In many private homes, heating with wood and stoves remains a priority. Someone has a metal stove, someone has a brick one, but they have one thing in common – it is not the most comfortable type of heating. Too much attention and little comfort. Exit – stove heating with a water circuit.

To begin with, let’s understand the terminology. When they say “furnace”, most often they mean a heating device made of brick, which is heated with wood. But often so called and metal furnace on wood or coal. The principles of operation of brick and metal units are the same, the method of heat transfer changes. Metal ones have more convective component (most of the heat is transferred by air), while brick ones are dominated by heat radiation – from the walls of the furnace and the heated walls of the house. Our article is mainly about brick stoves, but most of the information can be applied to metal wood (coal) units as well. Stove heating with a water circuit can be made on the basis of stoves of any kind.

Innehåll i artikeln

Conventional stove heating: advantages and disadvantages

In our country, houses were traditionally heated with brick stoves, but gradually this type of heating was supplanted by water systems. All this is because, along with the advantages has a simple furnace heating a lot of disadvantages. First about the advantages:

Today, stove heating is perceived more as an exotic, since it is very rare. You can not argue that it is very pleasant to be near a warm stove. Some kind of special atmosphere is created. But there are also many serious disadvantages:

As you can see, the disadvantages are significant, but some of them can be leveled, if you build a heat exchanger into the stove, which is connected to the water heating system. Such a system is also called furnace water heating or furnace heating with a water circuit.

Furnace water heating

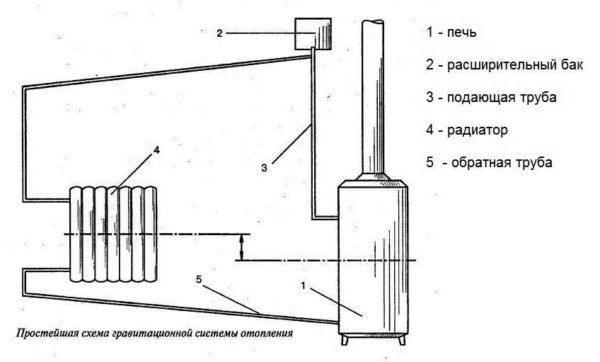

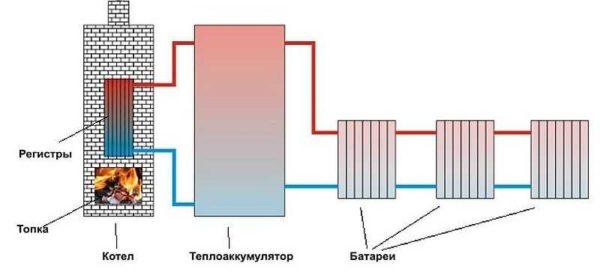

When organizing water heating from the furnace, a heat exchanger (water circuit) is built into the furnace, which is connected to the radiators by pipes. The coolant circulates in the system, which spreads the heat from the furnace to the radiators. This solution increases the comfort of living in winter. The whole point is that radiators can be installed in any room, that is, the furnace can stand in one room, and all the other rooms will be heated from the batteries, which run heated water.

The other disadvantages of stove heating in this case are preserved, but the pluses of water heating are added – you can regulate the temperature in each room (within certain limits), a large inertia smooths the unevenness of the temperature regime. By the way, the same scheme works with metal stoves on wood or coal.

Types of systems

There are two types of water heating systems: with forced and natural circulation (EC). Heating with natural circulation is energy-independent (electricity is not required for operation), the coolant circulates due to natural physical processes. The disadvantage of this method of heating – the need to use large diameter pipes, that is, the volume of the system will be large and will have a large inertia. This is not very good when heating the stove – it will take a long time to warm up. But after burning longer in the house is kept warm.

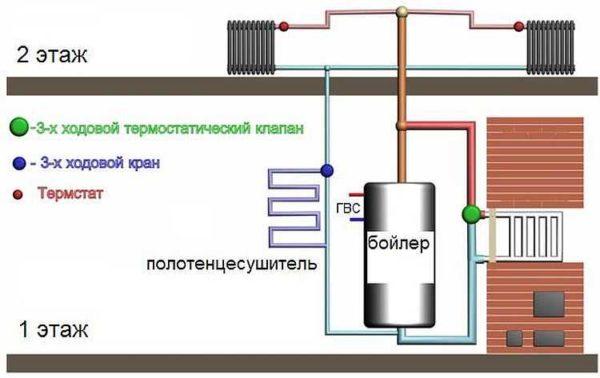

Another disadvantage – to create conditions for the movement of the coolant, the supply pipe is raised up – under the ceiling or at the level of radiators (in extreme cases). When heating a two-storey house, from the boiler the pipe goes upstairs, divorced to the radiators, and then goes down and bypasses the batteries on the lower floor.

Another important disadvantage is the relatively low heating efficiency of systems with EC – the coolant moves slowly, spreads little heat.

