One of the most reliable ways to connect wires is soldering. This is a process in which the space between two conductors is filled with molten solder. The melting temperature of the solder must be lower than the melting temperature of the metals being joined. At home, most often used soldering soldering soldering iron – a small device that works from electricity. For normal operation, the power of the soldering iron should be at least 80-100 watts.

Obsah článku

What you need for soldering with a soldering iron

In addition to the soldering iron itself will need solder, rosin or flux, it is desirable to have a stand. Also in the process of work may require a small file and small pliers.

Rosin and fluxes

To get a good connection of wires, it is necessary to clean them from contaminants, including oxide film. If mono-core wires can still be cleaned manually, then multi-core conductors can not be cleaned normally. They are usually treated with rosin or flux – active substances that dissolve impurities, including the oxide film.

Both rosin and fluxes work well, only fluxes are easier to use – you can dip a brush into the solution and quickly treat the wires. You need to put the conductor in rosin, then heat it up with a soldering iron so that the melted substance covers the entire surface of the metal. The disadvantage of using fluxes – if they remain on the wires (and they remain), gradually corrode the adjacent shell. To prevent this from happening, all soldering places should be treated – wash off the flux residue with alcohol.

Rosin is considered a universal means, and fluxes can be selected depending on the metal that you are going to solder. In the case of wires, it is copper or aluminum. For copper and aluminum wires take flux LTI-120 or borax. Very good works homemade flux from rosin and denatured alcohol (1 to 5), in addition, it is easy to make it with your own hands. In alcohol add rosin (better dust or very small pieces of it) and shake until dissolved. Then this composition can be treated conductors and twists before soldering.

Solder for soldering copper wires with a soldering iron use PIC 60, PIC 50 or PIC 40 – tin-lead. For aluminum are more suitable compositions based on zinc. The most common – CO-12 and P250A (made of tin and zinc), mark A (zinc and tin with the addition of copper), CA-15 (zinc with aluminum).

It is very convenient to use solder, which includes rosin (PIC 61). In this case, there is no need to pre-treat each conductor in rosin separately. But for high-quality soldering you need to have a powerful soldering iron – 80-100 W, which can quickly heat up to the necessary temperatures soldering place.

Auxiliary materials

In order to normally solder the soldering iron wires need more:

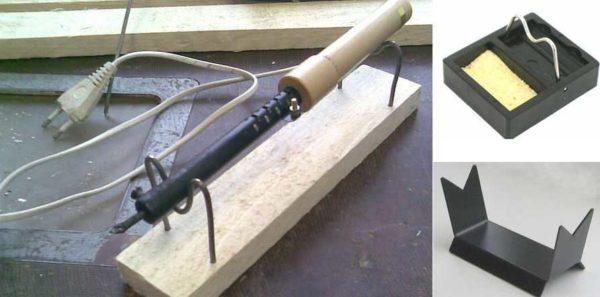

- A stand. It can be it from metal completely or on a wooden / plastic stand fixed metal holders for the soldering iron. It is also handy if there is a small metal box for rosin.

Soldering with a soldering iron is more convenient with a homemade or factory stand – not very important - File. Before working sharpen the dalo of the soldering iron. It should be even and clean without traces of soot. Then soldering is easy.

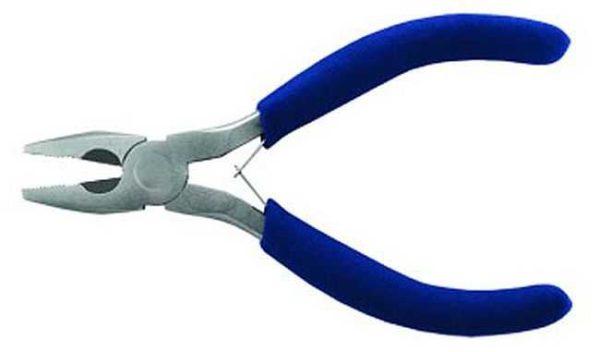

This is how to sharpen the soldering iron’s stinger. - Pliers. It is difficult to hold wires with fingers during soldering – copper and aluminum have high thermal conductivity, which leads to rapid heating of nearby areas. Therefore, it is more convenient to solder wires with a soldering iron if they are held with pliers. Only the tool should be miniaturized, with thin handles and jaws. In principle, you can use tweezers, but on its top (where they are held with fingers) it is desirable to put a heat-shrinkable tube – steel also heats up quickly.

Pliers – to hold the wires in place

Alcohol may be required to wash off flux, insulation – duct tape or heat-shrink tubing of various diameters. These are all the materials and tools without which soldering wires with a soldering iron is impossible.

The process of soldering with an electric soldering iron

The whole technology of soldering wires with a soldering iron can be divided into several consecutive stages. All of them are repeated in a certain sequence:

That is, in fact, everything. In the same way you can solder two or more wires, you can solder a wire to some contact area (for example, when soldering headphones – the wire can be soldered to the plug or to the pad on the headphone), etc.

After you have finished soldering the wires with a soldering iron and they have cooled down, the connection should be insulated. You can wrap duct tape, you can put on and then heat shrink tubing. If we are talking about electrical wiring, it is usually advised to first wind a few turns of tape, and then put on a heat shrink tube on top, which is heated.

Differences in technology when using flux

If an active flux is used instead of rosin, the tinning process changes. The cleaned conductor is lubricated with the composition, after which it is heated with a soldering iron with a small amount of solder. Then everything is as described.

There are differences and when soldering twists with flux. In this case, each wire can be twisted rather than tinned, then treated with flux and immediately start soldering. Conductors may not even be stripped – the active compositions corrode the oxide film. But instead you will have to wipe the soldering points with alcohol – to wash off the residues of chemically aggressive substances.

Features of soldering multicore wires

The soldering technology described above is suitable for monocore wires. If the wire is multicore, there are nuances: before tinning wires untwist to be able to dip everything in rosin. When applying solder, it is necessary to make sure that each wire is covered with a thin layer of solder. After cooling down, the wires are again twisted into a single bundle, then you can solder with a soldering iron as described above – dipping the stinger in solder, heating the solder joint and applying tin.

Is it possible to solder copper wire with aluminum wire?

The connection of aluminum with other chemically active metals can not be done directly. Since copper is a chemically active material, copper and aluminum do not connect and do not solder. The matter is too different thermal conductivity and different conductivity. Aluminum heats up more and expands more when current flows. Copper heats up and expands much less. Constant expansion/contraction in different degrees leads to the fact that even the best contact is broken, a conductive film is formed, everything stops working. That is why copper and aluminum are not soldered.

If there is such a need to connect copper and aluminum conductors, make a bolted connection. Take a bolt with a suitable nut and three washers. At the ends of the wires to be connected, form rings according to the size of the bolt. Take a bolt, put on one washer, then the conductor, another washer – the next conductor, on top – the third washer and all fixed with a nut.

There are several other ways to connect aluminum and copper lines, but soldering does not apply to them. You can read about the other methods here, but the bolted method is the simplest and most reliable.

Soldering wires is a game-changer! I remember my first time trying it – a total mess! But once I got the hang of it, everything clicked. Just keep your iron clean, heat it well, and don’t rush. Trust me, it makes all the difference in making solid connections!

Absolutely! I totally relate. My first attempt at soldering was like spaghetti – all over the place! But once I learned to keep my iron clean and steady, it transformed my projects. Patience really pays off in creating those solid connections. Great tips!