The bathroom is a room that requires a higher temperature. It feels more comfortable, and the warm air will carry away excess moisture more quickly after a shower or bath. Heating in the bathroom is not often done. A more common way is the installation of a towel dryer, which we will talk about next.

To make everything work without problems, you need to choose the right connection scheme and correctly implement it. If you do not do everything with your own hands, you will have to follow the plumbers. Only in this way can you be sure that you will be left with a normally working dryer.

Straipsnio turinys

Types of dryer designs

Towel dryers there are different forms. When choosing them, people are often guided solely by aesthetics, which is not quite justified. These devices work normally with good water circulation, but not all models provide such circulation. With some of them it is necessary to make a long wisdom, finding the right connection scheme, otherwise they simply refuse to work.

So, all towel dryers can be divided into four groups:

Very often it happens that after installation of the towel dryer it simply does not work. If the error is serious, also the riser to which it is connected stops working. Therefore it is necessary to know and fulfill the rules of connection.

Where to connect and where to hang

Connect the water towel dryer can be connected to the riser of hot water (DHW), and to the heating. If there are both of these options, then choose DHW. On it there are three reasons: less fuss with permission for connection, it is possible to connect at any time of year and, the most important – such towel dryer heats all year round.

If there is no HTW in the house, it will be necessary to connect to a heating riser. For this purpose it is required the permission of MC and the project. You buy a towel dryer, preferably a simple design, go to the Housing and Utilities Department with its passport (copy), write a statement. If permission is given, you order a project, you will also need a copy of the passport with the dimensions of connection. Then, according to the project, you do it yourself or hire performers, for example, plumbers from the Housing and Utilities Department. Call representatives of the Housing and Utilities Department for acceptance.

When determining the place of installation of the towel dryer, questions may arise about at what height it should be hung. It is most convenient to place it so that it is at head level and below. This is if you put a U-shaped or snake. If we are talking about “ladders” of great height, the top bar is located not at the level of the hand of the raised hand, about 190-200 cm.

When choosing the place of installation of the towel dryer it is necessary to take into account the remoteness from the riser. In principle, the closer to the riser, the better – more chances that it will work. But, it is possible to take away and on a meter or so, only at fulfillment of conditions:

- low hydraulic resistance of the towel dryer, simple shape and cross-section of 1″ or 3/4″;

- sufficient pressure, 2 atm or more;

- outlet by pipes of normal diameter, on a step less than riser.

At the same time it is obligatory to follow other connection rules. Then there will be chances that such a “remote” device will work normally.

How to make branches and how to change the standpipe

If the riser is metal and you are not going to change it, then installation of a towel dryer is possible with steel or polypropylene pipes. If you change the riser (the best option) and put polypropylene, there is no choice – PP pipes go to the branches. Polypropylene to take for hot water, better – reinforced with fiberglass.

Why is not suitable metal plastic? Because its fittings have a strong narrowing of the lumen. This has a very bad effect on circulation. As a result, even 100% workable schemes do not give normal heating.

A little about why to change the riser. It makes sense to do this in old houses when repairing in the bathroom or a bathroom looking where you have a riser. First of all, the pipes are usually old and worn out. To them even a branch can be problematic to weld, so much metal is worn out. Secondly, modern repair involves hidden laying of communications and you will also want to close the riser. To hide the old pipe, and in a few years to redo everything again, is not a good solution.

A little bit about how to change. You need to agree with the neighbors below and above, as well as with the housing and utility company (DEZ, MC). With the neighbors that you cut off the riser from them and install a new one on the thread. Why them? Because to leave the old pipe in the ceiling is dangerous: will collapse and flow, flood you or the neighbors below. That’s why it’s better to go through the ceiling with a new pipe.

Agree or not with the neighbors, go to the housing and utility company and agree on the date of replacement and the time for which the riser will be disconnected. The work can be done by “local” fitters, yourself, if you have the qualifications of a welder, or people hired by you. After tapping, the water is turned on, you check the performance of the towel dryer and the system as a whole. If for 30 minutes it will not begin to cool down, then it is put correctly. At this point, the replacement or installation of the towel dryer is complete.

