Preparing firewood requires a lot of effort: it needs to be cut, chopped, stacked in the firewood bin to dry. The most effort is spent on chopping the firewood. Facilitate and speed up the process can wood chopper. They are presented in sufficient quantity, but cost a solid amount of money. At the same time, make the simplest woodchopper with your own hands can be made from scrap metal – pipes, angles, etc. Everything will require literally a few thousand – if there is no metal, it will have to be bought.

Obsah článku

Mechanical woodchoppers

If the volume of firewood preparation is small, a mechanical woodchopper can easily cope with it. They are distinguished by the simplicity of the design, the minimum number of complex nodes, and also by the fact that the costs are minimal, even if there is no suitable iron in the household.

Simple woodchopper with their own hands: mechanics

The simplest mechanical woodchopper resembles a well crane. The design is one to one, only instead of a bucket, a torch and handles are fixed. The connection of the rack (racks) and the crossbar can be made the simplest – hinged. Only a good lubricant is required.

The principle of operation is probably clear to everyone. Churbak put on a stand, sharply pull down the lever, due to the force of inertia cutter gains significant force and splits churbak. The process is repeated until the logs of the required thickness are obtained.

Such a mechanical woodchopper with their own hands to collect simply, and, literally, from what is available – pipes, a corner of any size, as a cutter you can even use an axe. In addition, such a design can be made collapsible – so that it was possible to carry it.

The minuses are many. Cutting firewood requires considerable effort. And more effort is applied to stop the course of the cleaver after the log has collapsed. The second disadvantage – such a wood chopper occupies a solid area, because the longer the lever, the less effort must be applied. Nevertheless, even such a primitive mechanical device much reduces the labor intensity of the process.

In this design, the cleaver must be heavy. Therefore, the blade itself is welded to an all-metal dummy. A more affordable option – welded to a pipe (round or square) and pour it with concrete. Agree, to make such a woodchopper with their own hands on the strength of anyone who knows how to handle a welding machine.

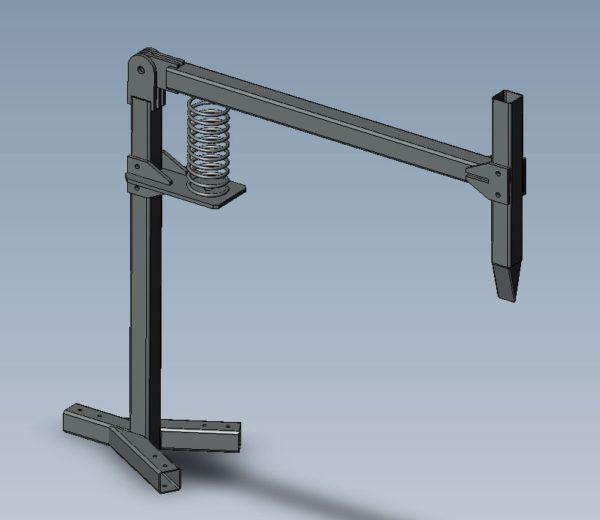

Spring woodchopper

There is a refined design of a manual mechanical woodchopper, which, with smaller dimensions, cuts wood better, requires less effort. In this model, the main working unit is a spring, which is fixed on the bed, and its upper part rests on a stationary bar, on which the cleaver is fixed.

In this design, the main force – to hold the cleaver after the log is split – takes on a spring. Accordingly, the main thing is to choose the spring and the stop so that the minimum effort is applied, but they were sufficient to split even difficult, knotty logs. The spring stop can be made movable. Then it is possible to adjust the parameters to specific conditions. In reality, “readjustment” is required for a particular person. If one person will work with the tool, then you can do everything stationary, having picked up the height experimentally.

It is no less important to make a movable articulation of the frame and the lever, on which the cleaver is fixed. The best option is bearings. They should be of high quality, preferably – self-aligning.

The minimum height of the homemade woodchopper is about 800 mm. But then you either have to work bent over, or install the machine on a table/bench. A more comfortable option, requiring minimal effort, – made under your own height. You determine at what height you are comfortable to stand the log, to this figure add the height of the log itself, you get the height of the bed. In this case, too, you will have to bend over, but only when you set the log on the stand, not every time the cleaver is lowered.

To add mobility to the design, weld a bed, on one side of which the wheels are fixed, on the second side the stops are welded. To make such a woodchopper with their own hands is somewhat more difficult, but if there is a spring and bearings – it is such a difficult task.

Inertial vertical woodchopper

Another uncomplicated option for self-manufacturing. To make such a woodchopper with your own hands you need two pipes of a larger and smaller diameter. You will also need a heavy plate – the base, and, in fact, the cutting part – the cutter / cleaver.

The design is one of the simplest, little effort is required. On a massive platform is fixed thick-walled pipe, or better – a pin. The height is about a meter. This is the leading pipe. On it moves freely cleaver, which is welded to the rings of the pipe of slightly larger diameter than the leading pipe. It cuts wood in the following way: you lift the cleaver up and release it. You can give a little acceleration downwards. The log splits due to gravity.

