The construction industry is considered to be one of the most actively developing industries. New technologies and materials are gradually replacing traditional ones. For example, plastic ducts are increasingly being used instead of metal ones.

Περιεχόμενα του άρθρου

Air ducts made of plastic: what materials are made of

Under the word “plastic” hides a whole group of materials with different properties and performance characteristics. Ventilation ducts are made of such plastics:

When choosing plastic ducts, it is worthwhile to focus on the characteristics of plastics. For example, to connect a kitchen hood, it is better to use polypropylene ducts. If the temperature of the extracted air is high, PVC or PVDF ducts are suitable. For the distribution of ventilation in residential and other technical rooms are quite suitable boxes made of polyethylene.

Pros and cons, area of application

Plastic ducts are perceived by many people negatively, because they are not sure that plastic does not emit harmful substances during operation. Perhaps low-quality plastic is unsafe, but even in household appliances there are so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here the most severe operating conditions – elevated temperature, large amounts of fat, vaporization of chemically active substances.

In general, experts recommend putting plastic on the exhaust ventilation ducts. There are no restrictions. But on the inflow – you need heat-resistant, made of special plastic. Especially if the supply is heated or recuperated.

Where can be used

Another consideration for which it is not recommended to use plastic air ducts – problems with the fire department. There have been cases that they did not sign a permit for the use of gas equipment, if the ventilation is made of plastic. But it was a frame house, and there the requirements are different. If there are doubts, it is better to check with the local fire inspector. And in general, there are recommendations in normative documents.

According to SNIP 41-01-2003 paragraph 7.11 plastic air ducts can be used in low-rise residential, public, administrative and industrial buildings of category D. They can not be laid in basements, cellars, attics and technical floors, in rooms with standardized conditions of fire safety.

Advantages and disadvantages

Plastic ducts have both adherents and opponents. Their main disadvantages:

These are the disadvantages of using plastic ducts. The advantages are more than enough:

In general, plastic ducting is not an ideal solution, but the ease of installation and good performance characteristics outweigh the disadvantages. In general, experts recommend putting plastic on the exhaust ventilation ducts. There are no restrictions. But on the inflow – you need heat-resistant, made of special plastic. Especially if the inflow with heating or recuperation.

Also in the selection should be based on the operating conditions. For example, on the exhaust ventkanal from wet rooms it makes sense to use a plastic duct, as galvanized are subject to corrosion, and stainless steel are very expensive.

Cross-section of plastic ducts and their dimensions

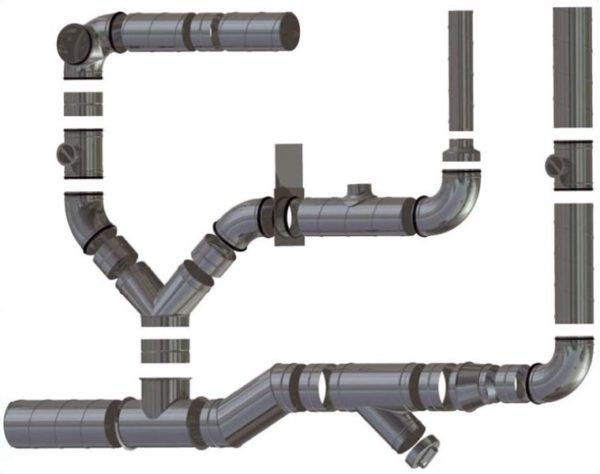

Plastic boxes for ventilation are made:

- Round cross-section.

- Rectangular cross-section (rectangles and squares).

Each type is rigid and flexible. Rigid boxes are cast in special molds. Their main characteristic (except for geometric dimensions) is the wall thickness. For a plastic duct to hold its shape, the wall thickness should be 3 mm. Thinner ones bend, thick-walled ones have more weight and a significantly higher price.

The second type – flexible plastic ducts. They are made in the form of a corrugation. Wire frame is enveloped in a layer of plastic so that the wire itself is sealed in plastic. Such ducts are easier to install, as they can be bent at any angle.

The length of one piece of corrugated plastic pipe for pipe ventilation – up to 2.5 meters, so that short routes can be made exclusively from one solid piece. Installation is very simple: fastened at both ends, laid out on the trace, fastened in several places. It is desirable to stretch the corrugation as much as possible – to reduce wall irregularities and resistance to air flow.

But, even in a well-stretched corrugation, due to uneven walls, the movement of air is difficult. Therefore, under equal conditions, corrugated ducts are put larger. In addition, dirt, grease and dust accumulate faster on the uneven surface. The walls are very thin and have very little mechanical strength. Semi-rigid variants (as in the photo above) are more reliable. They bend worse, but have higher reliability.

Cross-section of round plastic ducts

The most common round plastic ducts:

But there are also much larger sizes – up to 2.4 meters in diameter – for industrial premises. Sold round ventilation pipes in sections of 500 mm, 1000 mm, 1500 mm, 1500 mm, 2000 mm, 2500 mm.

