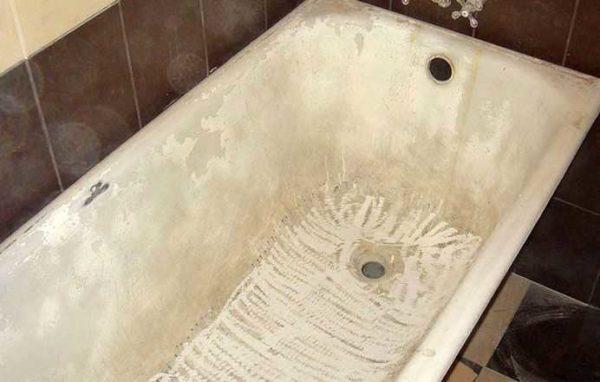

Sooner or later, the enamel on the bathtub turns gray, stains and rusty sweat, and chips appear. Replacement often entails almost a complete repair, and this is a lot of money. There are several ways to update the bathtub and one of them is an acrylic insert in the bathtub. It just needs to be “planted” on a special foam and the bathtub will be like new again.

Contents of the article

Types of acrylic inserts in the bathtub

There are two technologies for the production of acrylic bathtub inserts. The first technology – molding from a heated sheet of sanitary acrylic in a special mold. These inserts are called molded. The second technology – composite (combined) inserts. The base is made of ABS plastic, after which the inner surface is covered with a thin layer of acrylic.

Cast inserts

A cast acrylic bathtub insert has a very smooth surface that is easy to care for. The pores of acrylic are small, so dirt penetrates them poorly, and what remains on the surface is easily washed off. If everything is done according to technology, such an insert can last up to 10 years or more.

The disadvantages of cast inserts are that when molding the maximum (bottom and corners) walls are very thin, quickly wiped, sometimes broken.

The disadvantage – high price, as the sanitary acrylic itself costs a lot, and the equipment on which it is made expensive. It turns out that the molded insert costs about 30% of the cost of a new bathtub.

To reduce the cost can use low-quality acrylic (not sanitary). It has wider pores and its color is not white, but with some shade – grayish or pinkish. Such liners are very poorly washable and can be washed only with special compositions with a soft texture. In general, the use of such a low-quality product is very problematic.

Composite

Composite inserts are made of two materials – the base is ABS plastic, on top of which a thin layer of acrylic is applied. Externally, they do not differ much from fully acrylic, but they cost much less. But they also serve less, as the thin layer of acrylic in the most loaded places is quickly erased. The service life of such an insert is 5-6 years, even with good quality.

They are also worse in operation – acrylic can be scratched, and it is difficult to fix it. If the cast acrylic liner can be renewed by grinding, the composite one cannot. To restore the surface, complex technology is used, which does not always give a good result. Another problem is the delamination of acrylic from the base. Such a defect is manifested when the manufacturing technology is violated. Therefore, the installation of such an acrylic insert in the bathtub will extend its service life for a few years at most.

Choice of insert

So, choosing a molded insert in the bathtub, pay attention:

- The color of the acrylic. A good insert will be white, without shades. The surface is perfectly even and smooth, a little silky to the touch.

- Wall thickness. It is easiest to assess it on the sides. We choose according to the principle of the thicker, the better. If allowed, you can try to bend the walls near the bottom. With a slight pressure acrylic should bend a few millimeters, but not much and even more so, should not crumple.

- Inspect the surface carefully inside and outside. Everything should be even and smooth. Bumps are allowed on the edges, but their condition should not be catastrophic. Any influxes and other defects, a sign of poor quality.

The main points of installation

First of all, it should be said that acrylic inserts can be found only for standard bathtubs. To make everything work for a long time, the coincidence of the shape must be perfect, because they are molded according to the sample. In fact, they make the same bathtub, but made of polymer. That’s why this technology is also called “bathtub to bathtub”.

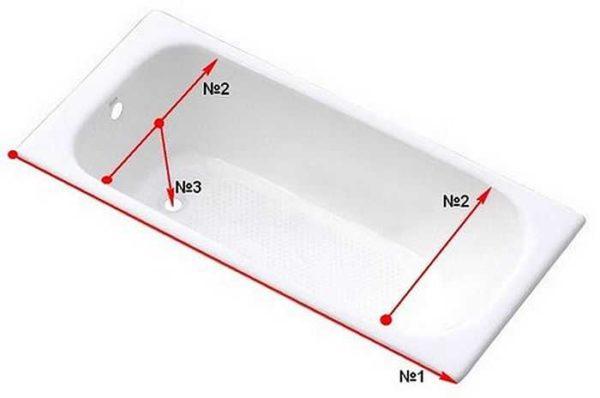

If you decide to improve the appearance of the bathtub on this technology, you will need to measure it accurately. Suggested dimensions of 150×70 or 170×70 do not talk about anything, you need to know the depth.

In addition, the bathtub should be standard and have thick walls, which gives a small change in size under load. The ideal case is cast iron bathtubs. With their thick walls and high mass, they are the best support for the insert.