Whether to leave the bypass

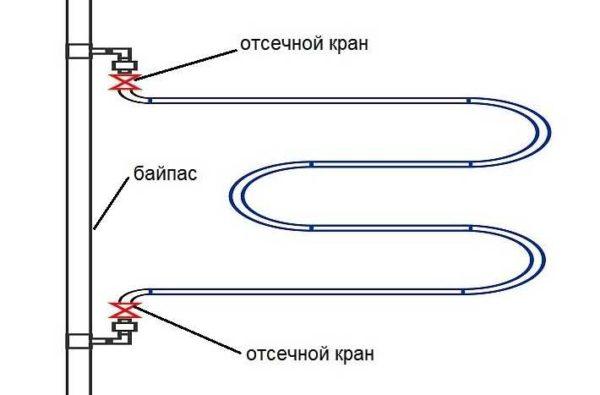

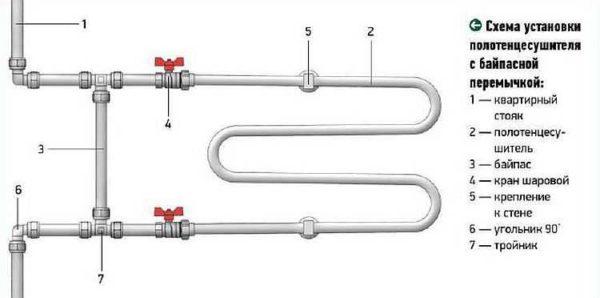

Let’s start with what a bypass is. It is a jumper between the inlet and outlet of the appliance, which provides water circulation when the appliance fails or is disconnected.

If with the scheme there is a bypass, on an input and an output of the device it is possible to put cut-off ball valves. This is convenient – you can disconnect if necessary, when repairing or replacing and not to close the whole riser.

If there is no such jumper, no taps can not be put. In this case the towel dryer is a part of a riser, closing the taps you completely close the riser.

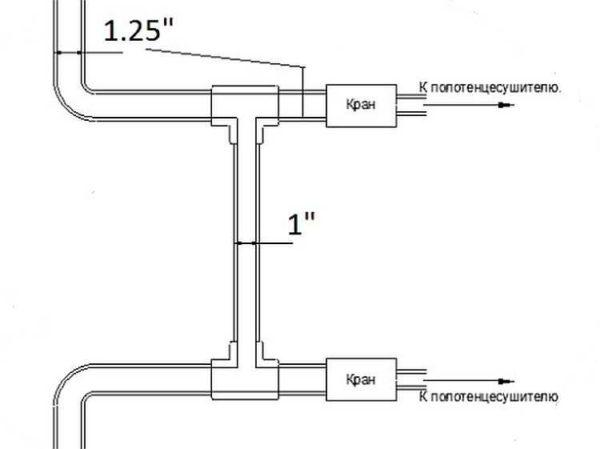

Bypass can be straight, as in the first photo in the chapter or offset, in the photo below. The offset bypass is placed at the upper supply for better operation (better circulation). At the lower supply, the offset only hinders the operation. If you do not know where the water is coming from, it is better to make a straight bypass.

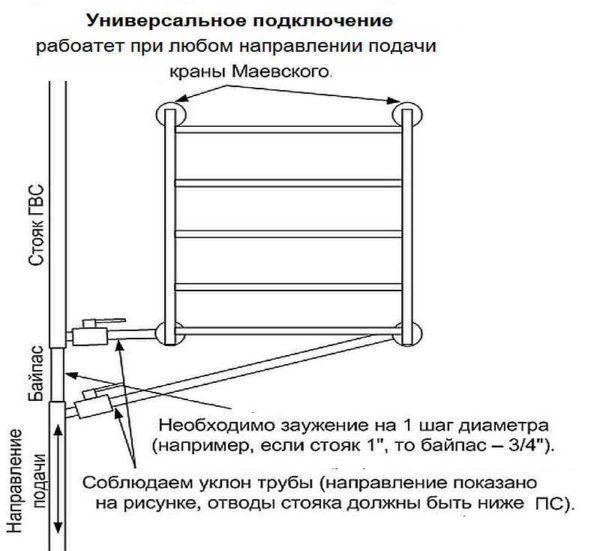

Bypasses, whether straight or offset, are made narrower. Narrowing, as well as offsetting, improves circulation, but only in the case of upstream. Taper is made with a pipe that is one step smaller than the main, if the riser is inch, the bottleneck is made 3/4″. The size of the insertion is at least 10 cm.

Once again: an offset or narrowed bypass works only at the upper water supply. At the bottom, it interferes with circulation. If you are not sure, make the bypass straight and not tapered.

