Building a house or renovating it often requires welding work. It takes a long time to ask for help from professionals each time. And most of the work does not require high qualifications. If you are planning construction or repair, you have a large dacha or house, it will be cheaper for you to do all (or almost all) welding work yourself. And we will tell you how to choose a welding machine for home and dacha.

Obsah článku

Electric welding machine for home and dacha, types, advantages and disadvantages

Both at home and in production, electric welders are most often used. For the most part, household models operate from the 220 V network, but you can find machines that are powered by a three-phase network of 380 V. Some of them weld on direct current, some – on alternating current.

Transformer welding machines

Give an output of alternating current welding transformers. Their design is simple and reliable: two step-down transformers with the possibility of adjusting the output current. Adjustment is not very accurate, and its range is small. And this is one of the disadvantages. This unit rarely breaks, but it weighs a lot: even a household, not the most powerful model, will drag on a couple of tens of kilograms. Industrial models can weigh a hundred kilograms and even more.

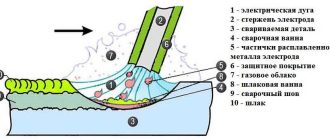

About two decades ago, electric welding was only on “transoms”. Today, this is far from the case: DC welding current sources are more widespread. And all because of the shortcomings of the transformer welding machine. The current it produces is alternating, its polarity is constantly changing. When welding, this is expressed in the fact that the arc “jumps”, which causes a large number of sparks. The arc is difficult to control, obtaining a quality weld is possible only with a highly skilled welder. But even under this condition, they are used only for welding ferrous metal: the possibility of adjustment is limited, fine-tuning is almost impossible, which limits the scope of their use.

Another significant disadvantage: when working, especially when igniting the arc, the voltage in the network drops significantly. Such surges do not like modern electronics, which we have more than enough in the house and at the cottage. Therefore, for home use transformer welding machines are bought very rarely. Even though they are reliable and inexpensive. If someone has them, they stand in the garage or shed as a backup “just in case”.

Rectifiers for welding

In essence, these are the same welding transformers, but they have a rectifier unit at the output. They are sometimes referred to as DC welding transformers. They produce a constant current, because of which the arc is more stable, it is easier to work, but experience is still needed, albeit to a lesser extent than on transformers. Their disadvantage: power losses at the rectifier, but the constant arc is compensated for.

The design is reliable, there is nothing to break: a step-down transformer, rectifier unit and regulation. These are all components of the welding rectifier. The price is a little higher than for transformers. But also this type of welder is not popular today. The disadvantages are almost the same: a large mass, voltage surges when working. Connecting the welder to the household network and working with it will cause voltage fluctuations and, consequently, dissatisfaction of neighbors.

Welding inverters

As soon as they appeared on the market, were an expensive treat. With the development of technology and the emergence of a new element base (IGBT transistors), their characteristics have become better, the weight is less, and the price is lower. Modern household welding inverters can weigh from 3 kg and produce a current of 160-180 amperes, which is enough to work with an electrode 3-4 mm. Their cost is about 3-6 thousand rubles. Not very much, given the rates for the services of welders.

They give out a stable arc, it is easy to control it. Get a good seam can be a non-professional, and even with a little practice. The design is such that it allows you to adjust the welding current and voltage in a wide range. This allows you to use the same machine for welding different metals, different thicknesses.

Another important advantage – inverter welding does not “sit” the network. Almost does not affect it in any way. The only condition: the socket for the welding machine must be grounded. Protection class of these units IP21, which means that they are grounded through the power grid. Therefore, the connection of the inverter welding machine to the household network only through a grounded socket.

If you need a mobile, light welding machine for home and dacha, choose it from welding inverters. Learning to weld with it is simple. Super-welder will not become soon, but almost all the work at home or on the construction site can do themselves after a short period of time.

Welding machine for home and cottage: transformer or inverter?

Questions about what welding machine is better – inverter or transformer – does not arise almost no one. Even at the enterprise, where there are good transformers, when inverters appear, they stand idle. But for home and no questions: inverters are definitely better. And here’s why:

The only spoon of tar adds prices: it is higher than for transformers. But there are good brands that cost a little. For example, inverters Resanta. For professional use, they are suitable with difficulty, but as a welding machine for home or for the dacha – very even well proved themselves. Prices for household modifications (140-160 Ampere) 110-130$.

