Vienmēr ir prieks lietderīgi izmantot izlietotos materiālus. Un, ja runa ir par kurināmo un apkuri, tas ir arī ļoti izdevīgi. Atkritumeļļas apkures krāsnis ir lielisks piemērs. Tajās var izmantot jebkuru degtspējīgu eļļu. Transmisijas eļļa, dīzeļdegviela, mašīnu eļļa, konditorejas eļļa, augu eļļa... Patiesībā jebkura eļļa. Šīm iekārtām nav problēmu ar degvielu. Ko viņi atrada, to arī ielej. Un krāsns uz atkritumeļļas ar savām rokām tiek izgatavotas arī no izmetamiem materiāliem: vecs gāzes vai skābekļa balons, dažāda diametra cauruļu sekcijas vai metāla gabali.

Raksta saturs

Darbības princips mājās krāsnis

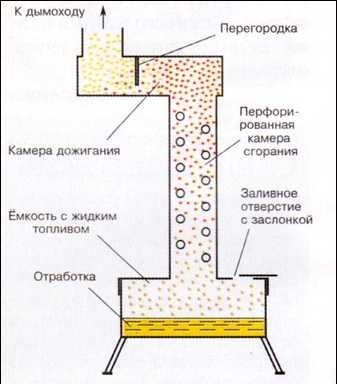

Ja atkritumeļļu vienkārši aizdedzina, tā nežēlīgi gruzdēs un vēl aktīvāk "smirdēs". Tāpēc tiešu sadedzināšanu neizmanto. Vispirms gaistošās vielas tiek iztvaicētas, pēc tam tās tiek sadedzinātas. Tas ir konstrukcijas izstrādes pamatprincips. Tāpēc dažos variantos krāsnij ir divas sadegšanas kameras, kas savienotas ar caurulīti, kurā izveidoti caurumi.

Apakšējā kamerā degviela tiek uzkarsēta un iztvaicēta. Degošie tvaiki paceļas augšup. Izplūstot caur caurulīti ar caurumiem, tie sajaucas ar gaisā izšķīdušo skābekli. Jau šīs caurules augšējā daļā maisījums aizdegas un sadeg otrajā kamerā. Un tvaiku sadegšana notiek, izdalot daudz vairāk siltuma un mazāk dūmu. Izmantojot pareizo tehnoloģiju, dūmu, kā arī kvēpu praktiski nav.

Otrā metode, kas paredz "smagās" degvielas (jebkuras izcelsmes naftas) sadalīšanu "viegli uzliesmojošās" sastāvdaļās, ir efektīvāka, bet arī grūtāk realizējama. Efektīvai iztvaikošanai apakšējā kamerā tiek uzstādīta metāla bļoda. Tā tiek uzkarsēta, uz tās krītošie atkritumu pilieni uzreiz pārvēršas gaistošos degošos tvaikos. Šajā gadījumā spīdums ir (pareizā režīmā) balts-zils, kā tad, kad deg plazma. No tā izriet cits šīs konstrukcijas nosaukums - plazmas trauks.

Lai sasniegtu visaugstāko degvielas sadegšanas efektivitāti, atkritumeļļa apakšējā kamerā jāievada ļoti mazās porcijās. Dažos variantos - pilieni, dažkārt - plāna strūkla. Tāpēc šo tehnoloģiju sauc par pilienveida padevi.

Šie ir mājās ražotu sildierīču "darbības" pamatprincipi. To kombināciju un variāciju skaits ir ļoti liels. Daži no tiem ir aprakstīti turpmāk.

Piemērs atkritumu dedzināšanai plazmas traukā ir redzams zemāk pievienotajā videoklipā. Šī ir atkritumeļļas krāsns "Gekkon", tajā ir iebūvēts ūdens sildītājs un tā var darboties kā apkures katls.

