Everyone wants to make their home unique and one of the ways to do that is with stucco decorations. In the past, all elements were made by hand, cost a lot of money and were not available to everyone. Modern technology allows you to produce not too complex elements in bulk, which reduced their price. And looks stucco in the interior is still amazing, even in modern interiors, in kitchens and relatively small rooms.

Contenuto dell'articolo

Types of stucco and materials

Stucco decorations are distinguished by their application: for decorating buildings and interiors. They are made of different materials. Gypsum, polystyrene foam and polyurethane are used mainly indoors. This is due to the characteristics of the materials: gypsum – afraid of humidity, polyurethane and polystyrene foam – direct sunlight. For decoration of buildings use special stucco made of polymer (glass fiber concrete), sandcrete, chamotte. But the price of these decorations and the cost of installation is high.

Is it worth using polystyrene foam?

Interior decorations made of polystyrene foam (Styrofoam) are the most affordable on the market. They are very light and flexible, mounted very simply – on glue. Due to their flexibility, they can be installed on walls that are not quite level. And it seems all is not bad, but, due to the peculiarity of the material, the surface is slightly grainy, not too dense. With gypsum decor polystyrene molding is incomparable – too visible difference. But inexpensive.

When using moldings, cornices or other products made of polystyrene foam, after installation, it is better to paint them, otherwise after some time the products will turn yellow. Paint stucco with water-based paint, but you can use any other composition that is compatible with the base.

Styrofoam stucco should be used only if the budget is very limited or if you will soon make repairs again. In other cases, it is better to choose between polyurethane and gypsum.

Gypsum or polyurethane?

In the interior are usually used either polyurethane or gypsum moldings. But what to choose? What to give preference to? To answer the question, you need to know the advantages and disadvantages of moldings from both types of materials.

Gypsum stucco is more diverse, always has a clear pattern, is made of natural material, does not age, does not change performance characteristics (if not wet). But it is heavier, fragile, due to which it is more difficult to install. To the minuses should be attributed and higher cost. Although, if you take a high-quality polyurethane stucco, it costs almost as much. But there is still a difference – due to the cost of installation (the plaster is higher, as it is more difficult to install).

Polyurethane stucco has a small weight, does not break and does not crumble, is not afraid of humidity, easier to install. But it has its own, and serious, disadvantage: very often at the joints over time there are cracks. Most of all “cracks” if the interior stucco was mounted on concrete, brick, wooden walls, on cellular concrete. Rarely you can see cracks if the decor was glued to drywall walls. This is due to the different reaction of materials to changes in temperature and moisture. In gypsum board and polyurethane they are close, so the joints “do not tear”. In other materials, this problem is present. It is also worth saying that the number of cracks depends on the qualifications of installers: some have one crack per room or several rooms, others have several of them in each room.

Manufacturers of polyurethane stucco advise to use a special glue for joints, the connection to make not in a straight line, but at an angle of 45 °, during installation do not spare expensive glue and put it on the glued joints with excess. Came out glue wiped, or after drying cut off. These are additional, and labor-intensive operations (especially trimming of dried glue, as well as adjusting the pattern when connecting at an angle), so not all teams use them. Much more often glue polyurethane stucco butt, and put glue very thin layer, and if it is not enough, the voids are filled with putty. The strength of this connection is not very strong, so there are cracks. And in large numbers.

Methods of installation

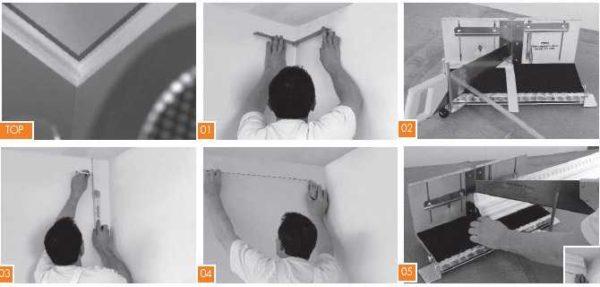

Stucco in the interior of any type is attached to the adhesive composition, just the composition of this for different materials is different. The surface to which the molded elements are glued, must be previously leveled, cleaned of dust, dirt, dried. Decor elements should be brought into the room, kept at least a day, but better – two. During this time will equalize the temperature and humidity of the decor and the base.

