For the improvement of a site, it is often necessary to use either mortar or concrete. Knead it manually – hard and long, and the quality of the solution is not the best: it is difficult to achieve uniformity. Buy a concrete mixer for its periodic use do not want not everyone. A good way out – concrete mixer with their own hands. You need a little money, the performance of homemade units is no worse than Chinese, and sometimes even better.

Περιεχόμενα του άρθρου

Manual concrete mixer

At the construction site there is not always electricity, and large volumes of mortar and concrete are not always required. The solution is to make a concrete mixer of small volume, which will rotate manually (manually driven). The designs of these models are simple and uncomplicated.

From a milk flask

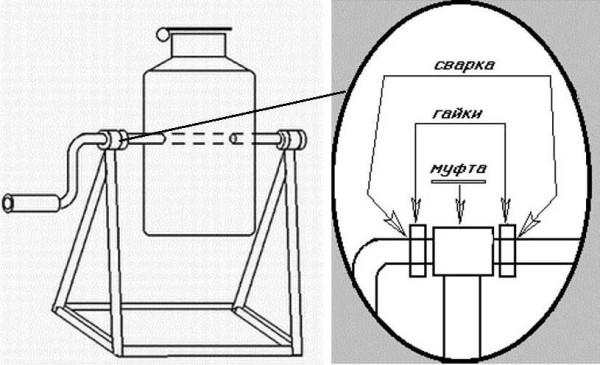

The simplest manual concrete mixer can be made by having an ordinary metal flask (in the past in such milk was sold). More will need scraps of pipes or other scrap metal. The design is simple, such a concrete mixer with his own hands is realized in a couple of hours. The main thing is to weld the frame. The assembly of the concrete mixer itself will take a couple of tens of minutes.

Make a bed, from a round tube bend the handle. In the upper part of the bed weld two water pipe couplings (for example). Their inner diameter is slightly larger than the diameter of the pipe used for the handle. The pipe is passed through the flask, welded to the body.

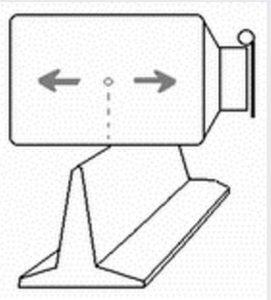

To make the barrel spin easily, you need to find the center of gravity. To do this, you can put it on some thin object, and moving forward/backward, find this very center. This is the center through which you will have to pass the handle. Having passed the handle, it is attached to the walls of the case. Here you may encounter difficulties: flasks are usually made of aluminum alloy, and the handle can be made of steel. It will not be possible to join them with the help of welding. The only available solution is cold welding. It is quite realistic. The other modes – with bimetallic gaskets or argon-arc welding in home conditions are not realized. Another way out is to weld plates on the handle, which are riveted to the sides of the flask.

To the handle is not much play and did not fall out when working, nuts are welded to it on both sides of the coupling.

In general, this is all the manufacture of a manual concrete mixer with their own hands. For one mixing in a 40-liter bidon you can get 2,5-3 buckets of solution. For use at the dacha or on the plot near the house (without building) is more than enough.

If there is no bidon, you can adapt a barrel (thick-walled). Then the problem with welding the handle disappears, but you will have to come up with a system for fixing the lid. You can make something similar to the one on the bidon.

In the video below is an example of self-made from gas cylinders.

From a barrel (manual and electrically driven)

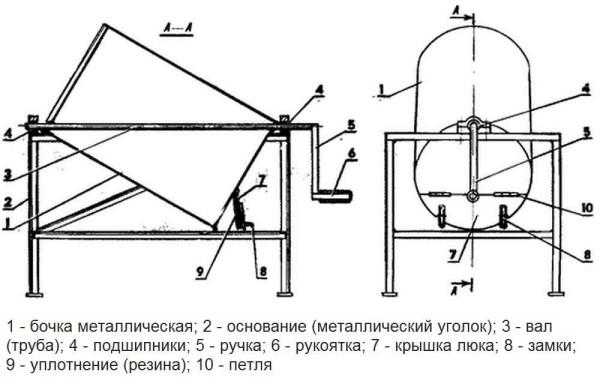

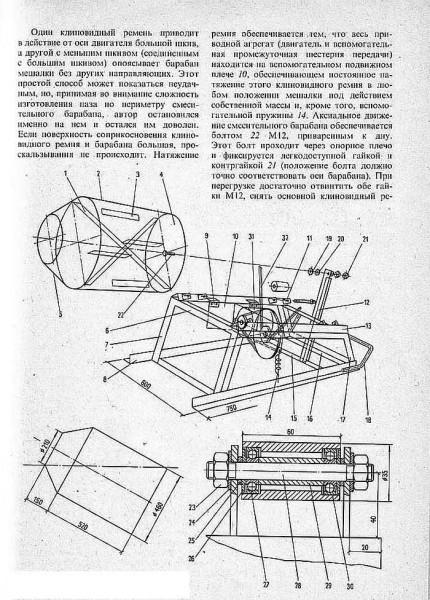

This design the author called “drunken barrel” – because of the peculiar trajectory of movement. The whole point is that the axis of rotation goes through the container obliquely. Because of what the solution falls over from one wall to the other. The design is also simple and effective. What is important – there are no problems with welding dissimilar metals. The drawing of a manual concrete mixer from a barrel is given below.

