Having a private house or dacha, from time to time you face the need to weld something. It is expensive to pay for the services of a welder every time, especially since many jobs do not require special qualifications. Then there is a desire to buy a welding machine and learn to weld them yourself. But first you need to choose the right welding inverter.

It is easiest to learn welding on inverter welding machines. They are controlled electronically, thanks to which they have several functions that greatly facilitate the life of a novice welder. These units allow you to get a quality weld even without having a lot of experience.

A cikk tartalma

About categories and prices

All inverter welding machines of manual arc welding, working with fusion electrodes, denoted MMA conditionally can be divided into two large groups:

- Domestic – for periodic use and uncomplicated work. If you are not planning a large-scale construction, you will need the machine once every two or three months to fix something, weld, etc., the working resource of the units of this group is enough. These are the cheapest of the inverter welders. They cost 3-5 thousand rubles or so, produced in China.

- Professional – for daily multi-hour work. This is an option for those who will use the inverter in production or plan large-scale construction: build a dacha or a house, weld a metal fence and stairs. The cost of these units is about 300-400$.

There is also an intermediate class – semi-professional. By characteristics and price, they are approximately in the middle. This is a good choice for those who like to master something, and also likes a good tool. All gradations are very conditional, but if you tell the seller about what class you want to have a device, he will understand you and offer several options.

There are also universal or combined welding inverters. They can weld in several modes, one of which is usually manual electric arc welding. These units belong to the class of professional, are convenient for their versatility – some can also work as a torch, as well as cook in the inert gas environment, which allows you to weld thin metal and stainless steel without problems. This equipment will come in handy if you also have a car – you can make repairs yourself, as well as weld all sorts of “small things” for the household.

Define the characteristics

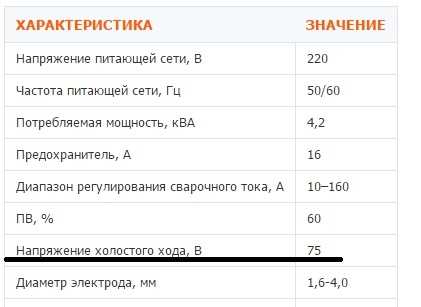

Choose a price category – it’s good, but you also need to pick up the technical characteristics. First, let’s determine the power supply. If you choose an aggregate for private use in the house or at the cottage, most likely, you will be more satisfied with power supply from the 220 V network. Welding inverters are also available from 380 V, but hardly anyone has such sources at home. And if there is – choose three-phase inverters. They are much smaller, but they are also available.

Welding current

How to choose a welding inverter by technical characteristics? In this case, proceed from those products and their thickness, with which you plan to work. First of all, choose the maximum welding current that the unit can deliver. It is denoted Imax, the unit of measurement is Amperes.

There is a fairly clear relationship between the thickness of the metal with which you want to work, and the current that will be needed for welding. This dependence is presented in the table.

| Electrode diameter, mm | Metal thickness, mm | Welding current, Amps |

|---|---|---|

| 1.5 mm | 1,2 – 2,0 mm | 30 – 75 А |

| 2,0 mm | 1,5 – 3,0 mm | 40 – 100 А |

| 2.5 mm | 1,5 – 5,0 mm | 50 – 120 А |

| 3.0 mm | 2,0 – 12,0 mm | 100 – 150 А |

| 4,0 mm | 4,0 – 20, mm | 120 – 200 А |

| 5,0 mm | 10 – 40 mm | 170 – 270 А |

If you are going to weld ferrous metal (angles, channels, etc.) with a thickness of no more than 1 cm, it is enough for the inverter to produce 160-180 Ampere. If at least from time to time, you have to work with a greater thickness, you need a current of up to 200 Ampere. Iron sheets thicker than 2 cm are not used anywhere in the home, so 220-250 Ampere for home or cottage is clearly overkill. It is hardly worth overpaying for unnecessary power, it is better to spend the money to buy a unit of higher class (or a good chameleon mask, without which it will be difficult for a novice welder).

Minimum Imin current is needed when welding thin metals with an inverter. If you need to weld steel or stainless steel up to 2 mm thick, you will need to heat the parts to be welded as little as possible. This is where the minimum current will be needed. As a rule, the lower limit of adjustment is 10 A, but there are units on which less than 30-40 A can not be set. They are good for those cases, if you have special equipment for “delicate” operations (for example, welding semiautomatic machine).

The organization of current regulation is also important. It can be stepped or smooth. Smooth adjustment is better – it allows you to more accurately select the mode of operation for each metal and electrode.

No-load voltage

This characteristic is measured when the equipment is turned on with no load. It is denoted as Uxx, and the unit of measurement is Volts (V). It determines how easily a weld arc will ignite and how stable the arc will be. The range of values is 40-90 V. The higher the idle voltage is stated, the easier the welding will be.

Supply voltage

As already said, most of the inverters work from the 220 V network. But on Russian grids more or less stable voltage is maintained only in large cities. In rural areas, a voltage of 190 V is already good. But inverter welding machines are good because they are undemanding to the supply voltage. They calmly weld at 180-190 V, and some models and at 150 V can “pull” the electrode 3 mm in diameter.

