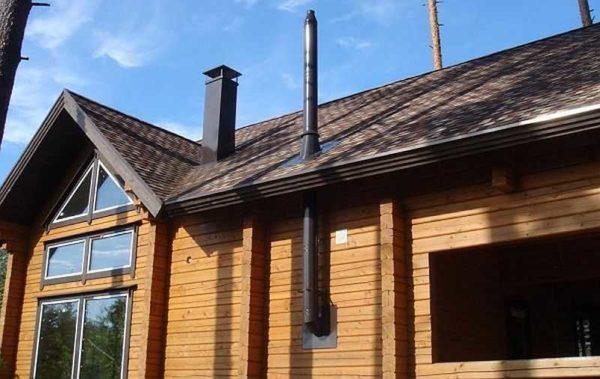

In recent years, more and more chimneys are made of sandwich pipes. The point is relatively low price, long service life, quite attractive appearance. It is also important that it is possible to independently install a sandwich chimney. The case is not very simple – a lot of nuances, but you can cope with your own hands, without involving specialists.

Innehåll i artikeln

What is a sandwich pipe and what they are

Sandwich pipe named so for its multilayer: there are two layers of metal, between which there is an insulator. Such a structure solves many of the problems that were inherent in a simple chimney made of metal pipe. First, the insulation layer does not allow the outer metal casing to heat up to critical temperatures, from the pipe does not go hard radiation. More comfortable conditions are created in the room. Secondly, the same insulator significantly reduces the amount of condensate that is formed when the pipe goes outside. Thirdly, since the outer casing is no longer so high temperature, it is easier to make the passage of the chimney through the roof or wall.

Vilka material är tillverkade av

Sandwich pipes are made of galvanized or stainless steel. Galvanized sandwich pipes for chimneys are rarely used. Unless for the removal of combustion products of low-power wall-mounted gas boiler or gas water heater. Can be used for insulated ventilation. For more serious heating devices they are unsuitable – at high temperatures, zinc burns out, steel quickly rusts, the chimney comes into disrepair.

Sandwich pipes for high-temperature flue gases are made of stainless steel. And stainless steel is used in different grades – from alloys with a small content of alloying metals, to high-alloyed heat-resistant. Different can be and the thickness of the metal – from 0.5 to 1 mm, as well as the thickness of insulation – 30 mm, 50 mm and 100 mm. It is clear that the scope of application will be different, and the price too.

The main steel grades that are used in the manufacture of sandwich pipes for chimneys, their purpose and main characteristics are summarized in the table.

| Stainless steel grade | Main characteristics | Användningsområde |

|---|---|---|

| AISI 430 | Possesses sufficient resistance to atmospheric influences, but poorly tolerates high temperatures | Used for external covers of sandwich pipes |

| AISI 439 | Contains titanium, which increases resistance to elevated temperatures and aggressive media. | Suitable for gas boilers, low-power solid fuel units (up to 30 kW). |

| AISI 316 | Alloying additives – nickel and molybdenum – give high resistance to acids, increased temperature resistance. | Optimal for gas boilers of any type. |

| AISI 304 | Cheaper version of AISI 316 with less alloying additives. | Economical variant for gas boilers of medium and small capacity |

| AISI 316I, AISI 321 | Can withstand temperatures up to 850°C | Can be used for heating solid fuel stoves |

| AISI 310S | Higher temperature resistance – up to 1000°C (and price) | For bath and pyrolysis solid fuel stoves |

As is clear from the table, different grades of stainless steel have different purposes. Cheaper alloys are used for the outer casing, more heat-resistant and expensive – for the inner casing. This is necessary to reduce the cost of production, and you do not need high resistance to temperatures outside the chimney. There are even more budget options – the outer casing is made of galvanized steel. Externally, these products lose stainless steel, but serve normally (with normal insulation and its thickness).

Insulation and its thickness

Between the two layers of metal there is an insulator. Most often it is stone wool. The thickness of the insulator is from 30 to 100 mm:

- With 30 mm thick insulation, the flue gas temperature should not be higher than 250°C. Only small and medium capacity gas boilers produce such temperatures.

