Heating systems are divided into systems with natural (gravity) and forced circulation. In systems with forced circulation it is mandatory to install a circulation pump. Its task is to ensure the movement of the coolant through the system at a given speed. And to make it cope with its task, to choose the right circulation pump.

Contenido del artículo

Purpose and types

As already mentioned, the main task of the circulation pump is to ensure the required speed of the coolant movement through the pipes. For systems with forced circulation, only under such conditions will the design capacity be achieved. During the operation of the circulator in the system slightly increases the pressure, but this is not its task. This is rather a side effect. To increase the pressure in the system there are special booster pumps.

There are two types of circulation pumps: dry rotor and wet rotor. They differ in design, but perform the same tasks. To choose which type of circulation pump you want to install, you need to know their advantages and disadvantages.

With a dry rotor

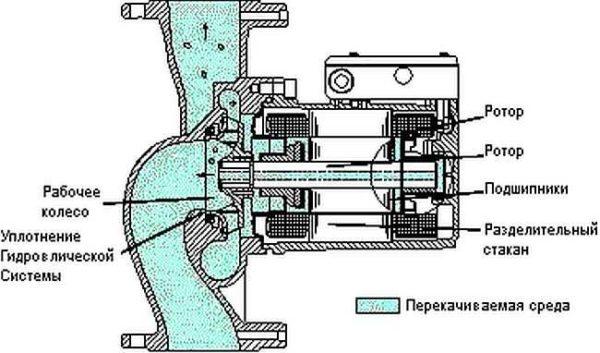

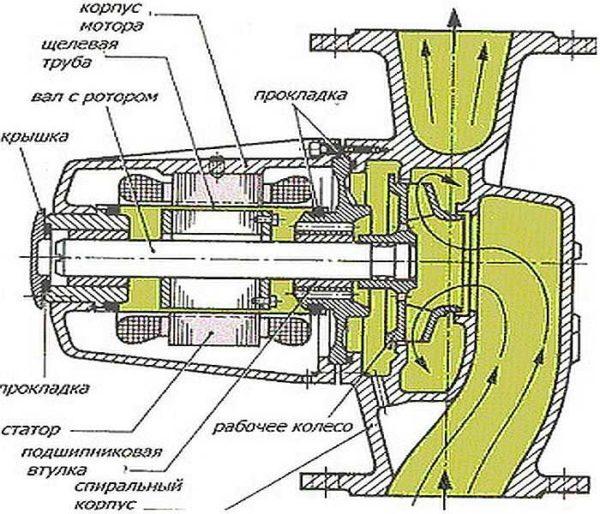

Received its name in connection with the peculiarities of the design. Only the impeller is immersed in the coolant, the rotor is in a sealed casing, it is separated from the liquid by several sealing rings.

These devices have the following properties:

- Have a high efficiency – about 80%. And this is their main advantage.

- Require regular maintenance. In the process of operation, solid particles contained in the coolant get on the sealing rings, breaking the tightness. To prevent depressurization and maintenance is necessary.

- The service life is about 3 years.

- When working emit a high level of noise.

Such a set of characteristics is not very suitable for installation in heating systems of private houses. Their main advantage is their high efficiency, which means less energy consumption. Therefore, in large networks, circulators with dry rotor are more economical, and are mainly used there.

Wet rotor

As is clear from the name, in this type of equipment, both impeller and rotor are in the liquid. The electrical part, including the starter, is enclosed in a metal sealed cup.

This type of equipment has the following properties:

- Efficiency of about 50%. Not the best indicator, but for small private heating systems it is not critical.

- Maintenance is not required.

- Service life – 5-10 years, depending on the brand, mode of operation and the state of the coolant.

- During operation, they are almost inaudible.

Based on the above properties, it is not difficult to choose a circulation pump by type: most stop at devices with a wet rotor, as they are more suitable for operation in the conditions of an apartment or private house.

How to choose a circulation pump

Each circulation pump has a set of technical characteristics. They are selected for the parameters of each system individually.

Selecting the technical characteristics

Let’s start with the selection of technical characteristics. For professional calculation there are a lot of formulas, but for the selection of a pump for the heating system of a private house or apartment you can do with average norms:

It is not difficult to choose a circulation pump for heating by following these rules. Calculations are elementary. But it should be said that these figures are average. If your house in some point is very different from the “average figures”, it is necessary to make adjustments either upward or downward technical characteristics. For example, you have well insulated the house, the capacity of the previously purchased boiler turned out to be excessive. In this case, it makes sense to take a pump with a smaller capacity. In the reverse situation – in the house in severe cold chilly – you can put a more productive circulator. It will temporarily solve the problem (in the future it is necessary to insulate or change the boiler).

