Works related to electricity require attention, compliance with the rules and accuracy. And wiring in a wooden house with your own hands requires even more attention: the material is very flammable. Therefore, when planning and installation, pay attention to the requirements and recommendations of regulatory documents. If you do not have enough experience, it is very desirable before connecting, and even better also before the start of installation, invite a competent electrician for consultation. He will be able to point out to you the shortcomings and miscalculations.

Inhalt des Artikels

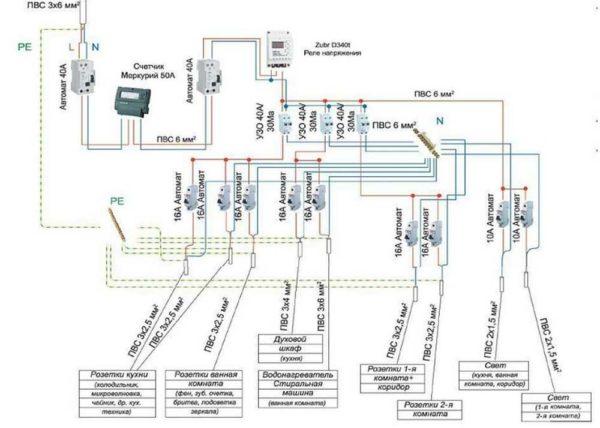

Scheme of electrical wiring in the house

According to current norms when connecting electricity without a transformer, the consumed power for a private house should not exceed 15 kW. It is found by adding up the power of all electrical appliances that can be turned on at the same time. If the found figure is less than 15 kW, the input circuit breaker is put on 50 A. If the power is greater, you need another transformer. Its parameters you will specify in the project, as in this case, without it can not do without it.

Where to put the input panel, the requirements for the housing

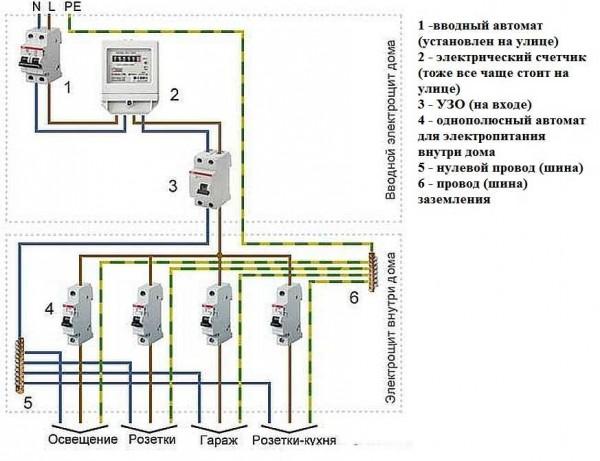

Recently, representatives of energy supply organizations require the installation of meters (and input circuit breakers, respectively) on the street. This is done in order to be able to control consumption even if the owners are not at home. But this requirement is not supported by anything, and if you want, you can install everything inside the house. But more often, in order not to bicker with the controllers, the requirements are fulfilled, and install the automatic machine and meter on the street.

For installation on the street automatic circuit breaker (AC) and meter should be in a sealed enclosure, protected from dust, dirt and moisture. The protection class for the installation should be at least IP-55. For convenient control of readings in the door of the box for the electric meter should be a window. For installation inside a wooden house, the requirements are somewhat lower: IP-44, but the housing must necessarily be metal.

