When installing or repairing wiring, wires and cables have to be installed. Also, if a new powerful appliance is to be installed, sometimes a separate line from the electrical panel has to be installed. In any case, you have to mount the wires on the walls or ceiling in some way. What can be a cable mount for each of these cases and will further understand.

Contents of the article

General rules

With hidden or exposed cable installation, indoors or outdoors, there are a few general rules:

In principle, the recommendations are all. They are universal and uncomplicated. The distance, if necessary, can be reduced. For example, at the bends of the route fasteners are installed at a small distance from the place of the bend – 5-10 cm. The task is to ensure reliable fixation and prevent sagging.

Methods of fastening to different surfaces

Walls and ceilings are made of different materials with different structure and density. Depending on this characteristic, the method of attachment changes:

- Dense – wood in any form, plaster and soft plaster mortars (including gypsum). In all these materials perfectly goes nail or self-tapping screw. In some – chipboard, OSB and some others – it is better to pre-drill a hole with a slightly smaller diameter than a self-tapping screw, and then screw it in. Nails are more often hammered in immediately without pre-drilling.

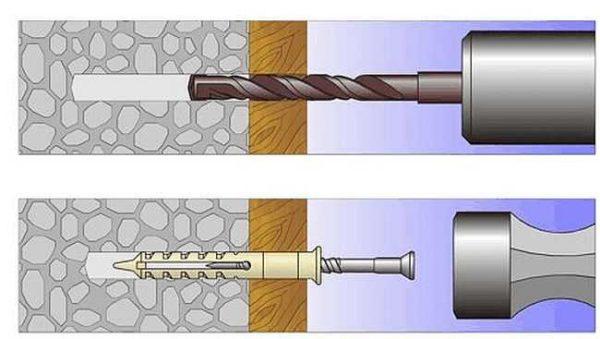

- Solid. This category of materials includes brick, concrete, screeds, cements. In them, even with a pre-drilled hole, you can not screw in a self-tapping screw. For such materials use dowel nails (they are also called dowels). This is a fastener consisting of two parts – a plastic dowel cap and a metal (sometimes plastic) screw. In such cases, a hole is drilled in the material with a drill bit diameter equal to or slightly smaller than the dowel diameter. A plastic cap is inserted into the hole. Its upper edge should be at the same level with the surface (if necessary, you can tap it a couple of times with a hammer to level it or cut off the excess with a sharp knife). Then the fixing element (plate, clamp, etc.) is applied, which is fastened to the inserted dowel with a screw.

- Thin or soft. This is plastic, drywall, fiberboard, aerated concrete, foam concrete, etc. In them, ordinary fasteners do not hold, you need a special one that has an extended “back” part. It has a larger support area, due to which the fastener can be held. Some examples of such fasteners (umbrella, butterfly dowel and drill dowel) are shown in the photo.

Actually, these are all the surfaces that are found inside the house when laying wiring. But the cable sometimes needs to be attached to the pole, for example, when the electricity input from the pole to the house stretches or to the pipe – when the cable goes up the flammable wall.

To a concrete pole

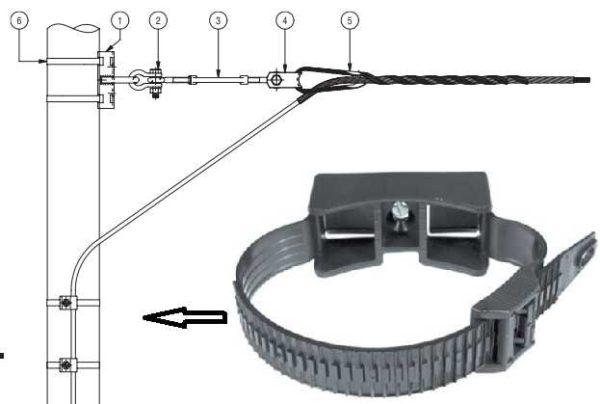

The cable is attached to a reinforced concrete pole with long black plastic ties. These last about 5 years.

You can use clamps for installing sewer pipes, but under them you have to drill holes, which is very difficult. Another option – if there is a ground wire on the pole – a round wire with a diameter of 5-6 mm, you can attach ties to it. Another option – to fix on the pole strips of metal – to make something like clamps, and to them to fix the cable.

In a metal pipe

If the cable goes up the wall of the house in a metal pipe, it is simply run inside. Since for outdoor wiring use pretty solid cables, its rigidity is usually enough to more or less hold inside the pipe.

From above and below the pipe is closed with some kind of cork (you can cut it out of foam plastic and then paint it together with the pipe). This cork will additionally fix the position of the cable (not pressed to the edge), and to prevent it from moving inside the pipe, it is fixed to the wall at the exit from it.