- A heavy cleaver is the key to success in this model

- Mechanical vertical wood chopper: drawing with dimensions

- To increase efficiency, you can make a weighting device

But this mechanical wood splitter immediately splits not all chunks. To increase its efficiency, you can make a weighting device on the cleaver. It can be “added” if necessary. The second option is to hit the stake a couple times with a hammer. This method is good if the chisel is stuck in the wood. The alternative is to lift the chisel up and sharply lower it. But it is easier to swing the hammer.

Electrically powered wood chippers

A manual woodchopper, of course, makes it easier to make firewood, but still requires a solid physical effort. Not as much as they are spent waving a conventional cleaver, but still … To make the effort even less helps electric motor. On its basis make wood choppers of various designs. But it is more difficult to make such a woodchopper with your own hands. Here and the device is more complex, and requires at least a minimum knowledge of electricity – it is desirable to connect the motor through the starter, and with buttons “start” and “start”.

Screw (cone)

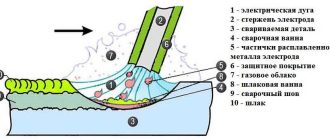

One of the most common models – cone or screw woodchipper. The difference between them is only in the absence/presence of threads on the stabbing element, which in this model is made in the form of a cone.

Chunks are split due to the fact that the rotating motor cone crashes into the wood, gradually tearing it into pieces. In the case of large logs, the edges are split first, then the middle is torn apart.

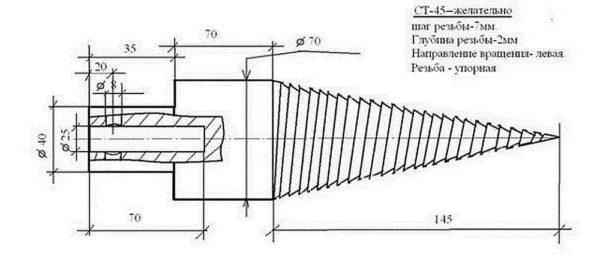

Taper and carving parameters

At first, the cutting part was milled in the form of a smooth cone. If you use a smooth cone, when working, you have to put quite a lot of pressure on the chisel to make the cylinder “bite” into the wood. The process is much easier if the surface is threaded. In this case, the chump is as if screwed onto a screw, and then split.

The main thing is to make the threaded cone correctly. If there is a lathe and work experience, you can try to do it yourself. If not – you will have to order. Thread make different, but the optimal recognized parameters: pitch 7 mm, depth of 3 mm (minimum – 2 mm). Another important point – the depth of the seat on the motor gearbox – not less than 70 mm.

If there is a cone with a cut thread, it will not be difficult to make this woodchopper with your own hands.

Electric motor and gearbox

You need an electric motor powerful enough (2 kW and above or 5-9 l / s), but with a small speed: 250-600 r / min. At 250 rpm and below, the bark is very slow, and if the rpm is more than 500 – it is dangerous to work, as it can tear the log out of your hands.

If you manage to find an engine with such parameters, you can put the made pike (screw) directly on the crankshaft (on the photo above). If the revolutions are higher, it is necessary to put a reduction gearbox or make a chain or belt transmission to reduce the speed.

The ratio is calculated depending on the engine rpm. For example, there is a 900 rpm engine. Making the gearbox 1:2 we get 450 rpm. This is just the optimum variant.

Gears can be belt or chain. Chains work many times louder, require constant swabbing, and it is usually more expensive to grind sprockets with the required parameters. Belt transmission is desirable double (as in the photo above). In this case, there will be less slippage.

Where to locate the motor

If the design provides for the presence of a gear, it is better to put the motor at the bottom, and the screw itself is fixed on the work surface. The height of the work surface is chosen under your height, so that you do not have to work in an incline.

There is also such a parameter as the height of the location of the screw above the work surface. The gap from the table to the cylinder should be in the region of 8-20 cm. It is not worth placing higher – it can turn small-diameter chunks. The optimal distance is 8-12 cm. Even small-diameter chunks do not turn.

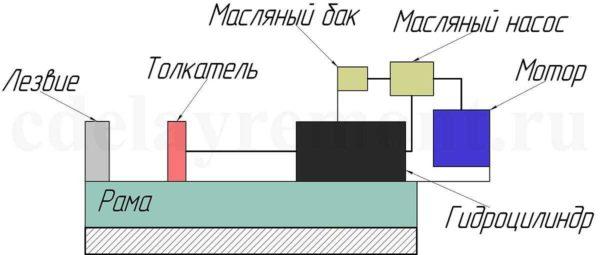

Hydraulic woodchopper

Hydraulic wood splitter – the most powerful, but also the most complex and expensive in manufacturing. In addition to the bed, motor and cutting blades, you need a hydraulic cylinder of sufficient power. They are not cheap. In addition, you also need an oil tank and a pump.

Hydraulic cleaver for firewood develops a solid force, so in its manufacture it uses metal of considerable thickness – 6-10 mm, depending on the power of the drive. The developed force is quite enough to break the log into 6-8 logs at one time. That is why the knives are made in the form of a “star”.

When making knives, they are spaced a few centimeters apart. So that only one is in use. For example, first – horizontal, then – vertical, then – right and finally – left. At the same time, strengthen each of the knives by welding reinforcing plates from behind. Steel is desirable to use a hard steel, previously sharpened on the same principle as on cleavers.