Heating is the key life-support system of a private house and its stable operation is very important. One of the parameters to be monitored is the pressure. If the pressure is too low, the boiler will not work, if the pressure is too high, the equipment will wear out too quickly. To stabilize the pressure in the system requires an expansion tank for heating. The device is not complicated, but without it the heating will not work for a long time.

Artikli sisu

Why do you need an expansion tank for heating

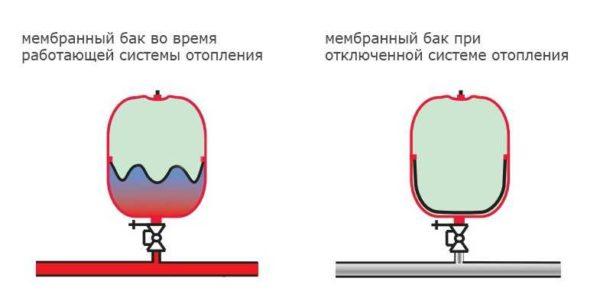

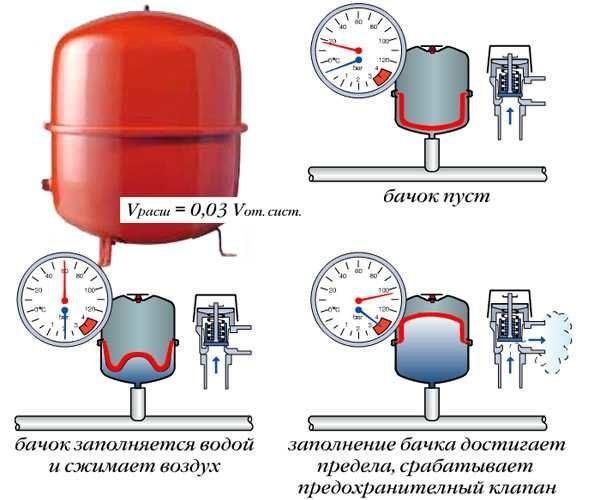

When operating the heating system, the coolant often changes its temperature – then heats up, then cools down. Understandably, this changes the volume of liquid. It increases or decreases. Excess coolant is just displaced into the expansion tank. So the purpose of this device is to compensate for changes in the volume of the coolant.

