Maja veega varustamiseks või krundi kastmiseks kasutatakse sageli kaevu. Kui varem sai ka eramajas hakkama värava ja ämbriga, siis tänapäeval ei ole see võimalus isegi daša juures enam rahuldav. Kaasaegse taseme mugavused saab ju kätte, kui paigaldada kaevule pump. Selleks, et süsteem toimiks korralikult, tuleb seadmeid õigesti valida.

Artikli sisu

Pumbatüübid ja nende kasutamine puurkaevude puhul

Paigaldusviisi järgi on pumbad pind- ja sukelpumbad, tööpõhimõtte järgi - tsentrifugaal- ja vibratsioonipumbad. Ja sukelpumpade ja pinnaveepumpade hulgas on mõlemat tüüpi mudeleid. Nii selgub neli sorti seadmeid. Selleks, et valida kaevu jaoks õige pump, peate mõistma iga selle seadmetüübi nõrkusi ja tugevusi.

Pind

Pinnapump on atraktiivne tänu lihtsale paigaldamisele ja liikuvusele. Seadmed ise on pinnal ja ainult voolik lastakse kaevu. Teine punkt - väikesed kulud, mis on seletatav sellega, et korpust ei ole vaja teha hermeetiliseks.

Pinnapumpa kaevu jaoks on väga lihtne ühendada

Kõigile eelistele vaatamata võib pinnamudeleid kasutada ka madalate kaevude puhul. Maksimaalne sügavus on 8 meetrit, kuid soovitavalt vähem. See on peamine piirang ja nende peamine puudus. Teine negatiivne punkt on madal kasutegur - mitte rohkem kui 25%. See on kõigi pumpade seas kõige madalam näitaja.

Miks ei tehta sellist tüüpi võimsamaid seadmeid? Sest töötsükli eripära tõttu küllastub suurest sügavusest tõstetav vedelik õhumullidega (nähtust nimetatakse kavitatsiooniks). Kui tööorganisse satub suurel hulgal õhumulle sisaldav vesi, põleb see läbi.

Probleemi saab vältida ejektori abil, mis on sisseehitatud puurkaevu langetatud torustikku. Sügavus, millest ejektoriga pinnaseseadmed saavad vett pumbata, on palju suurem - kuni 15 meetrit, kuid kasutegur on veelgi väiksem - umbes 15%, mis tähendab, et elektriarved on suured.

Sukelduvvahendid

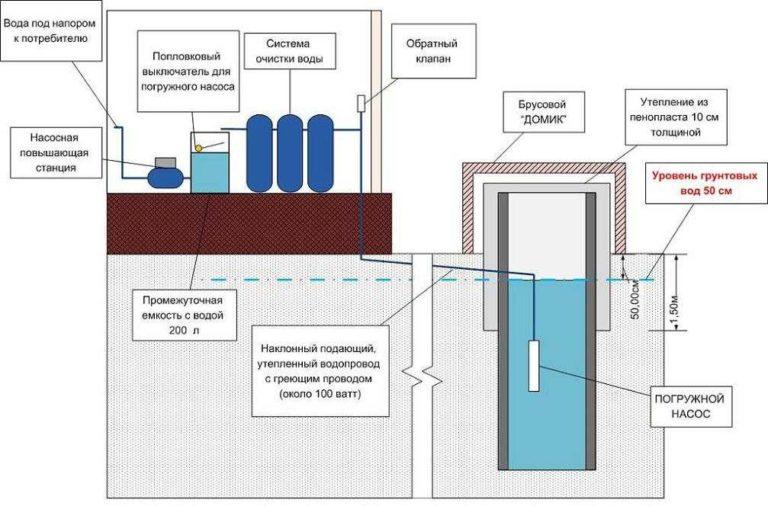

Kaevu sukelpumpade kasutegur on parimal juhul umbes 45%, keskmiselt - umbes 35%. Nimetusest selgub, et need on veesambas. See ongi peamine raskus - see tuleb hästi kinnitada ja siis läbi kaevu seina viia põhijuhe majja.

