Not every bathtub can be fitted with a ready-made screen. Some people have it high, some, on the contrary – low, there are also bathtubs of non-standard sizes. In addition, not everyone wants to put plastic – do not trust the material or do not like the appearance. In all these cases, you need to make a screen under the bathtub with your own hands or call a master. In any case, it does not hurt to know how you can and should do everything.

Artikkelens innhold

Materials and requirements for them

Screen under the bathtub with their own hands make from:

- galvanized profile, covered with sheet material:

- moisture-resistant gypsum board;

- moisture-resistant or laminated plywood at least 10 mm thick;

- GFB (a good choice, as it is absolutely unafraid of moisture and does not deform);

- brick;

- 50 mm thick aerated concrete

- plastic panels and rails for their installation (this option is only decorative, suitable only for cast iron or steel bathtubs).

All these constructions, except for the last one, need finishing. Most often it is porcelain stoneware or ceramic tiles, the same as laid on the walls of the bathroom.

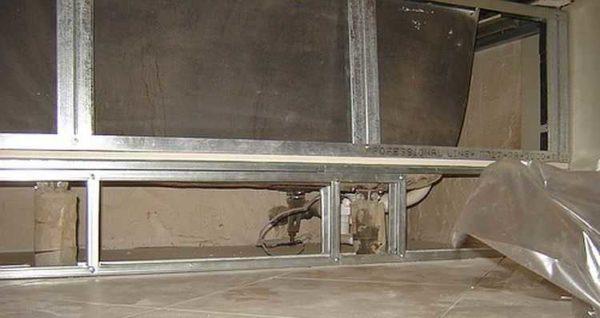

The most common variant of a homemade screen for a bathtub – from profiles and plasterboard. To make the design was reliable and did not sag under load, profiles should be taken with a thick wall, you can – reinforced. Also a prerequisite – good quality galvanizing. If possible, it is necessary to take branded profiles, so that there were no problems later – after all, in the bathroom high humidity is the norm.

Sheet material for the frame must be moisture resistant. This is a prerequisite. And even in this case, before installation, it does not hurt to primer it with a composition that increases water-repellent properties. It is not bad if this composition is also antibacterial – protection against mold and fungi will not hurt.

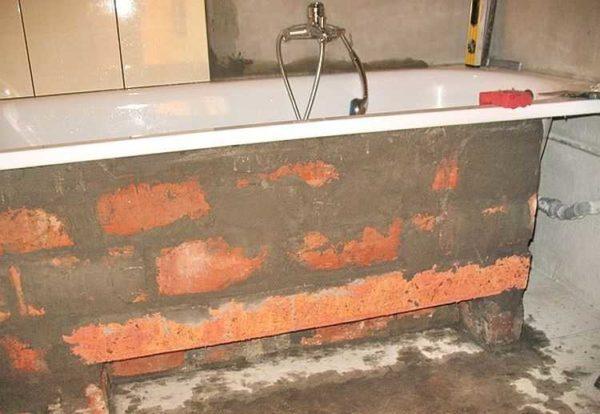

Brick screens are made mainly for acrylic bathtubs – so that it was possible to transfer some of the load to the wall of brick. Although, if desired, the frame of the profile can be made with sufficient load-bearing capacity – make double reinforced posts.

If it is decided to make a screen under the bath from brick, it should be used ceramic, red. Silicate is better not to take because of its hygroscopicity. Ceramic brick is also hygroscopic, but its absorption capacity is less. To minimize possible problems (coloring from high humidity), it is desirable to cover the masonry on the inside with a layer of plaster. This is not easy, but if desired, it is possible to apply the mortar as the screen is erected. Special care is not required, the main thing is to protect the brick from moisture.

Another option for a screen under the bathtub, which can be made with your own hands – from aerated concrete. This material is easily processed. The required relief is formed easily, though a sharp iron, and the block is cut with an ordinary saw. With all that, the blocks have a good load-bearing capacity. So this material can be used for a homemade screen under the acrylic bath. In addition, the blocks have large dimensions, so that folds this small wall very quickly.