In the upper part of the frame in the center are installed bearings, in which the handle is threaded. Thanks to them, the 200-liter barrel spins easily. Only choose a container with thick walls – it will last longer. Inside no additional blades are not welded: they only hold components, interfering with mixing and complicate unloading.

In the original design, the loading/unloading hatch is located in the bottom. It is a cut off part (about 1/3), attached to the bottom by means of hinges, equipped with sealing rubber around the perimeter and closed with two locks. When loading, the barrel is turned so that the hatch is at the top. When unloading – turn downwards. The mortar gravity moves into the container, and sticking can be removed by tapping the body with a hammer or sledgehammer.

This design has served the author for 10 years, although it was made for one-time work, but it turned out to be very successful: for 20-30 revolutions well mixed 2.5 buckets of mortar. During this time, it was repeated and improved by neighbors and friends. Most of the modifications concerned the hatch. Experimentally revealed the most successful its design – similar to the one used in the milk flask. Such a “neck” is welded to the body of the barrel on one side (look at the photo above). Also make handles on both sides – for the possibility of working with two people.

This design is easily turned into an electric homemade concrete mixer. A not very powerful engine is put – 1 kW for a barrel of 200 liters is enough, to the axis of which a small sprocket is attached, to the axis-pipe is welded a larger sprocket (to reduce the number of revolutions), they are connected by means of a chain (from a scooter, for example).

Electro-concrete mixer with their own hands from a barrel and washing machine engine

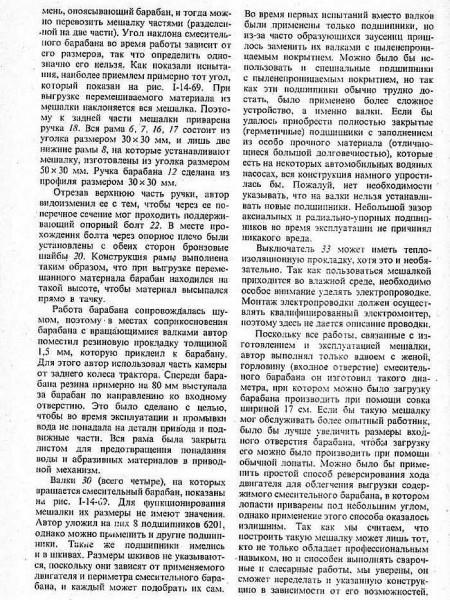

This concrete mixer is of the reducer type. For the manufacture of this model needed:

- galvanized steel barrel for 180 liters (diameter 560 mm, height – 720 mm);

- washing machine motor – 180 W, 1450 rpm;

- flywheel and starter gear from Moskvich 412;

- two pulleys from a washing machine with a diameter of 300 mm and 60 mm;

- wheels from a garden cart;

- scrap metal for the frame.

First of all, we clean everything from rust, treat it with rust converter and coat it with primer.

We weld the frame from pipes, channels. Strengthen the corners of the frame by welding plates of metal. Everything must be rigid and reliable. Crossbar make serious: on it will “hang” the barrel with mortar, and everything will vibrate and spin.

Weld the pins, the landing place for the gears. Brushed from rust, treated with a rust converter, primed.

Attach the wheels from the cart. They have wide treads and justified themselves: it is not difficult to drag the concrete mixer even just on the site.

From pipes we weld more constructions for a stop and installation of all “stuffing”.

We begin to assemble the drive. First put a large gear on the previously welded pin.

In the landing place we install the assembly – a small gear, connected to the wheel for belt transmission.

To the plate welded in advance, attach the motor.

It is suspended so that the two wheels of the belt transmission are at the same level. It is also necessary to ensure that the belt is tensioned properly.

It remains to attach the barrel. In it in the center make a hole for a large pulley, drill a hole for fasteners. Put it in place.

Only the electrical part remains. The cable is connected via a starter with a push button.

A few photos of the main assemblies. Maybe someone needs to look closer.

The second version of the gear is from a car disk

The barrel is 200-liter, its edges were cut, bent and welded to form a familiar “pear”.

The automobile disk was bolted to the bottom (with rubber gaskets). It was selected so that a notch was formed for the belt drive. A hub was attached to the disk beforehand.

Paddles were welded inside the barrel for more efficient mixing of the mortar.

All this equipment was attached to the frame.

Where the plate is welded – a place for the motor. It is set so that the belt runs smoothly. Power supplied through a toggle switch, sequentially included timer from the washing machine, from which we removed the motor.

In general, the speed of rotation turned out to be 35-40 revolutions per minute. That should be enough.

Homemade agitators in the video version

If the general principle of how to make a concrete mixer with your own hands is understood, you can modernize and remodel it, adjusting it to the available parts. Will help in this video, collected in this section.

Wreath type

Another option, only no longerreducer, but of the crown type. The crown, by the way, you can buy (cast iron or plastic) and install it on the barrel.

With rollers as a support

Collapsible barrel agitator

Photos of assemblies of homemade concrete mixers (may be useful).

Each or almost every concrete mixer, made with their own hands, has some original solutions. Few people repeat the design completely without making any changes – you have to adjust to those parts and nodes that are available. Some interesting solutions are in the photo.

I remember building a garden shed using a homemade electric mixer. It saved me tons of time mixing concrete! Manual ones are great for small jobs, but if you’ve got a big project, electric mixers are the way to go. Super handy for DIY enthusiasts!