To the cable

To attach the cable to the cable, special metal and plastic hangers are used. They consist of two parts – there is a hole for the cable and a larger one for laying cables.

Which are better – metal or plastic? Metal ones are more durable, but longer to install – you need to screw in a screw. Plastic ones will last about 5 years, but they are installed quickly – the “tail” is pulled through the appropriate hole, tightened. That’s all.

Fasteners for cables and wires: types and varieties

With the same type of installation of wiring and cable, the same types of fasteners can be used. It is selected based on the available conditions, opportunities and tastes of the owners. The main task – to ensure quality fixation and not to break the insulation during installation, or during further work and operation. And the type of fixing you choose from the possible options. There are quite a lot of them – there are special ones that are produced specifically for cables, there are borrowed from other areas, there are – homemade.

Clips for cable fastening

With the help of clips, you can fix the cable on the wall, ceiling, on the floor. You just have to choose the right design, and there are many of them. Fastening the cable with clips is a very popular method – it can be very neat and almost invisible. This is if it is supposed to be open wiring.

Clips for cable installation there are metal and plastic, and different shapes. The simplest have the form of a shackle, which on one and the other side has holes for self-tapping screws or dowels. All they are good, but for installation it is required to drill two holes, and it takes a lot of time.

There is an option that allows you to maintain a fire clearance when installing power cable on combustible surfaces (pictured left). This fastener is fixed with a single self-tapping screw to the surface. It is good because threads can be added to the same fastener if necessary. To do this, you will not have to remove it, you will need to unscrew the screws that hold the upper part of the clip.

The third option is a kind of loop from a strip of metal. To install it, first you need to lead the cables inside, then combine the holes and fix it on the surface.

All these clips can be used both on the wall and on the ceiling. But when laying a large number of threads on the ceiling, they are inconvenient – too many holes are required for installation. They are made of metal, part then painted – so that when laying externally, the fasteners stand out less.

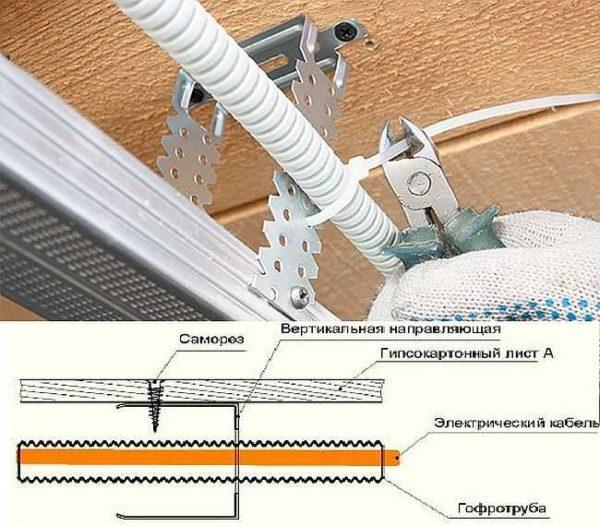

Plastic clips are used mainly for fixing cables in corrugated hoses. There are different sizes for different diameters of corrugations. They can be installed both singly and assembled in lines – for more accurate installation of large bundles of wiring. This type of clips are used mainly for concealed wiring, but if the corrugation is laid outside, it is more convenient to fix it with their help.

Dowel clip

More inconspicuous during installation is a dowel clip. This is a curved strip of plastic with characteristic branches at the ends, which due to the force of elasticity will hold the fastener in the material of the wall or ceiling. The shape of these products is for round and flat cables of different sizes. But serious cables will not be fixed with them – they are too small. But they look very neatly on conductors of small cross-sections, including television, telephone and Internet.

They are installed simply: a hole of suitable diameter is drilled, a conductor is inserted into the clip, the ends are tucked into the hole and forcefully inserted there. Really good option – quickly mounted, you look neat. It is used mainly for open wiring.

Dowel tie

Another option for fast cable fastening is a dowel tie. It is made of non-combustible self-extinguishing plasticizers, allows you to quickly mount cable lines. It can be used for both open and concealed installation.

There is a coupler with a split and non-split lock. The split lock allows you to change the number of wires if necessary. The method of installation is the same as a regular dowel. The difference is that the dowel is also plastic.

Cable ties with a dowel pad (CSP)

Another option for quick installation. It consists of a dowel with a thread and a pad with a cable tie attached to it. First, the dowel is installed, and the pad with a tie is screwed onto it. The wires are attached to the finished route.

Material – non-combustible plastic, color – gray, temperature of use – from -45°C to +85°C. Can be attached to concrete, brick and wooden surfaces.

