Welding thin metal is a challenge even for some experienced welders. Beginners in welding in general have a hard time. There are a lot of peculiarities and complexities that make it harder to select modes and electrodes. It is easier to do this with welding semiautomatic machines, but they are quite rare in the home, much more common are inverters. Here is about welding thin metal inverter and we will talk about it.

And the first difficulty in welding metal of small thickness is that you can not heat it much: it burns through, holes are formed. Therefore, work on the principle of “the faster, the better” and no trajectories of movement of electrodes is not a question at all. Thin sheet metal is welded by conducting the electrode in one direction – along the seam without any deviations.

The second difficulty is that you need to work at low currents, and this leads to the fact that the arc has to make a short. If there is a slight breakaway, it simply goes out. There may also be problems with the ignition of the arc, so use machines with a good volt-ampere characteristic (idle voltage above 70 V) and a smooth adjustment of the welded current, which starts from 10 A.

Another annoyance: with strong heating there is a change in the geometry of thin sheets: they are bent in waves. It is very difficult to get rid of this disadvantage. The only option is to try not to overheat or to dissipate the heat (read about the method with heat dissipating pads below).

When butt welding thin sheets of metal, their edges are carefully processed and cleaned. The presence of dirt and rust will make welding even more problematic. Therefore, carefully align and clean everything. Place the sheets very close to each other – without a gap. The parts are fixed with clamps, clamps and other devices. Then the parts are tacked every 7-10 cm with short seams – tacking. They will prevent the parts from shifting and they are less likely to bend.

How to weld thin metal with an inverter

Welding machines that produce direct current are good in that we can weld in reverse polarity. To do this, we connect a cable with an electrode holder to the “+” and connect the “-” to the part. With this connection, the electrode is more heated, and the metal is heated minimally.

On how to choose a welding inverter for home or cottage read here.

It is necessary to weld using the thinnest electrodes: from 1.5 mm to 2 mm. At the same time, choose one with a high melting coefficient: then even at low currents, the seam will be qualitative. The current is set small. For electrodes with a size of 1.5 mm, it should be about 30-45 amperes, for “two” – 40-60 amperes. Realistically put sometimes lower: it is important that you can work.

| Tloušťka kovu, mm | 0.5 mm | 1.0 mm | 1,5 mm | 2.0 mm | 2,5 mm |

|---|---|---|---|---|---|

| Průměr elektrody, mm | 1.0 mm | 1,6 mm – 2 mm | 2 mm | 2.0 mm – 2.5 mm | 3 mm |

| Current strength, A | 10-20 ampere | 30-35 ampere | 35-45 mm | 50-65 mm | 65-100 mm |

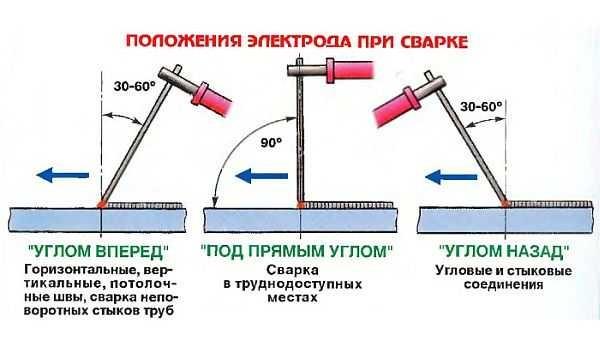

To make the metal less heated, the parts are placed in a vertical or at least inclined direction. Then the welding is done from top to bottom, moving the tip of the electrode strictly in this direction (not deflecting and not returning). The angle of inclination – angle forward, with its value of 30-40 °. In this way, the heating of the metal will be minimal, and this is one of the most important tasks for welding thin metals.

A general recommendation on the choice of electrodes for welding thin metals: buy high-quality imported electrodes for such work. Problems will be many times less.

About the manufacture of a shed on a metal frame read here.