- A 50 mm layer of insulation can withstand temperatures up to 400°C. Scope of application – any gas and liquid-fuel boilers, wood-fired boilers, provided that the chimney is outside (through the wall).

- Stone wool layer of 100 mm allows to withstand heating up to 850°C. Such a sandwich chimney can be installed on a solid fuel boiler of any type, in fireplaces and hearths.

In addition to the thickness of the insulation, it is necessary to pay attention to its brand, or rather – on the temperature range in which it can operate. Not any stone wool can withstand heating up to 850°C, but only some special brands. If you need a chimney for solid fuel boiler, you will also have to take into account the thermal resistance of the insulation.

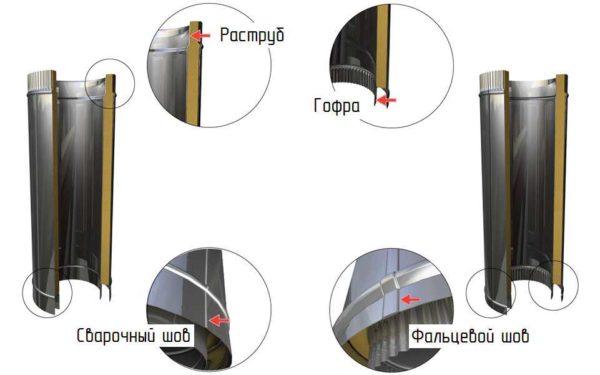

Types of connection

Connect the elements of the sandwich chimney can be connected to each other in two ways: sockets and corrugated edges. Rastrubnoe connection assumes the presence of a slightly wider chamfer on one side. With this design achieves a high degree of tightness of the chimney. This type of sandwich pipe is well suited for gas boilers, where it is important not to allow leakage. There is a disadvantage: installation requires high accuracy.

The corrugated edge of the sandwich allows you to assemble the chimney without problems. The minus of this solution – to ensure tightness requires a significant amount of high-temperature sealant, and it costs a lot.

It is also worth paying attention to the longitudinal seam. It can be welded or rebated. If the seam is welded, it must be made in an argon protective environment (so that alloy metals do not burn out). This type of connection is necessary for solid fuel boilers, sauna stoves and fireplaces. For all others can be used and rebate connection.

Metoder för installation

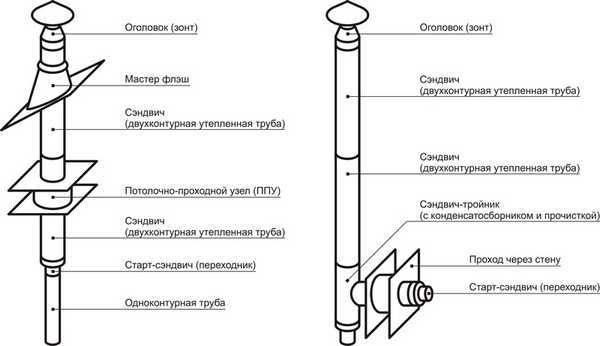

There are two ways to lead the chimney outside. The first is to run the pipe through the wall, and then on the outer wall to raise to the required level. The second – up through the ceiling and roof. Both are not ideal.

If the chimney is on the street, because of the temperature difference in it is actively formed condensation. Therefore, in the lower part of the chimney must be installed tee with condensate collector (cup) and cleaning hole. This unit allows you to carry out maintenance of the chimney without much difficulty: the cup is unscrewed, the condensate is drained. Also without problems periodically dislodged soot – through the cleaning hole you can run a special brush for the chimney.

If the chimney will be led out through the roof, you will need several passage units – the number of floors. If the house is one-story, you will need one passage through the ceiling, and the second – through the roof. It will also be necessary to master flash or apron for round galvanized pipe.

Installation of a sandwich chimney on the street requires only one passage assembly – through the wall. But it will be necessary to attach it to the wall every 1.5-2 meters. If the walls of the building are combustible (wooden house or frame house), the walls are necessarily protected by a non-combustible screen.