Organization of entry into the house

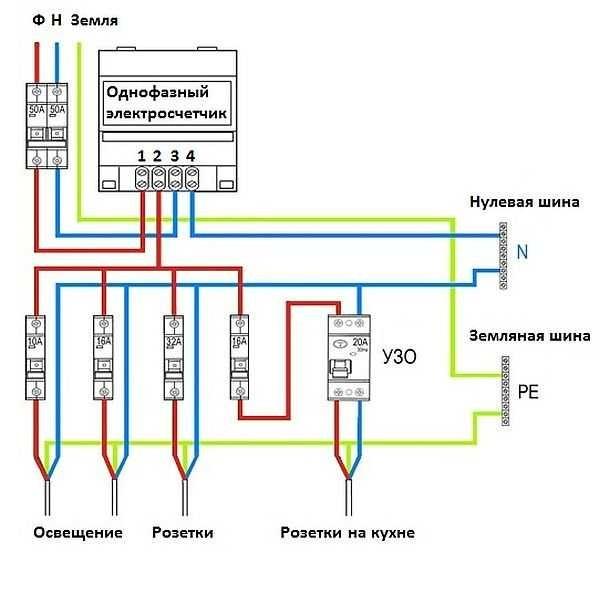

After the input automatic circuit breaker is installed electric meter, then installed more RCD – for emergency power failure in the presence of a short circuit, and then the cable is led to the electrical panel inside the house. The rating of the automatic circuit breaker inside the house should be one step lower than the one installed outside. In this case, in the presence of problems, the first automatic circuit breaker will work in the house and you do not have to climb the wall every time to the automatic circuit breaker installed there.

In the switchboard are installed single-pole circuit breakers, to which are connected the wires that run through the rooms. They are mounted on DIN-rails, their number is dialed depending on how many separate “branches” of power supply will be required. To find out how many automatic machines should stand in your switchboard, count the number of necessary groups, added “to develop” two or three free automatic machines. These will be “branches”. According to the received quantity you select the electric board by size.

Divide consumers into groups

When planning the scheme of electrical wiring in a wooden house, all connection points are divided into separate groups (they are often called consumption groups). For example, all outlets on the first floor are powered from a single automat, a separate device is put on the lighting devices in the house, another – on the street lighting. If there will be used some powerful electrical equipment – boiler, electric boiler, electric stove, etc.. – for them it is desirable to conduct separate branches of power supply and install personal automatic machines. Separate protection devices are installed for power supply of household buildings (if you do not want to pull to them separate inputs and install a separate meter, but only if the power of all electrical appliances does not exceed 15 kW).

From a safety point of view, it is better to make as many separate power supply branches as possible. This will increase the number of circuit breakers and increase the cost of the project, but will reduce the number of potentially dangerous connection points. It’s at the branch circuits where problems most often occur: contacts oxidize, heat up, and then start to spark. Therefore, it is better to make as few connections as possible.

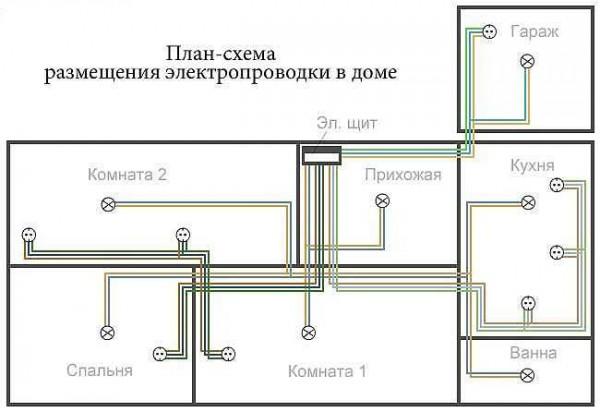

And, at the last stage, it is desirable on the plan of the house to draw a scheme of wiring of electricity on the premises. Groups of consumers in this case, it is easier to draw different colors. So you can more fully imagine how the wiring scheme will look like in a wooden house, it will be easier to do it with your own hands. For example, everything can look like the photo below.

Types of wiring in a wooden house

After installing the switchboard and installing all the necessary automatons, you can proceed to the wiring of electrical cables in the house. In a wooden house there are three ways to lay electric cables:

- Open or outdoor wiring – on special insulators. This method was very popular at the beginning of the last century, and today it is again in fashion in rooms decorated in a retro style.

- Wiring in cable channels or special wires. In fact, this is also open wiring – it is available at any time, only the wires are laid with special trays. One of the varieties of this type of wiring – in baseboards.

