Recently, wooden houses are becoming more and more popular – from beams, logs. They are beautiful and cozy, but finishing such a house is a serious matter. There are too many features that must be taken into account. Special attention should be paid to wet rooms. Only a properly made bathroom in a wooden house will not become a source of problems.

Inhoud van het artikel

How to make the floor

The floor in the bathroom in a wooden house can be made of any waterproof material. Traditionally it is ceramic tiles or porcelain tiles, but you can put linoleum (economy option), PVC tiles (the quality and characteristics of the coating is similar to commercial grade linoleum), adhesive cork (it is 100% airtight, as it is covered with several layers of varnish). You can even make a wooden floor, but the board will have to be treated with special compositions and take care of the ventilation of the underfloor space.

All coverings except for the wooden board are compatible with a warm floor. It can be water or electric heating. Only when choosing a floor covering, pay attention to its compatibility with a warm floor. Ceramic tiles in this case it is better to take not very thick – to accelerate the heating of the array, but in principle, any is suitable. In the characteristics of other materials should be a note of compatibility with a warm floor.

Bathroom in a wooden house is most often decorated with tiles. In any case, the floor is made mainly of this material. It is practical, easy to maintain. Ceramic floor tiles or porcelain tiles can be laid on cement or “dry” screed. As a base for dry screed use moisture-resistant plywood, hvl, chipboard. There is also a new material that can be used in dry screed – Aquapanels from Knauf.

If there is a need, on the dry screed you can lay a film floor heating, and on top – the selected finishing material. In the cement you can lay a water heated floor or cable mats (you can just a heating cable). Film floor to use in the screed is undesirable, since the film in concrete quickly deteriorates and heating simply ceases to work.

Under all other types of bases, you can also use these two types of bases. Only there is an additional requirement for the screed: for linoleum, PVC tiles and cork, the base must be strong and even. The permissible deviation is 2 mm per 2 meters. That’s why the usual screed is poured even saomlevyvayuschimaya mixture. Otherwise

Cement screed on a wooden floor

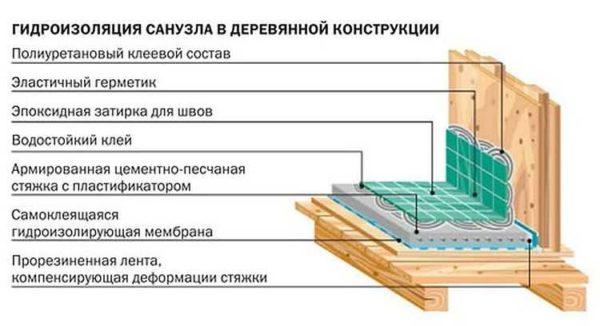

Usually to finish the bathroom proceed after the rough floor is ready. If you decide to make a cement screed, the order of actions is as follows:

After the concrete gains strength (one or two weeks, depending on the temperature), you can glue tiles on the floor or lay a suitable floor covering of another type.

There are some other points. To avoid the flow of water between the screed and the wall, it is desirable to glue the joint with waterproofing tape (available from Knauf), or you can lubricate with liquid waterproofing. The next point: before starting tile laying, the surface is dedusted (well cleaned with a vacuum cleaner), then primed (for cement substrates under the tiles). The primer reduces the absorbency, which gives the glue the opportunity to gain its strength, and not dry out because the water all went into the concrete. In this case, the bathroom in a wooden house will not create problems for its owners – the tiles on the floor will lie for years and will not bounce.

Dry screed

To make a tile floor in the bathroom in a wooden house, it is not necessary to use cement. You can make a so-called dry screed. On the rough floor lay a moisture-resistant sheet material. This can be plywood, chipboard or fiberboard. The best option is plywood with a thickness of at least 14 mm. Chipboard can also be used, but it is more prone to warping when humidity increases. HDF has not shown itself very well in operation – poorly tolerates shock loads (can split on impact). Therefore, it is desirable to lay all the same plywood.

It is laid apart – so that the seams do not coincide. Between the sheets leave a gap of 3-4 mm. It is necessary to compensate for thermal expansion when the temperature rises. Fix the plywood around the perimeter with nails to the rough floor, then in the middle in a staggered order (the distance between the fasteners – about 15 cm). Seams are sealed with a moisture-resistant sealant, which does not become rigid after drying.

Since the tiles require a rigid base, often lay a second layer of the same plywood. Lay it on the same principle – with a spread, but so that the seams of the first and second layer do not coincide. The rules are the same, but the second row is attached to the first, not to the rough floor.

On the perimeter of the made base glue waterproofing tape (available from Knauf). In addition, although the plywood and moisture-resistant, it is desirable to cover it with a layer of liquid waterproofing. Only choose a composition on which it will be possible to lay tiles. After drying, you can immediately start laying tiles.

Preparing the walls for finishing

The bathroom in a wooden house, as in any other is usually tiled. If the house is made of beams, logs or made by frame technology, immediately on the walls of the tiles will not stick – the surface does not allow. Under the tiles, the walls are covered with moisture-resistant sheet material:

Fiberboard and HDF are also used, but for the same reasons (warping and fragility) it is undesirable to use them. The sheet material is attached to the purlin, which can be made of galvanized metal profile for gypsum cardboard or wooden planks. When using bars, they must be treated with antiseptic compounds.

Lattice of wooden bars is usually made under the paneling with wood (bathroom in a wooden house can be paneled with wood, and then impregnated with protective compositions). Under the tiles try to make a frame of galvanized profile. But this is not a rule. It is simply easier to fix wood to wood, and to galvanized it is easier to mount GVL and other sheet materials.

