A properly functioning ventilation system is essential for good health. One of the components of ventilation is the ceiling diffuser. Through this device, air intake and inflow occurs.

Зміст статті

What is a diffuser

Diffuser is a part of ventilation system, designed for air inlet/outlet into the room and for its effective mixing. It also performs decorative functions – it closes the entrance/exit to the ventilation duct. Outwardly looks like a conventional ventilation grille, but has a slightly more complex structure, may have additional devices – impeller and static pressure chamber.

Difference between a diffuser and a ventilating grille

What is the difference between a diffuser and a ventilation grille? Actually, nothing. A vent grille is simply the simplest of the diffusers. So why is the price so different? There are reasons.

When developing diffusers, manufacturers calculate air movement, place blades and baffles in such a way that the air in the room is mixed in the best way. Therefore, the air is mixed and evenly distributed throughout the room.

Manufacturers of cheap ventilation grilles hardly do any research, copying external signs and not caring about efficiency. The air hits a certain point, obvious zones with different temperatures are observed. So much for the difference in price.

When to put a diffuser

Where and when you can apply ventilation grilles, and where do you need diffusers? In conventional apartment buildings of old construction there are only exhaust ventilation ducts, which work due to pressure differences. Outlets of ventilation shafts are located in the walls. In this case, you can put ventreshetki, as the installation of a more complex device on the situation has almost no effect.

But if you have made a suspended ceiling, behind which you hid the ductwork connected to this channel, it is desirable to install diffusers. They work more efficiently. Since the presence of a suspended/stretched structure hinders air movement, more efficient devices are needed for the ventilation system to work properly.

If the ventilation system has been specifically designed, you are likely to be given precise recommendations as to what, where, what type should stand. In such a situation, any substitution can negatively affect the performance of the system.

Types of diffusers

In a store or a company selling ventilation equipment, you will be offered a large number of diffusers of different appearance and materials to choose from. It is more or less easy to decide on the materials – you choose what you like best or what is better suited for the operating conditions. If the ventilation ducts are made of metal, it is logical (though not obligatory) to use grids made of metal. They are galvanized, stainless steel, there are ordinary steel, but painted with powder paint.

If the ventilation ducts are made of plastic pipes, it is better to connect them with plastic diffusers. Here, I think, everything is clear. With the other parameters a little more complicated, let’s understand.

Place of use

According to the purpose of diffusers are divided into:

- supply;

- exhaust;

- universal (supply and exhaust);

- combined.

The names speak for themselves: they are used in different parts of the ventilation system. The supply and exhaust ones differ in the direction and position of the blades and partitions. There is no too big difference, just some work better for air outlet, others – for air inlet. In principle, you can put the supply air inlet on the exhaust air outlet or vice versa. There will be no catastrophe, but the performance of the ventilation system may drop a little. In private houses and apartments, it is impossible to notice the difference, due to the small capacity. Tangible changes can be only in ventilation of large capacity.

Universal diffusers pass air in both directions equally. So they can be installed without any hesitation. But, as usual, “universal” diffusers perform slightly worse than specially designed models.

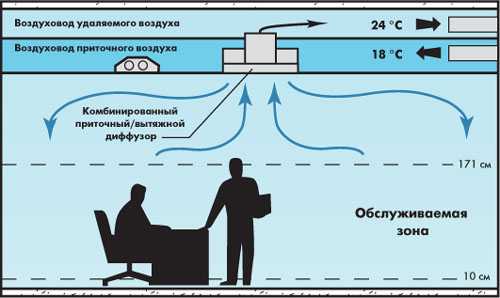

Need clarification only, perhaps, with combined models. They differ in the fact that part of the device works on the inflow, part – on the outflow. Accordingly, they are connected to different parts of the ventilation system. That is, it is possible to install only one universal diffuser on the ceiling, and it will be necessary to connect it to two branches – supply and exhaust. The method of connection is described in each specific model, there is no point in talking about it in general.

Матеріали

Diffusers are made of:

- plastic;

- aluminum;

- steel (ordinary or stainless steel).

In private houses and apartments, plastic diffusers are most often used. For this situation, it is the best option. At a relatively low price, they have excellent performance characteristics, long service life, easy to maintain, not subject to corrosion. They have no problem docking with plastic ducts, which are increasingly used in private homes.

Metal diffusers are used in industrial premises, where only non-combustible materials can be used. They cost significantly more, weigh more, which complicates installation.

There are also diffusers, the outer part of which (grille) is made of wood. Such devices will perfectly fit into the interior of a wooden house.

Location

According to the place of placement, diffusers are:

- ceiling;

- wall;

- floor.

Most often you can see a ceiling diffuser. They are used in 95% of ventilation systems, both in supply and exhaust systems. Mainly because the air is mixed in the upper part of the room, without causing much discomfort to a person. And also because with the device false ceilings easier to make a ventilation system, if previously it was simply not there. Most often, the devices are attached to the main ceiling, and in the stretch / suspended ceiling cut a hole that covers the grille.

Sometimes supply ventilation is made through the basement. Then floor diffusers are installed. This is very rare.