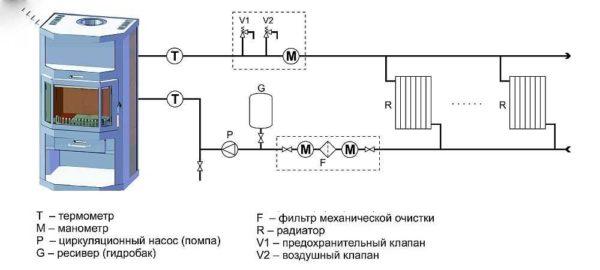

Stove heating with a water circuit and forced circulation is characterized by the presence of a circulation pump (pictured below), which works constantly. Its task is to drive water at a certain speed. By changing this speed it is possible to change the intensity of heating of the premises. This leads to the fact that, all other things being equal, such heating is more efficient. But the system requires power supply – the pump must work constantly. If it stops, the system boils and fails. If you rarely have power cuts, it is enough to have an uninterruptible power supply with a set of batteries. If you turn off the light often and for a long time, you will have to put a generator, and the total cost of such a solution is considerable.

There is still a third type of system: mixed or combined. Everything is designed for natural circulation, but a circulation pump is put. While there is electricity, heating works as forced (with a pump), when the light is turned off, the coolant moves independently.

Heat accumulator

Since the furnace is not constantly heated, but has a cyclic algorithm of work, the house is hot and cold. And the presence of radiators saves from this weakly. Although the differences are not so critical, they are still there. Especially not enough heat at night, and get up and topline is very unwilling. To solve this problem, the furnace is put powerful, and the system is built into the heat accumulator. This is a large container filled with coolant, which stands between the furnace and the heating system.

That is, there are two separate independent circuits. The first one carries the heat from the stove and is usually made with natural circulation. The second drives the coolant to the radiators, and usually there is a circulation pump.

This way of organizing water heating is good because while the furnace is stoked, the water in the tank is actively heating. If calculated correctly, it heats up to 60-80°C, which is enough to maintain the normal temperature of radiators for about 10-12 hours. At the same time, there is neither extreme heat nor extreme cold. The atmosphere is quite comfortable.

Installing a heat accumulator in the system (sometimes also called a buffer or buffer tank) also reduces the risk of boiling the system. The second circuit will definitely never boil, but to the first will not boil, it is necessary to correctly calculate it – that even in the mode of natural circulation of the coolant moved at a sufficient speed and did not have time to overheat.

Register for the furnace

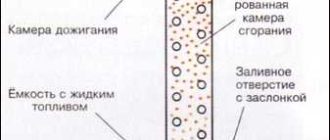

To heat the coolant, a water circuit (also called register, heat exchanger, coil, water jacket) is built into the furnace. Its shape can be any, but most often make rectangular flat containers or a set of pipes connected in a single system (like radiators).

To connect the heat exchanger to the system, two pipes are welded into it: one at the top – for hot water intake, the second at the bottom – for pumping cool water from the return pipe.

Often there are questions with determining the size of the water circuit for the furnace. It can be approximately calculated based on the heat loss of the building. It is believed that to transfer 10 kW of heat requires a heat exchanger area of 1 square meter. m. But it is necessary to take into account the time of operation of the furnace – after all, it is not constantly heated. While it is not very cold – once a day for about 1.5 hours, when it is cold – twice. During this time it is necessary that the furnace has time to heat all the water in the heat accumulator. Therefore, the calculation of the heat exchanger area is based on the daily amount of heat needed to compensate for heat losses.

For example, let the heat loss for a house be 12 kWh. In a day it will be 288 kW. The furnace is stoked, let’s say for 3 hours, all the necessary heat should be accumulated during this time. Then the required power of the water circuit for the furnace is 288 / 3 = 96 kW. To translate it into area, divide by 10, we get that for these conditions the area of the register should be 9.6 m2. What shape you choose is up to you. It is important that the outer surface of the register is not less.

Well, and a couple more points. First – the capacity of the furnace must be greater than the found capacity of the heat exchanger. Otherwise, the required amount of heat will simply not be released. The second nuance: the capacity of the heat accumulator should also correspond – it should be larger by about 10-15%. In this case, the boiling of the coolant is excluded.

Just do not forget that the heat capacity of water and antifreeze is very different. The accumulator with antifreeze as a coolant should be much larger than the capacity for water (in the same system).

What else is worth remembering is that the heat accumulator is desirable to be well insulated – to keep the heat longer. In this case, furnace heating with a water circuit will be even more economical.

Is it possible to install a heating register in an existing furnace?

Of course, it is more correct to build a furnace around a manufactured register. But if the furnace is already standing, it is still possible to build a water circuit into it. True, you will have to try hard – they have a considerable size and still have to somehow hold on. So it is not an easy task. In addition, do not forget that you will have to make two outputs – to connect the supply and return piping.

Place for the location of the register is also not very easy to find. Very undesirable is its direct contact with the fire, but should be in the environment of hot gases. In this case, you can hope that the heat exchanger will last a long time.