Never put taps on the bypass. Every tap is a loss of pressure, which means that it impairs the circulation of the entire riser pipe. To all, it is absolutely unnecessary detail, which brings only harm, and any noticeable improvement of circulation in the towel dryer is not observed. Well, and besides, it is a violation of SNiP 31-01-2003 (p. 10.6) – interference in the communal communications, for which a fine can be issued.

Ways of connection

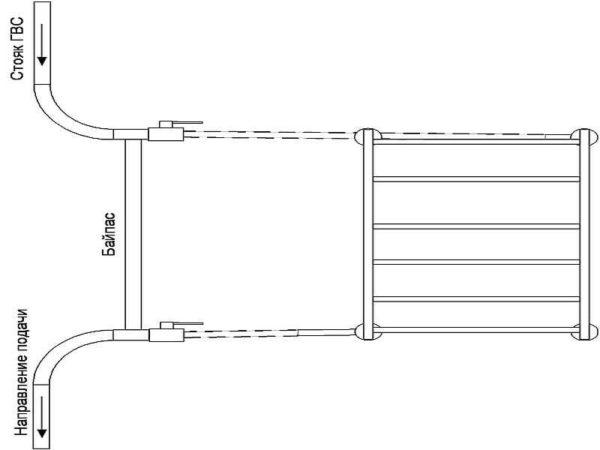

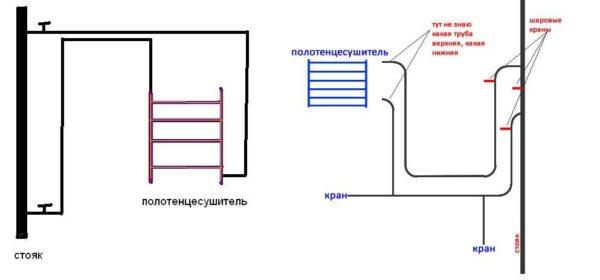

With lateral and diagonal connection, the outlets should be located at the same level with the inputs of the towel dryer or slightly higher/lower. What will definitely not work is installing the towel rail if the diverters are spaced less than the distance between the inlets. The photo below is an example of a non-working diagonal connection with closely spaced outlets. Black indicates a variant of its correction, with the upper water supply.

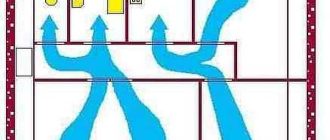

At connection it is necessary to place branches strictly horizontally or a little under an angle. Slightly at an angle is from 2 cm per meter (2%) or a little more. The direction of the slope depends on the connection scheme and the end to which the branch pipe will be connected. To be a little clearer, consider several typical schemes of connection of towel dryers.

Connection of a towel dryer “ladder”

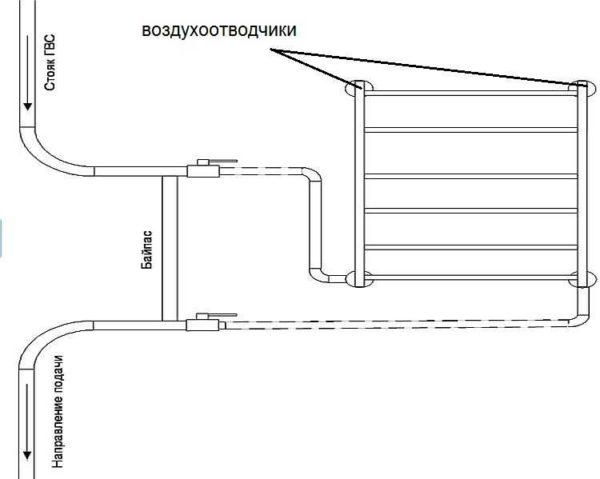

This scheme works regardless of the direction of hot water supply. Type of connection – bottom, both outlets should be located lower than the bottom edge of the dryer. With the upper supply, the option when the edge is between the outlets is admissible, but the work may not be so effective.

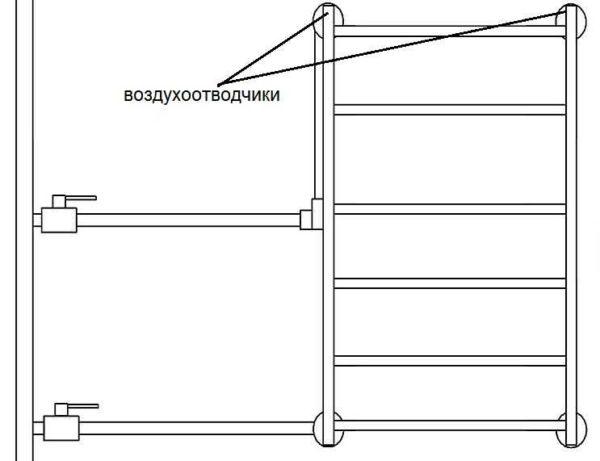

In this scheme it is possible to put cutoff cocks. For its normal operation are necessary:

- Installed on the upper leads of the Maevsky cocks (air vents) to drain the air accumulating in the upper part. They will need to be periodically opened and drain the air (as it begins to heat up worse). There is an option – to put automatic air vents. They are also compact. This will simplify operation.