Cross-section of rectangular ventilation pipes

Rectangular plastic air ducts for domestic use come in the following sizes:

The larger the cross-section has a plastic pipe for ventilation, the thicker its walls are made. This is necessary so that the products do not change the geometric dimensions. To save money on shorter walls (picture a), the thickness can be smaller (2-3 mm, for example), and a wider part (in the photo labeled b) is made thickened – 3-4 mm.

What is better: round or rectangular duct?

What shape ducts are better? Round or square? If we take into account the capacity, then the round ones are better. In them, vortex flows meet less resistance, the movement of air masses is faster. In rectangular corners remain practically unused. That is why rectangular ones have a larger cross-sectional area than round ones.

Despite the worst characteristics, rectangular pipes made of plastic for ventilation are more often used. It is easier to hide them, emptying them low over the wall cabinets, for example. Also, when arranging a suspended or stretched ceiling, they require less height, since there are flat and wide models. Even if the false ceiling is not provided and there is nowhere to hide the vent channel, a rectangular box at the junction of the wall and ceiling looks better than a round one.

Ιδιαιτερότητες της εγκατάστασης

Installation of plastic ducts is many times easier than working with metal. Cut plastic pipes for ventilation can be cut with a hacksaw with a metal blade or a Bulgarian with a cutting disk. In any case, the cut turns out smooth, without burrs.

Shaped elements and attachment to the wall and ceiling

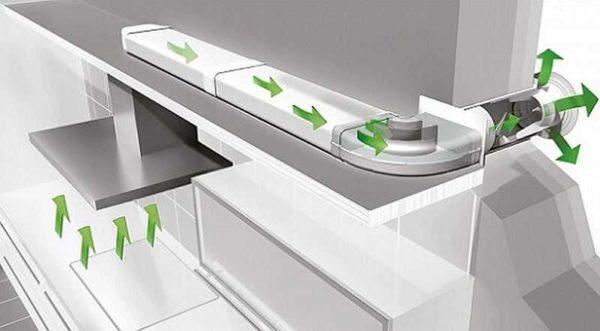

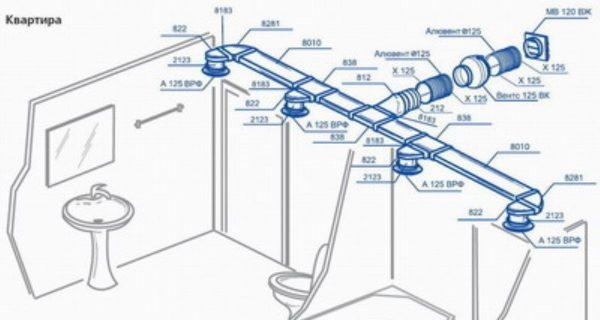

For turns, branches, constrictions, expansions, there are special shaped elements – corners, tees, adapters. There are adapters from one size to another, and from round to rectangular. This will come in handy, for example, if you need to insert a fan. There are couplings for joining two pipes. Everything is assembled even easier than a child’s constructor.

Mount the pipes to the walls or ceiling with the help of special clamps. They are also made of plastic, attached to the ceiling or walls with dowels or self-tapping screws. The pipes are simply “snapped” into the installed clamps.

Instead of plastic clamps for fastening the ventilation ducts, you can use perforated hangers for drywall. If a rectangular plastic pipe is mounted, they are fixed with two dowels / self-tapping screws at a distance equal to the width of the pipe. The remaining edges are bent downward and fastened to the sidewall of the pipe with self-tapping screws. This method is more labor-intensive, but hangers are cheaper. But the use of self-tapping screws is not the best way out. On them, on a piece of screw sticking inside the duct, after a few years, dust will stick to them, which will lead to a deterioration of traction. In 8-10 years, a dust plug will form at the place of each self-tapping screw. As a result, the ventilation may stop working altogether. It will have to be cleaned.

Features of the assembly

If it is necessary to fix the air ducts on the ceiling, their large sections are assembled on the floor, after – “try on” on the ceiling, mark the places of installation of fasteners. Having fixed two sections they are connected to each other. This is how the entire system is assembled. Really nothing complicated. It is difficult to design and pick up the dimensions, and mount the duct on the ready-made scheme can be independently without problems.

To ensure tightness in the system, experts recommend lubricating the joints with sealant. It is recommended neutral silicone sealant of white color. After drying, it remains elastic and does not crack from vibration, compensates for thermal expansion.

If at the junction of the two elements of the system formed a “pocket” – the plastic is poorly adjoined due to the mismatch of geometric dimensions, the joint is also lubricated with sealant, and then wrapped with special metallized tape. In such cases, it is recommended to remove the “pocket” by tightening it with a self-tapping screw. Do not do this for the same reason – in this place will “grow” a dust plug, which will block the air flow.

Man, when I installed plastic air ducts, it changed everything! Way better airflow, and they’re super lightweight. No more drafty spots in my pad. Trust me, if you’re looking to improve your air game, go for these ducts. You won’t regret it!