If you have a low voltage in your village, pay attention to this indicator. It is usually written simply as “voltage” and through the dash put the minimum and maximum value: for example, 150-245 V. Sometimes you can see such a record: 220 V +10%, -30%. This means that normally the device will cook, if the supply voltage will be within the range from 154 V to 244 V (220 V – 30% = 154 V and 220 V + 10% = 244 V).

Operating mode at maximum current

If you have to work at the maximum possible current, then the unit will have to give time to cool down. That is, you cook for a while and rest for a while. These intervals are counted by 10 minutes, denoted in the technical data as “PV at maximum current”, measured in percent – %.

For example, if the characteristic is 40% of the maximum current, it means that out of 10 minutes 4 you can cook, and 6 will wait until the device cools down. Normal characteristics are considered to be at least 50-60%, good – 70% and above.

Note that this requirement applies only to the maximum current or close to it. At medium or low currents, there is no need for forced stops. You will still have to change electrodes or position, move the workpiece from time to time. So there will be pauses.

These are all the technical parameters that are needed. Now you know how to choose a welding inverter by characteristics. But this is not all. There are also additional functions. For beginners, they can be very useful. And also some operational aspects can affect the choice.

Additional functions of inverter welding machines

The presence or absence of service functions is not critical, but greatly facilitates life, especially for a beginner. A set of them is usually standard:

- “Hot start” HOT START – affects the ignition of the arc. At ignition, an additional impulse is given, which makes it easy to start welding.

- “Arc Force” – ARC FORCE – when the electrode is sharply approaching the metal, the welding current is automatically increased. This prevents the electrode from sticking.

- “Anti-stick” – ANTI STICK – turns off the power when the electrode sticking, turns on after it comes off. Convenient function, especially it is relevant for novice welders.

There are some other useful functions. For example, indication and automatic shutdown in case of overheating. This is a useful addition – it is not always possible to keep track of the time, or the overheat indicator. Automatic shutdown saves you from burnout and costly repairs.

Pay attention to the set: in addition to the welding machine usually comes a cable pritaniya (sometimes it is removable, sometimes stationary), two welding cables – one with a clamp for attachment to the part, the second – with an electrode holder. It is better if the cables are light, flexible and long. But this luxury is not always available. More often working cables are about 2 meters long, which is not always convenient. Looking at the cables, pay attention to how they are terminated, soldered (better) or clamped/bolted.

Pay attention to whether there is a warranty period, and how close the nearest service center is to your home / cottage. The absence of a service network is a worrying sign. It means that even in case of a warranty breakdown, you will have to repair it yourself for money. You will not send to repair the device through half of our not insignificant country.

How to choose the manufacturer of the welding inverter

Now you know how to choose a welding inverter by technical characteristics. The most difficult task remains: to choose the brand of the apparatus, or rather, the manufacturer.

Chinese welding machines or ?

In the category of household welding inverters, almost all units come from China. There are brands that are completely unknown to anyone, there are working for years and have earned a certain authority. Famous Chinese brands – this is usually equipment produced by solid factories equipped with modern equipment.

“Owners” of the brand are Europeans, Americans and even Russians, and production facilities are located in China. This scheme has long been worked out and is well known. That is why recently in the descriptions of the devices there have even appeared two lines: “home of the brand” and “country of manufacture”. To call these inverters “Chinese” like, and not quite right, but they are produced there. In general, it is up to you to decide.

Known on the market Chinese inverter welding machines have not the lowest prices. But they are tested, and most of them have a network of service workshops or a repair contract with a similar service. Here are a few such brands that have mostly, not bad reviews:

-

-

- Resanta welding inverters. The homeland of the brand is Latvia, the manufacturer is China. There are three ranges:

- SAI – models with a maximum welding current from 140 A to 250 A, supply voltage from 170 V to 250 V. Price from 6.5 thousand rubles for SAI 140, up to 14 thousand rubles for 250 amp model.

- SAI PN – models operating at reduced voltage – from 150 V. Price from 11 thousand rubles. for 160-ampere unit, up to 18-19 thousand rubles for 250-ampere capacity.

- SAI K – compact models that have less weight and dimensions, and characteristics like the SAI. At a price from 7.3 thousand rubles for a 160-ampere unit, up to 12 thousand rubles for 250 A.

Welding inverters Resanta lines SAI, PN (low voltage) and K (compact) (To increase the size of the picture click on it with the right mouse button).

- Welding inverters Svarog: home brand – Russia, manufacturer – China. Allowable deviation in the supply voltage 220 V +/- 15% (190 – 250 V).

- Household models ARS 165, ARS 205;

- Professional PRO ARC-160 PFC, ARC-205V, ARC-315.

- Resanta welding inverters. The homeland of the brand is Latvia, the manufacturer is China. There are three ranges:

-

-

- Welding inverters Fubag (Fubag), the birthplace of the brand – Germany, the manufacturer – China or France. IN series are assembled in France, and IR series in China. Allowable deviation in the supply voltage 220 V +/- 15% (190 – 250 V).