- Closed (hidden) wiring. In a wooden house is possible, if it is provided for wall or ceiling cladding. In this case, the cables are laid in a corrugated metal sleeve (not plastic) or in metal pipes and in this form are divorced in the house. And the bending angles should be 90 °, 120 ° or 135 °: so provides the possibility of re-tightening – replacement of damaged sections of the cable without destroying the finish. Then all the wiring is hidden behind the finishing materials.

Features of closed wiring in a wooden house

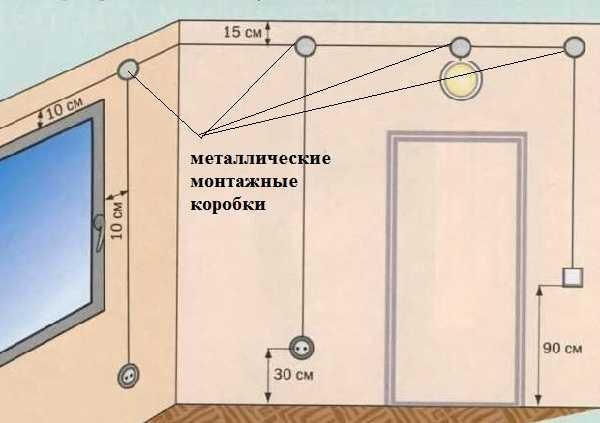

As you have realized, closed wiring can be done at the stage of construction or major repairs. And when laying it there are peculiarities: all nodes of connections should be mounted in special metal boxes, to which there should be free access. They can not be hidden under the finish, so their covers are selected to match the tone and / or try to locate in places that do not attract attention.

If the hidden wiring in a wooden house is conducted not by cable, and insulated wires, the wall thickness of metal pipes is regulated:

- for copper wire with a cross-section of up to 2.5 mm2, the wall thickness can be any;

- for cross-section up to 4 mm2, the thickness of the metal wall must be at least 2.8 mm;

- if the conductors have a cross-section from 4.5 to 10 mm2 the pipe must have a wall of at least 3.2 mm;

- if the cross-section is from 10.2 to 16 mm2, the wall shall not be thinner than 3.5 mm.

When laying electrical cables, there are no requirements for the wall thickness of the metal pipe, because it is acceptable to lay cables (they have double and triple insulation) in a metal corrugation or, as they say, in a metal sleeve. This is much more convenient and faster.

But in any case, since the wires will be hidden, access to them is extremely limited. Making changes to the existing network – troublesome and expensive. Therefore, before you start installing closed wiring in a wooden house, carefully check the scheme and do everything very carefully and scrupulously.

Rules for installing electrical wiring cable channels

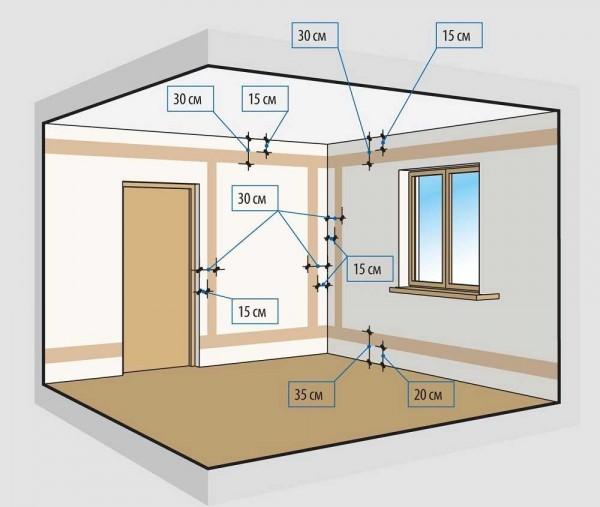

When arranging open wiring or laying it in cable channels, too, there are their own rules. They relate to the distance from the floor, ceiling, corners and other structures can be located. All these rules for greater clarity are shown in the photo.

