When building a house and improving the site, it is often necessary to make round holes in the ground. They are needed for fencing – for the installation of posts, for the construction of arbors, arches and other light household structures. The same pits, but of greater diameter and depth are required for the pile foundation. Make these pits motorized or hand drill. In stores, they are available in sufficient quantity, but many prefer self-made: they are often more productive and reliable than factory-made products. In addition, you can make a drill with your own hands of any design, and there are many of them.

Inhalt des Artikels

Designs and application

There are three main designs of earth drills:

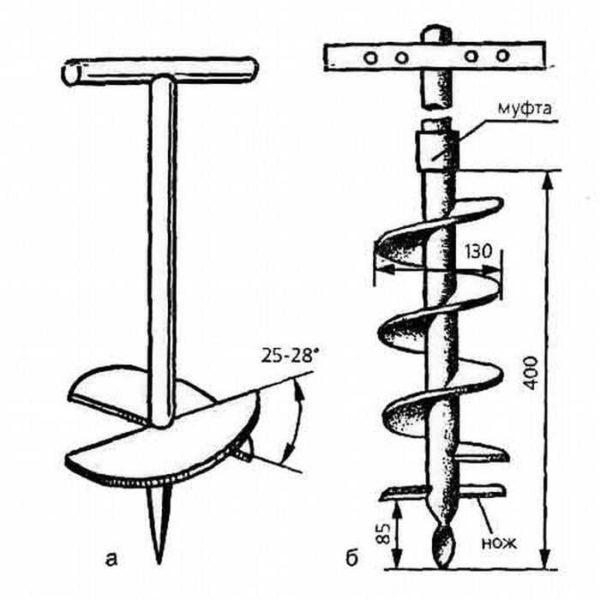

- Garden. Usually it is two semicircular blades, welded at an angle one to the other. A hand drill of this design is used to organize holes for planting plants, from which it is called “garden”. But the same tool makes pits when installing posts for fences, gazebos and other lightweight structures.

- Screw drill. It differs in that it has a longer cutting part. It is used for the same purposes – to make holes for posts. Because of its design – a longer cutting part – it needs to be taken out less often, so drilling is usually faster.

- Drill for TISE piles. This design is similar to the garden drill, but has an additional hinged blade to form an expansion at the bottom of the pile, characteristic of this type of foundation.

Garden earth drills are simpler to make. Depending on the type of soil on which drilling is carried out, their design is slightly modified. This is the beauty of homemade drills – they can be “sharpened” for specific conditions and it is not only in the size – the blades can be made removable, on bolts, but also in the features of the design. Yes, ordinary drills in the store are inexpensive, but they are “universal”. They work well on “light” soils”. On loams, clays, marl, etc., they are ineffective.

Making a garden drill

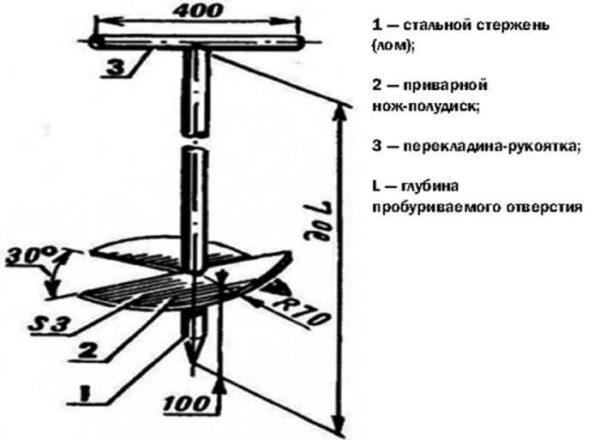

A garden drill is the simplest but effective design. It consists of:

This is the basic design, and to it there are many refinements. But let’s first talk about what you can make an earth drill from.

Materials

As already said, the rod is most often made from a pipe of round or square cross-section. Diameter – from 3/4′ to 1,5′, profiled pipe can be taken from 20*20 mm to 35*35 mm.

Blade blades can be made from:

It is easier to make blades from a saw disk. In this case, the cutting edges are already ready. It will be possible to sharpen the side edges additionally, so that the ground is cut easier.

Spade-drill is made of different materials – there are a lot of its designs. They make a simply sharpened rod. Then you need a section of a rod with a large diameter. The second option – from a strip of steel to make something like a drill. And yet – a combination of these two.