Clips (staples) with a nail

An excellent option for fixing cables to dense surfaces – wood and its derivatives, plaster. On the side of the plastic staple there is a hole in which a nail is inserted. In terms of shape, there are round rectangular staples – under different shapes of conductors.

Cable fastening with such staples is fast and does not catch the eye. Most often small-sized wires are attached too – TV, telephone, Internet.

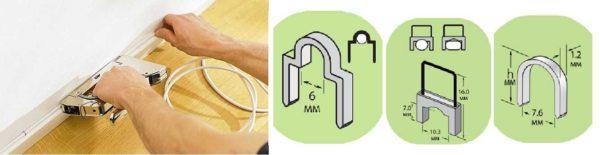

U-shaped staples from a stapler

Even the smallest staples and clips are still quite noticeable. There is a way to make fasteners almost invisible, at least in some cases. If you have a construction stapler, you can attach wires and telephone cables to wooden surfaces or plaster with special staples. They have long legs and a rounded back. There are special staples for stapler designed for cable installation with plastic stoppers (middle picture). They do not allow you to crush the wire, which happens when working with ordinary staples, if you set too much force on the trigger mechanism.

This method is good for high speed – just one press on the stapler lever and the staple is already installed. In an hour you can fix a decent meterage. Another positive moment – the fasteners are not visible, when dismantling in the wood there are very small holes, which are also almost invisible. With plaster and chipboard, OSB is somewhat more difficult – the damage may be greater, however, they are still less noticeable than from nails, even the smallest.

The disadvantage of fixing cables with a stapler is significant size limitations. Such staples are not large. The maximum size of the width of the staple is 12.5 mm, and even then not in all types. It is more than enough for installation of telephone “noodles”, Internet cable or other similar conductors, but it is not always possible to fix VVG or NYM in this way. In addition, these cables have a more rigid insulation, which requires more frequent installation of staples.

Fasteners to organize the bundle of conductors

Not always wires need to be fixed permanently. In some cases, you just need to organize the bundles so they don’t get tangled. For example, there are usually a lot of wires that go to your desk. Fix them rigidly to nothing – after some time may require remodeling, and from the nails are holes, which on the table is nothing to disguise. For these purposes there are various devices. They are more often called wire or cable holders.

For example, the same staples, but of a different structure. On the right side of the photo above, you see a cable clip, to the back of which a double-sided adhesive tape is attached. For attaching to furniture or plastic panels, this is very convenient – the glue can then be washed off, and the surface remains undamaged. In the center – the second variant with the same idea, and on the left is the so-called mounting pad for attaching cable ties. First, these pads are attached to the surface – they also have Velcro on the back side. Then the wire bundle is attached to the holes with a regular plastic tie. Not so convenient and neat (the tails of the ties will stick out), but it can be used too.

A few more options for fixing the harness of electrical wires you see in the photo above. The essence is the same, the methodology is different.

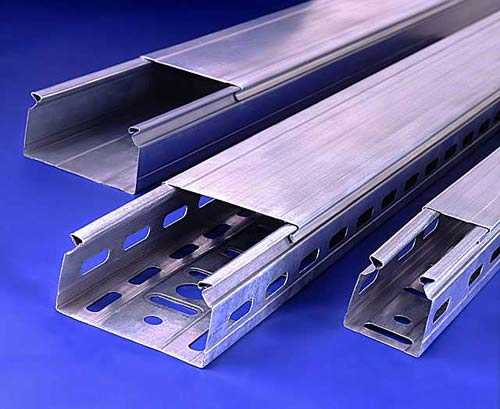

Cable trays – for hidden laying of large bundles

When arranging ceiling lighting from spotlights, you have to lay a large number of wires, and they have to be fixed to the ceiling slab. If we are talking about apartments, the ceiling is most often a concrete slab. It is hard and long to drill a lot of holes in it, it is not much easier to fix wires individually or in small groups. For such cases use suspended cable trays. They are usually made of galvanized wire or perforated metal.

There are different sizes, there are several different types of fastening – on the studs attached to the ceiling, on hangers “T” or “G”-shaped.

The installation procedure is as follows: first, the structure is assembled and mounted on the ceiling, then the cables are thrown into it. If desired, they can be fixed with ties to the grids, but usually this is not necessary.

In addition, there are metal trays made of perforated and non-perforated metal. The latter are necessary when laying cables inside combustible walls – in frame houses, for example.

The same trays can be used when laying cables in the underground space. But then you can apply a perforated version. It will also wonderfully protect from rodents and accidental damage.