Techniques and methods of welding thin metal sheets

Sometimes thin sheets need to be welded at an angle. In this case, it is more convenient to use the method of flanging: the edges of the sheet are bent to the required angle, fasten short transverse seams every 5-10 cm. After welding as mentioned above: a continuous seam from top to bottom.

The video shows how to weld thin sheet metal with an electrode using a welding inverter. The method of flanging is used: the edges of the parts are bent, then tacked in several places with short seams. After welding with a thin electrode with a thickness of 2 mm.

It is not always possible to avoid burning when welding without tear-off. Then you can try to tear off the arc for a few moments, and then again lower the electrode to the same place and advance it a few millimeters more. So, tearing off and returning the arc, and cook. With this method, it turns out that the metal during the time of the arc breakaway has time to cool down. In the video you will see how the color of the welding place changes after the electrode is removed. The main thing is not to let the metal cool down too much.

Welding thin metal with a breakaway arc is demonstrated in the first part of the video. The method of joining – overlap (one part overlaps the second by 1-3 cm), using an electrode with a rutile coating (for structural and low-alloy steels). Then shown welding stainless steel stainless steel electrode with basic coating, and finally the same stainless steel electrode welded the joint of black metal. The seam, by the way, turned out to be of higher quality than when using the recommended electrodes.

About the choice of electrodes for welding with an inverter machine read here.

If welding thin metal does not require the creation of a continuous seam, use a spot weld. In this method of welding small tack welds are located at a small distance one near the other. This method is called an interrupted weld.

In general, butt welding thin iron is difficult. Overlapping is easier: the parts are not so overheated and there is less chance that everything will “hang”.

Read about the types of welds and joints here.

When electrically welding thin metal butt joints, you can lay a thin wire with a diameter of 2.5-3.5 mm between the sheets (you can knock off the coating on damaged electrodes and use them). It is placed so that on the front side it was flush with the surface of the metal, and on the back protruded almost half the diameter. During welding, the arc is conducted on this wire. It takes the main thermal load, and the welded metal sheets are heated by peripheral currents. In this case, they are not overheated, they do not warp, the seam is smooth, without signs of overheating. After removing the wire, it is difficult to see traces that it was present.

Another way is to put copper plates under the joint. Copper has a very high thermal conductivity – 7-8 times higher than steel. Placed under the place of welding, it takes away a significant part of the heat, preventing overheating of the metal. This method of welding thin metals is called “with heat dissipating pads”.

How to weld a pergola made of metal read here. Perhaps you will be interested to read how to make a brazier from a gas cylinder or metal? The thing is necessary and for mastering welding suitable.

Welding galvanized steel

Galvanized steel is the same thin sheet steel, only coated with a layer of zinc. If you need to weld it, the edges to be welded will have to have this coating removed completely, down to pure steel. There are several ways. The first is to remove mechanically: with an abrasive wheel on a bolgar or grinder, sandpaper and a metal brush. There is also a way – to burn out with welding. In this case, twice pass the electrode along the seam. In this case, there is evaporation of zinc (it evaporates at 900 ° C), and its vapors are very poisonous. So this work can be done either outdoors or if there is a hood at the workplace. After each pass it is necessary to knock down the flux.

After the complete removal of zinc, the actual welding begins. When welding galvanized pipes, two passes with different electrodes will be needed to get a good weld. The first weld is welded with rutile-coated electrodes such as MR-3, ANO-4, OZS-4. In this case, the oscillations have a very small amplitude. The upper seam – facing to make wider. It is approximately equal to three diameters of the electrode. Here it is important not to rush and weld well. This passage use electrodes with the main coating (for example, UONI-13/55, UONI-13/45, DSC-50).

Read more about choosing electrodes for inverter welding here.

Welding thin metal is a game-changer! I remember the first time I tried it—man, talk about a rush! The sparks flying and getting that perfect bead was epic! Just gotta keep your heat right and use the right filler. Totally worth it for those slick projects!