Priekšrocības un trūkumi

Galvenais un galvenais pluss ir tas, ka tiek izmantota izlietotā degviela un eļļas, kas citādi būtu jāiznīcina. Ja tiek ievērota tehnoloģija, sadegšana ir tik pilnīga, ka atmosfērā praktiski nerodas kaitīgas emisijas. Arī citi plusi ir tikpat pārliecinoši:

- vienkāršs dizains;

- augsta efektivitāte;

- zemas iekārtu un degvielas izmaksas;

- iedarbojas uz jebkurām organiskām, sintētiskām, augu izcelsmes eļļām;

- drīkst saturēt līdz 10% piesārņojošo vielu.

Ir trūkumi un nopietni. Galvenais no tiem ir tas, ka, neievērojot tehnoloģiju, degviela sadeg nepilnīgi. Un tā tvaiki nokļūst telpā, un tas ir ļoti bīstami. Tāpēc galvenā un galvenā prasība: krāsnis, kas darbojas ar atkritumeļļu, tiek uzstādītas tikai telpās, kurās ir ventilācijas sistēma.

Ir vairāk trūkumu:

- lai nodrošinātu labu vilkmi, skurstenim jābūt taisnam un augstam - vismaz 5 metrus;

- ir nepieciešama regulāra trauka un skursteņa tīrīšana - katru dienu;

- problemātiska aizdedze: vispirms ir jāaizdedzina bļoda, pēc tam jāpievada degviela;

- ir iespējamas ūdens sildīšanas iespējas, bet to neatkarīga konstrukcija ir sarežģīts uzdevums - jūs nevarat ievērojami samazināt temperatūru sadegšanas zonā, pretējā gadījumā viss process sabruks (kā iespēja - uzstādīt ūdens apvalku uz skursteņa, šeit tas noteikti nenovērš degvielas sabrukšanu).

Šo īpašību dēļ šādas iekārtas reti tiek izmantotas dzīvojamo māju apkurei. Ja tās ievieto, tad atsevišķās telpās un pabeigtā formā.

Piemērošanas joma

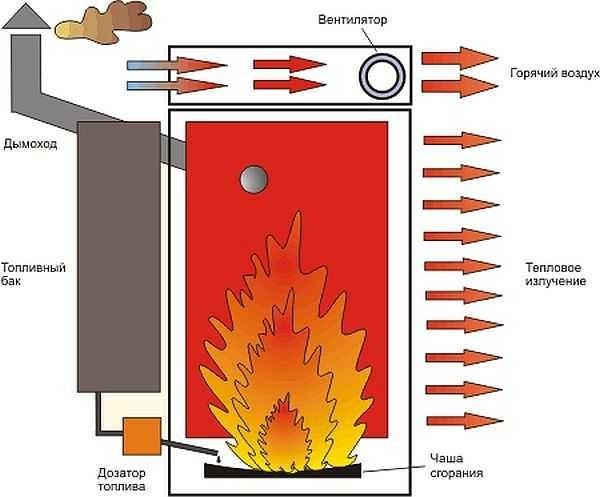

Pamata versijā gaisu sasilda paštaisīta krāsns uz atkritumeļļas. Tās sauc arī par siltuma lielgabaliem, siltuma ģeneratoriem vai kalorifikatoriem. Dzīvojamo telpu apsildīšanai šādā veidā izmanto reti: gaiss tiek izžāvēts, skābeklis no kvēlojošām metāla sienām tiek sadedzināts. Taču, lai uzturētu normālu temperatūru ražošanas vai tehniskajās telpās, šādi aparāti ir ļoti efektīvi: tie ātri paaugstina temperatūru. Tos var redzēt degvielas uzpildes stacijās, automazgātuvēs, garāžās, ražošanas cehos, kur nav degtspējīgu materiālu, noliktavās, siltumnīcās utt.

Daudzas iespējas var pabeigt: tajās var uzstādīt spirāli ūdens sildīšanai vai izveidot ūdens apvalku. Šāda iekārta jau pieder ūdens sildīšanas kategorijai, un to var ievietot ūdens sildīšanas sistēmā. Bez automatizācijas atkritumeļļas krāsns ar ūdens kontūru prasa pastāvīgu uzraudzību, taču vasarnīcai, saimniecības ēkām ar mājlopiem u. c. tas ir lielisks risinājums.

