Paljud tooted on valmistatud lehtmetallist - drenaažisüsteemid, lainelise terase või metallplaatidega kaetud katusekattematerjalide vormitud osad, keldriprofiilid, lainelisest terasest hoonete nurgad jne. Kõike seda võib teha spetsiaalne painutusmasin - lehtmetallile. Kuidas teha lehtede painutusmasinat oma kätega ja me räägime selles artiklis.

Artikli sisu

Lehtpainajate tüübid

Lehe painutusmasinaid on kolme tüüpi:

- Lihtne käsitsi, metalli painutamine, mille puhul metalli painutamine toimub, kui teatud kohas rakendatakse jõudu. Need seadmed võimaldavad painutada lehtmaterjali sirgjooneliselt mis tahes nurga all - alates mõnest kraadist kuni peaaegu 360 °.

- Hüdraulilised masinad, milles lehtmetall painutatakse löögi abil surumismasina kujule. Maatriks võib olla sirge, võib olla kõver. See seade on professionaalne, mida kasutatakse keskmise ja suure võimsusega ettevõtetes.

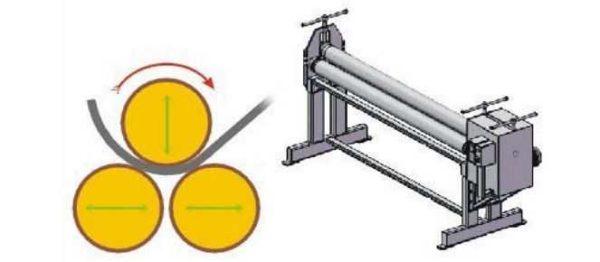

- Rulli- või rullpainutajad. Neis ei painutata metallilehte sirgjooneliselt, vaid ümardatakse. Selle seadme abil saate ise valmistada torusid või muid sarnaseid tooteid.

Kõiki neid seadmeid nimetatakse lehtede painutusseadmeteks. Oma kätega teha lihtsaim seade esimese rühma, veidi raskem - kolmas (rullid lehtmetallile). Siin me räägime neist - sellest, kuidas teha lehtede painajat oma kätega.

Lihtne käsiraamat

Metallist vormitud osad maksavad palju raha. Isegi rohkem kui lainetatud teras või metallplaat, seega on mõistlik teha lihtne lehtmetalli painutusmasin, mille abil saab teha nii palju nurki, valuvorme ja muid sarnaseid osi, kui vaja, ja ainult nende mõõtmete alla.

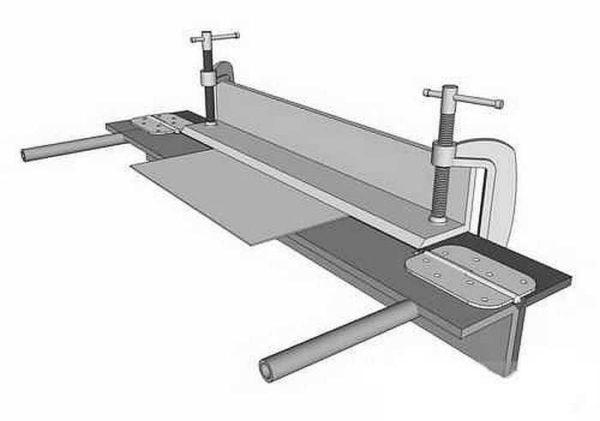

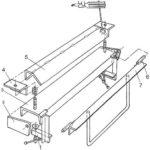

- Joonis lehtmetalli painutuspingi kohta

- Lehtede painutaja - külgvaade

- Teine mudel

Kui te olete välimuse pärast mures, siis peaksite seda olema. Tänapäeval on müügil mitte ainult tsingitud, vaid ka värvitud plekk. Kõikide kujunduste puhul on leht kinnitatud tihedalt, nii et töötamisel ei libise lauale ja seetõttu ei kustutata ja kriimustata värvi. Ka painutuskohtades ei ole see samuti kahjustatud. Nii et toodete välimus on üsna korralik. Kui proovite, siis näevad need isegi paremad välja kui see, mida turul müüakse.

Võimas lehtede painutaja Sõnnist

Selle lehtede painutuspingi jaoks on vaja tasast pinda (lauda), eelistatavalt metallist, kolme nurka, mille riiuli laius on vähemalt 45 mm, metalli paksus vähemalt 3 mm. Kui kavatsete painutada pikki toorikuid (üle meetri), on soovitav võtta laiemad riiulid ja paksem metall. Võite kasutada tavasid, kuid see - suure paksuse ja pikkusega metallilehtede painutamiseks.

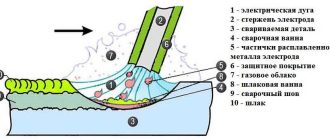

Vaja on ka metallist uksehinge (kaks tükki), kaks suure läbimõõduga (10-20 mm) kruvi, "pöidlad" nende peal, vedru. Samuti vajate keevitusaparaati - hingede keevitamiseks ja aukude tegemiseks (või metallipuuriga puurimist).

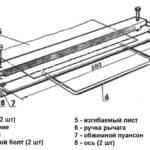

Isetehtud lehtede painutaja jaoks kasutati tavr 70 mm - kolm 2,5 m pikkust tükki, kaks 20 mm läbimõõduga poldi, väike 5 mm paksune metallitükk (kõrvadest väljalõikamiseks), vedru. Siin on tööde järjekord:

- Kaks Taurust on volditud, mõlemast otsast lõigatakse sangade jaoks sisselõiked. Soonte servad on 45° nurga all viilutatud. Kolmas Sõnn lõigatakse samamoodi, kuid sisselõike sügavus on veidi suurem - sellest saab klamberraud, seega peaks see vabalt käima.