- Tip for an earth drill from a strip of steel

- Spade – one of the variants of the tip

- Combined tip for crushing rocks.

And lastly – about the handle. It is more convenient if it is made of a round tube. Its diameter can be selected according to the reach of your palms. The main requirement is that it should be comfortable for you.

Knives and the method of fixing them

First of all, you need to decide whether you make a drill with your own hands with removable or stationary blades. If the blades are removable, at one end of the rod you weld shelves of thick steel. Shelves are made at an incline – so that the planes of the blades were separated at an angle of 25-30 °.

After the shelves are welded, two or three holes are made in them – for fasteners. Then the same holes will have to be made in the blades, and install them on bolts of solid diameter.

In the disks themselves in the center will have to cut holes – so that they fit more tightly to the rod, but this operation is required and monolithic version – with welded blades.

Sheet steel

If you are going to make the blades from sheet steel, cut a template out of paper, and then cut a circle of steel on it. Drill a hole in the center – in it you will need to insert and weld the rod. Circle or square – depending on the chosen rod. The size of the hole – a little larger than the dimensions of the rod.

Next, you need to decide how you will make the blades – from two halves of the circle (as in the photo above) or in the form of an open circle with offset edges – one turn of the spiral (in the photo below).

The edges should also be displaced by 25-30° degrees. In this case, the drilling efficiency will be maximized. If you work on dense soils (clay, loam with a predominance of clay), the blades under load can vault. To avoid this, add stops made of angle or thick steel strip.

The blades bend because the steel used is unhardened, but it is almost impossible to find it in the sheet, and if you can, it is unlikely to be bent.

From a saw blade

If you have an old sawing disk of the right diameter – you have found an almost perfect option. They use hardened steel, and it is elastic and strong. But such a disk can not be bent, so it is sawn in half and these halves are divorced at the required angle.

Such a homemade drill for earthworks shows a fairly high performance. Even used disks have a well-sharpened edge. And for drilling to go even easier, the drill with their own hands is also sharpened on the sides.

Modifications

In dense soils, it can be difficult to cut the ground with large blades. In this case, several blades of different sizes are welded to the rod. At the bottom, near the peak, weld the smallest, above, a few centimeters away – large. There can be three such tiers, maximum – four. The entire cutting part should not be more than 50 cm, otherwise it is physically very difficult to work.

If the drill is needed for shallow holes – for installing poles, etc., then this design is optimal – it has a relatively small weight, it is easy to work with it. The process of work is as follows – lowered into the hole, rotated a few times – pulled out, dumped the soil stuck between the blades. But if it is necessary to drill deep pits, it will be a pain to carry a small amount of soil from the depth. For such cases, a box is welded above the blades to collect soil.

And all these are drills made with their own hands. All of them are characterized by high efficiency – it is much easier to work than purchased ones.

Screw drill

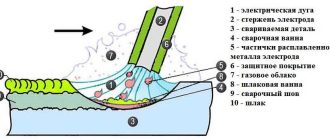

The auger drill because of the large number of turns creates a significant resistance, that is, it is much more difficult to work with it than with a garden drill. But augers are used mainly in the presence of a mechanized drive – when making a drill for wells of great depth – for water, devices for underground probes for heat pump, etc.

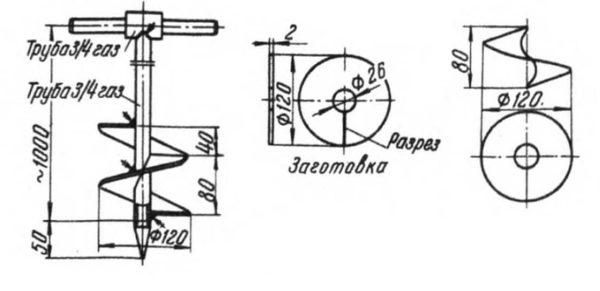

To make a homemade auger drill, you will need several disks of metal. The number of disks is equal to the number of turns. Disks are cut out identical, in them, in the center, a hole is cut for the rod, as well as the same sector – so that they can be welded.

The disks are welded on one side, then, slightly stretching the resulting harmonic, weld the seam on the other side. Rings are welded on the end disks. Welded disks are put on the rod, the bottom edge is welded.

Next, you will need a winch. The workpiece for the auger is fixed, the hook of the winch is clung to the ring and stretched to the required length, after which the auger is welded.

