During construction or repair, it is constantly necessary to mark some lines, which should be located at the same height, be horizontal, vertical, have a certain angle of inclination. All this can be done with a water and bubble level, but these actions take a lot of time and effort. It is much easier to carry out such operations with a laser level or, as they say, a laser level, a builder of planes and lines. About how to choose a laser level and we will talk further.

A cikk tartalma

Types of laser levels

If you look at the prices of these measuring tools, you will see a very big difference – from 20-30$ to 850$. As you realize, everything is not just for nothing. A tool with different capabilities and accuracy cannot cost the same.

To choose a laser level, first of all, it is necessary to determine the type of work for which it will be needed. Under these works and select a laser level. They are of the following types:

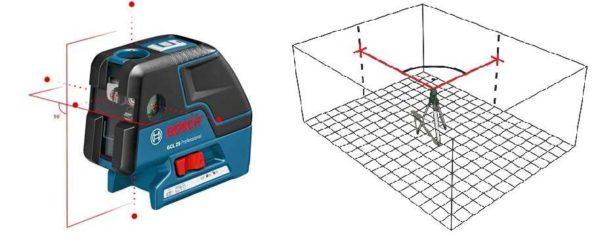

- Point (axis builders). Display usually three to five points in different planes. Neither lines nor planes, they do not build. You can see only points, but at a great distance (to make it clearer, you can compare their principle with laser pointers). They are used on large sites to transfer marks. Will come in handy in repair for marking the lines of wallpaper pasting, marking for fasteners for pictures, shelves, etc. In more serious operations, this type of tool is not used.

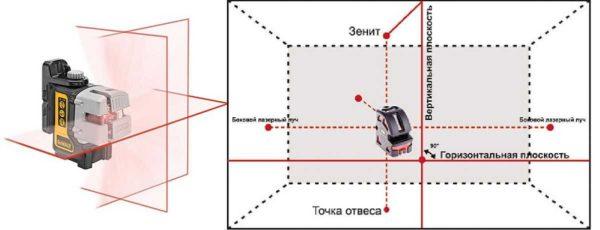

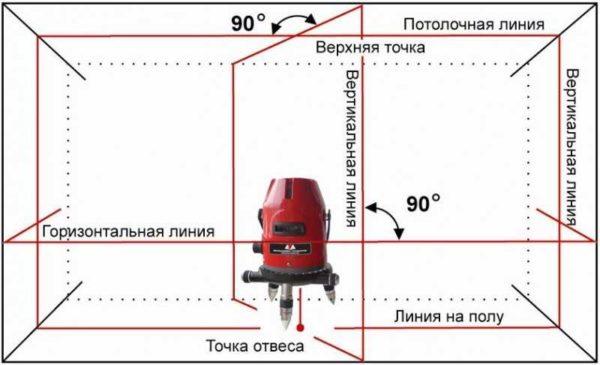

The simplest laser levels give only points in one or more planes - Crosspliners, line planners, line levelers. Sometimes called plotters of planes, because in fact, form a plane of a certain size (depends on the sweep angle). When working with such a laser level, on any plane that falls within the laser is displayed straight. This is used in construction and finishing work. Range – usually up to 20 meters, if necessary, it can be increased (if there is a mode of operation with a receiver). For repair and interior decoration of premises, it is convenient if the device can form lines vertical, horizontal, give a “cross” on the floor and on the ceiling. Due to the peculiarities of the ray sweep, the line is displayed only on the part of the room in which the device is directed. For example, on one wall and part of the ceiling/floor. To get marks on another wall, the instrument must be turned around.