Types and device

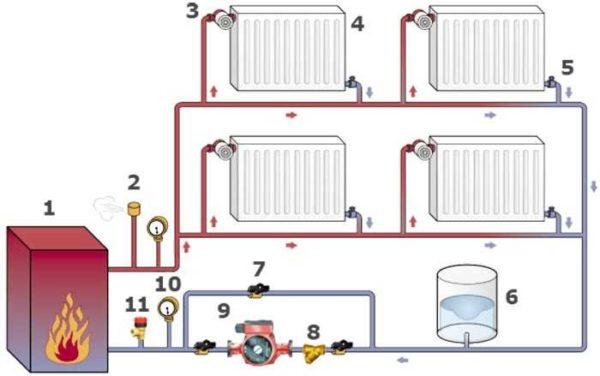

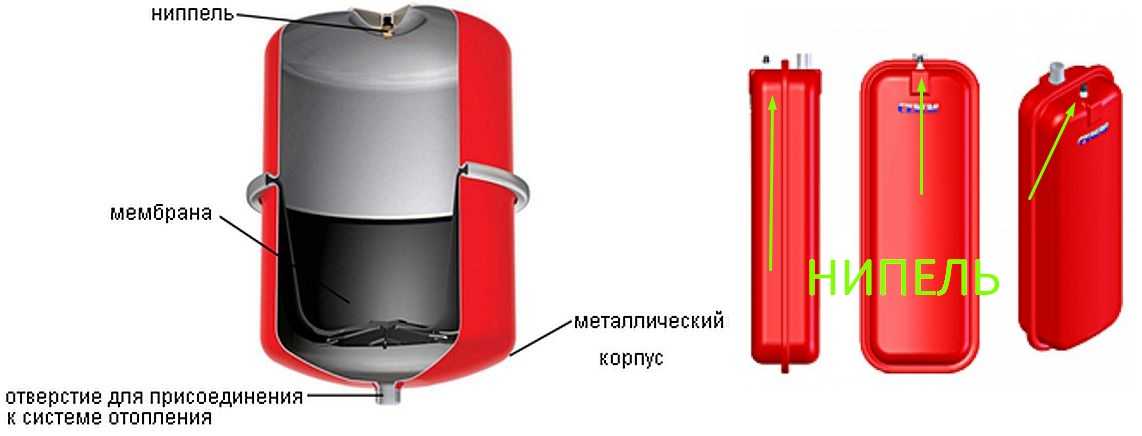

There are two systems of water heating – open and closed. In a closed system, the circulation of the coolant is provided by a circulation pump. He does not create additional pressure, just pushes the water at a given speed through the pipes. In such a heating system is an expansion tank for heating of the closed type. It is called closed because it is a sealed container, which is divided into two parts by an elastic membrane. In one part there is air, in the other part the excess coolant is forced out. Because of the presence of a membrane, the tank is also called a membrane tank.

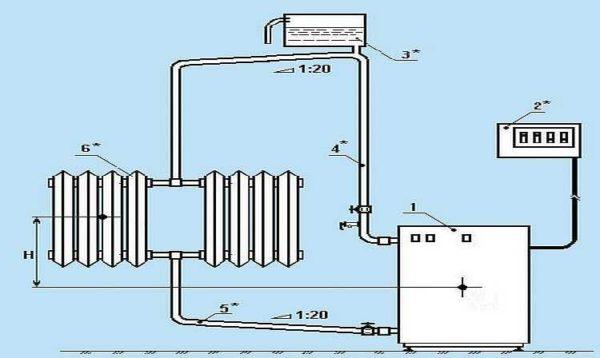

Open heating system does not provide for the presence of a circulation pump. In this case, the expansion tank for heating is simply any container – even a bucket – to which the heating pipes are connected. It does not even require a lid, although it can be.

In the simplest version, this is a welded metal container that is installed in the attic. There is a significant disadvantage with this option. Since the tank is not hermetic, the coolant evaporates and it is necessary to monitor its amount – all the time to refill. You can do it manually – from a bucket. This is not very convenient – there is a risk of forgetting to refill the water. This threatens that the system will be inflated, which can lead to its breakdown.

More convenient is the automated control of the water level. True, then in the attic, in addition to the heating pipes, will have to pull the water supply and somewhere to withdraw the overflow hose (pipe) in case of overfilling the tank. But there is no need to regularly check the amount of coolant.

Volume calculation

There is a very simple method of determining the volume of the expansion tank for heating: 10% of the volume of coolant in the system is calculated. This should have been calculated during project development. If this data is not available, you can determine the volume by experience – drain the coolant, and then pour in a new one, measuring it at the same time (let it through the meter). The second way is to calculate. Determine the volume of pipes in the system, add the volume of radiators. This will be the volume of the heating system. Here from this figure find 10%.

Formula

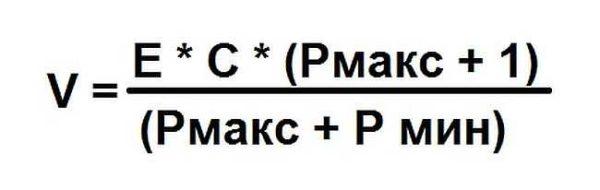

The second way to determine the volume of the expansion tank for heating is to calculate it using a formula. Here, too, you will need the volume of the system (marked with the letter C), but you will also need other data:

- maximum pressure Pmax, at which the system can operate (usually take the maximum pressure of the boiler);

- initial pressure Rmin – from which the system starts to operate (this is the pressure in the expansion tank, indicated in the passport);

- coefficient of expansion of the coolant E (for water 0,04 or 0,05, for antifreeze it is indicated on the label, but usually within the range of 0,1-0,13);

Having all these values we calculate the exact volume of the expansion tank for the heating system according to the formula:

The calculations are not very complicated, but is it worth bothering with them? If the system is of the open type, the answer is unequivocal – no. The cost of the tank from the volume does not depend very much, plus it can be made independently.

Expansion tanks for heating of the closed type is worth counting. Their price from the volume depends strongly. But, in this case, it is better still to take with a reserve, as insufficient volume leads to rapid wear and tear of the system or even to its failure.

