During renovation, one of the tasks is to paint the radiators. To make the result pleasing, the paint for radiators must be chosen correctly. It is not as easy as it seems – there are a few pitfalls to be aware of.

Article content

What paints are suitable for heating radiators

Our heating systems are unpredictable – the radiator can be cold, or it can be heated to high temperatures. And although most systems today operate at low temperatures, it is better to be reinsured. Therefore, the paint for heating radiators should be heat resistant – it should withstand heating up to 90°C. It should also be designed for painting metal.

There are universal compositions that meet these requirements, there are special ones, on which it is written: “Paint for pipes and radiators heating”. If there is no large inscription, look for a similar line on the favorite paint in the section where the area of application is described. If there is nothing similar, it is better to look for another option.

What else you should pay attention to is the presence of the address of the manufacturer and the name of the company. Today there are many fakes on the market. The label is very similar to some famous brand, but there is no address information. If this is the case, it is better not to risk – it is unknown what is in this jar.

Types and differences

In addition to the above requirements, it is desirable that the paint for heating radiators does not smell strongly, and it is better to be odorless at all. Another wish is the durability of the coating. Normal appearance of the surface should be maintained for several years. Well and definitely – the color should not change over time. All these requirements and wishes meet not so many compositions.

Alkyd enamel

Alkyd enamel forms a strong shiny film on the painted surface. If the surface was properly prepared (cleaned, degreased and primed), a double layer of alkyd enamel will hold at least 4 years. These paints are made on different bases, because of which they have different properties:

The form of release of this type of paint – buckets or metal cans of different capacities. Packing is usually from 0.5 kg to 3 kg in tin cans, in buckets up to 25 kg, then packed in barrels. This paint is applied with a brush, roller, some types allow application of paint spray.

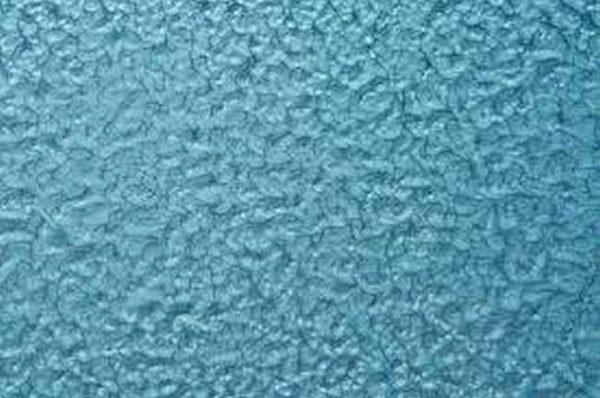

In the group of alkyd enamels there is a very interesting variant – hammer. It contains special coloring pigments that create various visual effects. The surface painted with them looks like a beaten hammer (hence the name). This texture perfectly hides the imperfections of the painted surface. Very interesting volumetric coating is obtained.

If you need to paint old cast-iron batteries or pipes with a non-ideal surface – this is your chance to do without putty and grinding. Pure white color in this group can not be found, but there are light tones, although not as many as saturated – the surface looks more interesting if the color is bright or deep.

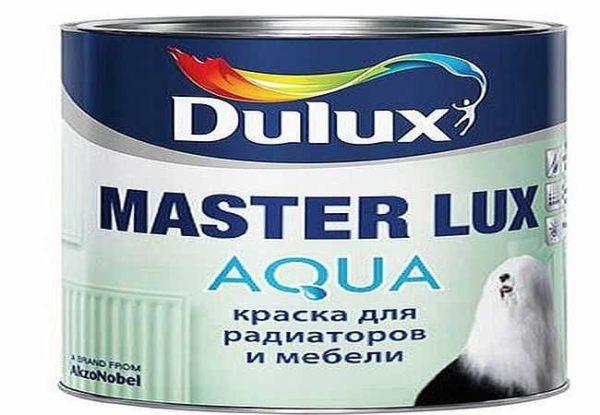

Acrylic enamel

These are water-based compositions with polyacrylates as a film-forming component. Virtually have no odor, and that is weathered in a matter of hours. They are commonly referred to as “odorless radiator paints”. Despite this, when working in a closed room, after work it must be ventilated – it is, after all, chemistry, so that harmful vapors are present, although not on such a scale as in solvent-based enamels.

These paints are used for painting facades or interior walls, there are also acrylic paints for painting. They are naturally not suitable for painting radiators. Look for acrylic metal paints with a temperature range of at least +70°C.

What they are convenient, because they are diluted simply with ordinary water, but after drying they do not rub off, do not soak. The created film is very similar to a plastic surface, remains elastic, does not crack, and cleans well. Usually it is semi-glossy or matte.

Acrylic paint for heating radiators can be sold packaged in buckets or paint, at authorized sales points you can order any color from the RAL palette. They are colored using special pigments.

What is the disadvantage of these paints? As all water-based compositions, it requires careful preparation of the surface. First you need to remove all rust, then treat the surface with a rust converter, degrease, if necessary, fill in irregularities, then – primed. Only after that you can paint radiators or heating pipes. If this is not done, rust will soon show through the paint layer.