Kā izveidot krāsni uz atkritumeļļas

Šobrīd jau ir vairāk nekā ducis dažādu dizainu. Tās izmanto dažādas siltumenerģijas ieguves metodes, tām ir dažādas struktūras.

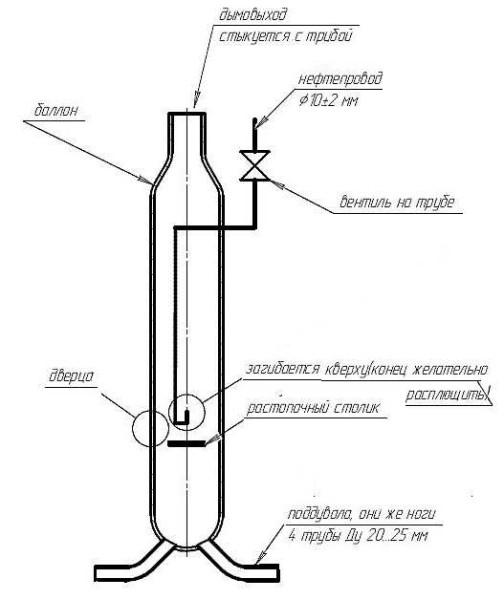

Krāsnis atkritumeļļas sadedzināšanai no caurules

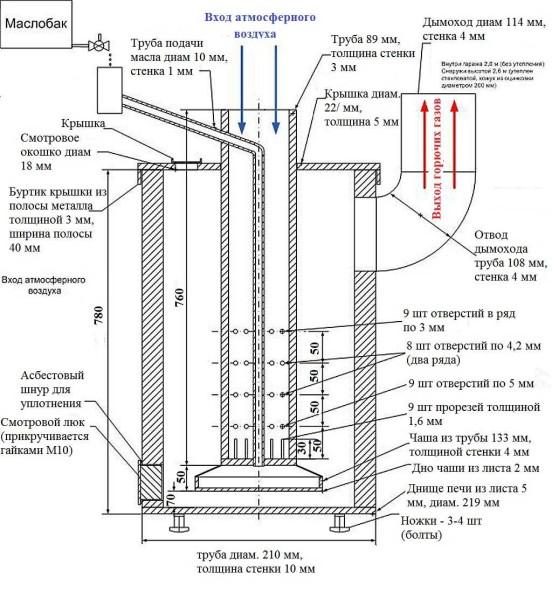

Krāsni ir vieglāk izgatavot, ja korpuss jau ir gatavs. Tam var izmantot gāzes vai skābekļa balonu, biezu sienu mucu vai cauruli. Tālāk sniegtajā shēmā ir paskaidrots, kā izgatavot krāsni uz atkritumeļļas no caurules.

Šīs ierīces darbība ir balstīta uz iztvaicēšanu plazmas traukā. Tas var izdalīt līdz 15 kW siltuma (vidēji tas var apsildīt 150 kvadrātmetrus lielu platību). Siltuma padevi nav iespējams palielināt jebkādu izmaiņu dēļ (krāsns izmēra vai gaisa padeves palielināšanas dēļ): tiks pārkāpts termiskais režīms, un lielāka siltuma vietā jūs iegūsiet vairāk čada, un tas nav droši.

Montāžas secība ir šāda:

- Ķermeņa veidošana.

- Ņemam biezu sienu cauruli ar diametru 210 mm un sieniņu biezumu 10 mm. Augstums 780 mm.

- No tērauda loksnes, kuras biezums nav mazāks par 5 mm, izgriežam apakšējo daļu 219 mm diametrā un metinām to vienā pusē. Tas ir dibens.

- Kājas ir piemetinātas pie apakšdaļas (tās var būt izgatavotas no skrūvēm).

