Plastic plumbing and heating – it’s no longer a surprise to anyone. But the pipes have to be cut. And with what? There is a tool for this, which is usually called pipe cutters. And also – cutter, pipe cutter. There are several designs that look different, although they perform the same function. And the price can be different – from a few hundred rubles to ten thousand or more.

Contents of the article

Types of scissors for pipes

More and more often the distribution of cold and hot water supply, even heating, make plastic, polypropylene, metal-plastic pipes. They are easier to install, but for a quality connection requires an even cut. And cut pipes with special scissors or a cutter. There are different types, so you need to learn about them beforehand.

Actually, the design is not so important. It is important how smooth a cut can make scissors for pipes, what diameters they cut, with what materials and types of reinforcement work. But let’s start with the types and types of designs.

Mechanical, with a manual “drive”

There are options for home use and for professional use. But even if you need only for repair or for yourself, very cheap ones are better not to take. A smooth cut even on a thin pipe will not turn out.

What design is better to choose? If you are only for home use, it makes sense to buy the first type. Simple in operation, although they require effort, but for the assembly of plastic plumbing or a system of polypropylene, not much will have to be cut. You can still consider roller pipe cutters. Also inexpensive and oversized tool. Guillotine private citizens in general do not need much when they need it, and the gun is not so relevant because of the high price.

Electrically driven

Electric and battery-powered pipe shears – this is already a tool for professional use. It is good in that it does not require the application of physical effort. All you need is to press the button and hold the pipe steady while the device works. Electric shears are usually equipped with a button to return the knife to its original position. Electrically powered pipe cutting shears can be:

These are most similar in design to the “pistol” type model. They look more massive due to the plastic protective housing. Yes, and the motor and batteries (if any) also have to be hidden somewhere. But since almost no effort is required when working, the weight is not critical (from 1 to 2 kg).

Price range

Let’s talk about prices for the completeness of the picture. The cheapest scissors for polypropylene pipes – in the form of scissors. There are copies for 5$ or so. There are also more expensive – 50$ and above. Immediately it should be said that the cheapest are suitable for cutting thin-walled plastic or unreinforced polypropylene of small diameter. No more than 14-16 mm.

Roller pipe cutters are also there with a very low cost – even less than 5$. Their purchase is a dubious venture. A large backlash on the cutting element will not give you a normal result. And also the body is incomprehensibly made of what, poor grip of the pipe. In general, it is not worth it. Even for home use, it is better to take at least the middle price range.

Scissors for polypropylene pipes in the form of a gun – more serious equipment. Provided that the mechanism is made of hardened steel, not silumin or other incomprehensible alloys. The minimum cost is about 30-40$.

How to choose scissors for cutting pipes

For home use or for use from time to time, usually take mechanical scissors for cutting pipes. The design is chosen in this case, so that it was “cheap and reliable”. Most often buy scissors with a ratchet. In principle, a justified choice. They work and beginner professionals. It is only necessary to choose the right model.

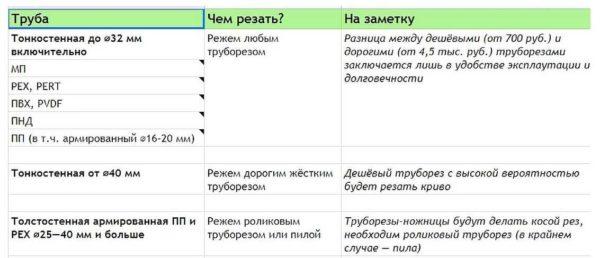

In general, you can give the following recommendations on the choice of the type of pipe cutters. Thin-walled pipe without reinforcement from any material is cut with a normal quality pipe cutter or shears regardless of the design. Limitations on diameter – 32 mm, on wall thickness – up to 4-5 mm. Any pipes, what kind of pipes? Yes all: metal-plastic (MP), polyethylene (PERT, PEX), polyvinylchloride (PVC), PVDF, low-pressure polyethylene (LDPE), polypropylene (PP, PPR or PPR), including reinforced with fiberglass and even small pipes (diameter 16-20 mm), reinforced with aluminum foil. For the same pipes, but with a diameter of 4 mm and more, you need more powerful shears. They should be larger in size and “stiffer” in assembly.

For reinforced polypropylene and PEX with a diameter of 25-40 mm, a good roller cutter is required, and for even larger ones you need a guillotine or the same roller shears, but from the professional series.

Technical parameters

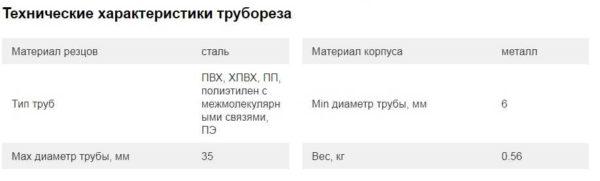

There are no difficulties in this point. It is necessary to keep track of two positions:

- the maximum diameter of pipes that the shears can cut;

- what kind of pipes they can cut.

Look carefully at these characteristics. It can be frustrating: you buy scissors for polypropylene pipes for a couple of thousand, and then it turns out that they do not cut polypropylene.

Another piece of advice. It is better to take a cutter that can cut the pipe to the size of a larger diameter than you plan to install. For example, at most you will cut the pipe 32 mm, but take a tool for 40 mm. Why? Very hard goes the pipe of the maximum size. And it is they are usually made the main distribution. Smaller diameter goes only on the branches. And the tool for a larger diameter in size is slightly larger (and slightly more expensive), but cuts easier.

By the way, cheap tools have a pipe, the declared largest diameter, sometimes just does not fit in the holder. So you need to check. If you do not have a piece with you, compare the dimensions of the cutting part with similar ones. Are the dimensions more or less the same? Great. If the ones you choose look smaller, it’s better to put it aside.

Body

The body of the scissors can be made of silumin or other similar alloy and steel. Inexpensive silumin models can break if you apply a lot of pressure when cutting large diameter pipe. So if you are going to get silumin ones, get one that looks solid and weighs more than a hundred grams. Inspect the body for cracks, cavities, burrs – there are such damages. They are immediately put aside. Then we examine it according to such signs:

Inspect the handles. The main thing is that they were comfortable. You will have to squeeze them, so sharp edges that are uncomfortable in the hand are also put aside. The best option – rubberized or with rubber overlays. But this is not a budget series.

What can be the blade

The main working part of scissors for cutting pipes is the blade. It can be made of tool steel (cheaper and softer type of steel) and alloy steel (more expensive and durable). As a rule, alloy steel blade can cut plastic and copper pipes. Polypropylene pipe cutters have a blade made of tool steel.

The type of steel is not everything. You have to look at the thickness of the blade. If it is thin, with a large diameter, the cut goes to the side and cuts the pipe at an angle. And what we need is a 90° angle.

Why should the cut be made strictly at right angles? To make the joint strong and durable. This is important for pipes of any type, but it is critical for metal-plastic pipes and for polypropylene pipes reinforced with foil.

The thicker the blade, the easier it is to work. By the way, there are models of scissors for polypropylene pipes with a removable blade, there are those in which the blade and the “ladder” of the ratchet mechanism are one and the same. The second option is more durable. The fewer connections, the longer the service life.

What else can be used to cut pipes

Sometimes you just need to make a couple of cuts on the pipe. Buying even inexpensive pipe cutters for such a case makes no sense. Here is what else you can evenly cut plastic, metal-plastic and polypropylene pipes:

After working with this tool, it is usually necessary to correct the cut. If there are burrs, they are removed, chips are poured out. In general, the cut should be even and the pipe clean.