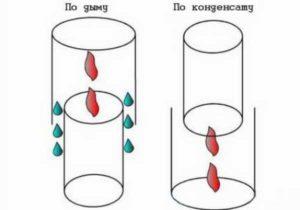

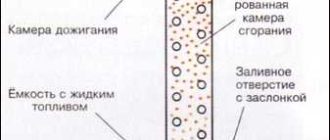

By smoke or condensate

As mentioned above, one side of the sandwich pipe is slightly wider, the second side is slightly narrower. Due to this difference in diameter, the modules are connected one to the other. If the wider end is turned upwards (in the picture on the right), the assembly is called “by condensate”. With this method of assembly, condensate droplets flow downwards unimpeded. The disadvantage of this method – in case of insufficient sealing of joints, smoke can seep into micro cracks. This type of sandwich chimney installation is used when the pipe is led through the wall. This is exactly what is required free flow of condensate, and small leaks of smoke are not terrible – they are not critical on the street.

If a narrower edge is turned up, the second element is put on top of it with a wider part. This type of assembly is called “by smoke” (in the figure on the left). In this case, condensate running down the wall may leak through a joint that is not well sealed. However, the smoke passes freely. This type of assembly is used if the chimney goes indoors (out through the roof). Condensate running down the pipe, of course, spoils the appearance, but it is not as dangerous as flue gases leaking into the room. All the more so if the joints are well sealed, the condensate will not leak out either.

In order that the connection of sandwich chimney modules was reliable, each of them is usually lubricated with heat-resistant sealant, and then still tightened with a clamp.

Parameters

Sandwich chimneys are good in that they have a modular structure, which allows you to assemble any configuration, with any parameters. Before you go to the store, you need to know the required diameter of the chimney, the height of the pipe and those additional elements that will be needed.

Chimney diameter

When choosing the diameter of the sandwich pipe, there is a simple rule: it can not be smaller than the diameter of the outlet pipe of the boiler. If the outlet pipe you have 120 mm, then the inner diameter of the sandwich must be the same or larger. It can be wider, but less – definitely not, and the narrowing can not be made throughout the chimney. If the chimney is slightly wider than the spigot, an adapter is purchased, which is placed directly on the output of the boiler, and then there is the working size.

If there is no boiler yet, but you know its power, you can choose a chimney oriented on these data:

- boiler power up to 3.5 kW – internal diameter of the sandwich – 80 mm;

- from 3.5 kW to 5.2 kW – at least 95 mm;

- more than 5.2 kW – 110 mm and more.

But it is better to buy (or at least choose) the boiler, and then already determine the chimney, because many manufacturers are insured, making the outlet spigots wider – to improve the draught.

Chimney height

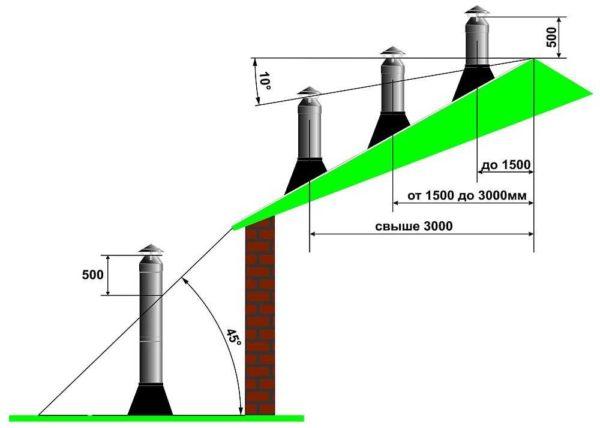

The height of the chimney above the roof surface depends on the place of its output, but its minimum height should be 5 m. That is, if the height of the house is small, the pipe in any case lead out to a height of 5 meters. If the height of the house is higher than 5 meters, the pipe must rise above the roofing material to the next height:

- Must rise above the ridge by 50 cm if it exits at a distance of less than 150 cm from the ridge.

- If the distance from the ridge to the chimney is more than 300 cm, the chimney may be lower than the ridge level, but the angle must not be more than 10° (see picture).

