Parents always try to choose the best for their children, including furniture. But looking at the unkind prices for wooden beds, you’ll wonder whether it’s worth buying such a thing for a few years. Children’s bed with their own hands can be assembled from several boards and bars for a few days. Particularly complex work or special tools are not required. Basically you need hands and desire.

Contenu de l'article

Making a wooden bed

In the presented version is suitable for middle school age and teenagers, but it can be remade for children from 3 years old. It is assembled from wooden parts, boards and bars. The project can be used as a basis, adding design ideas.

Materials and tools

No special tools are required for manufacturing. In the work will be needed:

Materials needed are as follows:

- timber – 50*100 mm;

- board 25*100 mm and 25*75 mm;

- wood glue;

- wood putty;

- sandpaper.

The number of planks is calculated based on the planned dimensions. Requirements for wood – low humidity (no higher than 16%) and the absence of knots or their small number.

Children like to sleep higher. How to make a loft bed read here.

Making legs

The independent manufacture of a child’s bed begins with the legs. From the bar 50 * 100 mm cut billets – for the headboard longer, for the footboard – shorter. You need 2 pieces of each length. Glue the blanks in pairs. We take one, smear with wood glue, put the second, checking whether they are evenly aligned, twist with self-tapping screws. In principle, you can use a bar 100 * 100 mm and do not bother with glue, but the price for it is very bite.

The heads of the screws are recessed into the wood, then sealed with wood putty. After drying sand to a smooth state (with sandpaper with medium or fine grain).

Sand the joints to perfection – everything should be smooth and even.

Holes for screws

For the backrests you need boards with a 25 mm wide groove. If you have a router, you can make it yourself or turn it out in a carpentry shop. Chocks can also be bought ready-made, according to their diameter, choose a drill bit.

Holes for screws are drilled in the ends of the slats with grooves. Precisely determine their distance from the edge – they must be strictly at the same level on all strips.

The holes should be of the same depth, half the length of the stud. To be guided during drilling, a marker is attached to the drill – a strip of painter’s tape. It is used to control the depth of the hole.

Assembling the headboard and footboard

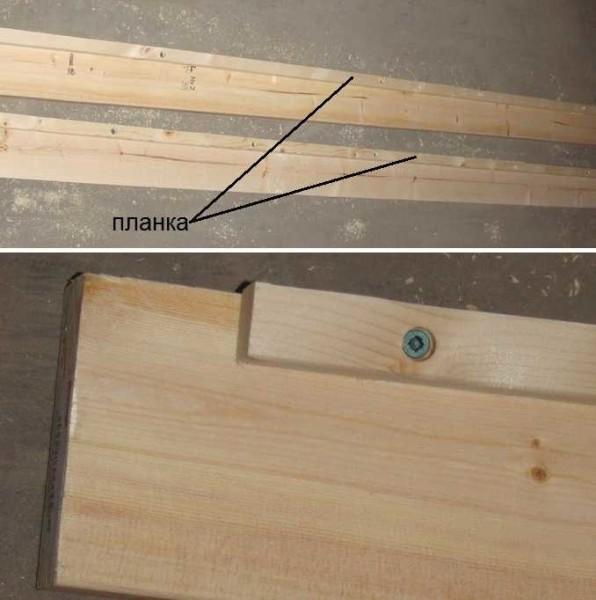

From the board 25*50 mm cut planks of equal length to fill the headboard and footboard. They are inserted into the groove, smeared in advance with glue.

In the foot also drill a hole for the screws. First find the middle and draw a line with a pencil. You put the assembled backrest, aligned on the top edge, put the screws on the line and mark the places where you need to drill holes for them (two at the top, two at the bottom). Pour a little glue into the holes and put the backrest. It is necessary to fit tightly, without gaps. You can tap with a fist or a mallet, trying not to damage the wood.

Repeat the operation with the other leg. Not very beautiful joint at the top can be closed with a board, planting it on self-tapping screws and plastering the holes.

One important point that concerns the gluing of the parts. Until the glue has not cured, the joints are movable and the parts can skew. Therefore, having set the corners at 90 °, the part is fixed with clamps or some other way and left until the glue dries. The work continues after drying, starting it with sanding the joint, which glued.

How to make a sports corner for children read here.