Kinnitage kaevu sukelpump tavaliselt keti või tugeva kaabli abil (optimaalselt - roostevabast terasest). Need kinnitatakse spetsiaalsesse korpuse ülemisse ossa, vaba ots keritakse värava külge, näiteks sellisele, mida kasutatakse ämbrite tõstmiseks. Selle seadme abil tõstetakse vajadusel seadmed pinnale.

Loe kaevust saadava veevarustuse kohta (koos skeemide ja paigaldamise kirjeldusega) lähemalt siit.

Sama oluline on ka sukelpumba asukoha valik kaevus. See tuleb teha nii, et põhjani jääks vähemalt üks meeter (muidu võivad liiv ja muda sisse sattuda). Samal ajal on vaja, et korpuse kohal oleks piisav veekiht (vt kasutusjuhendit, erinevatel mudelitel on erinevad nõuded). Kui veesamba kõrgus kaevus on väike, võib see olla probleemiks. Kuigi on mudeleid, mis võimaldavad horisontaalset paigaldamist kaevu (nt Aquario ASP).

| Nimi | Tüüp | Surve | Võimsus | Võimsus | Tootja | Hind | Märkused |

|---|---|---|---|---|---|---|---|

| Grundfos SB 3-35 M | tsentrifugaalne, sukelduv | 33 м | 6,6 m3/h | 800 W | Itaalia | 250$ | Ülekuumenemiskaitse |

| Grundfos SB 3-35 AW | tsentrifugaalne, sukelduv | 33 м | 6,6 m3/h | 800 W | Itaalia | 330$ | Ujumislüliti |

| Grundfos SB 3-45 A | tsentrifugaalne, sukelduv | 43 м | 6,4 m3/h | 1000 W | Itaalia | 280$ | Ujumislüliti + ülekuumenemiskaitse |

| Beebi 10 m/ 16 m /25 m /40 m | vibreeriv, sukelduv | 40 м | 0,43 m3/h | 250 W | г. Livny | 24$ - 34$ (sõltuvalt juhtme pikkusest) | Alumine veevõtukoht, läbimõõt vähemalt 100 mm |

| Malysh-M-L 10 m/ 16 m /25 m /40 m | vibreeriv, sukelduv | 40 м | 0,95 m3/h | 240 W | г. Livny | 23$ – 33$ | Ülemine veevõtukoht |

| Malysh-K 10 m/ 16 m /25 m /40 m | vibreeriv, sukelduv | 40 м | 0,95 m3/h | 240 W | г. Livny | 25$ – 34$ | Madalam veevõtukoht + soojuskaitse |

| Malysh-3 10 m/ 16 m /25 m /40 m | vibreeriv, sukelduv | 40 м | 0,43 m3/h | 160 W | г. Livny | 25$ – 34$ | Alumine veevõtukoht, läbimõõt vähemalt 76 mm |

| Jileks VODOMET PROF 40/50 A | tsentrifugaalne, sukelduv | 50 м | 2,4 m3/h | 520 W | Venemaa | 160$ | Ujumine + tahkete ainete olemasolu 2 kg/m3 |

| Jileks VODOMET PROF 40/75 A | tsentrifugaalne, sukelduv | 75 м | 2,4 m3/h | 670 W | Venemaa | 205$ | Ujumine + tahkete ainete olemasolu 2 kg/m3 |

| Jileks VODOMET PROF 55/35 A | tsentrifugaalne, sukelduv | 35 м | 3,3 m3/h | 460 W | Venemaa | 135$ | Ujumine + tahkete ainete olemasolu 2 kg/m3 |

| Jileks VODOMET 55/35 M | tsentrifugaalne, sukelduv | 35 м | 3,3 m3/h | 460 W | Venemaa | 135$ | Tahkete osakeste olemasolu 2 kg/m3 |

| Vodolei BCPE 0,32-25 U kuni 140 U | tsentrifugaalne, sukelduv | 25 m kuni 140 m | 1,2 m3/h | 440 W kuni 2500 W | Promelectro | 132$ – 290$ | Kaitse ülekuumenemise eest |