Welding automatic machines (semi-automatic)

These are more complex and much more productive devices. The basis is one of the above-described sources of welding current, plus a device for feeding the welding wire, torch and control unit. Welding on such devices is carried out in the environment of shielding gases, metals are joined using a special soldering wire. This allows you to easily connect parts of thin metal, as well as weld non-ferrous metals. For home, such equipment is unlikely to be in demand, but in automobile workshops for body repair they are often used.

Semiautomatic welding machines can work in two modes MIG/MAG. MIG – welding with inert gas supply. It is used when joining stainless steel to preserve the alloying metals in the steel. MAG mode – when active gases are fed into the fusion zone, protecting the metal from interaction with air oxygen. Some models can also work in the MMA mode of welding – manual arc welding. This mode in semiautomatic machines is convenient when joining thin metals. When welding thick parts, this equipment shows low productivity, so for these cases it is more profitable to take machines for manual electric arc welding.

Working with them is not difficult: there is an automation unit that controls the process. The seam turns out beautiful and even, there are no problems with the occurrence of the arc at all. Even if they weld very thin sheets of metal (0.5-0.8 mm), they do not “lead” and the seam does not pull. For these purposes, they are ideal.

How to choose a machine for electric welding

If you have decided on the type of welding machine (transformer, rectifier, inverter, automatic machine or generator), you need to choose a model. There are several key parameters that will facilitate this process:

- Supply voltage: 220 V or 380 V. For households usually take welding machines that work from 220 V. All types of welding machines except inverters are quite demanding to its characteristics. It is only inverters without problems can work in the range of 180-250 V. At the others, when increasing, the protection is triggered (they are disconnected), and when decreasing, the parameters fall strongly. Three-phase devices for 380 V, as a rule, more powerful and reliable, but also cost more expensive (minimally – about 20-30 thousand rubles). They are more often purchased for production, large service stations. For welding “for yourself” with your own hands, the power of these units is excessive.

- Output current. If you choose a welding machine for home and cottage, you will use it periodically, for most works is enough current 160-180 Ampere (inverters at this current you can work with electrodes 3-4 mm without problems). If you expect to weld thick metal, more than 190-250 Ampere you do not need. Industrial models can deliver up to 500 amps.

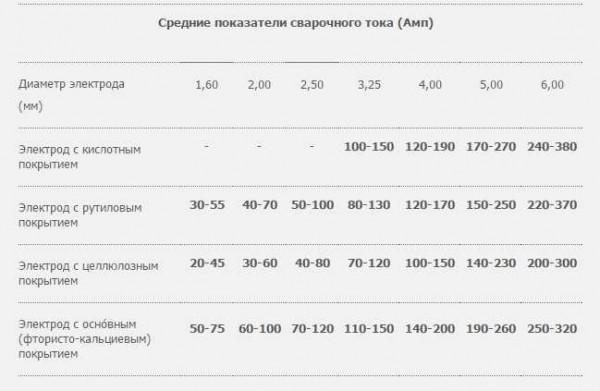

What current should be welded with different electrodes (general recommendations, accurately select by experience) - No-load voltage. It is measured on the apparatus without load. It can be from 45 V to 80-95 V. From this parameter depends on the ease of ignition of the arc. The higher the idle voltage, the easier it is to start welding. Also, higher characteristics guarantee a more stable arc, which facilitates welding. This parameter is taken into account when selecting the type of electrodes: for some, a low voltage is sufficient for ignition (riutyl coating), while others need higher values (basic coating).

| Hrúbka kovu, mm | Priemer elektródy, mm |

|---|---|

| 1.2 – 2.0 mm | 1,5 mm |

| 1.5 – 3.0 mm | 2,0 mm |

| 1,5 - 5,0 mm | 2,5 mm |

| 2,0 - 12,0 mm | 3,0 mm |

| 4,0 - 20, mm | 4,0 mm |

| 10 - 40 mm | 5,0 mm |

- Maximum diameter of electrodes with which the machine can work. This indicator, in addition to the selection of electrodes, also affects the thickness of metal with which the machine can work.

