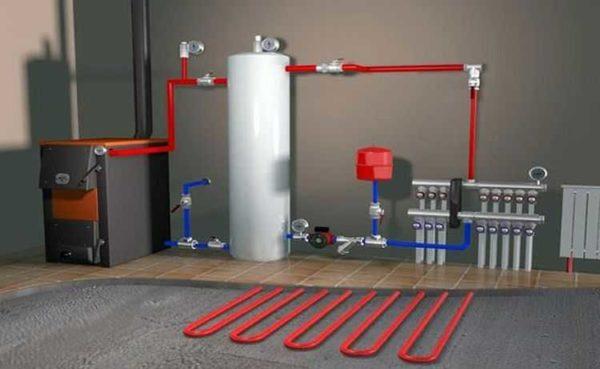

Circulation pumps are used in heating systems with forced or natural circulation. It is necessary to increase the heat transfer and to regulate the temperature in the room. Installation of a circulation pump – the task is not the most difficult, if you have a minimum of skills to cope can be done independently, with your own hands.

Artiklens indhold

What is a circulation pump and why it is needed

Circulation pump is a device that changes the speed of movement of the liquid medium without changing the pressure. In heating systems is put for more efficient heating. In systems with forced circulation it is an obligatory element, in gravity – can be put if you want to increase the thermal capacity. Installing a circulation pump with several speeds makes it possible to change the amount of transferred heat depending on the temperature outside, thus maintaining a stable temperature in the room.

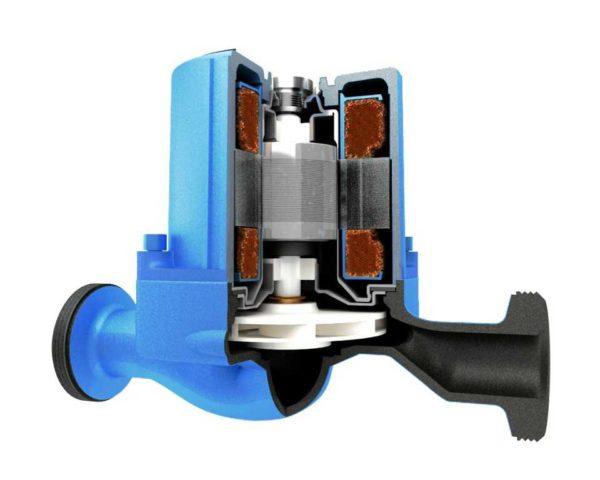

There are two types of such units – with a dry rotor and a wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but they are very noisy and require regular maintenance. Units with wet rotor work almost silently, with normal quality of heat carrier can pump water without failures for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than enough for heating any private house.

About the choice of circulation pump for heating systems read here.

Where to put

Install a circulation pump is recommended after the boiler, before the first branch, but on the supply or return pipeline – it’s all the same. Modern units are made of materials that normally tolerate temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel more comfortable, put it in the return.

There is no difference in hydraulics – the boiler, and the rest of the system, is absolutely indifferent, in the supply or return branch is a pump. What matters is correct installation, in the sense of piping, and correct orientation of the rotor in space. The rest is not important.

There is one important point about the installation location. If the heating system has two separate branches – on the right and left wings of the house or on the first and second floor – it makes sense to put a separate unit on each, rather than one common – directly after the boiler. And on these branches the same rule remains: immediately after the boiler, up to the first branch in this heating circuit. This will make it possible to set the required thermal regime in each part of the house independently of the other and also in two-storey houses to save on heating. How? Because the second floor is usually much warmer than the ground floor and requires much less heat. If there are two pumps in the branch that goes upstairs, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, and without compromising the comfort of living.

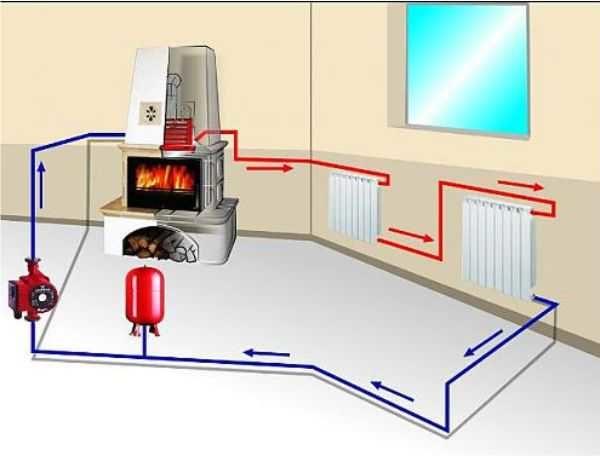

Strapping

There are two types of heating systems – with forced and natural circulation. Systems with forced circulation can not work without a pump, with natural – work, but in this mode have a lower heat output. Nevertheless, less heat, it is still much better than its complete absence, because in areas where electricity is often cut off, design the system as a hydraulic (with natural circulation), and then cut into it a pump. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

Forced circulation

Since a heating system with forced circulation is inoperable without a pump, it is installed directly in the break of the supply or return pipe (your choice).