Homemade devices for fixing the cable

Many factory-made devices have a relatively low price, but when hundreds of them are required, the sum runs up a lot. And if the wiring is hidden – it is required, for example, to fix the cable in the groove, why brick up extra money, if you can do with improvised means. This is what they make a homemade cable fastening:

- Strips of tin + nails or dowels – depending on the material of the wall. Tin is preferably galvanized, and it can be “extracted” from beer cans. It is cut into strips 7-10 mm thick, a hole is made in the center, in which a nail is inserted. First, along the route with a step of 60-100 cm nail the fastener, then tin strips clamp the cable or wire. To fix the cable was reliable, it is desirable to clamp the ends in a lock.

- From galvanized metal, cut into strips about 1 cm thick you can make a simple U-shaped bracket. At the ends of the nails, use as conventional staples – tacking the conductor every 50-80 cm. Can be used to attach wires to walls and ceilings.

- Also, a strip of tin can be used to fasten the cable in a loop. The strip covers the cable then the strip is attached to the wall (see photo on the right). This option can also be used to fix conductors in the groove. From the usual external fixing it will differ only the step of installation of fixers – they can be put less often, as their task – to hold the cables until the moment does not harden the mortar, which is used to fill the groove. In the same way you can fix the wires in a protective sheath – corrugation, pipe, etc. Only the strips will need a longer length and, possibly, width – for a more reliable fixation. A nail or self-tapping screw is suitable for wood, a dowel is required for brick and concrete.

- Bundles of wires can also be secured using improvised means. A longer strip of tin can be used to fix several conductors located near each other. It is more convenient to use perforated metal for this purpose (for example, mounting hangers for suspended ceilings), but you can do with ordinary tin strips.

These are the main types of fasteners for cables, which you can make with your own hands. There are probably other options – the imagination of craftsmen is inexhaustible, but these are the most common.

Fasteners for hidden laying

If the cables are laid at the stage of repair, increasingly resort to laying inside the walls, floor or ceiling. Since the result of the work is not visible, the aesthetics is given a minimum of attention. But a lot of attention is paid to reliability and safety – access for remodeling is very, very difficult. Therefore, and fasteners for the cable when laying inside the wall, ceiling, under the floor is chosen reliable. It can be:

- Ties of any type – with dowels, mounting pads, etc.

- You can pick up a suitable size of the clip type.

- Make homemade fasteners.

For laying large bundles of wires on the ceiling, it is more convenient and faster to use trays, but you can still use the same fasteners. The only bad thing is that you have to drill a lot of holes for installing fasteners in concrete or brick. This is especially inconvenient when working on the ceiling. About how to better optimize the work in this case below.

If it is not supposed to have false walls or a clean floor, under the wires are made recesses – gutters. In them lay the wires, then smear with mortar and then already make the finish. From the point of view of aesthetics, the option is ideal. From the point of view of operation – problematic, as it is almost impossible to replace or repair the wiring without breaking the walls. Nevertheless, the wiring is done in this way, just trying to lay quality cables, and even with at least some reserve in power or number of pairs.

According to safety rules in combustible walls (wooden, panel and frame) laid cable in a non-combustible sheath or in an all-metal tray. If it is a non-combustible sheath, it is usually a corrugated tube made of non-combustible plastic. In this case, the sheath itself, inside which the cable is located, is attached. This does not affect the choice of type of fastening, but it affects the selection of the size of the fasteners – it is simply necessary that the clamps could cover the sheath.

Laying cables inside combustible walls is difficult: the requirements are very strict. They can be performed in frame or panel houses, but in log or log houses is very difficult. It is necessary to lay all-metal trays in the walls. In this case, you have to remove a large amount of wood, which does not improve the thermal performance and appearance to make ideal is not possible. Therefore, in wooden houses more often resort to the open method of installation – over the walls.

Fasteners for outdoor cable installation

In the case of outdoor cable installation about the appearance of the fasteners are more stringent requirements. Since everything is in plain sight it is necessary to select the most inconspicuous variants or on the contrary, the most decorative for example retro-wiring. This is an extensive topic and is described in detail here. Other options:

There is a choice, but all methods are not ideal, so everyone decides for himself how and how to fix the cable.

Fixing cables to the ceiling

Fixing cables to the ceiling is necessary mainly when installing stretch ceilings or ceilings made of plastic panels and plasterboard. In the case of gypsokrtonom everything is somewhat simpler: there is a system of hangers, which can be plastic ties to fix the wiring harnesses. In other cases, everything is a little more complicated: you have to drill a large number of holes for fasteners, because they use all the same clips and staples, and under each you need to install a dowel (if the ceiling is made of concrete slab).

You can speed up the installation in several ways:

- By using cable trays (described above).

- Having attached a certain number of lines to the ceiling, hang small bundles of wires from them using plastic ties.

- Use a long perforated strip of metal for fastening.