Making the basis for the mattress

We take two boards 50 * 100 mm long, equal to the length of the mattress or a couple of centimeters more. On the edge of the glue and self-tapping screws we put a 25*50 mm board. It is 10 cm shorter in length – leave 5 cm from each edge. When screwing the lath, make sure that the edges are aligned precisely. Drill a hole for each self-tapping screw – close to the edge so that the wood does not burst. In addition, make a hole with a larger diameter for the flat – they must be hidden.

Since the glue joint in this case is rigid, you do not have to wait for the glue to dry.

From a 25*100 mm board, cut strips to the width of the mattress (you can add 1-2 cm again). They are attached to the newly made strips with a stop. The installation step is 10 cm, 2 self-tapping screws on each side of each strip. A hole is pre-drilled for each self-drilling screw (the drill diameter is 1-2 mm less than the self-drilling screw diameter), the flat should go into the wood.

Holes for fasteners are puttyed with putty, after drying sanded. Cutouts for the installation of legs are made in the edge strips.

Assembling the bed

We finally fix all chips and defects on visible parts of the bed with putty, after its drying we sand it to smoothness. Then primed and painted in the chosen color. After painting it remains only to connect the backrests and the basis for the mattress and you can consider that the children’s bed is ready.

Connect the parts can be connected with the help of special fittings – staples and curtains, or simply – nailing a corner, bar, on which to lean the assembled shield for the mattress.

How to make a two-story children’s bed read here.

Homemade bed-machine

Few boys will refuse a bed-machine. And to please the child does not necessarily have to go to the store. With the help of plywood or MDF sheet, paint and water-based varnish, the usual sleeping place turns into a dream come true: a bed for a child in the form of the Batmobile or any other.

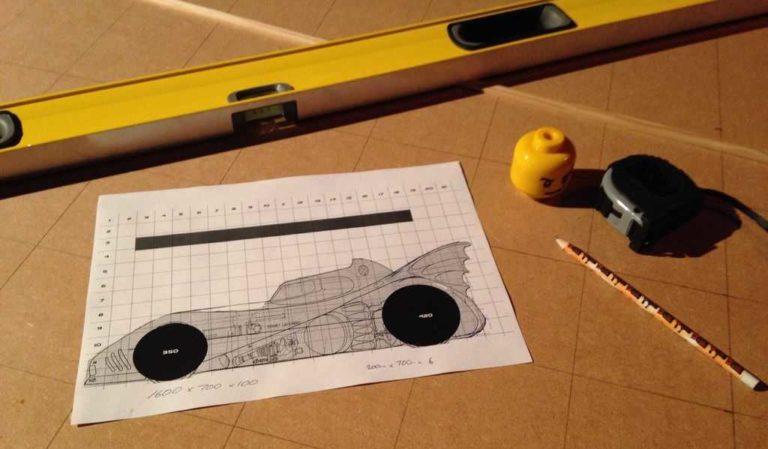

First find an image of the car, which suits you, find a program with the ability to visualize drawings. The image can be broken into squares with a side of 100 mm – so that then it was easier to translate into a real scale. It is most convenient when the whole part will lie in the sheet of plywood or MDF you bought, even better if it turns out to make two side parts of the bed from one sheet. Once you are satisfied with the result, you can transfer the design to the sheet.

Everything starts with drawing the sheet into squares with a side of 100 mm.

Transfer all the lines from the paper to the plywood. At first the lines are thin, after you draw everything more or less, you can outline the resulting contours with a bold line – it will be easier to cut out. After cutting out the first piece, we will circle it and get the second one.