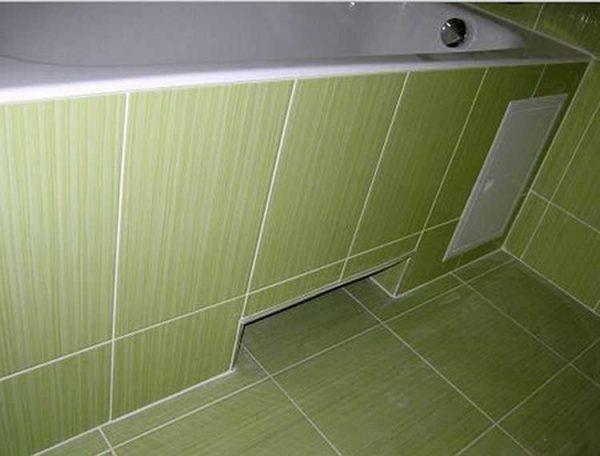

Pay attention! In the photo above, you can see underworked on one side of the block. This is done so that after laying tiles, it was flush with the sides of the bathtub, and not protruding outward. For the same purpose, when installing blocks slightly recessed, leaving a gap equal to the thickness of the tiles and tile adhesive.

In the photo, the master keeps the underworked part directed downward, but when laying the block is turned over. In this position, glue is applied to its lower part, which fixes the block to the floor. Glue is applied to one more side edge and to the top. This ensures fixation with the edge of the bathtub and the previous block. The technology of making a screen under the bath from aerated concrete is not difficult, if there is any experience of masonry, you will cope.

Constructions

We will talk about how you can make a screen under the bath with your own hands so that it was functional, beautiful and convenient. Everyone has his own ideas about convenience and beauty. Therefore, we will consider the possible options, and you will decide how you better make it.

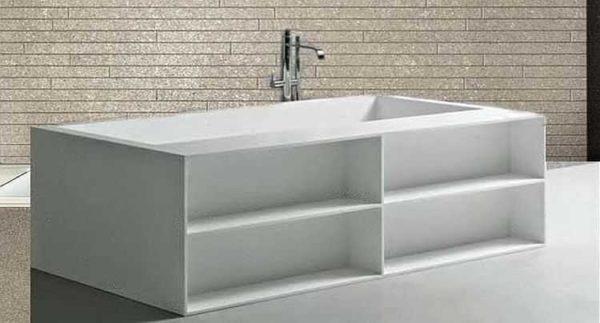

With a wide edge or not

Sometimes around the bathtub make a wide edge. It turns out it is as if inserted into the case. On the one hand it is convenient – you can put something on the sides and from an aesthetic point of view the bathtub more harmoniously fits into the interior.

But not everyone can afford to allocate a large space. Bathrooms are usually not happy with their size and an extra 10-15 cm can be critical. In addition, this type of installation can be inconvenient for the elderly. To get into the bathtub, you have to make a big step, which is not always possible for them.

But this option has another positive moment: under the bathtub you can make shelves of large width. They can be open or with sliding/swinging doors.

Similar shelves are made and without a wide edge, but their depth is much less. Although, maybe this is not a minus, but a plus – less different things will be collected, it is easier to get something out and put away.

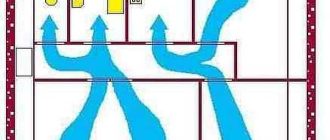

Footwell

It is more convenient to wash the bathtub or wash laundry in it, if the screen has a recess for feet. Its depth can be small – 10-12 cm is enough, width – about 35-45 cm. Such dimensions allow you to reach the walls and the opposite side without strain.

With the dimensions determined, the matter is small – to choose how it will look. The easiest to organize is a square recess. It can be made of brick, aerated concrete and profile.