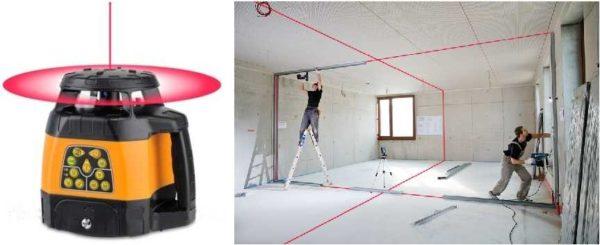

A linear laser level gives one or more planes with a certain sweep angle - Rotary Plane Planners. The functions are the same as crossliners, only the planes are rotated 360°. For this purpose, a complex system is used, which is reflected in the price. Tools of this type can justify only professionals (prices for this type of laser levelers start from $ 400). For home use, they are of no use.

Rotary laser levels turn the plane by 360 °

Now choosing a laser level is easier, you already know what type of tool you need. For most people, it is a line/plane builder.

Basic technical parameters

To choose a laser level, you need to be guided in the characteristics of the device, to know the possible minimum and maximum values of at least the basic characteristics that will determine its capabilities and operations in which it can be used. There are several characteristics that are inherent in all laser levels. These are the key parameters that determine the possibilities of their use.

Number of beams

The simplest models can produce one or two beams. For some works, this is enough – for most finishing works, wall or ceiling markings, furniture assembly. If it is supposed to be an ordinary repair, you can choose a laser level, which can produce two lines. This will not undermine your budget – such models are inexpensive, but allow you to significantly reduce the time for drawing all kinds of lines and marks.

For more serious work – installing partitions, leveling walls, floors, etc. need two intersecting planes. In this case, a set of horizontal + vertical planes is desirable. So you can also output the plane of the floor and ceiling. When choosing a model with this functionality, pay attention to the possibility of using the planes separately. Crossing planes is not always necessary, and the battery charge “eats”.

In addition to planes, in serious work, such features as nadir, zenith, plumb. Why do you need a plumb line, everyone knows, nadir and zenith are required when installing racks in the middle of the room. For example, in the construction of partitions, in other similar works.

For professionals, even more complex models are needed. They can deploy several parallel planes horizontally and vertically, have the function of sweeping the half-plane: right-left. This is important if several people will work on the object. Each person will set the necessary marks, which will allow to perform different operations at the same time.

Measuring range

The range of the beams is one of the key indicators that affects the choice of a laser level. Most of the inexpensive models spread the beams to a distance of up to 20 meters. For work inside an apartment or a private house, even for marking the foundation of a private house, this is enough. But for work on a large construction site, for marking the site itself, this is clearly not enough. For such operations, you need to look for models with a range of 50 meters.

Note that many models of laser levels have the ability to significantly increase the range of action. There are special receivers for this purpose (usually purchased separately). In models that are compatible with receivers the range of measurements is indicated through fractions. For example, 50/100 meters. This means that the maximum range without a receiver is 50 m, with a receiver – 100 m. If there is a dash in the second part, the leveler is not compatible with the receiver. Such models (with a receiver) are taken to work on the street. With them even in the daytime you can see the laser trace. If there is no receiver, you will have to work at dusk, as in the sun the laser trace is practically invisible.

Accuracy

Any measuring device has a certain error, and electronic levels are no exception. They can give some deviation of the rays from a perfect straight line. This deviation is the error of the leveler. It is indicated in millimeters per meter of beam passage. Highly accurate devices can give a deviation of only a fraction of millimeters, less accurate – up to 3-4 mm per meter.

It is clear that a smaller error is better. But for repair or construction work in the volume of a private house, the difference in 2-3 mm per meter – it is practically nothing, and with the increase in accuracy of the leveler price rises significantly. For private use is quite enough average accuracy – about 2 mm. Significant, visible to the eye errors, such devices do not give, and no one will check you. High-precision laser levels are needed for architects and foremen, as well as professionals. Their work must comply with the norms.

Batteries or batteries

The operation of the laser level is based on the use of LED. They consume little electricity, so they need two or three finger batteries to work. On them, they can work for 15-25 hours (depending on the number of simultaneously working beams).