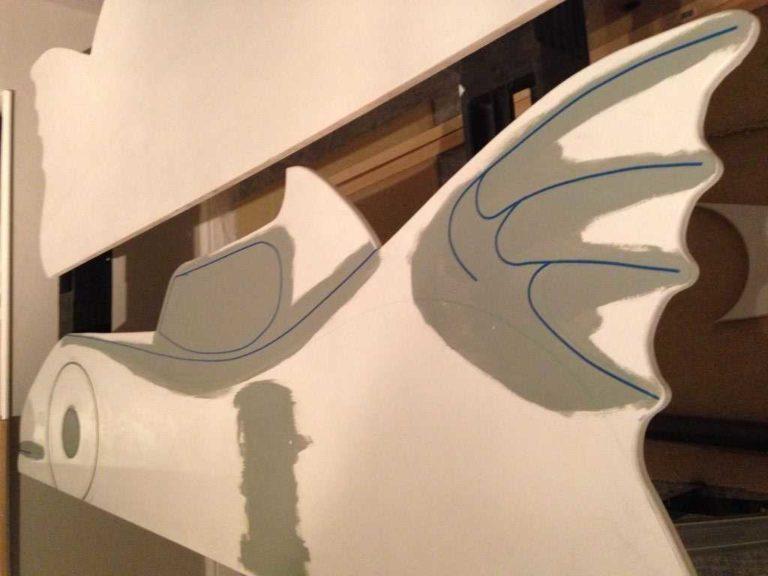

In this project there are also superimposed details – we draw them separately. When everything is ready, take a jigsaw and saw out the contours.

The edges are well sanded with a machine or by hand. Then we start sawing out recesses, holes, etc. The technique is traditional – we use a drill, drilling one hole near the other, then we file the lintels. The uneven edge is sanded in any available way, rounding it from the outside, and from the inside everything should be smooth.

After working out all the details – this is what you get.

About making a playhouse in an apartment or house, read here. How to build a playhouse for children in the countryside or near the house is described here (with photo reports).

Priming and painting

For painting it is necessary to choose safe materials. Best of all – water emulsion with latex, and to protect the paint from scratches and abrasion is suitable for water-based varnish.

If the parts are made of MDF, it is very desirable to primed everything, and better twice. This material can strongly absorb paint, especially at the ends. Priming reduces the absorbency and the paint will lay down more evenly.

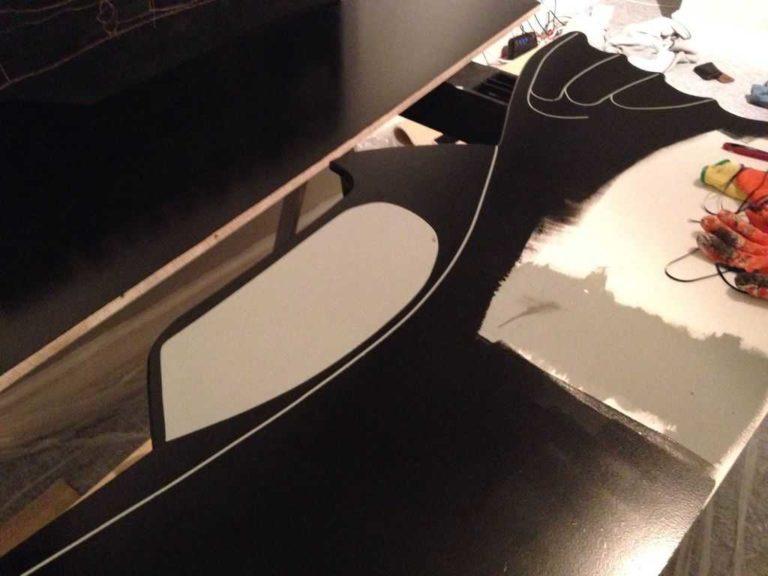

After the primer dried, the areas that are supposed to be gray were painted first. By design, there are also thin gray stripes. In order not to draw them on the black, a thin strip of painter’s tape of 3 mm is glued on the gray paint, removing which then we will get the desired pattern.

Assemble the bed-car

We take one sidewall, fix with self-tapping screws a wooden bar 25*25 mm minimum. Install self-tapping screws at 20-30 cm intervals. Fix a board-restrictor to the front end of the bar. Repeat the same operation on the second part (be sure to fix the strips at the same height).

Having installed the second part, twist the construction. In the middle you need to install a stop bar, which will firmly hold both sides and will not let them move apart.

On the bars attached to the sides, as on the frame, lay cut boards, which serve as a support for the mattress. They can be fixed with self-tapping screws (two on each side), or simply laid down. In this case, the bed will be quickly disassembled.

On the basis of the same design, a bed for a girl is made. In shape, the railing is simpler, there is less work with them, but it is more difficult to paint. So also its own moments.

How to make a playhouse for an apartment read here.