On a large part of Russia, wood is still the most affordable fuel and many people heat with wood boilers. Everything would be all right, but in the usual solid fuel boilers, the tab burns out in 2-3 hours, which is quite inconvenient – you can not leave the house for a long time. There are long burning boilers. In them, one tab of wood can burn up to 8-10 hours, but they cost a lot of money. However, as usual, there is a way out – to make a pyrolysis boiler with your own hands. Not to say that this is a simple job – welding skills should be at a high level, and the materials cost a lot. Nevertheless, there are a lot of homemade pyrolyzniki.

Artikkelin sisältö

The principle of operation of the pyrolysis boiler

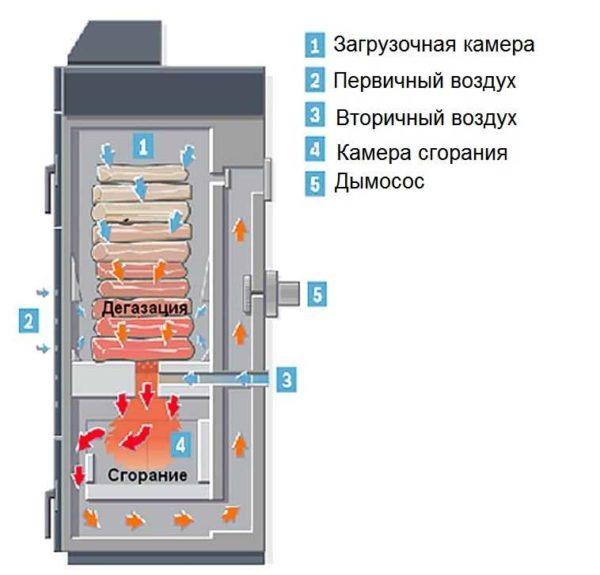

Applied to heating boilers, pyrolysis is the combustion of fuel with insufficient oxygen. In this case, the fuel emits a large number of gases, almost all of them combustible. These gases are directed to a special combustion and afterburning chamber, where secondary air is supplied. The gas-air mixture ignites, releasing a large amount of heat. Heat energy is released much more than can be extracted by conventional combustion of firewood or coal. The fact is that many of the volatile substances formed during the combustion of fuel have a very high combustion temperature. As a result, from the same amount of fuel, pyrolysis boilers extract more heat.

Due to the peculiarities of the combustion process (release of a large amount of gases), such units are also called gas-generator boilers.