- 70 mm attālumā no apakšas izveidojiet skatīšanās logu. Caur to var kontrolēt degšanu un uzsildīt trauku "starta" laikā. Attiecīgi izmēri padara to jums ērtu. Pašas durtiņas ir izgatavotas no sagriezta caurules gabala, piemetinot plānu plecu. Bet aizvērt visu ir jābūt hermētiskam, jo pa durvju perimetru gulēja azbesta aukla. Var izmantot plīts lējumu, tad tam tiek izgriezti cauruma izmēri. To var pieskrūvēt tieši pie korpusa (azbesta aukla šeit ir obligāta).

- Korpusa pretējā pusē, 7-10 cm attālumā no augšējās malas, iemūrējiet dūmgāzu izplūdes cauruli. Tās diametrs ir 108 mm, sieniņu biezums - 4 mm.

- Izgatavojiet vāku.

- No 5 mm bieza metāla izgrieziet 228 mm diametra apli.

- Uz malas metiniet plecu no 40 mm platas metāla sloksnes, metāla biezums - 3 mm.

- Vāka centrā izgriež caurumu ar diametru 89 mm, otru caurumu ar diametru 18 mm izgriež sānos. Mazākais caurums kalpo kā vēl viens skatlogs, tam ir izgatavots vāks, ko izmanto kā drošības vārstu.

- Izveidojiet gaisa un degvielas padeves cauruli.

- Ņemiet caurules gabalu ar diametru 89 mm, sieniņu biezums 3 mm, garums 760 mm.

- No malas 50 mm pa perimetru izurbj 9 caurumus ar diametru 5 mm.

- 50 mm virs šiem caurumiem izveidojiet vēl divas rindas ar caurumiem, kuru diametrs ir 4,2 mm, katrā rindā 8 gabali.

- 50 mm augstāk tiek izveidota ceturtā 3 mm diametra caurumu rinda. Tiem jābūt 9.

- Tajā pašā pusē gar bolgara malu izgriež 1,6 mm biezas un 30 mm augstas spraugas. Ap cauruļvada apkārtmēru jāizveido 9 gabali.

- No otra caurules gala ar 5-7 mm nobīdi izgrieziet caurumu, kura diametrs ir 10 mm.

- Izgrieztajā atverē ievietojiet degvielas padeves cauruli. Tās diametrs ir 10 mm, sieniņu biezums - 1 mm. Tā beidzas tajā pašā līmenī, kur gaisa padeves caurule. Izliekuma garums un leņķis ir atkarīgs no tā, kur atradīsies tvertne ar degvielu.

- Gatavā gaisa un degvielas padeves caurule ir piemetināta pie vāka. Tā ir atklāta tā, lai nesasniegtu korpusa apakšdaļu 120 mm.

- Degvielas bļodas izgatavošana

- Tagad no caurules, kuras diametrs ir 133 mm un sieniņu biezums 4 mm, nogrieziet 30 mm gabalu.

- No 2 mm biezas tērauda loksnes izgrieziet 219 mm diametra apli.

- Metiniet to pie caurules gabala. Mums ir bļoda, kurā tiek padota degviela.

- Montāža.

- Korpusa iekšpusē 70 mm attālumā no bļodas apakšas ir uzstādīts. To varēs novērot (un aizdedzināt) no apakšējās pārbaudes lūkas.

- Mēs uzstādām vāku ar degvielas/gaisa padeves ierīci.

- Uz dūmvada ir uzstādīts skurstenis. Caurules diametrs ir 114 mm, un tās sieniņu biezums ir 4 mm. Tā augstums ir vismaz 4 metri. Daļu, kas paliek iekštelpās, var nenorobežot, uz ielas to labāk izolēt. Dūmvads - tikai vertikāli uz augšu, slīpi posmi ir izslēgti.

Pēc eļļas tvertnes uzstādīšanas varat sākt testēšanu. Vispirms bļodā ieliek nedaudz papīra, ielej degšķidrumu un visu aizdedzina. Kad papīrs ir gandrīz sadedzis, atver eļļas padevi.

Šis krāsns zīmējums uz atkritumeļļas nav velti dots ar šādu precīzu norādi par materiāliem. Ir jāizmanto tieši šādas rezerves daļas. Paštaisītas krāsns darba rezultātā, patērējot 1-1,5 litrus kurināmā stundā, var apsildīt telpu līdz 150 "kvadrātiem".

