Drilling wells is most often required when installing a well for water, but in addition periodically such work is needed: to install metal posts for a fence (arbor, pergola), to create a field to collect heat from the ground when installing a heat pump ground-to-air, when installing a columnar foundation and many other construction works. A small-sized drilling rig will facilitate and significantly accelerate the processes. Having some welding skill, it can be made with your own hands.

Contents of the article

Types of homemade drilling rigs

For independent drilling of wells (for water and not only) requires at least a small drilling rig. The depth of wells is rarely less than 20 meters and it is very difficult to do without the use of at least the simplest mechanisms. If we talk about drilling techniques and types of drilling rigs, then you can make with your own hands the following drilling rigs:

- Shock-rock rig. The principle of operation of this type of equipment is based on the force of gravity. At some height fix a heavy drilling shell with sharpened edges – a cup or a chisel. It is “dropped” several dozens of times. Each time the shell cuts through some part of the ground, and the rock gets stuck inside the hollow shell (for loose soils they are equipped with valves). The cup is removed from the borehole and the soil is removed. Then the process continues until the well reaches the required depth. For independent execution, such devices are the simplest. In the most budgetary version, it is a kind of bed, allowing you to fix the block above the well. A long rope with a tied chute is thrown over the block. The rope can be pulled “manually”, or a gearmotor with a drum can be installed.

- Auger drilling rig. Deepening into the ground is carried out by means of an auger – a rod with screw-welded blades. The auger can be used to manually drill holes of a couple of meters – for a pile foundation, for example. To penetrate dense layers such as clay or dense sands, considerable force is required. Therefore, you need a motor with a large torque, and they work from 380 V. And that, auger installations are practically useless on stony soils. And anyway – just a small stone like crushed stone or rock – the auger will not pass them.

- Rotary drilling. The same principle of rotation is used, but drilling mud (water) is fed inside the drill. This is an effective method – water brings the cuttings (crushed rock) to the surface, and the drill is very rarely taken to the surface. It is only constantly built up from the top by installing additional rods. There are rotary units of “dry” drilling – without muds, but they require more efforts, drilling speed is much lower. Therefore, such rigs are rarely made and used.

-

The choice of the type of drilling rig to make it with their own hands depends on the geology of the area where they will drill, also affects the depth of aquifers. The most universal method is the percussion-channel method. Well pass different soils with rotary equipment with the use of water (this method is also called hydrodrilling). For different types of soils, differently shaped bits are used, and the crushed soil is washed to the surface with water.

The most “capricious” on soils auger drill, but it copes well with viscous soils – clays, loams, but with boulders and stony ground it gets stuck.

Methods of purifying water from a well or well are described here.

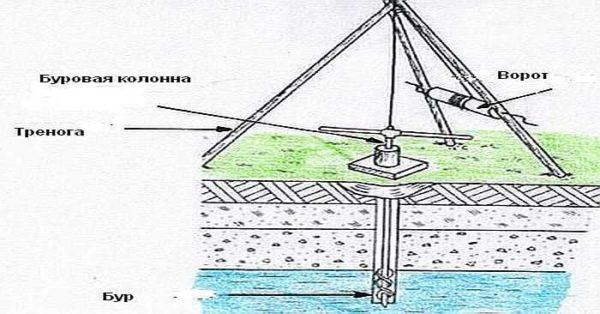

Types of homemade rope-under-rope drilling rigs

When making a drilling rig for rope-impact drilling, there are two important elements: a bed and a cup (chuck, chute). For the simplest version, you can make a bed of three or four pipes, which are connected above the place where drilling will take place. A block is fastened there, a flexible steel cable is thrown over it. At the end of the cable is tied to the drilling shell. That’s the whole construction. This “rig” is powered by muscle power – the cable is pulled, then sharply lowered. The projectile gradually deepens.

To reduce physical stress, a winch is installed, for even greater automation – a motor with a gearbox that rotates the winch shaft. It is important to devise a system that allows the winch shaft to be released and the chute to be dumped.

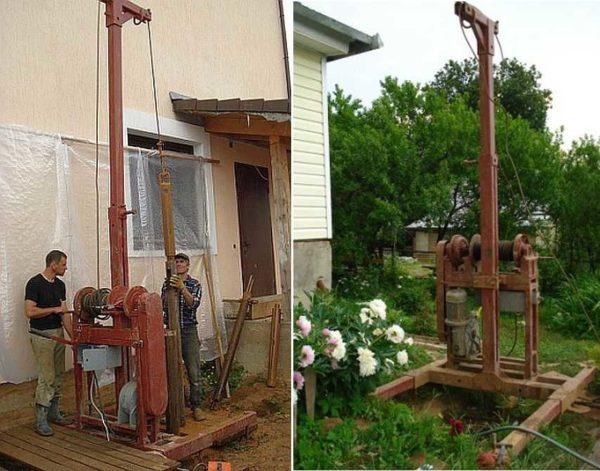

The tripod frame is not always convenient – it requires a large area. And for stability, the “legs” should be at an equal distance from the center. Crosspieces between all the supports will not hurt either. In this case, the drilling rig will stand reliably. There is another variant of the frame – in the form of the letter “H” with telescopic rods (pictured below).

The vertical rack is also telescopic. It allows you to change the height from which the projectile is dropped. Otherwise, the equipment is the same.

How the drilling rig of percussion-channel drilling works, made with your own hands from improvised materials, look in the video. Such a design is not difficult to repeat exactly.

More about how to penetrate and equip a well for water is described here.