How to make a purlin

When making purlins in a wooden house, it is worth remembering that it constantly changes in size. A few years after erection, it actively shrinks – takes operational dimensions. But then, throughout the entire period of operation, it slightly changes dimensions. This phenomenon is called seasonal fluctuations. Therefore, rigidly fasten the purlin is not worth it – it can break and all the trim will fall off. If you do the finishing without taking into account this feature of the bathroom in a wooden house will be a source of problems – tiles from the walls will fall off or will burst.

Therefore, the battens are made a little shorter – so that they do not reach the floor and ceiling. The second point – they are not attached directly to the wall, but through special devices. To fix wooden bars there are metal corners with slots on one of the shelves. These are the fixtures for the device of floating purlins (on the photo on the left). They are rigidly attached to the bar of the purlin, and to the wall of a wooden house – through a slot with a self-tapping screw with a large flat cap or a bolt with a washer. It turns out that the vertical movement of the wooden wall purlins on it will be in the same position.

The second way to make a floating purlin in a wooden house – in the bar with the help of a manual cutter to make several through kerfs with a length of about 10 cm. Through this kerf to fix the bar to the wall using the same dummy bolt with a washer. To prevent the head of the bolt from sticking out, make a recess with the router. Its depth is equal to (or slightly more than) the height of the bolt head, and the width – according to the size of the washer (pictured right). For a newly built house, the fastener is installed in the upper quarter of the kerf, for an established house – approximately in the middle.

As for galvanized profiles, they are attached to the same corners for floating battens. The second option is perforated hangers. This type of fastening is not so reliable, but still gives some freedom of movement. Perforated hangers can be used in an established wooden house where the movement is already small.

Tile base

Moisture-resistant sheet material is attached to the battens. The priority here is moisture-resistant gypsum plasterboard. Sometimes it is fixed in two layers – to increase the bearing capacity and for better heat and vapor insulation. Before laying the sheets of the second row, the joints of the first putty, and the GKL itself is located so that the seams of the two rows do not coincide.

But it is still GKL – non-ideal base, because both cardboard and gypsum hygroscopic, and their absorbency is reduced by impregnation. Therefore, for greater reliability, moisture-resistant GPB is impregnated with a protective composition. For example, FLACHENDICHT (Flechendicht). This is a waterproofing, which is designed for waterproofing of HDF and other gypsum bases.

You can still use Akvapanels from Knauf. They are made on the same principle as GKL, but the core – cement with filler, and the “wrap” – slyklovolokno. Both materials are not afraid of moisture without pretreatment. Their difference is that they are made absolutely flat, without indentations on the edges, which are in the GKL. They are joined butt-to-butt, on the interlocking edges a special adhesive composition is applied. Immediately after installation, the surface is smooth, ready for further finishing. It does not even need to putty. And one side of the aquapanel made flat – to paste wallpaper or paint, and the second rough – for tile laying.

Also as a base for tile on the walls in a log or log house can be used moisture-resistant plywood, GVL. Fix them also on the frame, leave gaps in the seams, which are filled with silicone non-drying sealant.

Ceiling

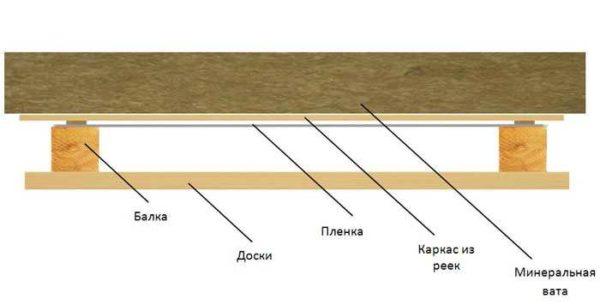

The ceiling in the bathroom of a wooden house is usually made of suspended – from moisture-resistant HDF, which is putty, then painted. More options – to make a tension, aluminum rack, PVC panels, underlay beautifully treated board. The problem is not that, but how to keep the vapor out of the ceiling. For this purpose, vapor barrier membranes are used. They are attached to the ceiling usually with staples from a construction stapler.

The main task when installing a vapor barrier is to ensure tightness. To do this, the material is placed on the walls, membrane strips are laid with overlap and glued twice with double-sided tape. Also tape all the places of installation of fasteners. Everything is done carefully.

The second component that ensures a normal microclimate is good ventilation. In the bathroom of a wooden house, it should be both natural and forced – with a fan. With this approach, the fan in the bathroom will be turned on at times when natural ventilation will not cope.

How to finish a bathroom in a wooden house

In this chapter, let’s talk about finishing methods, selection of materials and design techniques. The traditional way of finishing – walls and floor in tile or porcelain stoneware – is already a bit of a pain in the ass. And not everyone wants to cover wooden walls with such a “cold” material. If before there were almost no alternatives, today there are, and in sufficient quantity.

We have already written about moisture-resistant materials for the floor – PVC tiles, linoleum, adhesive cork. All of them are normally used in bathrooms. Another option is to make a plank floor and cover it with varnish or oil. The second option does not create a hard film on the surface, and protects no worse.

On the walls of the bathroom it is not necessary to lay tiles. Even such a variant as mosaic is used mainly fragmentarily – prefer to tile the walls in the area of direct splashes – near the bathtub, in the shower, near the sink. Another option – to make the panels tile to a height of 120-150 cm, and all the space free of ceramics to finish with wood. Pine for these purposes is not very suitable – it is too resinous. More often use larch or more expensive species. Most often put imitation timber, but it is a matter of taste. In any case, the wood on the walls in the bathroom is also subject to processing and you can also use lacquer or oil-based impregnation.

In general, you can use any finishing materials suitable for bathrooms. Just a little it is practiced – natural wood has become too rare finishing material to use the usual wallpaper or paint in a wooden house.