More expensive professional models can be battery-powered (INSTRUMAX GREENLINER 2V for $135 and INSTRUMAX CONSTRUCTOR 360 4V for $145). They cost a lot more, and the choice of such models is much smaller. By the way, there are models that can work from a charger (INSTRUMAX 3D RED).

Protection class of the device housing

If you need to choose a laser level for working on the street, you should pay attention to the protection class of the housing. It is denoted as IP and two digits behind it. A level for working outdoors should have IP54 or higher (the numbers can be higher).

This means that the inside of the device is protected from dust, the device is not afraid of rain and high humidity (ADA CUBE PROFESSIONAL EDITION and another model ADA CUBE 3D BASIC EDITION, both for 75$).

To work indoors, you can take IP with much lower indicators, and in general, for indoor work is enough housing with minimal protection from dust – IP20 or so.

Additional parameters and functions

In addition to the main parameters, there are some additional parameters. They simplify the work, so it’s more about usability. After all, additional functions affect the final result only indirectly or partially.

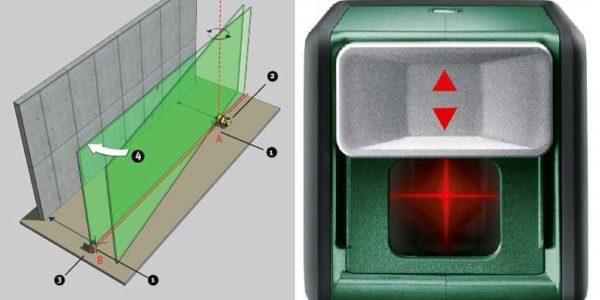

Self-leveling

In order for the measurements to be correct, the leveler must be set vertically upwards. In simple models, their position is checked by simpler devices, usually a bubble level. Some models have it built into the housing, some do not. Then you have to resort to the usual construction level, which is not entirely convenient. In addition, incorrect readings are possible – if during the work it changes position and you do not see it, the work will be done incorrectly. To avoid this situation, you have to recheck the position of the device several times.

Some laser levels have a self-leveling or self-leveling function. If you deviate from the vertical by a small angle (usually up to 4°), they adjust the position of the mirrors and prisms so that all readings are correct. If the tilt exceeds the maximum allowable tilt, they either sound/beep a light signal or turn the beams off. Operation is restored when they return to normal.

Having a laser level with this function, it is easy to set the device at the very beginning of the work. Also during its use, you can not worry about the fact that it has changed position – it will give a signal.

However, sometimes the level needs to be set at a certain angle. The presence of the self-leveling function will not allow you to do this. Therefore, it is desirable to purchase a model in which this function can be blocked.

Self-Leveling

This function allows you to save battery power. If the device does not move for 10-15 minutes, it turns off. On the one hand this is useful, but on the other hand, some jobs require more than 15 minutes and self-shutoff can be unnerving. Whether or not you need this feature is up to you.

Temperature mode of operation

If you plan to work in the warm season or only indoors, the temperature mode does not matter. Basically, the laser level can be operated at temperatures from +5°C to +40°C, i.e. they are suitable only for heated rooms or work in the warm season.

If you need to choose a laser level for working outdoors with the possibility of operation in the cold season, there are “frost-resistant” models that can withstand temperatures as low as -10°C. Even more resistant to frost you need to look specifically, there are very few of them.

Mounting type

In addition to the standard installation of the laser level on a horizontal plane, there can be several additional options for its mounting:

With these options everything is clear. You can, of course, do without them, come up with some of your own ways. These are just options for more comfortable operation.

What else you should pay attention to is how close you can install the leveler to the vertical plane. The closer to the wall the beam can be placed, the easier it is to level the wall surface, make markings for niches in the wall, etc. It depends on the design of the housing – the slots for the exit of beams should be either on a par with the edge of the housing, or even slightly outside it.

Shockproof housing and the possibility of self-adjustment (adjustment)

It is very useful if the laser level has a shockproof housing. Construction or repair is a high-risk zone for any tool, so it often falls. If the housing is shockproof, there is a good chance that even after a fall it will survive.