A non-standard variation looks more interesting – the entire screen is made of two levels, when the upper part overhangs the lower (in the photo below). In this variant you can mount moisture-resistant LED tape for backlighting. It should turn out interesting.

The next option – part of the screen to make a slope. In the case of a profile, this is easily realized – with bricks – almost impossible, with aerated concrete – it is possible, but difficult.

There is another option – to raise the upper edge of the screen above the floor by a few centimeters. You will get it on legs and no problems with a place for your feet. But there are problems with cleaning. High cladding will not be pulled up – ugly, and if you leave a small gap, then how to clean? Problem.

In general, of all these options you can choose something most suitable for yourself, although they do and a blind flat screen in the floor.

Hatches for revision

The screen under the bath must necessarily have a removable/openable part, through which you can access the communications. There are several possibilities to do this. The first is to install a plastic hatch. Not everyone likes it externally, but this is the easiest and cheapest option.

The next possibility is to make a removable panel, which will be attached to the frame on magnets. Not to say that this option is difficult to realize, but it requires more experience – it is necessary to calculate the place of installation of the hatch so that the whole tiles are placed on it.

One moment: if you grout the seams with a light paste, the hatch will still stand out. There is no grouting of the joints in this place, and there are small gaps, which on a light background are very even noticeable.

The most technological, but also the most expensive way – to put special hatches for revision. They are of two kinds – hinged on chains and swivel.

These hatches, unlike plastic hatches, are designed for laying tiles on them. With good installation and proper calculation, it is not easy to see it.

How to make a screen under the bathtub with your own hands

Far from always by the general appearance of the same screen, you can guess how to make it. Those who have at least some experience in repair and construction work, probably, will realize, but ordinary people – hardly. To get oriented was easier, we will put a few photo-reports on the manufacture of homemade screens for the bathroom of different types and kinds.

From the profile and plasterboard

Making a screen under the bath from plasterboard occurs in three stages: first collect the frame, then cover it with plasterboard, and then put tiles on the glue.

The order of work is as follows:

- On the floor and walls make a marking.

- Cut pieces of profile according to the dimensions.

- Fix the lower guide from PN 27*28 to the floor with dowels.

- Install side strips made of PH 27*28. The height is from the floor to the edge. They are fixed to the walls, mostly with dowels.

- From the profile PN27*28 cut off a piece equal to what lies on the floor. This piece will go under the edge of the bathtub. It is supported on the previously installed side posts. The result is a frame. So far, it is fixed only on three sides. The top is not fixed with anything. It will be fixed later.

- The posts are cut from the 27*60 profile. Their height is the distance from the floor to the edge of the bathtub. The posts are inserted into the resulting frame, fastened to the floor. The distance between the posts is 35-40 cm. It is also desirable to make horizontal crosspieces at about the middle of the height. So the construction will be more rigid. If the horizontal lintel is not put, the screen may break under load (if someone bumps his knee).

- Do not forget to put the posts under the chosen hatch, as well as under the notch for feet.

- When the entire frame is assembled, take a can of foam foam, foam the upper profile.

- When the foam has polymerized, install the hatch.

- Moisture-resistant gypsum board is primed on both sides (you can paint with oil paint).

- Cut to size, mount on the frame.

- The joints of the sheets can not be smeared, but you can also putty.

- We dilute the glue for tiles (for wet rooms), lay the tiles.

- A day after laying grout the seams.

Screen under the bath from plasterboard is ready.

An interesting variant of a more rigid design of the screen under the bath is in this video. It will definitely not break even with significant loads. And all you need is to fix the posts to the body of the bathtub. To do this on liquid nails glue a piece of profile to the wall of the bathtub. Then the uprights are fixed to this profile using short pieces.