| Vodolei BCPE 0,5 (16 W kuni 100 W) | tsentrifugaalne, sukelduv | alates 16 m kuni 100 m | 1,8 m3/h | 400 W kuni 2050 W | Promelectro | 115$ – 255$ | Kaitse ülekuumenemise eest |

| Vodolei BCPE 1,2 (12 W kuni 80 W) | tsentrifugaalne, sukelduv | alates 12 m kuni 80 m | 4,3 m3/h | alates 500 W kuni 2820 W | Promelectro | 140$ – 280$ | Kaitse ülekuumenemise eest |

| Vodolei BCPEU 0,5 (alates 16 U kuni 63 U) | tsentrifugaalne, sukelduv | alates 16 m kuni 63 m | 1,8 m3/h | 400 W kuni 1270 W | Promelectro | 125$ – 220$ | Ülekuumenemiskaitse, väiksem läbimõõt |

Mõned selgitused lauale. Erinevate omadustega mudeleid on palju rohkem kui tabelis esitatud. Siin on esitatud ainult mõned, et näeksite ligikaudset hinnavahemikku ja omadusi. Kirjelduses, et pumbad kaevude Vodolei on sulgudes indeks mudelid, mis näitab kõrgus lift võrdse jõudluse. Kell pumbad "Baby" indeksis on pikkus nööri teiste võrdsete omadustega.

Vibreeriv

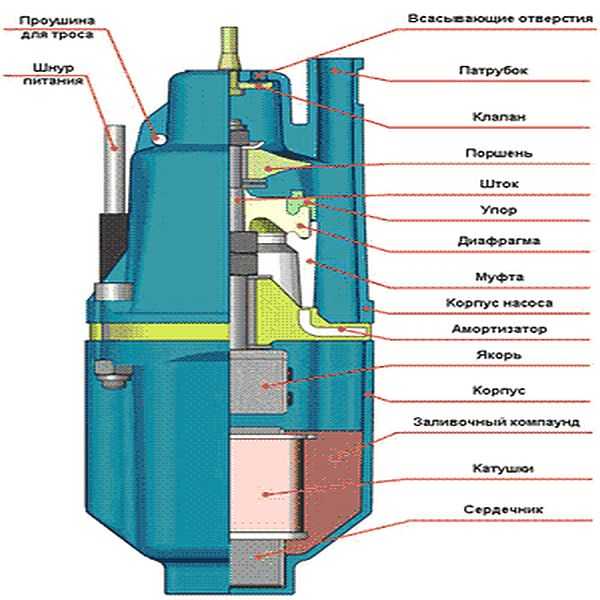

Kaevu vibratsioonipumba puhul toimub vee pumpamine membraani või kolvi abil. Need tekitavad vaheldumisi, siis tekib haruldus, mille tõttu vesi imetakse sisse, seejärel survestatakse, surudes seda väljavoolu. Selline töötsükkel tekitab üsna märgatavat vibratsiooni, mistõttu selliseid seadmeid nimetatakse vibratsioonipumpadeks. Vibratsioonipumbad võivad olla välis- või sukelpumbad. Sukeldatavad vibropumbad töötavad vaiksemalt - vesi summutab müra, välised on mürarikkad seadmed.

Vibratsioonipump - seade on lihtne, odav, väikeste mõõtmete ja kerge kaaluga, tänu millele on see väga mobiilne (kaal - paar kilogrammi) ja seda saab kasutada väikeste mahtude pumpamiseks - vähemalt tünnis saab seda langetada, lihtsalt ärge unustage õigel ajal välja lülitada. Kõik see on tõsi, kuid sellel on palju puudusi:

- Vibratsioon mõjutab negatiivselt vastupidavust, kasutusiga on väike.

