

For heating of this type, only harmless antifreeze based on propylene glycol should be chosen. The system is equipped with an open expansion tank with a lid, where the coolant should be poured.

Filling process. The coolant can be poured directly into the tank or through the make-up valve. In the latter case, a pump is used. Before the start of filling, the Maevsky valves on all radiators should be opened. As they are filled, they are gradually closed. Pumping is stopped when the level in the expansion tank starts to rise.

What to pay attention to. Before starting pumping, open all stop and control valves in the system. After starting and heating the coolant to the required temperature, it is necessary to bleed the air from the radiators again through the Maevsky cocks. If after that the liquid level in the expansion tank has dropped, antifreeze is topped up to about ½ of the volume.

How to drain the coolant

The working fluid from the system is drained into the sewer, if water is poured in, or a special tank if antifreeze is used. Drainage includes several consecutive stages:

- a hose is connected to the boiler return line tap, the other end is led out into a tank or sewer;

- the return line valve is opened and the coolant is drained from the pipes;

- after the liquid is drained, the valve is closed again;

- Mayevsky valves are opened to fill the highest point with air;

- the coolant is drained from the system again;

- Mayevsky valves are opened in the whole heating system;

- the coolant is drained for the third time.

At the end of the work, the hose is switched to the supply line.

Since the work requires certain skills, it is recommended to call specialists to fill and drain the coolant of heating systems.

When I had to top up the coolant in my heating system last winter, I learned a few tricks. Make sure to turn off the boiler first and let it cool down. Use a funnel to avoid spills and check for any leaks afterward. Keeps the house nice and warm!

Oh man, I totally get you! Last winter, I spilled coolant everywhere because I forgot the funnel. Such a mess! Now I always double-check that boiler’s off and take my time. It’s crazy how those little steps keep everything running smoothly and the house toasty! Gotta love that warmth!

Totally feel you on that! Last winter, I had a similar issue. I didn’t let mine cool down and ended up with a mini geyser in the basement! Definitely learned to use a funnel and double-check for leaks after that. No more surprises, just cozy vibes!