There are acrylic enamels that do not need priming, but all other preparation should be carried out in full. For example, acrylic water primer-paint Aquametallic (the cost per 1kg – about 250-350 rkb depending on the packaging). It is suitable for painting cast iron and black metal, not used for painting non-ferrous metals or galvanized surfaces.

Not a bad option – enamel acrylic PROFI VD-AK-1179. This option – glossy, has good covering and adhesion. Under this coating primer is needed. And in general, the range of these paints is wide, there are many of them in stores.

Powder coating

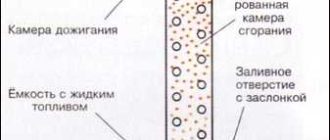

This type, perhaps, at the moment is the most durable and resistant to damage, but for its application requires the creation of certain conditions. You need a special gun for spraying powder, a power source with low voltages, as well as the ability to heat the surface to high temperatures.

The coloring composition of these paints is powder. It is necessary to cover the surface to be painted evenly. To do this, the powder is given a positive charge, and the part to be painted – a negative charge (for this purpose a current source is needed). After that, the paint is heated, as a result of which the powder polymerizes (sintered), forming a strong film.

Powder coatings are available with different polymerization temperatures – from +200°C to +350°C. As you realize, it is not easy to heat up a cast iron battery to 200 degrees. This requires a chamber. Therefore, this type of coloring at home is practically not found. If you really want exactly this paint for your heating radiators, you can go to the service station, which is engaged in painting cars. They do it exactly according to this technology. Perhaps you will be able to negotiate with them.

Oil paints

Most of the old batteries are painted exactly with oil paints, but today it is no longer at all unpopular – too many disadvantages. First, the smell is very strong and does not weathered for a long time, secondly, the paint cracks and, over time, changes color. In the presence of equal in price special paints for radiators for heating, this choice becomes quite rare. The only thing that presents difficulties is the cleaning of already painted old batteries, as the surface is usually cracked and to apply another coating on top, even if it is compatible, makes no sense – it will still be ugly.

Paint in cans

In recent years, there have been many paints in aerosol packages – spray cans. There are such paints for heating radiators. The principle of choice here is similar: you need to pay attention to the temperature regime.

Some complexity without experience is the process of applying such paint. In fact, everything is simple here: you need to spray from a distance of at least 20 cm from the painted surface, lead the jet quickly, evenly, without stopping long in one place.

Paint from cans is applied in several passes. You may need two, three, and maybe more layers – depending on the complexity of the relief. To get a uniform color, the direction of the jet changes. If in the first pass moved from top to bottom and bottom to top, then in the second – from right to left and back.

One more thing: the place where you will work cover with paper or newspapers, and quite a large area. At first it is hard to control the movements.

Glossy or matte

When choosing paint for heating radiators, you need to choose what type of surface you want to get – matte or glossy. You have to choose with the type of surface in mind. The fact is that glossy paint emphasizes the unevenness of the surface. Paint most often cast iron batteries, and their surface is far from ideal. Covering it with a glossy composition, you will only emphasize its imperfection.

Matte compositions in this regard are better – they visually hide many irregularities. So this is not a bad option. But there is a disadvantage: matte white paint quickly acquires a grayish tint. It happens due to the fact that dust and dirt are clogged in the pores, and they have a matte paint wide. This dirt from there is not washed out. The way out – a fresh coat of paint or painting in a color other than white. A sensible choice is to match the paint to the color of the walls. From a design point of view, this is a better solution than white radiators.

There is another solution – to fix the unevenness of the radiator. Do this with the help of metal putty, you can use automotive. First remove old paint, rust and other contaminants, then the surface is degreased and then all the irregularities are sealed with putty. After it dries with sandpaper with medium and then with fine grain, the surface is sanded to a smooth state. Then it is dusted, primed and painted. In this case, you can safely use glossy enamels for radiators. If the surface is carefully leveled, the result will please you.

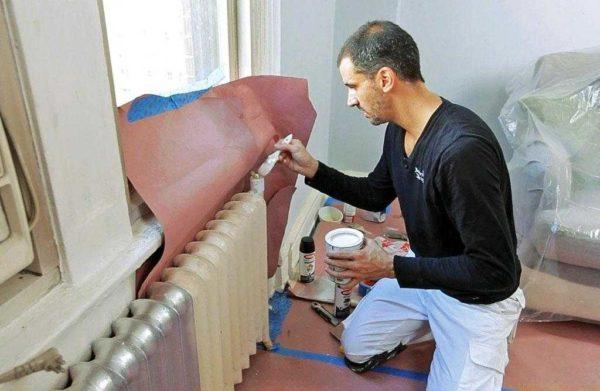

The order of painting radiators for heating

Just a few phrases about the order in which it is more convenient to paint heating radiators. To work more easily, first paint the inner surface. If you are right-handed, it is better to move from right to left, if you are left-handed – vice versa. This way there is less chance of getting dirty. Then the outer surface is painted in the same direction.

The composition is applied from the top, rubbed with up and down movements. Rub the paint thoroughly, not trying to achieve a perfectly painted surface at once. After the first layer, slightly less colored places are allowed. This is much better than sweat. They will be covered when the second coat is applied, and sweat will have to be removed with sandpaper after they are completely dry.