- If the chimney exits at a distance from 150 to 300 cm from the ridge, its height can be at the same level as the ridge element or higher.

Under such conditions, a normal draft is ensured. The smoke will escape normally regardless of weather conditions. To prevent getting into the chimney leaves, put special umbrellas, weathervanes, and in windy places – deflectors, which still improve the draught.

If you can not get the pipe to this height, put a smoke pump – you get a forced draft. The fan will not be needed all the time, but in some conditions, when the natural draught is not enough, the forced draft saves the situation.

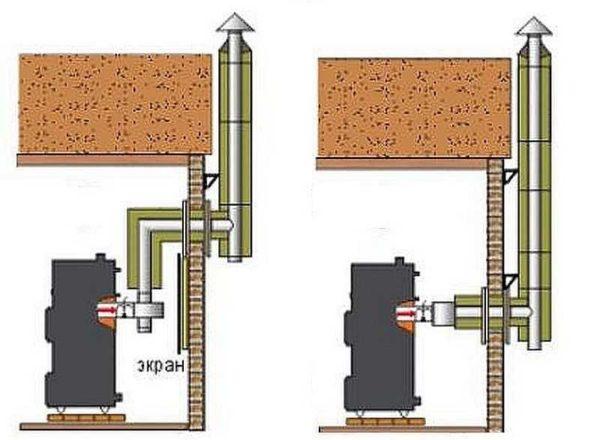

Installation of a sandwich chimney through the wall

When withdrawing the smoke tube through the wall, there are two ways. The first option (on the photo on the left) – to raise it in the room closer to the ceiling, and there to lead it out. The second – to make a conclusion at the level of the flue pipe from the boiler. In this case, almost the entire chimney is on the street.

Preferably the second option – it has only one elbow, which means that, under equal conditions, the draught will be better. Also with such a structure there is less chance of soot plugs.

If the flue outlet is not at the back of the stove, but at the top, the installation scheme changes a little – a 90° elbow is added, then a straight section for passing through the wall, and then the same as in the other schemes.

The stove itself is placed on a non-combustible base, and the non-combustible screen covers the wall behind the stove. The easiest way is to fix a sheet of metal to the wall. It can be fixed on ceramic insulators 2.5-3 cm high. Between the metal sheet and the wall will be a layer of air, so the wall will be safe. The second option is to put under the metal heat-insulating material – for example, a cardboard of mineral wool. Another option – a sheet of asbestos (as in the photo).

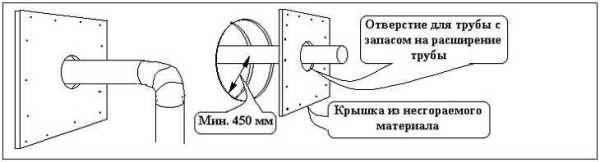

A hole is made in the wall. Its dimensions are determined by SNiP – the distance from the pipe to non-combustible walls, should be at least 250 mm on all sides, and to combustible – 450 mm. It turns out to be a solid hole, especially if we talk about walls made of combustible materials. There is one point, by which you can reduce the size of the opening for the passage of sandwich: make the dimensions according to the norms of non-combustible walls and cover the opening with non-combustible material.

The aperture can be round or square, as long as the fire standards are observed. Square openings are easier to make and cover, so they are more often made.

In this hole is inserted passage unit – a box made of non-combustible material. In it winds sandwich chimney pipe, fixed in the center. All gaps are laid with heat-resistant insulation, the hole on both sides is closed with non-combustible material. Usually it is a sheet of metal.

One important point: develop the chimney should be so that inside the wall there was no joint between the two pipes. All joints should be visible and maintainable.

Next, it is necessary to make or install a ready-made support bracket, which will hold the entire weight of the pipe. The design may differ in details, but the basic idea is the same – a support pad that transfers the weight to the wall with the help of stops.

- Homemade support platform for external sandwich chimney made of 50*50 mm and 40*40 mm angles.

- Self-made support platform made of perforated angle bar

- Construction from U-shaped metal profile

A similar design can be welded from a profile pipe with a small cross-section of 25*25 mm or 25*40 mm.