- Series of welders Fubag IN can work in MMA and TIG mode (welding in argon medium, for TIG mode requires a special set of equipment – purchased additionally). Price from 11.8 thousand rubles for a device with a capacity of 16 amperes, up to 18 thousand rubles for a capacity of 220 amperes.

- A series of inverter welding machines IR – it is only welding MMA, there are functions “antizalipaniya” and “hot start”. Price from 7 thousand rubles. for 160 ampere and up to 9.5 thousand rubles for 220 ampere.

- Welding inverters Fubag (Fubag), the birthplace of the brand – Germany, the manufacturer – China or France. IN series are assembled in France, and IR series in China. Allowable deviation in the supply voltage 220 V +/- 15% (190 – 250 V).

-

- Another representative of Russian inverters manufactured in China – inverter welding machines “Kedr”.

- Series “Kedr MMA” – work only with fusion electrodes. There is a function of “hot start” and “anti-sticking”. Prices from 7.5 thousand rubles. for the lowest-powered (170 Ampere) and up to 9.5 thousand rubles. for a unit with a capacity of 220 Ampere.

- Series “Kedar ARC” units of professional series, they still have the function of arc stabilization, the price from 10.5 thousand rubles for a unit with a capacity of 160 amperes, and up to 28 thousand rubles for a 400-amp unit.

- Another representative of Russian inverters manufactured in China – inverter welding machines “Kedr”.

-

- Welding inverter machines “Interskol”. This is another brand native to Russia, producing equipment in China. Feature of the equipment: the plug for connection to the power grid is not included in the set. It is stated that the device works at a power supply from 140 to 240 V. There are two lines:

- “Interskol ISA, for MMA (manual electric arc welding with a fusion electrode). Prices from 6.5 thousand rubles. for a machine producing 160 amperes, up to 10 thousand rubles. for a power of 250 amperes.

- Intersokl ICP series – in addition to welding MMA can work in MIG/MAG mode (inert or shielding gas). Price for ICP 160 ampere – 19 thousand rubles, for ICP 200 ampere – 21 thousand rubles.

- Welding inverter machines “Interskol”. This is another brand native to Russia, producing equipment in China. Feature of the equipment: the plug for connection to the power grid is not included in the set. It is stated that the device works at a power supply from 140 to 240 V. There are two lines:

- Welding inverters FoxWeld (“FoxWeld”) – Chinese production. Not bad characteristics, a wide choice. There are several lines of budget welders for dacha, working at reduced voltage.

- FoxWeld Dachnik – the price from 7.2 thousand rubles for a unit with a capacity of 160 A. Digital display with large numbers facilitates the perception of information. Power supply voltage – 180-240 V, however, not the best indicators of work at maximum current: SP 40%. No-load voltage is 56 V.

- FoxWeld Corundum – With generally similar characteristics has a better volt-ampere characteristic: idle voltage 78 V.

- FoxWeld Master can work with an argon-arc welding set. The SP at maximum current is even lower: 35%. There are functions of “hot start” and “anti-jamming”, arc afterburner.

Russian welding inverters

Welding machines that are produced in Russia are few. A few years ago appeared inverters “Torus”, which meet the stated characteristics and give a stable arc. What is pleasing – a long warranty – 3 years. Such a term is very rare, so it already gives hope that everything should work well. There are two lines.

- Household devices “Torus” – 165, 175, 200, 210 (this is the power in amperes). Price from 13 thousand rubles for 165 amp model to 15 thousand rubles for more powerful – 200-210 amperes, PV at maximum current 60%.

- Professional line of Torus 235 Prima, 250 Extra, Torus 255 Pro (from 17.3 thousand rubles to 20.5 thousand rubles), PV at maximum current of 80%.

The declared supply voltage is 165-242 V. Please note, welding cables are not included in the basic package. They must be purchased separately.

Tests welding inverter welding machine Torus 250 look at this video.

Produce in Russia and inverter welders Inforce. They belong to the category of professional, there are only two models for 200 and 250 amperes. They can work both in MMA and TIG mode (torch and gas cylinders are purchased separately). Current regulation is smooth – from 50 to 200/250 amperes, the ratio of work/rest at maximum current – 60%. The price of Inforce inverters is 16-21 thousand rubles.

In Nizhny Novgorod at the company ElektroIntel produces inverter welding machines Neon (Neon). This equipment is designed to work in harsh conditions: it welds normally at temperatures from -40°C to +40°C. Apparatuses are universal – they also work both in the manual arc welding mode and in the TIG mode. For apparatuses of this type, the price is very low. For example, welding inverter NEON (Neon) VD 160 costs 9.7 thousand rubles. The second modification, which can be suitable for domestic use (for construction, for example), is NEON VD 180, sold at a price of 12.5 thousand rubles. The devices have all service functions and a multiplate structure (more repairable than single-board analogs). Work/rest ratio of SP at maximum current is 80% (measured at +40°C).