The adhesive composition is applied to the molded element and the surface to which it is glued, evenly distributed. Then it is necessary to wait for about 10-20 minutes, and then put the decorative element in place, align, press well and hold for a while – until the glue does not set. If mounted heavy or bulky elements, they can be fixed with a few self-tapping screws. Then the fasteners can be removed (or left), the holes are filled with putty, and after drying, sanded.

When reinforcing stucco, in the joints are very often formed unevenness, height differences, mismatch pattern. These defects are eliminated with the help of sandpaper with fine grain, folded in several layers. This “tool” is processed joint to a complete match. And when sanding polyurethane under a layer of white paint (primer) shows yellow material – the polyurethane itself. To make the seam was invisible, it is better to remove the entire primer layer to the material, then apply putty, after drying, grind.

This is the general technology of installation of stucco in the room. But there are peculiarities of each of the materials, and we will talk about them in detail.

Features of gluing polyurethane and foam moldings

Polyurethane moldings of good quality, with a clear pattern, outwardly does not differ from gypsum. Tactile (touching), the difference is easy to determine, but “by eye”, especially under the ceiling, almost unrealistic. But polyurethane moldings have two significant disadvantages: cracks that eventually appear at the joints and change in size.

Change in the size of polyurethane moldings for the interior becomes noticeable after six months or more. If you have not glued for some reason part of the decor, leaving some parts “for later”, in a few months you simply will not be able to dock them. Even if earlier all exactly became and combined. And the difference will be not only in length, but also in width. “Shrinkage” can be 2-5 mm, depending on the density of the material and the shape/size of the element. Therefore, do not leave unfinished work, install all the decor at once.

As it is already clear, because of the “shrinkage” of polyurethane (and also because of the different thermal and thermal expansion of the decor and the walls / ceiling) at the joints of the elements appear cracks. To make the cracks less, the elements should be joined at an angle of 45°. Please note: all joints are made at an angle. Not only in the corners. Even if two straight elements are joined – cornices, baseboards, moldings – their edges are cut at an angle, increasing the area of the joint. Thus, the amount of glue increases, the strength of the connection increases, it is less likely to “tear”.

How to glue gypsum moldings

Plaster stucco in the interior can be more diverse, there is an opportunity to make individual decorations or from ready-made small fragments to collect a unique pattern. Gypsum decor is also mounted with the help of glue, but its composition is different. There are differences in the method of application: before applying glue, plaster fragments are dipped in water for a couple of seconds. Then the adhesive composition is applied to the surface, with a spatula with fine teeth evenly distributed over the surface. Then everything is familiar: put in place, press down, leave to dry.

When installing large fragments of gypsum stucco, on their back surface are applied notches with a depth of a couple of millimeters, after which the adhesive composition is applied. After installation, massive elements are fixed with self-tapping screws. Their number depends on the mass of the fragment and on your desire. All holes are putty, after drying, sanded. Joints are caulked as well, there are no problems with them.

Stucco in the interior

If we talk in general, then stucco products can be divided into two categories: ready-made decor and individually made products. Unique decorations are made only from plaster – the technology allows, but the cost of such decor is much higher. Therefore, it is often combined – where possible put parts from mass collections, supplemented with individual fragments.

Ready-made decor is of various kinds: baseboards, moldings, cornices, columns, semi-columns, pilasters, rosettes, corner elements. These elements are available in polyurethane, foam and gypsum collections. Companies engaged in the manufacture of gypsum decor, usually make some more small details that can be added to the standard design.

This is not yet individual production, but it is far from mass production, especially since the decoration can be selected to your taste, combining different elements.

In a classic interior

Stucco decorations are characteristic of interiors decorated in the styles of the classical direction. But such rooms should be high and spacious. Then even the most complex decorative designs look organic.

Stucco and modern interior style

The current pace of life dictates its own rules of interior design: everything should be more concise. How, it would seem, can you combine stucco decorations and modern design? Very much possible. The most common way – to decorate the corner between the wall and the ceiling cornice. It can be wide or not very wide, can be with a pattern, ornament or just smooth with a few protrusions. Such decoration fits into most interiors of modern direction.

If the design is not too ascetic, quite suitable and shaped elements, rosettes, various decorative panels, cornices and other “things”.

Photo-ideas