Selection of cable cross-section and its connection

The cross section of the cable cores is selected depending on the planned load (in kW) and the core material. It is not necessary to make all wiring with the same cable core. You can save money without compromising safety. For this purpose, each section is selected depending on the power of devices that will be connected here. Their power consumption is summed up, about 20% of the reserve is added and the cross-section is selected according to this value in the table.

For connecting the power supply in a wooden house, more fire safety requirements are added. The main thing is that the shell of the wire must be incombustible. Such wires have the letters “ng” in the name. To ensure the required degree of protection also requires double (VVG) or triple (NYM) cable insulation.

To wiring in a wooden house with your own hands was made correctly, it is best to use cables with multicolored cores. Then you will definitely not confuse the zero with the phase or ground. Usually the colors are distributed in this way:

If you buy a cable of European production, there the colors are different:

- “ground” – yellow-green;

- “zero” – white;

- “phase” – red.

Selection of sockets and switches

To ensure fire safety in a wooden house, sockets and switches with a metal mounting plate should be installed. First it is mounted on the wall, then the outer plate is installed. It is allowed to use plastic plates, but the plastic must be non-combustible and have the appropriate certificate of the fire inspectorate.

And, most modern appliances require three-wire sockets with a grounding wire for safe connection. Grounding is also required when connecting lighting, but this is often not done indoors. But for outdoor lighting, earthing is necessary: here the operating conditions are much more complicated.

Electrical wiring in a wooden house with their own hands: installation rules

In a wooden house, you need to constantly remember that the material is combustible and in this case it is better to be reinsured. Electrical wiring in a wooden house with their own hands is done with observance of the basic rules:

- First, the whole scheme is assembled, the operability of each branch is checked (with a tester). Each of the power supply lines check for the absence of a short circuit, “to the ground”. Only then the wires are connected to the circuit breaker. It is recommended to sign at once what is connected. Then it is easier to look for faults. Having connected one line, turn on the power supply, connect the load. If there are no alarms, great – you can continue. You turn off the automatic circuit breakers (which goes to the already checked line and input), work with the next line. After all the lines are checked and connected (signed), the input circuit breaker is switched on. Then, gradually, one by one, turn on the lines.

- Installation of wiring in a wooden house is carried out only with whole pieces of cable without connections and twists.

- Laying wiring is carried out in stages. Having laid a piece of cable, be sure to check the integrity of the insulation of the laid piece of cable. To do this, the cores and insulation are “prozvizvanii” relative to the ground and cores.

- When cutting the cable leave a reserve length – at least 15-20 cm. If the wrong connection can be redone without pulling cables.

- Be sure to follow the colors of wires.

With observance of these rules wiring in a wooden house, made independently, will be safe and reliable.

Wiring a wooden house was quite the adventure! I learned a ton about safety, like using proper insulation and keeping wires away from moisture. It took some trial and error, but seeing everything light up at the end made it all worth it. Definitely a DIY win!

Totally with you on that! I wired my garage once and thought I had it all figured out. Then, BAM, a short circuit! Lesson learned about moisture too. But when it finally lit up like yours, man, what a rush! DIY wins are the best!

Totally relate! I did some wiring in my shed and thought I was gonna mess it up. But just like you, I learned the hard way about moisture. When I flipped the switch and those lights came on, best feeling ever! Super satisfying to see it all come together!

Wiring a wooden house myself was such a thrill! I was kinda nervous at first, but once I got into it, it was so cool to see everything come together. Just a few trips to the hardware store and some late nights, and boom—my home was lit up!

I totally get that! I wired my shed last summer. I was a bit shaky at first too, but when those lights flickered on, it felt epic! Just gotta embrace that DIY spirit, right? Late nights and a few trips to the store are all part of the adventure!

Absolutely! I felt the same way when I tackled my first plumbing job. I was nervous, but when the faucet finally stopped leaking, it was a total win! You’re right—those late-night runs and DIY mess-ups just make the whole process memorable and fun!