Wall diffusers are used even less often. There are not so many situations. For example, in apartments after replacing windows with plastic ones. In this case you need fresh air inflow and you can provide it only by making a hole in the wall and installing a diffuser. Or when there is a lack of fresh air supply and you do not want to build/reconstruct a supply system.

Further we will talk about ceiling diffusers, as they are the majority, and all other diffusers are still to be found – they are usually delivered to order.

Конструктивні особливості

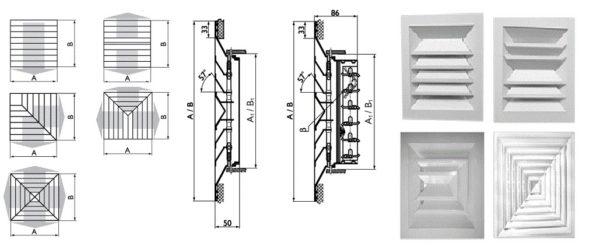

Ceiling diffusers are of different designs. There are vortex and slotted ones. These types can be made of any material, for any method of installation. But, as agreed, we are talking about ceiling models.

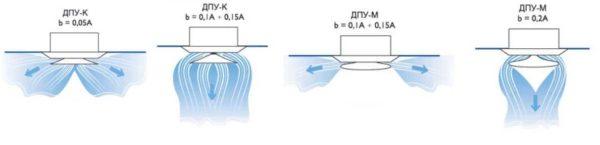

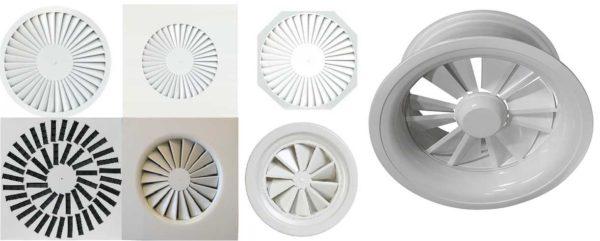

Swirl

In them, the grille baffles are arranged in such a way as to create swirls of air masses. This greatly increases the speed of air mixing and increases the performance of the system. Recognize them easily – by the characteristic radial arrangement of the lintels. Vortex ceiling diffuser is used where a quick change of air is necessary. It makes sense to put them in bathrooms and toilets – to quickly restore the normal atmosphere, although they are usually used in rooms with a large area and ceiling height.

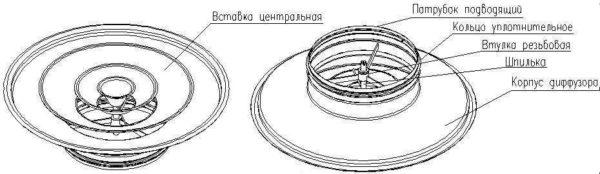

The inner part of the swirl ceiling diffuser is usually in the form of a cylinder, and the grid can be any – round or square, but the holes in it are located strictly on the circumference.

Vortex ceiling diffuser for supply ventilation can have an additional impeller, which is located behind the grille in the housing. The impeller may be movable or fixed. The movable impeller can be controllable – have several speeds of rotation.

Another variety is the static pressure chamber. It excludes too active movement of air masses. In case of using ventilation diffusers with a static pressure chamber, even at high flow rates, there will be no drafts in the room.

Slotted

Slotted ceiling diffuser is called so because of the characteristic shape of the openings – in the form of slits. The location of the slits, the shape and size of the partitions are specially designed and calculated. The distribution of the airflow depends on their position and direction.

They are used in rooms with low or medium ventilation capacity. They are used in living rooms, technical rooms with normal operating conditions (checkrooms, storage rooms, built-in closets).

Have one important feature – there are adjustable slotted diffusers, which can change the direction of air flow (like louvers on air conditioners). Talking about the types, they can be with or without a static pressure chamber.

In terms of shape, they can be any – with round, rectangular or square outer grille. There are long and narrow models. Such a linear slotted ceiling diffuser is little conspicuous. In rooms of a certain design (loft, modern) they can serve as a kind of decoration.

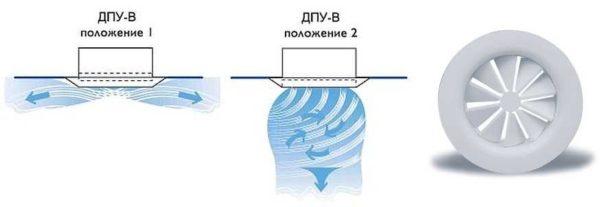

Adjustable

To create a comfortable atmosphere in any situation and at any time of the year there are adjustable diffusers. In their design, sliding plates are added, by turning which the throughput changes.

For adjustable diffusers there is a special name – anemostats. They are adjusted by turning the center part clockwise or counterclockwise. All lamellae in anemostats are fixed movably, by changing their position they open/close the lumen for air passage.

There are also models with built-in occupancy sensors and air composition analyzers. They are connected to a climate control system, which automatically maintains the set atmospheric conditions. But this is part of a whole expensive system.