- Nõudlik energiavarustuse kvaliteet. Kui pinge langeb 160 V-ni, väheneb jõudlus poole võrra, kusjuures võimsus suureneb, kuid mitte nii kriitiliselt. Sagedased kõikumised põhjustavad kiirendatud kulumist, nii et paari vibreeriva pumba jaoks hästi osta stabilisaator, saate kõige lihtsam, relee peal.

- Talub halvasti liiva ja muu prahi olemasolu pumbatavas vees. Konstruktsioon on selline, et filtrid sisselaskeava juures ei pane ja abrasiivsete osakeste (liivaterade) olemasolu viib kiiresti kolvi või diafragma rikki. Seetõttu ei tohiks selliseid filtreid kasutada liivasel pinnasel.

Need on ametlikud andmed. Ja mitteametlikud, kogemustest lähtuvalt, ütlevad, et selliseid pumpasid tuleb tihti vahetada - nad põlevad kiiresti läbi. Nii et see tüüp on hea kui ajutine lahendus - perioodiliseks kasutamiseks daššis. Alalise elukohaga maja garanteeritud veevarustuse jaoks on parem võtta tsentrifugaalmudelid.

| Nimi | Tüüp | Imemise sügavus | Tõstekõrgus (pea) | Võimsus | Võimsus | Hind |

|---|---|---|---|---|---|---|

| DIOLD NP-0,4 | Pinna vibratsioon | 8 м | 32 м | 2100 l/h | 400 W | 50$ |

| DIOLD NPV-800 | Pinna vibratsioon | 8 м | 60 м | 3000 l/h | 800 W | 52$ |

| METABO HWA 3500 INOX | Pinna vibratsioon | 8 м | 45 м | 3500 l/h | 1100 W | 170$ (kuivkäitumine ja ülekuumenemiskaitse) |

| METABO HWAI 4500 INOX | Pinna vibratsioon | 8 м | 48 м | 4500 l/h | 1300 W | 170$ (kuivkäitumine ja ülekuumenemiskaitse) |

| PATRIOT R 900 | Pinnalähedane aed | 8 м | 40 м | 3800 l/h | 850 W | 75$ (ujuk, korpus roostevabast terasest) |

| VIKHR PN-370 | Pinna tsentrifugaal | 9 м | 30 м | 2700 l/h | 370 W | 40$ (malmist korpus) |

| VIHR PN-1100CH | Pinna tsentrifugaal | 9 м | 50 м | 4200 l/h | 1100 W | 95$ (malmist korpus) |

| JAMBO 60/35 P | Pinna tsentrifugaal | 9 м | 35 м | 3600 l/h | 600 W | 85$ (polüpropüleenist korpus) |

| JAMBO 60/35 h | Pinna tsentrifugaal | 9 м | 35 м | 3600 l/h | 600 W | 95$ (malmist korpus) |

| JAMBO 70/50 CH | Pinna tsentrifugaal | 9 м | 50 м | 4200 l/h | 1100 W | 120$ (malmist korpus) |

| AL-KO Jet 3000 Inox | Pinna tsentrifugaal | 8 м | 35 м | 3100 l/h | 650 W | 100$ (roostevabast terasest korpus) |

Tsentrifugaal

Nendes seadmetes toimub vee pumpamine tänu keskvõllile paigaldatud tiivikute-labade liikumisele. Need asuvad pumba töökambris. See kamber on täidetud veega. Kui tiivikud pöörlevad, tekib keskel madalam rõhk ja servades kõrgem rõhk. See erinevus paneb vee liikuma.

Just tsentrifugaalkaevupumpa ostetakse sagedamini. See on vähem tundlik liiva olemasolu suhtes vees, selle töösügavus on suurem. Negatiivsetest külgedest - kõrgem hind, kuid ka kasutusiga on palju pikem.

Siin on näide sukeldatavast tsentrifugaalpumbast - Vikhr DN 900. Seda saab kasutada vee väljapumpamiseks üleujutatud keldritest, väikestest kuivendamiseks kasutatavatest kaevudest jne. Üldiselt seal, kus vesi ei ole väga puhas ja võib muud seadmed rivist välja lülitada.