If the boiler has an expansion tank, but its capacity for your system is not enough, put the second. Together they should give the required volume (installation is no different).

What will lead to the insufficient volume of the expansion tank

When heating the coolant expands, its surplus ends up in the expansion tank for heating. If the entire surplus does not fit, it is vented through the emergency pressure relief valve. In other words, the coolant is discharged into the sewer system.

Then, as the temperature drops, the volume of coolant decreases. But since there is less of it in the system than there was, the pressure in the system drops. If the lack of volume is insignificant, this drop may not be critical, but if it is too small, the boiler may not work. This equipment has a lower pressure limit at which it is operable. When the lower limit is reached, the equipment locks out. If you are at home at the time, you can correct the situation by adding coolant. If you are not, the system may defrost. By the way, working at the limit also does not lead to anything good – the equipment quickly fails. Therefore, it is better to be slightly reinsured and take a slightly larger volume.

Pressure in the tank

In some boilers (usually in gas boilers) in the passport is indicated, what pressure should be set on the expander. If there is no such record, for normal operation of the system, the pressure in the tank should be 0,2-0,3 atm lower than the working pressure.

The heating system of a small private house usually works at 1.5-1.8 atm. Accordingly, there should be 1.2-1.6 atm in the tank. The pressure is measured by an ordinary manometer, which is connected to the nipple, which is located in the upper part of the tank. The nipple is hidden under a plastic cover, you unscrew it and get access to the spool. Through it you can also release excess pressure. The principle of operation is the same as that of a car spool valve – you bend the plate with something thin, bleeding the air to the required values.

You can also increase the pressure in the expansion tank. To do this, you will need a car pump with a pressure gauge. It is connected to the nipple, pumping up to the required readings.

All the above procedures are carried out on the tank disconnected from the system. If it is already installed, it is not necessary to remove it. You can check the pressure in the expansion tank of the heating system on site. Just be careful! Check and adjust the pressure in the expansion tank for heating should be with the system not working and drained from the boiler coolant. For the accuracy of measurement and adjustment of the tank is important that the boiler pressure was zero. That is why we drain the water thoroughly. Then connect the pump with a pressure gauge and adjust the parameters.

Where to place in the system

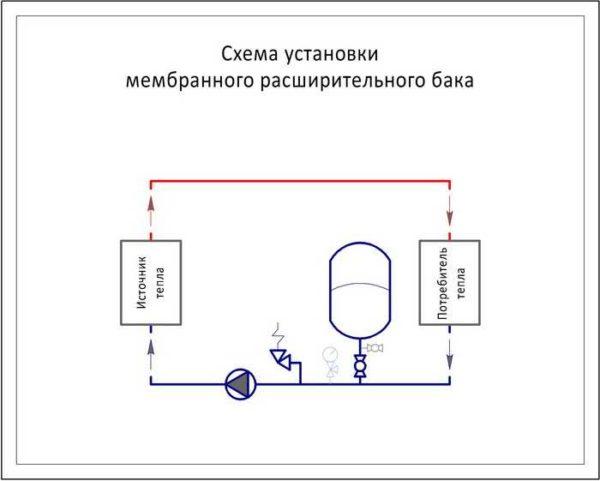

Expansion tank in a closed system is placed after the boiler before the pump, that is, so that it creates a flow in the opposite direction. This way the system works more reliably. So the specific place of installation depends on where you have a circulation pump.

It is connected to the system through a tee. In the pipe you cut a tee, the perpendicular output is directed upward, the tank is screwed on it. If the wall does not allow you to put the tank, you will have to make an elbow, but the tank is turned upward. Now you can consider that the expansion tank is installed.

But for the convenience of checking, it is desirable after the tank to put another tee, on the free outlet of which to install a stopcock. This makes it possible to check the membrane tank without draining the entire system – it cuts off the tank. Shut off the valve, drain the water from the boiler. Check the pressure on the disconnected branch (in the boiler). It should be zero. After that you can carry out all other adjustment works.

Hey, guys! Just gotta say, an expansion tank is a game-changer for heating systems. Last winter, mine saved me from a serious boiler issue. No weird pressure fluctuations—just smooth sailing! Seriously, if you’re heating your place, don’t skip this upgrade. It’s totally worth it!