- Bypass straight with a narrowing. The size of the narrowing – a pipe one step smaller in diameter.

- The branches are made with a pipe one step smaller in diameter than the main riser.

If you have a height passes this option, do it. The scheme works in any conditions, with towel dryers of type “ladder” of any kind.

The second variant of connection

When spilling hot water from above, you can make the upper outlet above the bottom edge of the dryer. With an offset bypass and its narrowing, heating should be fine. This method is not the best, but it works.

The presence of air vents and venting of air after stopping the system is mandatory.

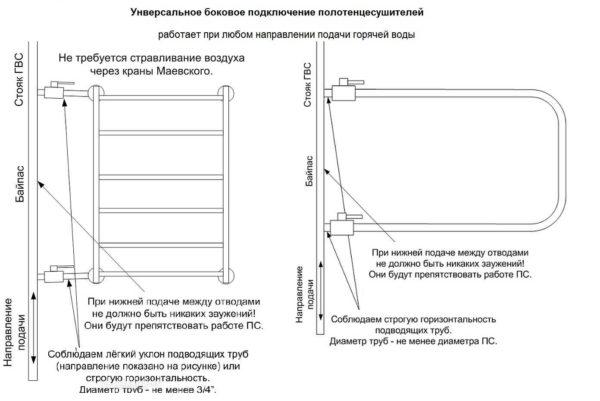

Universal side connection

It is possible to bring pipes from the side to a towel dryer of any of standard forms – U-shaped, snake and ladder. The connection itself depends on the form. In a standard variant there is a direct not narrowed bypass. Offshoots or strictly horizontal or with a slight slope. The slope is shown in the picture: the end of the upper branch is sloped slightly downward (2 cm per 1 meter), the lower one is sloped slightly upward. Diameter of branches, not less than diameter of a towel dryer.

Such scheme of connection is good that on a “ladder” it is not necessary to establish air vents (put plugs) as air simply leaves in a riser.

At the upper supply on the bypass can be made narrowing and / or shift the jumper in the direction of the towel dryer. This will improve circulation and the dryer will warm up better. This will only work with the top water supply.

With this scheme, you can also make the outlets at a slight incline or strictly horizontally.

Side connection of the dryer

The scheme of lateral connection with the location of the upper outlet below the upper edge of the towel dryer is acceptable. But with such a connection are necessary taps Maevsky, through which it will be necessary to bleed the air after disconnection of DHW for repair/prophylaxis. Also it may be necessary to periodically remove air.

Diagonal connection

There is no special sense in diagonal connection of the majority of towel dryers: their efficiency from lateral does not differ in any way, in any case there is no essential improvement, and consumption of pipes is more, longer are required and grooves, and it is labor-consuming.

Diagonal works well if the water supply comes from above. Then the upper outlet is connected to the far edge of the “ladder”, and the lower – to the near.

In this case, you can also make a narrow and offset bypass, but everything should work without it. At the bottom supply bypass without narrowing, exactly on the riser.

How to connect towel dryers of complex shape

In case of connection of towel dryers of a complex shape besides usual means it is necessary to consider features of structure of each concrete model. It is necessary to consider them from the point of view of hydrodynamics – where water will flow better, there and to supply water. For example, the popular model “Elegia” by Sunerja. It is not a ladder and not a zig-zag.

Installation of the towel dryer “Sunerzhi Elegia” is chosen lateral, because with any other circulation will be broken.

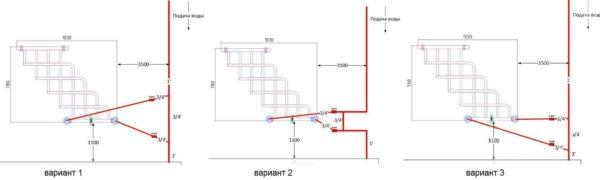

The model in the picture below with a bottom connection and a complex design, has three installation options. If the water is supplied from above, the second will work best, slightly worse – the first, the most inefficient – the third.