Kaevust veega varustamiseks saab kasutada süvaveepumpasid. Neid kasutatakse peamiselt vee võtmiseks kaevudest, kuid ka siinkohal on need rakendatavad. Siin on lühike video nende seadmete kohta.

Hüdroakumulaatoriga või ilma

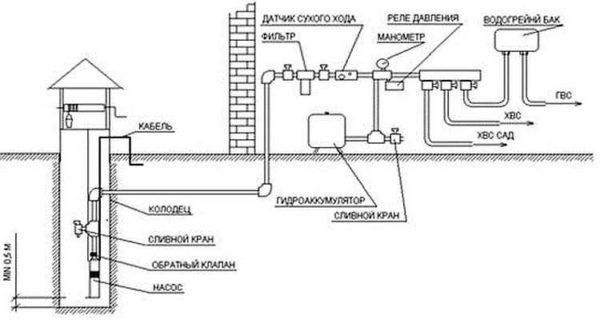

Kui korraldada veevarustuse kaevust, palju vett pumbast pumbatakse hüdroakumulaatorisse (mahuti), ja sealt on see juba toidetud veepunktidesse - kraanid, seadmed. Nad panevad sellise akumulaatori vintorile. Seda on vaja, et lahendada korraga kaks probleemi:

- Suurendage pumba kasutusiga. Kui veevarustussüsteem on ehitatud ilma hüdroakumulaatorita, lülitub pump sisse iga kord, kui majas avatakse kraan, käivituvad vett vajavad kodumasinad. Sageli on sellised sisselülitused - vaid sekundiks või kaheks ja iga käivitamine - miinus kasutusajale. Kui on olemas mahuti, siis tuleb sellest väike vooluhulk. Veetaset reguleerib ujukmehhanism. See lülitab pumba sisse alles siis, kui veetase mahutis jõuab kriitilisele tasemele (mis on seadistatud paigaldamisel).

- Suurendada kogu veevarustussüsteemi, sealhulgas sellega ühendatud seadmete kasutusiga. Fakt on see, et iga pumba sisselülitamine on veekahjustus. Kuna ühe päeva kohta loetakse sadu sulgemisi, väheneb süsteemi seadmete kasutusiga oluliselt. Kui on olemas hüdroakumulaator, on kõik hüdraulilised löögid sisemise juhtmestiku ja kodumasinate poolt ära lõigatud - neid summutab akumulaatoris oleva vee paksus.

Nii et veevarustuse mahuti - kasulik asi. Mis mahus peaks olema hüdroakumulaator? Sõltub vooluhulgast (kuidas lugeda ütleb allpool), panna ja 25 liitrit, ja 150 liitrit, kuid mida rohkem varu, seda parem - harvem pumba sisse lülitatakse. Boonusena akumulaatori paigaldamine - mingi reservi vesi elektrikatkestuse korral.

Kuidas puhastada vett kaevust loe siit.

Valik tehniliste omaduste alusel

Määrake kindlaks, millist tüüpi kaevupumba te panete - see on ülesande vähim osa. Seejärel peate valima tootja ja seejärel - leidma sobiva mudeli, mis suudab vajalikus koguses vett anda vajaliku peaga. Need on kaks peamist omadust kaevupumba valimisel - võimsus ja kõrgus.