You can put an acrylic insert in a steel bathtub, but only if it deflects very slightly. The whole point is that when the dimensions change, acrylic also deflects. If the bends are too significant, then after a while the insert will crack. Therefore, if your old bathtub is sagging, give up the idea of putting an acrylic liner, it may be better to restore the coating with the help of pouring acrylic. Another option is to make a rigid pedestal under the bathtub (made of bricks, for example), which will not let it sag.

Bathtub preparation

Before starting work, the bathtub should be thoroughly cleaned. If it has a finished edge, the trim must be removed. If it has a tile edge, it can be left on if the edge is at least 1 cm free. After that, it is necessary to carefully remove traces of silicone, cement, glue – in general, clean the sides to a clean enamel. Next, remove the connected drains.

Next, wash the bathtub itself. And it is necessary not only to wash it from dirt, but also thoroughly degrease it to improve adhesion during installation. Then, wipe it well with a sponge with baking soda. It is necessary to rub thoroughly every centimeter, including the sides. After everything is washed off, and the bathtub is dried.

The second way to prepare the bathtub for the installation of the insert is to remove the enamel. This can be done manually with the help of sandpaper fixed on a bar, or with the help of an attachment on a bolgar (a petal sandpaper wheel works best). Once the enamel has been removed, everything needs to be washed, then degreased and dried.

Which method is more reliable? The second. But such preparation takes a lot of time and effort. The first method, if done correctly, works just as well.

Preparing the insert

When preparing the insert in the bathtub, you need to cut its sides to the necessary size and make holes in the right places. To do this, put the insert in the bathtub, mark all the necessary places and remove it.

Although the liner is light, it is bulky. It is very convenient to install and remove it. Suction cup handles (for carrying glass) or a wide luggage strap passed under the bottom can help.

Having taken out the liner, cut it along the marked lines. This can be done with an electric jigsaw or a hacksaw. It is desirable to find a special blade – for plastic, but you can try an ordinary metal blade. The main condition – the edge should be even, without burrs. If necessary, the edge can be treated with sandpaper, but you can not scratch the adjacent surfaces of the bathroom.

You can only use a bolt cutter to trim the edge if you have mastered it masterfully and can cut exactly along the intended line. To cut the holes, you need a screwdriver or a drill and the appropriate sized drill bits. Use them to make holes for the drain and overflow. For fixing the edges, use clamps.

Installing the liner

The acrylic insert is installed in the bathtub on two-component assembly foam. Ordinary construction foam should not be used, it will not give the desired effect. Technological holes for the drain and overflow are covered with a layer of silicone sealant. In this place is very important tightness, as many problems arise precisely because of the fact that between the insert and the body of the bathtub penetrates water. That is why we do not spare the sealant, we put a thick roll. It is better to put it in two rings for insurance.

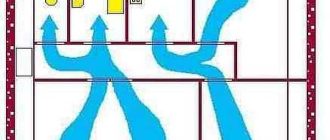

After that, we create a grid over the entire surface of the bathtub with two-component foam. The distance between the foam strips is about 10 cm, on the bottom less. The scheme of application is arbitrary, but the substance should be distributed evenly. You can use the photo as a basis. Foam should be applied quickly, the time of the beginning of polymerization is 15 minutes, before this time it is necessary to put the insert in place.

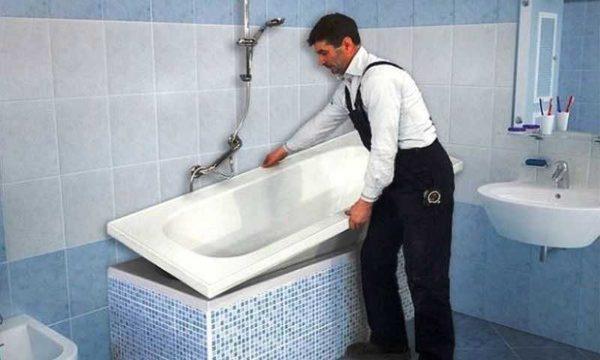

Next, the acrylic insert in the bathtub is put in place, well crimped. The bottom requires more effort – it is necessary to crimp thoroughly. Also press the insert well around the holes and along the sides. Fix the edges with clamps.

The next step is to install the drain. You can leave the overflow for later, but you will need to install the drain. In the case of a siphon in advance estimate whether the threads are sufficient for its installation in the bathtub with an insert.

After the drain is installed, the bathtub is filled with water almost up to the overflow hole and left so until the end of curing. The specific period depends on the foam, it can be found on the packaging. Water is poured to prevent the expanding foam from bending the liner.

While the foam is polymerizing, seal the joint between the insert and the bathtub around the perimeter. To do this, take a white or transparent silicone sealant (not acrylic). To ensure that later the silicone does not darken or in it did not get fungus or mold, look for compositions with antibacterial components. You can also use aquarium sealant. It is definitely not affected by fungi, it has been tested. After that, you can restore the curb around the perimeter of the bathroom.

Actually everything, the installation of the insert in the bathtub is finished, after polymerization of the foam it is ready for use.

Dismantling of the bathtub insert

Violations in the installation technology lead to unpleasant phenomena:

In these cases, it becomes necessary to remove the insert. This is done with the help of a bolgar with a small cutting wheel. Notch it in some places and picking up the acrylic, remove the insert.