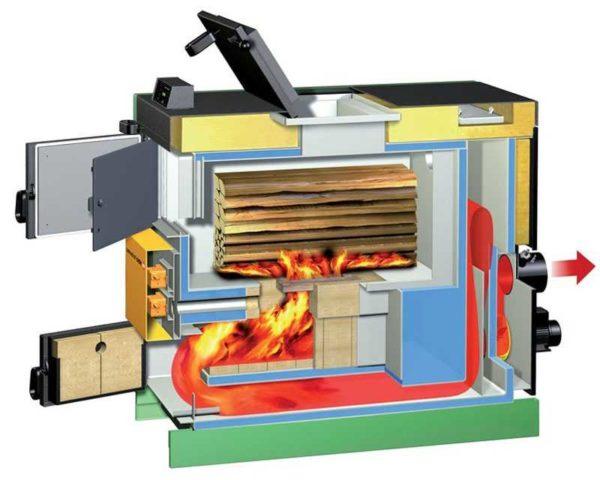

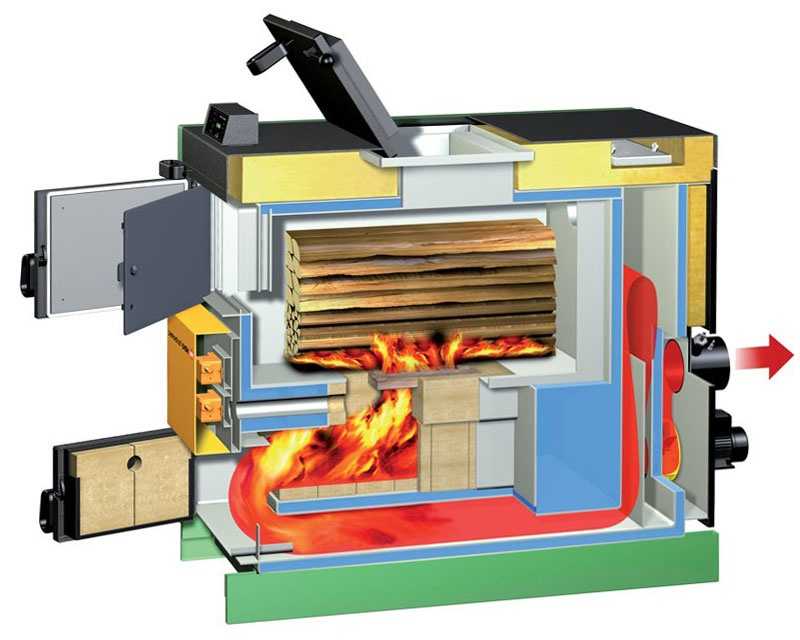

The structural feature of pyrolysis boilers is a furnace consisting of two chambers. In one chamber the fuel is laid (often it is the upper part of the furnace), in it there is a release of gases, and therefore this part is called the chamber of gas generation. Through a shallow neck the gases enter the second chamber – afterburning. Here they mix with secondary air, burst into flames and burn almost without residue.

On average, the efficiency of pyrolyzniki – above 85%. There are models that can give 92% and even a little more. But these indicators are possible only and exclusively when using dry fuel. Its humidity should be 5-8%. At 40% moisture content, combustion can completely extinguish, and at 20% will simply be ineffective. And this is one of the main disadvantages of this technology: firewood and coal have to be dried beforehand, for example, by making a platform near the chimney. Firewood dried in the woodpile will not work, as well as coal taken from the pile on the street.

The video demonstrates a boiler in which the afterburning chamber is at the top. Although boilers of this type have a simpler structure (the formed gases themselves rise up), self-modelers prefer the chamber with a lower afterburning chamber (as in the photo above).

What to pay attention to when making

If you are going to make a pyrolysis boiler with your own hands, you need to clearly represent not only the mechanism and the principle of its operation, but also take into account all the unpleasant moments that these units have. First of all, it is necessary to say that almost all pyrolysis gases are poisonous. That is, the unit must be completely airtight, the welds must be of the highest quality.

In addition, to ensure safety, a system for monitoring the combustion process (sensors for temperature, smoke, presence of draught) and automation, which, depending on the sensor readings, regulates the combustion process. If the homemade pyrolysis boiler is going to be made on natural draught, the automation can be the simplest – non-volatile. In the presence of a supercharger fan to supply air to the current, you need more serious (and expensive) devices, and they are powered by 220 V. The operation of this type of boiler without automation is dangerous, so you need a source of uninterruptible power supply, which will ensure the work of the fan and automation for 10-12 hours – the time of burning the tab.

The second point. In some models of pyrolyzniki temperature in the active phase reaches 1000 ° C and above. Ordinary structural steel under such conditions will quickly burn through. In order for the boiler to exist for a long time, you need heat-resistant steel and internal lining of the most thermally loaded parts. If the pyrolysis boiler is made with your own hands, the lining is most often made of fireclay bricks. In the working phase, fireclay heats up to a crimson glow and becomes very brittle. If, suddenly, you have to use the furnace at this time, be careful – it is easy to damage the lining at this point, and repairing it is long and difficult.

How much materials and parts will cost

Exactly how much the pyrolysis boiler will cost, made with their own hands, depends on the required power and the chosen design. However, if you buy heat-resistant steel, grates, make lining, put automation (albeit inexpensive), the sum runs up 850-1200$. This is the cost of materials and components, but with independent welding. They are voiced by those who have already welded pyrolyznik and use. If you have to pay for welding, then the costs should be doubled.

As you can see, in the case of owning welding, there are savings, but not the biggest. You can find ready-made versions of solid fuel pyrolysis boilers for 1500$. Although, as you know, cheap goods have a low price for a reason. On something there saved money. And you can even guess what: on the lining. It is the secrets of protecting the walls of the furnace from burning out that manufacturers take care of most of all, and spend a lot of money on research in this area. That is why quality equipment costs a lot of money.

Building a pyrolysis combustion boiler is a game-changer! I tried it last summer, and it totally boosted my efficiency. The video lessons really broke it down well—easy to follow along and super informative. It’s all about managing those temperatures right for optimal burn!

I just checked out the video on making a pyrolysis combustion boiler, and wow, it’s super helpful! I remember trying to build one myself and getting lost in the details. The step-by-step approach they shared really makes it easy. Can’t wait to give it another shot!

I recently watched a video on making a pyrolysis combustion boiler, and it was super helpful! The step-by-step tips were spot on. I love getting my hands dirty with DIY projects, and this one’s a game changer for eco-friendly heating. Can’t wait to try it out!