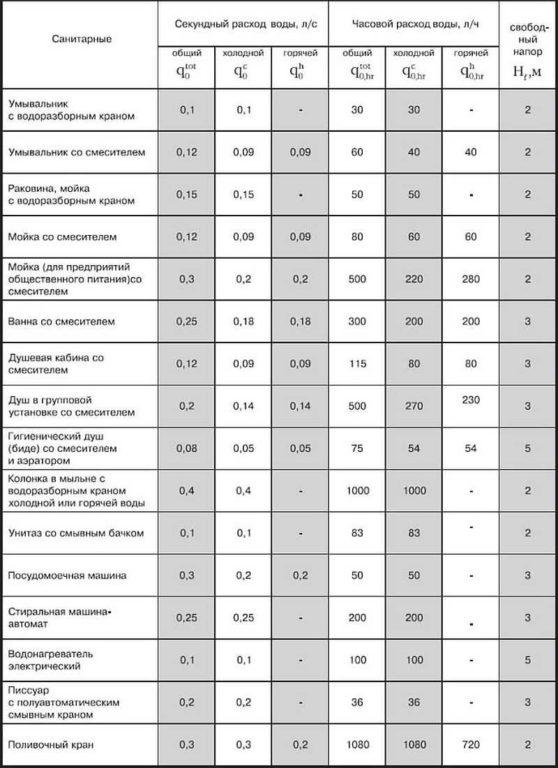

Võimsus (vooluhulk)

Puurkaevu jaoks vajaliku pumba võimsus (tavaliselt tähistatud Q, mõõdetuna l/s või l/h, harvemini kuupmeetrites/h) arvutatakse süsteemi koostise põhjal. See on teatud arv kraanid, WC, bidee, kodumasinad veetarbimisega. Arvutatakse kõigi nende tarbijate veevooluhulk (tavaliselt liitrites sekundis). Vooluhulga võib võtta keskmiseks 0,2 liitrit sekundis iga punkti kohta või leida selle tabelist.

Sellele arvule ei ole vaja lisada "igaks juhuks" reservi. Arvutus sisaldab juba rohkem kui kahekordset reservi ja olukorrad, kus kõik tarbimiskohad on sisse lülitatud samal ajal, on praktiliselt välistatud. Maksimaalselt saab üheaegselt töötada pool tarbijatest ja isegi seda paariks sekundiks ning tegelikkuses - veel vähem punkte lülitatakse üheaegselt sisse. Seega on reserv tõesti suur ja seda pole vaja suurendada.

Pea

Pumba rõhk (tähistatud tähega H, mõõdetuna meetrites) - see on väärtus, milleni pump suudab vett tõsta. Kaevupumba valimisel peate teadma:

- Sügavus, millest vesi tõstetakse (puurkaevu sügavus).

- Tarbimise tõusu kõrgeimale tasemele. Kui on olemas hüdroakumulaator, siis on see selle kõrgus, kui seda ei ole - see on tavaliselt maja kõrgeim dušš.

- Kogukõrgus (Hgeo) arvutatakse kaevu sügavuse ja veetarbimise kõrgeima punkti taseme summana.

- Vahemaa, mida vesi peab läbima (L) horisontaalselt, sealhulgas kõrgus kuni kõrgeima punktini.

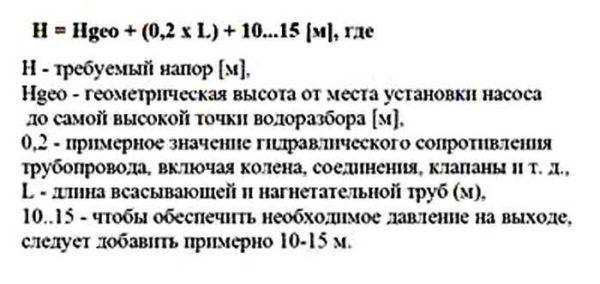

Täpse arvutuse valem on keeruline, nii et kaevu jaoks pumba valimisel kasutatakse tavaliselt lihtsustatud versiooni. Üks neist on pildil.

Vastavalt leitud joonisele ja kaevu pumba pea on valitud.

Mudeli valimine graafiliste omaduste järgi

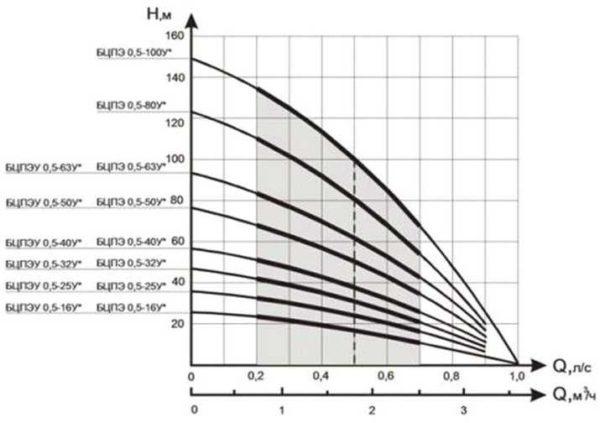

Pärast seda, kui olete kindlaks teinud pea ja jõudluse, on vaja valida mudel. Seda tehakse vastavalt tehnilisi omadusi näitavatele graafikutele (allpool oleval fotol).