Ceiling diffuser: installation

There are two ways to connect diffusers to the ventilation ducts: directly or through an adapter (static pressure chamber). The second option is more correct, but it requires a larger gap between the base and decorative ceiling.

If the shape and dimensions of ceiling diffusers and ventilation pipes are the same

To connect the ceiling diffuser directly to the ventilation pipes (outlets) in the place of installation in the ventilation pipe put a tee / splitter. In the free – third – outlet and put the device.

Cutting a hole directly in the pipe for its installation is not the right solution. The housing protrudes beyond the pipe, making it difficult to move air, the performance of the system drops, and over time a dust plug is formed, which can block the lumen altogether. In general, this should be avoided.

Select branches from the main pipe should be so that it was convenient to connect them with diffusers. To the round branch from the duct is not difficult to connect a round diffuser, and to the rectangular – rectangular. It is also important that their dimensions match. This simple truth should be remembered when creating a system, choosing tees or making branches with the appropriate parameters.

Matching diffusers are installed in the air ducts simply by inserting them. Smaller models can be fixed to the duct using a sealant (silicone neutral). Models with a round base are usually fixed in this way.

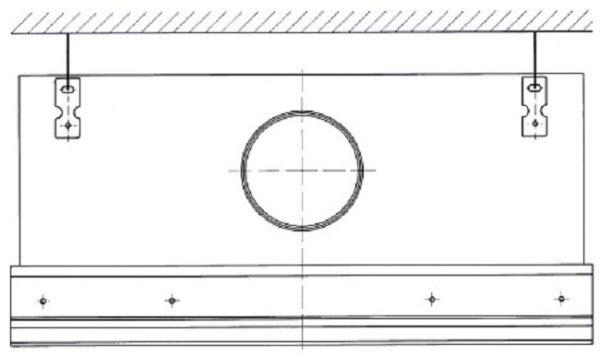

For suspended ceilings of various types (plasterboard, plastic, Armstrong) a special fixing system – Clip in – has been developed. It represents spacers of the type that can be seen on recessed ceiling lights.

More massive square/rectangular models are fixed to the walls of the box using self-tapping screws or on hangers to the ceiling. The first option is easier, but it is better not to use it, as the protruding screw of the screw collects dust. Unless the design provides special protrusions for fasteners. Otherwise, over time, in the place where the screw sticking out, a solid plug will form, preventing the passage of air.

round ceiling diffuser is connected to a rectangular ventilation duct.

If the outlet is made of corrugated material or there is a desire to do everything “right”, heavy housings are suspended from the ceiling on studs or hangers.

Use of adapters

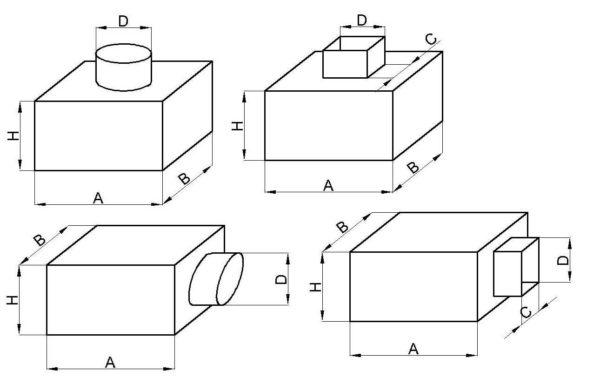

Adapters or static pressure chambers help to avoid such an unpleasant phenomenon as drafts. In this tank there is an even redistribution of air, which goes in an even flow over the entire surface of the grille. But these devices have a significant disadvantage – they “steal” the height of the ceiling. Models with a side connection have a smaller size, but still take up enough space.

Most often, the static pressure chamber is a parallelepiped, to the bottom of which the diffuser is attached. From the top or side there is an outlet for connecting the vent channel. It can be of any desired shape: circle, square, rectangle, oval.

There are adapters:

- With a built-in butterfly valve. If the model of the diffuser does not provide for adjustment, this can be done with the help of an adapter.

- With a removable filter. They also allow you to clean the incoming air.

- With a diffuser of the air flow. This is a sheet of metal with a fine mesh. It is put on powerful supply systems, allows you to evenly distribute the air flow over the entire surface of the grille.

Static pressure chambers for ventilation diffusers are most often made of galvanized steel. The thickness of the sheet – 0,5-0,8 mm. There are companies that will make the device according to your parameters. Also on sale are standard adapters – for standard solutions. They can be made of steel (galvanized, stainless steel) or plastic.

If necessary, the static pressure chamber is lined with insulation. This is necessary so that when the warm surface of the adapter and cold air interact, condensation does not fall on it.

If the diffuser is connected through an adapter, the main task is to fix this device. If it is a suspended ceiling, you can attach the camera to the profiles. In the case of a stretch ceiling, it will have to hang it from the main ceiling. The methods are known: studs or perforated hangers.

Man, I just installed a ventilation diffuser in my room, and it’s a game changer! The airflow is so much better now. It was super easy to set up, too. I didn’t think it would make such a difference, but wow! My space feels fresh and comfy. Totally worth it!