For a curved bathtub

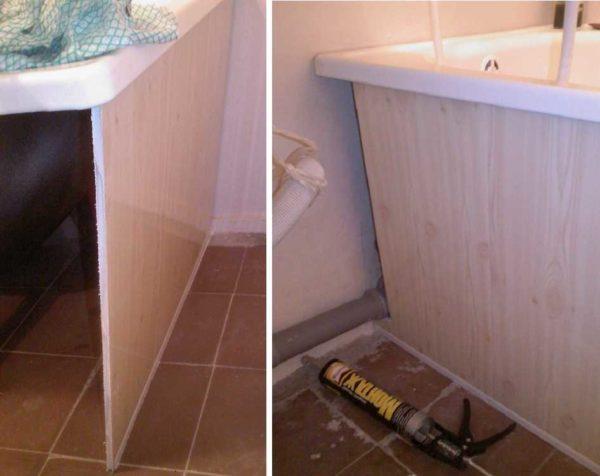

When making a screen for a curved bathtub, the main task is to repeat its smooth curves. In this case, you can also use a galvanized profile for plasterboard PN 27*28. Instead of plasterboard to put EPPS (extruded polystyrene foam) 50 mm thick, high density (preferably the most dense). Since the non-linear shape is most often acrylic bathtubs, they need a more reliable support than a sheet of plasterboard. Extruded high-density polystyrene foam – a fairly rigid material that will withstand the pressure of the walls of the bathtub filled with water.

You will also need a bolt cutter or metal shears, two or three cans of assembly foam. The order of work is as follows:

This technique is suitable for making with your own hands a screen under the acrylic bathtub. Mounting foam will support the walls and also insulate them. In such a bathtub will be kept warm for a long time.

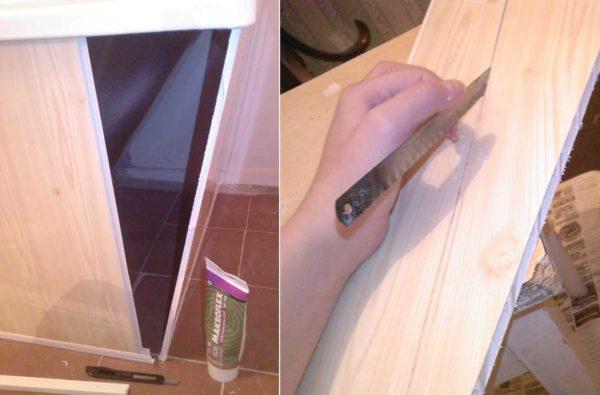

Screen under the bath from PVC panels

Durable this product can not be called, but it is built quickly and the cost is negligible. You will need two strips of PVC panels, starting guides for them, corners, liquid nails. From the tools – a ruler or tape measure, a metal blade, scissors.

For ease of use, the walls are sloped inward. This design determined the order of assembly: if you glue the profiles – at once, insert PVC strips into them is not possible. Therefore, first assemble the wall of plastic in the profile, then the whole wall put in place, gluing the profile (apply glue, slightly pushing the wall back, then it is pushed into place). Such a trick was successful with a short end wall.

With a long wall had to do differently. First, we assembled all the pieces in place in a single canvas (without the starting profile at the bottom). The strips rested on the floor and the recess of the curb. Then we slid the guide rail under the finished wall. This was possible because the slats are cut 1-2 mm shorter than necessary. In general, all the dimensions were measured very accurately, all the strips have the same length. The wall stands securely and without glue. It was not glued, because it is long and it is not clear how to put it back in place.

It remains to fix the joints with the walls and finish the corner of the screen. Carefully measure the piece that is missing, transfer the dimensions to the plastic, cut. Cut parts put in place.

Now it is necessary to ennoble the joints. Under the strips that adjoin the walls are slipped guide profiles. They could have been put in place immediately during installation – there would have been fewer problems.

We had to make a lot of trouble with the corner. It is necessary to simultaneously corner two planes in it. I managed to do it only with the help of a steel ruler. It took a lot of time.

It is not difficult to make this screen under the bathtub with your own hands. Only handle it carefully – the plastic is squeezed very easily. Another minus of this option is the lack of a revision hatch. As there will be problems – you will have to disassemble the part.