Krāsns rasējums no caurules vai cilindra video formātā

Video autors iepazīstina ar krāsni, kas darbojas ar atkritumeļļu no balona (skābekli vai gāzi). Konstrukcija ir līdzīga iepriekš aprakstītajai, bet ar oriģināliem uzlabojumiem (un tā ir nedaudz vienkāršāka).

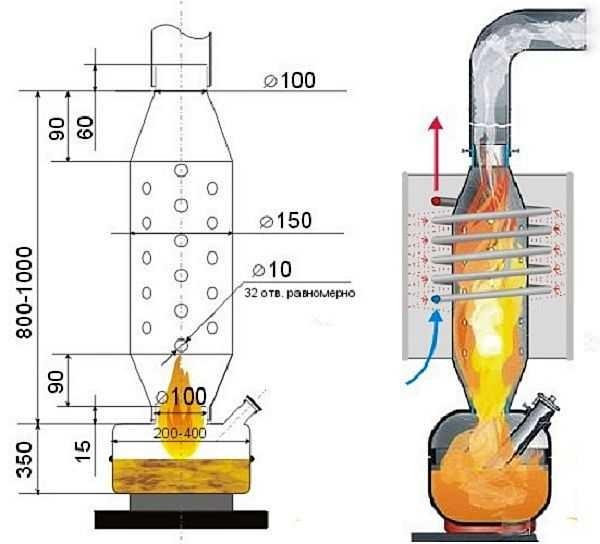

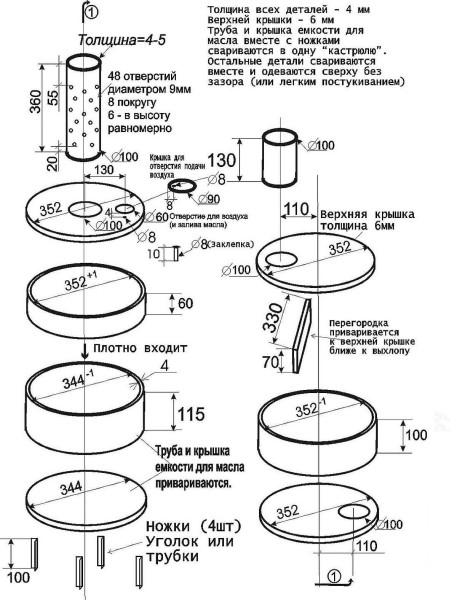

Mini atkritumeļļas plīts ar savām rokām

Šī paštaisītā krāsns ar nelieliem izmēriem un svaru (10 kg), kurināmā patēriņš ir aptuveni 0,5 liras stundā, dod 5-6 kW siltuma. To var kurināt spēcīgāk, bet tas nav nepieciešams: tā var uzsprāgt. Šo konstrukciju ir iecienījuši auto entuziasti: pat lielā aukstumā tā ātri sasilda garāžu, taupīgi patērē eļļu un ir kompakta. Tāpēc to var dēvēt par "garāžu".

Šī mazā gaisa lielgabala degvielas tvertne ir samontēta no standarta 50 litru gāzes balona apakšējās un augšējās daļas. Izrādās, ka tā ir ļoti izturīga konstrukcija (izņemot vismaz vienu apaļu šuvi no balona - tur ir O veida gredzens, kas piešķirs lielāku izturību. Cisternu var izgatavot no jebkuras citas tvertnes ar līdzīgiem izmēriem: diametrs 200-400 mm un augstums aptuveni 350 mm.

Papildus degvielas tvertnei ir jāizveido caurule, kurā tiek sajaukts degvielas un gaisa maisījums. Sienu biezums nav mazāks par 4 mm. Var izmantot piemērota diametra cauruli. Konusus metina no konstrukciju tērauda, kas nav plānāks par 4 mm.

Rasējumā redzamos šķidrā kurināmā plīts izmērus var regulēt uz augšu vai uz leju, bet tikai par 20 mm - ne vairāk. Īpaši uzmanīgi ir jāsavāra šuves vietās, kur atrodas piltuves: šeit kurināmā un gaisa maisījums ilgstoši saglabājas, kā dēļ temperatūra ir ievērojama.