Model selection

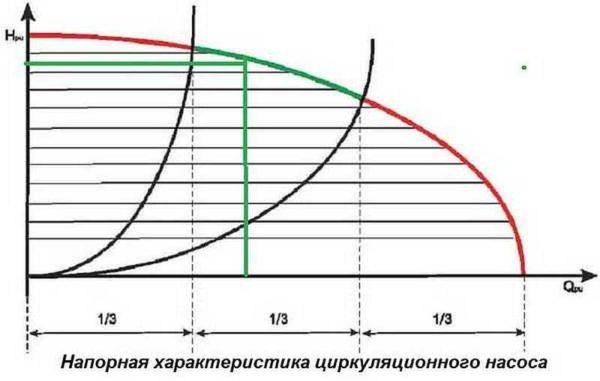

When choosing a particular model, pay attention to the graph with the pressure characteristic of the pump. On the graph, find the point where the head and capacity values intersect. It should be located in the middle third of the curve. If it does not fall on one of the curves (there are usually several of them, characterizing different models), the model whose curve is closer is taken. If the point is in the middle, the less productive one (the one located below) is taken.

A qué más hay que prestar atención

In the technical characteristics of circulating pumps there are several other positions that are worth paying attention to. The first is the permissible temperature of the pumped medium. That is, the temperature of the coolant. In quality products, this indicator is in the range from +110°C to +130°C. In cheap ones it can be lower – up to 90°C (and in fact 70-80°C). If your system is designed as a low-temperature system, it is not a big deal, but if you have a solid fuel boiler, the temperature to which the coolant can be heated is very important.

It is worth paying attention to the maximum pressure at which the pump can work. In the heating system of a private house, it is rarely higher than 3-4 atm (this is for a two-storey house), and the norm is 1.5-2 atm. But still, pay attention to this indicator.

What else to pay attention to is the material from which the body is made. Optimal – cast iron, cheaper – from a special heat-resistant plastic.

Type and size of connection. The circulation pump can have a thread or flange connections. Threads can be external and internal – the corresponding adapters are selected for it. Connection sizes can be: G1, G2, G3/4.

It is also worth paying attention to the presence of protection. There may be protection against dry running. In circulators with wet rotor it is very desirable, because the cooling of the motor is due to the moving medium. If there is no water, the motor overheats and fails.

Another type of protection is overheat protection. If the motor heats up to a critical value, the theromorelle cuts the power, the pump stops. These two functions will prolong the life of the equipment.

How and where to install a circulation pump read here.

Manufacturers and prices

When choosing manufacturers of a circulation pump, the approach is the same as when selecting any other equipment. If possible, it is better to take the equipment of European manufacturers who have been on the market for a long time. The most reliable in this sector are considered circulating pumps Willo (Willo), Grundfos (Grundfos), DAB (DAB). There are other good brands, but on them you need to read reviews.

| Nombre | Rendimiento | Presión | Number of speeds | Dimensiones de conexión | Maximum working pressure | Potencia | Body material | Precio |

|---|---|---|---|---|---|---|---|---|

| Grundfos UPS 25-80 | 130 l/min | 8 м | 3 | G 1 1/2″ | 10 bar | 170 W | Cast iron | 15476 rub |

| Kalibr NC-15/6 | 40 l/min | 6 м | 3 | external thread G1 | 6 atm | 90 W | Cast iron | 2350 rubles |

| BELAMOS BRS25/4G | 48 l/min | 4,5 м | 3 | external thread G1 | 10 atm | 72 W | Cast iron | 2809 rub |

| Jileks Cirkul 25/80 280 | 133.3 l/min | 8,5 м | 3 | external thread G1 | 6 atm | 220 W | Cast iron | 6300 rubles |

| Elitech NP 1216/9E | 23 l/min | 9 м | 1 | external thread G 3/4 | 10 atm | 105 W | Cast iron | 4800 rub |

| Marina-Speroni SCR 25/40-180 S | 50 l/min | 4 м | 1 | external thread G1 | 10 atm | 60 W | Cast iron | 5223 rub |

| Grundfos UPA 15-90 | 25 l/min | 8 м | 1 | external thread G 3/4 | 6 atm | 120 W | Cast iron | 6950 rub |

| Wilo Star-RS 15/2-130 | 41.6 l/min | 2,6 м | 3 | G1 female thread | 45 W | Cast iron | 5386 rub |

Please note that all specifications are for water movement. If the heat transfer medium in the system is a non-freezing liquid, adjustments must be made. You will have to contact the manufacturer for the actual data for this type of heat transfer medium. It was not possible to find such specifications in other sources.

Oh wow, picking a circulation pump can be a game changer! I remember when I upgraded mine, the heating kicked in like a pro! It totally made my cozy nights even cozier! Just make sure to check the specs—it’s like finding the perfect piece for a puzzle!