If dropped or transported carelessly, the leveler’s settings can become misaligned and it may start to lie. To eliminate this “phenomenon” in some devices provides the possibility of self-adjustment. For which it will be necessary to carry out certain manipulations described in the instructions.

Manufacturers and models

A good laser level – then not only suitable characteristics and a set of functions. It is also important the quality of performance, and this depends on the manufacturer. So, along with the characteristics, you will have to choose the brand. If you have a power tool of some company and it suits you, you can look for a leveler of the same company. If not, you will have to trust the general consensus.

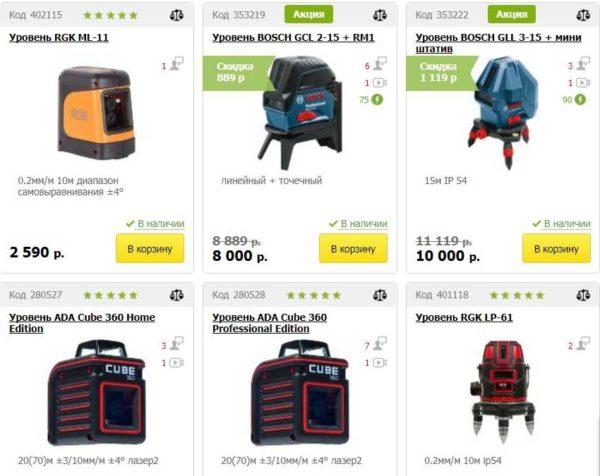

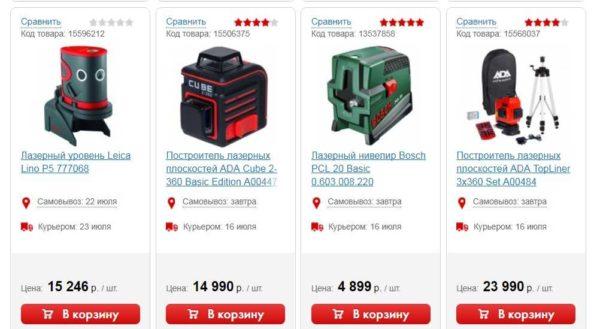

It is believed that good laser levelers (line and plane planners) are from Bosh (Bosch), they have household class devices (in green case), there are professional (in blue case), in each class there are several dozen models with different capabilities and prices.

Stably good reviews collect Makita (Makita). Models are also a considerable number, the quality is stable. Approximately in the same price category work INSTRUMAX and ADA, which also have many successful models of different types. Of the more budget brands are called Skill (Skill), Robotoolz (Robotoolz), Zubr, RGK.

Parameters for choosing a leveler for construction/repairs

If you are planning a full-scale repair or starting a construction project, the optimal set of characteristics for selecting a laser level is as follows:

- Two planes – vertical and horizontal with the ability to include them separately.

- Zenith, nadir and plumb.

- The angle of sweep of the planes – about 120-140 °, you can get a full 360 ° by turning it several times.

- Self-alignment with position change signaling.

- Possibility to lock self-alignment.

- Bright beam with a range of at least 10-15 meters.

You may still need a receiver, respectively, the leveler should work with it.

These conditions are satisfied by the following devices:

- Bosch GLL 2-40 – $170GLL

- Infiniter CL2 – $200

- 2 Professional – $200

- Geo-Fennel 40 pocket 2 – $220

- GTL 3 Professional – $220

- RED 2D Condtrol – $250

- Condtrol Laser 3D – $250

- Condtrol XLiner Combo – $280

- Bosch GLL 2-50 – $270

- X-Line Master 4D – $285

These are only a fraction of suitable laser levels. As additional selection markers you can add the method of fixation (magnets, for example), the presence of a case or tripod in the basic set. Or those additional features that you find convenient.