Skursteņa caurules garums - ne vairāk kā 3,5 metri. Pretējā gadījumā pārāk labas vilkmes dēļ kurināmais tiks ievilkts skurstenī, kas ievērojami palielinās patēriņu un samazinās siltuma jaudu.

Attēlā pa labi redzams paštaisītās krāsns ūdens sildīšanas variants. Ap sadegšanas zonas augšdaļu ir vairāki tērauda caurules vijumi, caur kuriem tiek padots ūdens. Lai gāzu temperatūra daudz nesamazinātos, spirāle ir noslēgta ar siltumu atstarojošu tērauda apvalku. No apakšas tiek padots auksts ūdens, kas iet cauri spirālei, uzsilst un nonāk sistēmā.

Brīnumu krāsns uz atkritumeļļas

Šī iespēja ir ļoti populāra dakšnieku vidū un garāžās. Ērta neliela krāsniņa, kas ir izgatavota ar apaļām vai kvadrātveida degšanas zonām. Dizains ir tik veiksmīgs, ka ir pat rūpnieciskās versijas. Piemēram, viens no uzņēmumiem to pārdod ar nosaukumu "Ritsa". Shēmā ir norādīti visi nepieciešamie izmēri.

Video ziņojums par to, kā montēt šo krāsni, palīdzēs orientēties darba kārtībā.

Tālāk pievienotajā videoklipā ir parādīts variants ar kvadrātveida konteineriem, to pildījumu un izmēriem.

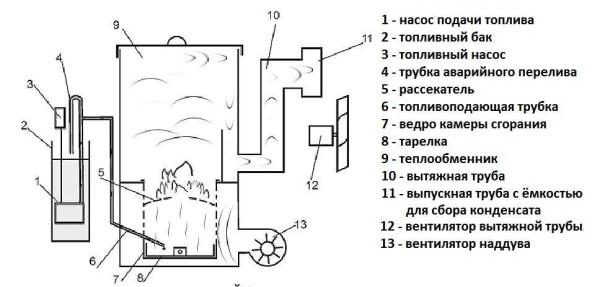

Rūpnīcas varianti

Krāsnis, kas darbojas ar atkritumeļļu, izgatavo ne tikai amatnieciskā veidā, bet arī rūpniecībā. Ir gan importētas, gan Krievijas. Bet to konstrukcijas veids ir atšķirīgs.

Eiropas vai Amerikas šķidrā kurināmā katli pieder pie šķidrā kurināmā plīts kategorijas. Tajos izmanto uzpildes principu: eļļa tiek izsmidzināta mazos pilienos, kas savienoti ar gaisa plūsmu. Un jau tad kurināmā un gaisa maisījums tiek aizdedzināts. Importētās rūpnīcu krāsnīs izmanto tādu pašu principu, tikai ir ievietots īpašs deglis, kurā degviela tiek uzsildīta pirms izsmidzināšanas.

Lai novērtētu tehnoloģiju un struktūras atšķirību, noskatieties šo videoklipu. Ierīce ir pilnīgi atšķirīga.

Krievijā ražotajās krāsnīs lielākajā daļā no tām izmanto pirmo principu - ir uzkarsēts (plazmas) trauks, kurā šķidrais kurināmais tiek pretraucēts gāzveida, sajaukts ar gaisu un sadedzināts. Pēc šāda principa ir konstruētas šādas iekārtas:

Rasējumi un shēmas

Modeļu krāsnīm, kas izmanto atkritumeļļu, tiek radīts daudz. Un zemāk ir dažas shēmas, kas var sniegt jums priekšstatu, un, krāsns uz atkritumeļļas ar savām rokām, būs efektīvs, ekonomisks un drošs.

Building a waste oil stove was a fun project! I remember collecting used oil from local restaurants, which was a bit of a scavenger hunt. Once it was all set up, the heat was great for those chilly nights! Totally worth the effort for the savings too!