A few general tips for choosing a welding machine. To decide which welding machine is better for the home, push back from the tasks that you will need to solve. For welding ferrous metal, a transformer is enough. If you need to weld structural or low-alloy steel – you need an inverter. For welding thin or non-ferrous metals – semi-automatic.

Dimensions are often a decisive factor. If you need a portable, portable and compact welding machine – it is an inverter, powered by a 220 V network. It has a very small size and weight. It is easy to carry even just on the shoulder, hanging on the belt. At the same time, it works with a wide range of materials, makes it possible to get a good seam.

If your power supply is far from ideal, then you will also fit inverter welder: they are not afraid of voltage fluctuations and work even when the voltage drops to 180 V. Some models, designed specifically for lower voltage, work at 160V.

These machines are also recommended for novice welders: some of them have several useful features that make the work of a newcomer in welding much easier:

- Hot Start mode – “hot start” – facilitates arc ignition. At the moment of welding start, an additional current pulse is given, which facilitates ignition;

- Anti-Stick. At the beginning of work it is difficult for a beginner to select welding parameters correctly. As a result, the electrode “sticks” to the part. When working with transformers and rectifiers, it is not easy to tear it off. In inverters, the current is automatically reduced, and the electrode can be torn off without much trouble.

- Arc Force – increased power. When the electrode is quickly approaching, the current is increased, preventing the electrode from sticking.

If you are new to welding and decide what is better – inverter or transformer – for you the choice is simple: unambiguously inverter (how to choose an inverter welding machine read here). It has only one disadvantage: after you learn to work on an inverter, you will not be able to work on a transformer without retraining. Of other disadvantages: he does not like dust, especially metal dust. Therefore, near him it is better not to clean metals and do not work with a bolgarka or grinders. Well, and like any electrical equipment, they do not like humidity and are afraid of condensation.

Welding generators

This is a fairly complex equipment that combines a generator (gasoline or diesel) and a source of welding current. And welding can be from both direct and alternating current. Equipment is already quite expensive, but it is the best option for those settlements or construction sites where there is no electricity yet, or it is very unstable. If your dacha settlement is not yet electrified, you need such a unit.

Can conventional electric welding machines be powered by a generator? They can, but if it is also powered by household appliances or other electrics in the network, they will have to be turned off for the duration of the work: the voltage will “jump”, because of which they can break down. There is another point: welding machines require a generator of a simpler design (they are not so demanding to the characteristics of the power source). Therefore, its scheme is much simpler. As a result, a welding generator costs less than a pair of electric welding + generator.

If you do not have electricity, or with it there are significant interruptions, it is more profitable to buy not a welding machine for home and / or dacha, but a welding generator.

The choice here starts with the type of generator: gasoline or diesel. Then you choose the type of source of welding current: transformer, rectifier or inverter. Then already go the usual parameters of electric welding, described above.

Welding machine for aluminum

The peculiarity of welding aluminum is a low melting point, and, as a rule, a small thickness of the metal. Therefore, conventional manual welding is not quite suitable here: experience is required, and not everyone has it. You need shielded gas welding (semi-automatic machines in MIG mode) or argon-arc welding machine (TIG welding). The process of welding aluminum with argon-arc welding see in the video.

There are also universal multifunctional welding machines. One such unit can work in three to five types of welding. But the cost of such universals is already hundreds of thousands. For home, they are absolutely useless. These are already professional welding machines, and for a wide range of works. For example, “Multiplaz 4000” works in the modes:

- manual electrode welding (MMA);

- argon-arc welding with a non-melting electrode (TIG).

Both of these modes can take place in the shielding gas environment in the modes of alternating (AC), direct (DC) or pulse (pulsating) (PULSE) current. It has not just a lot of adjustments, but very many, the range of parameters is very wide. In addition to all “standard” types of steel can weld aluminum, and even without pre-treatment, thin stainless steel, titanium. The seam will be very high quality. But whether you need such an installation at home or at the cottage – a question. Unless you plan to open a production facility or earn money by welding.