How to make a rotary drilling rig

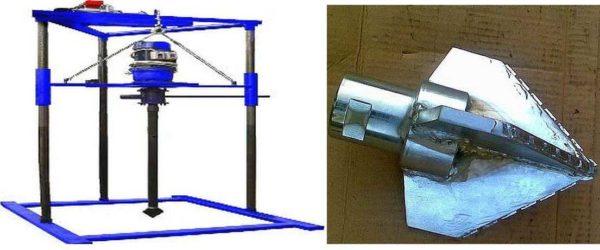

Hydraulic drilling rig should have a bed, which allows you to move up / down the motor, to which the drill is connected through the swivel. Also through the swivel, water is fed into the drill string.

When making a drilling rig with your own hands, the following order of actions is recommended:

The frame of the mini-drill rig consists of three parts:

- horizontal platform;

- vertical frame;

- movable frame (carriage), on which the motor is fixed.

The base is welded from a thick-walled pipe – wall thickness of 4 mm, minimum – 3.5 mm. Better – from a profiled section of 40*40 mm, 50*50 mm or so, but a round one will do. When making the frame of a small drilling rig, accuracy is not important. It is important to observe the geometry: verticality and horizontality, the same angles of inclination, if necessary. And the dimensions are “adjusted” according to the fact. First, the lower frame is welded, measured. Under the available dimensions, a vertical frame is made, and according to its dimensions – the carriage.

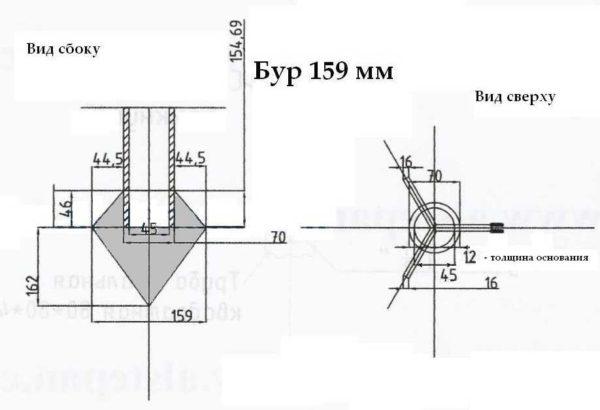

A simple drill forts can be made independently – they are welded from ordinary steel (drawing in the photo below). If you take high-alloy steel, it is difficult to weld it to the rods. For complex and stony soils, it is better to buy a drill in a specialized campaign – they have a complex shape, there are many different types.

To work more easily, connect two remotes with the possibility of reversing. One is put on the motor, the second on the winch. That is, in fact, everything.

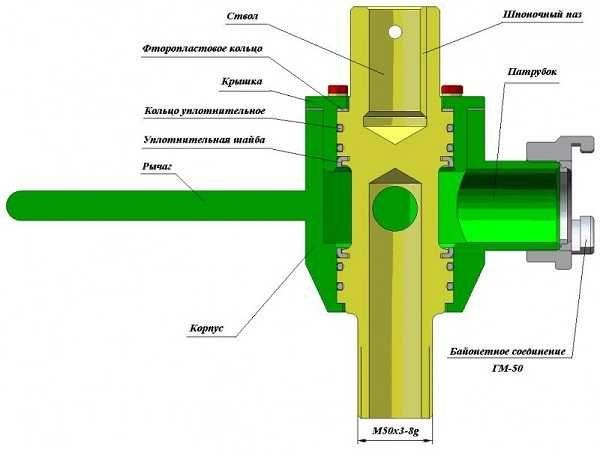

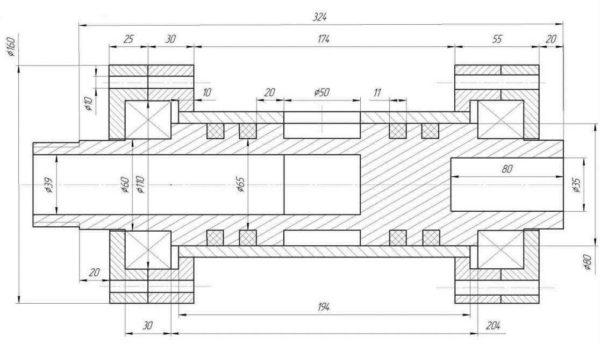

The main thing in the design of a rotary or auger drilling rig is a swivel, but it is unrealistic to make it without experience. For those who want to make it on their own, we will post a photo and its drawing.

How to conduct water from the well to the house read here.

The simplest installation for auger drilling

If the aquifers are shallow, the soils are soft, you can do without a mechanical drilling rig with an auger. It is the same tripod or any other frame with a block through which a rope is thrown. Only instead of a chisel or drilling cup, an auger is tied to the cable. In its upper part there is a bar, by means of which it is turned.

To facilitate the process, it is desirable to have a winch or at least a gate (like a well). But you can make a rotary drill similar to the one described above. Only the structure of the swivel will change – it is needed without an outlet for water supply. The work of one of the drills assembled by a masterful man with his own hands, from improvised materials – in the following video. You can also consider the features of the design.

And the last point – a video on how to make an auger for a drilling rig with your own hands.

I once helped my buddy build a homemade drilling rig, and it was such a blast! We used some junkyard parts and got way more depth than we expected. It’s amazing what you can create with a little creativity and teamwork. Totally worth the effort!

I built a homemade drilling rig last summer, and it was a game-changer! It saved me tons of cash and was super rewarding. If you’re into DIY projects, give it a shot! You’ll learn a ton and have some serious bragging rights at the next BBQ. Trust me, it’s worth it!