Drill for TISE piles

In the author’s version, the TISE drill is a blade with an earth receiver and a folding wider blade, which forms an extension in the lower part of the pile. But it is inconvenient to work with such a projectile – the folding knife greatly interferes. Therefore, in some constructions it is made removable, and in general, it is recommended to drill the pits themselves with an ordinary garden drill, and for the expansion to make a separate folding knife with an earth receiver. So the work is easier and faster.

As a knife here is a cut shovel, and the earth receiver is made from a herring jar. The knife is fixed movably, when lowering into the pile, it is pulled up by a kapron cable tied to the end. Having reached the bottom, the cable is loosened, the shovel begins to cut the sides of the pits, forming the necessary expansion.

The photo below shows the second version of a homemade drill for TISE piles. The design is more complicated, but also more effective. The plow-shovel is made from a piece of spring, sharpened and welded to the hinged structure on bolted connections.

The earth collector is from an old propane cylinder. The collection of earth occurs from the bottom, so the receiver is made with a rounded bottom. There are two holes in it, their edges are sharpened.

This projectile works well even on dense clay. True, to reduce friction, the borehole should be constantly wetted with water.

Drawings

Made with their own hands, the drill is good in that its design is “sharpened” for the owner. In the process of manufacturing, everyone makes his own changes, then many more finalize the product. But it is difficult to do without basic drawings. In this grav several drawings with the dimensions of various drills are collected. As you understand, the sizes are conditional, they can and should be changed, adjusting to the size of the required wells.

Drill from a shovel

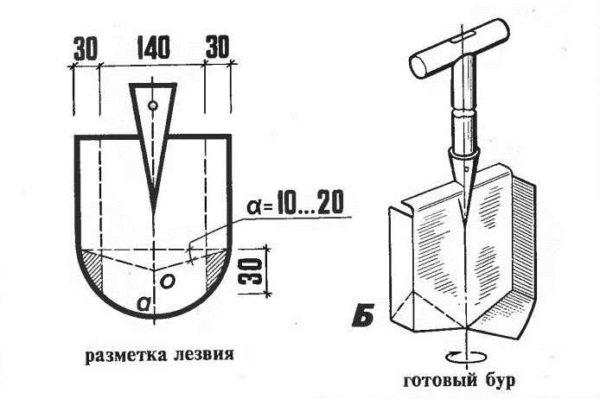

For planting plants, it does not make sense to make a serious design. In this case, you can make a garden drill from a shovel. Choose a high-quality, good steel shovel, make a marking, as shown in the drawing. According to the markings it will be necessary to cut out two small fragments, saw the lower part in the middle to a depth of 30 cm (on the photo).

Next, the edges bend one forward, the other – backward, to them bend the petals formed in the lower part. The resulting seams are welded from the outside and inside.

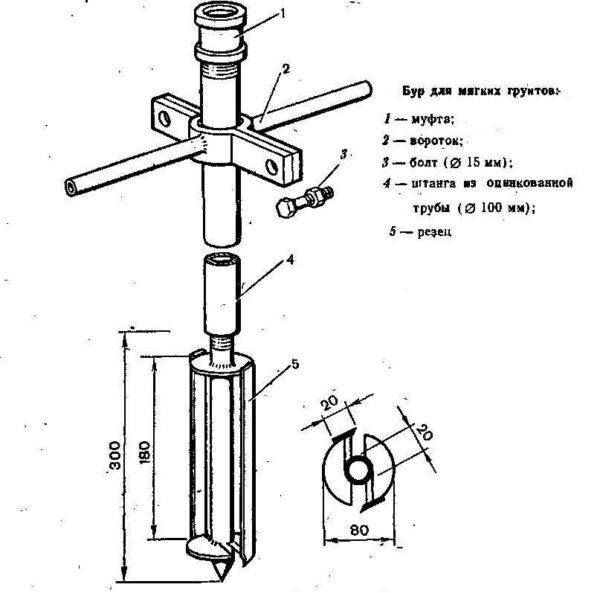

Drill for soft soils

If the soil is soft, the usual design does not work very well. For such cases, there is a special drill with an extended cutting part. It is a kind of cup with slits on the sides. The slits are provided with cutting edges. It is better to make them from well-hardened steel.

This drawing shows an interesting design of the handle – it can be repositioned as the length of the rod increases.

Basic drawings of an auger drill and a garden auger drill

Both of these units work well, but the garden one has to be taken out often, and the auger one is harder to spin. You choose according to your own preferences.