As you can see, a tee is connected to the pipe that passes through the wall. In the lower part there is a removable cup, in which condensate accumulates. Some models have a connector with a small tap at the bottom. This is even more convenient – you do not need to remove the cup, you can connect a hose to the connector, lead it to some container (it is very toxic, so you do not need to drain it near the house) and drain by simply turning the tap.

Then the tube is brought to the required level. Since in this case the distance to the ridge will obviously be more than 3 meters, you can that the height of the chimney was slightly lower than the ridge – not lower than 10 ° in relation to the horizontal line drawn from the level of the ridge.

But since the house is located in a low-lying area, the chimney was raised even higher than the ridge to ensure a draft. It was attached to the wall with clamps made of stainless steel, with a pitch of a little more than a meter. On the roof there are stretchers made of steel bars with a diameter of 6 mm. There are special clamps “with ears” to which the stretchers are attached.

Another important point, which many people forget: in the place of installation of the pipe, on the roof must install a section of snow retarder, otherwise, in the spring, the pipe can be blown away by snow (if the pipe is not led to the side of the gable, as in the photo).

How to install the chimney through the roof

When leading the chimney from sandwich pipes through the roof, you need to take into account the location of the floor joists and rafters on the roof. It is necessary to adjust so that the pipe passed between these elements. The minimum distance from the outer wall of the pipe to the combustible element should be at least 13 cm, and this – provided that the combustible element will be protected by insulation. To fulfill this requirement, it is often necessary to shift the pipe. This is done using two 45° angles.

Note that the installation of a sandwich chimney from a solid fuel boiler starts with a metal pipe without insulation. In the photo above it is black in color. After it is put an adapter to the sandwich, and in the passage unit enters the flue pipe with insulation.

A hole is cut in the ceiling, which meets fire regulations – 250 mm from the edge of the pipe, if the ceiling will be protected by thermal insulation material. Having cut out the hole, its edges are covered with non-combustible thermal insulation material. Minerite is best suited for this (nailed or fixed with self-tapping wood screws).

In the resulting box, the pipe of the sandwich chimney is introduced. It should be directed strictly vertically, without the slightest deviations. You can not rigidly fix it, you can only give direction by installing a few strips that will hold it, but it can move up / down without difficulty. This is necessary because its length increases considerably when it is heated.

The remaining space is laid with basalt wool (check the temperature range). Another option is to pour expanded clay, granulated foam glass. Previously, sand was still poured in, but sooner or later, it all spilled through the cracks, so now this option is unpopular. On the front side of all this “beauty” is closed with a sheet of stainless steel, under which is put (between it and the ceiling) non-combustible material. Earlier it was an asbestos sheet, but since asbestos is recognized as a carcinogen, they began to use cardboard from mineral wool.

There is another option. Cover the edges of the hole with mineral wool, and then insert a ready-made ceiling-pass assembly made of stainless steel. It has both a box and a decorative stainless steel screen at once.

Having led the pipe to the attic, make a hole in the roof pie. All films in the place of passage (vapor barrier and waterproofing) cut crosswise. The resulting triangles are wrapped and fastened with staples from a stapler. This way the damage is minimized. The exposed purlins are cut so that up to the pipe was at least 13 cm.

On the right photo above, the passage through the roof is wrong – the distance between the pipe and the boards is too small. It is necessary to cut them according to the standard and cover them with the same minerite. You should get something similar to the following photo.

Further, after the roofing material is laid, the pipe is put on the master-flush, the skirt is given the desired shape (under the shape of the roofing material).

The joint between the rubber and the pipe is sealed with heat-resistant sealant. The sealant is also applied to the surface of the roof under the “skirt”.

Note, each connection of sandwich modules is tightened with a clamp. For the internal chimney, this is also true.

I recently installed a chimney with sandwich pipes, and it was a game-changer! The step-by-step guide made it super easy. Love how it keeps the heat in and looks sleek too. Big shoutout to anyone who tackled this project – you’re a champ!