When feeding from below, there are still options 1 and 3, but only without narrowing bypasses – it will interfere, not help. The second option is completely excluded.

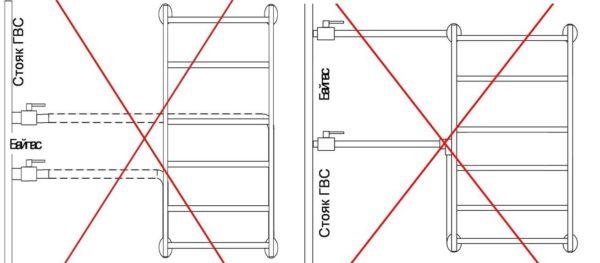

How not to do

All the schemes presented above work stably. As you noticed, all branches go straight, without bends in the form of an arc or rings. This is not accidental, in all irregularities, air accumulates, which interferes, and sometimes, and completely blocks the circulation.

In the photo, the installation of the towel dryer is wrong. At least two mistakes are made:

- branches are made already than interossevnoe distance of a towel dryer;

- they are made by a metal-plastic pipe with loops.

Such connection simply cannot work. Metal-plastic pipes – an excellent material, but not for connection of towel dryers. Their fittings have a strong narrowing of the lumen, which is bad for circulation. Plus in loops accumulates air, and also the flow on the upper loop, even when feeding from above, will not go – too much hydraulic resistance to water must be overcome.

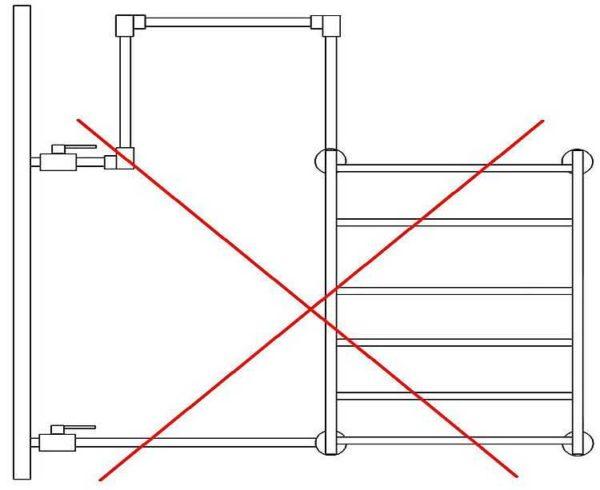

Unstable schemes

The following two schemes can work, but not always. In the lower part of the towel dryer, the water stagnates and, at some height difference, can not rise. To say specifically when it will work and when it will not, no one can. Depends on the pressure in the riser, on the diameter of the pipes and the construction of the dryer itself.

With this connection, even a working connection can suddenly (usually after a stop) stop working. Everything is simple: the pressure has changed, the pipes are clogged, the water from below does not “squeeze through”, the towel dryer does not heat.

Another variant of unstable scheme – with a loop from above. Again, under some conditions it will work. But sooner or later in the highest point will form an air plug and will block the circulation. The trouble can be helped by installing an automatic air vent at the highest point, but in case of pressure drop, even it will not save.

Incorrect connection of the dryer

The photo below are examples of how not to do it. After a few years of operation, they will stop functioning, the system will be clogged with dirt. Especially after renovation, because water carries a huge amount of dirt, which settles in the bends, in the lowest areas in the first place. It is necessary to redo and connect properly, well, and only flushing can help.

It is necessary to flush and towel dryer and connections to it. For this purpose the dryer is removed and washed in a bathroom, and branches are washed alternately connecting to the released outputs of a hose, the second end of which to lead out in a sewer. Manipulating the faucets to pass a stream of hot water through one outlet, then through the other. After flushing everything is put in place. It may be possible to start the system afterwards.

The installation process

The very connection of the towel dryer to the ready withdrawn branches is standard for plumbing – suitable fittings, linen and packing paste or fum-tape. For fastening to the wall there are brackets or special clamps-holders, into which the pipe is pressed. The process is shown in detail in the video.

I remember when I tried to hook up my towel dryer myself. I thought it was a piece of cake, but I ended up with a leak! Lesson learned: always check those connections twice. Now I just call in a pro to save myself the hassle.

Totally get you! I tried fixing my sink once, thinking I’d ace it. Ended up with water spraying all over! Now, I always bring in a plumber. Better safe than sorry, right? Cheers to learning the hard way!