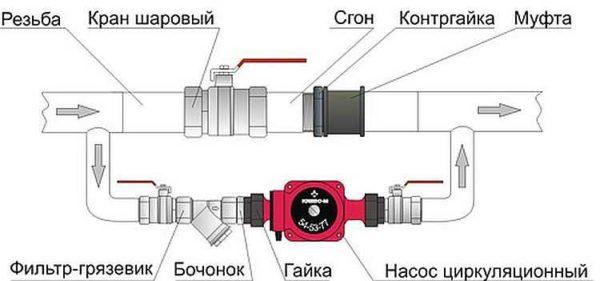

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, before the unit necessarily put a mesh filter-dirt filter.

It is also desirable to install ball valves on both sides. They will give the opportunity to replace or repair the device without draining the coolant from the system. Shut off the valves, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

Circulation pump piping in gravity systems has one significant difference – a bypass is required. This is the jumper that makes the system operational when the pump is not running. The bypass is equipped with a single ball check valve, which is closed the entire time the pumping is running. In this mode the system works as a forced system.

When there is a power failure or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, the system works as a gravity system.

Peculiarities of installation

There is one important point, without which the installation of the circulation pump will require rework: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the casing indicating which way the coolant should flow. This is how you turn the unit so that the direction of flow of the coolant is “according to the arrow”.

The pump itself can be installed both horizontally and vertically, but when selecting a model, make sure that it can work in both positions. And one more thing: with vertical positioning, the power (created head) drops by about 30%. This should be taken into account when choosing a model.

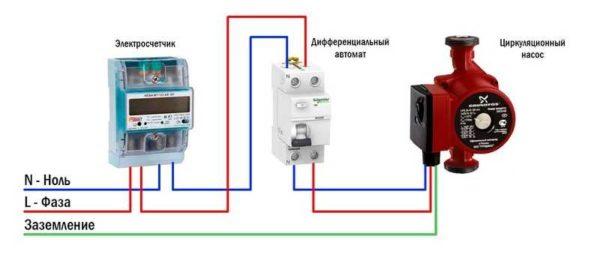

Connection to the power supply

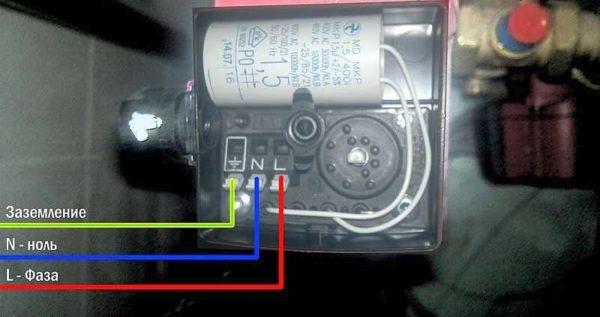

Circulation pumps work from a 220 V network. Connection is standard, it is desirable to have a separate power supply line with automatic protection device. Three wires are required for connection – phase, zero and ground.

The connection itself to the network can be organized with a three-pin socket and plug. This method of connection is used if the pump comes with a connected supply wire. It is also possible to connect via a terminal block or directly by cable to the terminals.

The terminals are located under the plastic cover. Remove it by unscrewing a few screws and find three connectors. They are usually signed (pictograms N – zero wire, L – phase, and “ground” has an international designation), it is difficult to make a mistake.

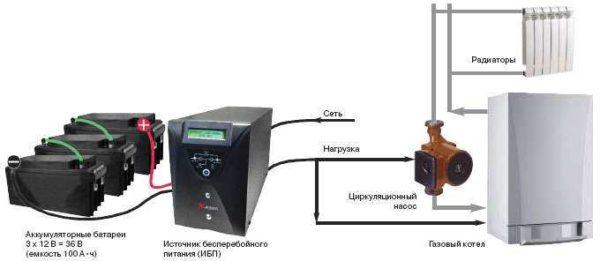

Since the entire system depends on the performance of the circulation pump, it makes sense to make a redundant power supply – put a stabilizer with connected batteries. With such a system of power supply everything will work and a few days, as the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 W. But when organizing it is necessary to calculate everything and pick up the capacity of accumulators. The disadvantage of such a system – the need to monitor that the batteries are not discharged.