Sarnased graafikud on esitatud tehnilistes kirjeldustes. Leiad koordinaattelgedel need väärtused, mida oled eelnevalt arvutanud, leiad nende lõikepunkti tasapinnal. See peaks asuma graafiku keskosas (joonisel on see väli värvitud halliks), siis töötab pump normaalrežiimil, mis tagab selle pika kasutusaja. Mida teha, kui punkt asub väljaspool nõutavat tsooni? Otsige teine mudel, see ei sobi teie puhul.

Punkt on leitud, see on tööomaduste keskosas. Siis on sellele punktile kõige lähemal olev graafik ja see on teie pumba mudel (need on allkirjastatud). Mis siis, kui korraga sobib rohkem kui üks mudel? See juhtub siis, kui punkt on umbes graafikute keskel. Võtke see, mille karakteristikud on punktist kõrgemal.

Kuidas teha maja kaevu jaoks, on kirjeldatud siin (koos samm-sammult tehtud fotodega).

Millele pöörata tähelepanu kaevu jaoks pumba valimisel

Lisaks tehnilistele parameetritele ja pumba tüübile peate pöörama tähelepanu veel mõnele lisaparameetrile:

- Kaitse tühikäigu vastu on väga soovitav. See on olukord, kus pump töötab, kuid vett ei ole. Sellised hetked viivad sageli rikkeid, mõnikord lihtsalt halveneb surve, "imeb" õhku jne. Sellisel juhul tuleb pump viia teeninduskeskusesse, ehk saab seda taaselustada.

- Ujumisanduri (ka "konnasüsteem") olemasolu või võimalus selle järelpaigaldamiseks. See on väike kinnine pirn, mis on kaablitükiga kinnitatud korpuse külge. Andur ujub vees. Kui see langeb alla teatava taseme, lülitatakse pump välja. Pärast anduri tõusu lülitub see sisse (kui kraanid on veel avatud). See on muide veel üks eelis hüdroakumulaatoriga skeemi puhul - kui pumba kaitse käivitub, ei pea te ootama, et see sisse lülituks, vaid kasutate paagis olevat vett. Pumba väljalülitamist te isegi ei märka.

- Kaitse ülekuumenemise eest. Pikaajalise pideva töö korral võib puurkaevupump üle kuumeneda. Selle vältimiseks ja selle kaitsmiseks tehke see kaitse.

- Pöörake tähelepanu korpuse kõigi osade koostekvaliteedile ja sobivusele. Puudub tagasilöök, pinnavigade (õõnsused, kobedused jne), osade suuruse mittevastavus. Need kõik on märgid kehvast kvaliteedist.

- Toitekaabli pikkus (võib olla kuni 40 meetrit). Ka see parameeter võib olla oluline - kõigil ei ole elektriühendust puurkaevu.

- Temperatuurirežiim. Kui valite pumba kaevu suvemaja hooajalise külastuse jaoks, ei ole erilist vahet (kui seda hoitakse soojas ruumis). Kui seade töötab aastaringselt, tuleb valida mudelid, mis võivad töötada väikeses plussis temperatuuril.

Pumba valik kaevu jaoks seda võib pidada täielikuks. Ei ole lihtne asi, kuid on vaja jälgida kõiki neid punkte. Siis töötab seade kaua ja probleemideta.

When I picked a well pump for my place, I just checked the flow rate and depth first. Got some good advice from a buddy who’d been through it. It made all the difference! Solid pump and good pressure now. Just make sure to read up a bit!