- Keevitage hinged mõlemalt poolt (keevitage eest ja tagant).

- Keevitage ühele palgile (see, mis on sinust kõige kaugemal, kui sa neid "avad") kaks klambrit mõlemal küljel. Need on vajalikud selleks, et saaksite nendele kinnituspoldi kinnitusriba kinnituspoldi paigaldada.

- Keevitage poldi mutter kinnitusklambrite külge.

- Paigaldage kinnitusriba (kolmas lõigatud T-tala), keevitage metallplaadid, mille keskel on ülalpool auk. Ava läbimõõt on veidi suurem kui poldi läbimõõt. Tsentreerige augud nii, et need oleksid samas vertikaalses asendis kui keevitatud mutter. Keevitage.

- Lõika vedru nii, et see tõstaks kinnitusplaati 5-7 mm võrra. Pange polt läbi klamberplaadi "kõrva", pange vedru peale, pingutage mutter. Pärast sama vedru paigaldamist teisele küljele tõuseb kinnitusplaat lahti keerates iseenesest.

- Keevitage kruvi pea külge kaks tükk betoonitangi - kruvikeeramise käepidemetena.

- Keevitage käepide liikuva (teile kõige lähemal asuva) härja külge. Kõik, saate töötada.

See võimalus on väga võimas - saate painutada pikki toorikuid ja kindla paksusega lehte. Alati ei ole selline skaala nõutud, kuid alati saab vähendada. Video pakub sarnast väiksema suurusega konstruktsiooni, kuid teistsuguse survevarda kinnitusega. Muide, keegi ei takista teid paigaldamast kruvile vedru - see hõlbustab riba tõstmist. Huvitav on selle konstruktsiooni juures see, et selle peal saab teha flangi, mida tavaliselt sellised seadmed ei saa teha.

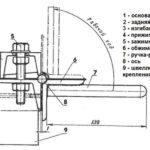

Erinevat tüüpi klambriga nurgast.

See mudel on keevitatud paksuseinalisest nurgast, voodi on valmistatud tavalise ehitusportaalina, mis on keevitatud samast nurgast. Käepide on pagasikärust. Huvitav kruvide disain - need on pikad, käepide on painutatud "G" tähe kujuliseks. Seda on mugav lahti kruvida/kruvida.

Selles omatehtud masinas lehtmetalli painutamiseks on palju funktsioone:

- Nurgad ei ole üksteise suhtes riiulid, vaid on suunatud ühele küljele. Selle tõttu ei osutu hingede kinnitamine kõige mugavamaks, kuid seda on võimalik teha.

- Kaugema (fikseeritud) nurga kummalegi poole keevitatud väikesed plaadid-tugiplaadid kinnitusriba jaoks.

- Samal ribal keevitatud kruvimutter (mõlemal pool).

Nüüd liigume edasi kinnitusriba ehitamise juurde (ülalpool oleval fotol). Ka see on valmistatud nurgast, kuid see on paigutatud masinale kaarega ülespoole. Selleks, et takistada riba paindumist töö ajal, on külge keevitatud tugevdused - metallist risttükid. Raua mõlemasse otsa on keevitatud väikesed metalltampoonid, millesse on puuritud augud poltide jaoks.

Teine oluline punkt on see, et painutuspunkti poole jääv serv lõigatakse ära, et saavutada teravam painutusnurk.

Kinnitusriba asetatakse masinale ja vedru pannakse mutri paigalduskohale. Käepide pannakse paika. Kui see ei suru riba, tõstetakse see vedru jõul pinnast kõrgemale. Sellises asendis on toorik selle alla surutud, joondatud ja alla surutud.

Pole halb valik koduseks kasutamiseks. Paksu metalli painutada ei õnnestu, kuid plekk, galvaniseerimine - ilma raskusteta.

Rullid lehtmetalli või rulli painutaja jaoks.

Seda tüüpi lehtmetalli painajal võib olla kolme liiki ajamit:

- käsiraamat;

- hüdrauliline;

- elektriline.

Valmistavad oma kätega käsitsi või elektrilise ajamiga lehtmetallist rullid. Manuaalsetesse pannakse 3 võlli, elektrilistesse võib neid olla 3-4, kuid tavaliselt ka kolm.

Selle masina jaoks on vaja head ja usaldusväärset alust. See võib olla eraldi voodi või mingi tööpink või laud. Konstruktsiooni aluseks on rullid. Need on valmistatud ühesuguse suurusega. Kaks alumist on paigaldatud paigale, ülemine on liikuv, nii et alumises asendis asub see rullide vahel. Muutes alumiste ja ülemiste rullide vahelist kaugust, muutub kõverusraadius.

Masinat juhitakse ühe rulliku külge kinnitatud käepidemega. Seejärel edastatakse pöördemoment ketirataste kaudu teistele rullidele. Need on valitud nii, et pöörlemiskiirus oleks sama.

Kui seade on ette nähtud torude tootmiseks, on ülemine rull ühel küljel tehtud eemaldatavaks ja varustatud kiirlukustussüsteemiga. Kui leht on kord toruks rullitud, ei saa seda muul viisil enam välja tõmmata.

Kuna ma olen iseehitushuviline, ehitasin kunagi omaenda lehtmetalli painutaja. See oli minu projektide jaoks mänguvahetuseks! Lihtsus ja tõhusus muutsid metalli painutamise nii palju lihtsamaks. Kudos kõigile tegijatele, kes jagavad oma näpunäiteid! Te inspireerite meid looma ja uuendusi tegema. Hoidke seda üleval!