One of the most common ways of installing electrical wiring is concealed. This is when wires and cables are laid in grooves made in the wall or floor. The process of making grooves is called shtrobing, and simi grooves – “shtroba” or “shraba”. How to do the correct way to do the walls under the wiring, according to what rules, what tool to use, and we will talk further.

A cikk tartalma

Rules of gutting

Laying wiring in the grommet refers to a closed method of installation. The remaining hole is then sealed flush with the wall, after which finishing materials are applied. That is, it is then difficult to determine where exactly the wiring runs. From the point of view of aesthetics it is good, but from a practical point of view carries obvious inconvenience: when working associated with drilling holes in the walls have to take into account that somewhere there is a wiring. You can find it with the help of special wiring detectors, but the wiring itself should be predictable. For this purpose, a number of rules have been developed, which must be adhered to in apartments and houses:

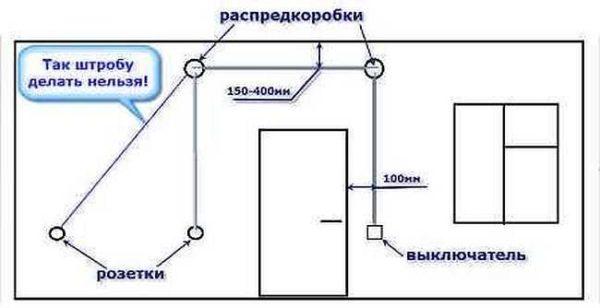

- Strobes are only made vertically and horizontally. Inclined lines are possible only when laying in visits with sloping walls – in attics, attics, staircases. In this case, the grooves are made parallel to the sloping surface.

- From utilities – gas pipes and heating pipes – grooves for laying wiring should be at a distance of at least 50 cm.

- When laying a groove under the ceiling from the corner down 15-20 cm. If it is necessary to lay another branch when modernizing the wiring, it is also lowered by 15-20 cm.

- From corners and openings (window and door) should be indented at least 10 cm.

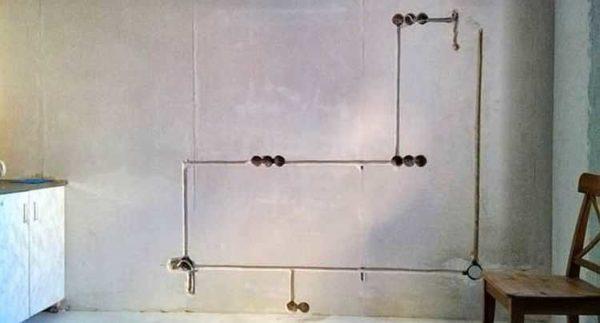

- The depth and width of the grommet depends on the dimensions of the mounted wiring, but usually enough up to 20 mm. The maximum allowed is 25*25 mm. This depth may not be enough if the wire is laid in a corrugated sleeve or metal tray. In this case, the groove can be slightly deepened. But if there will be a layer of plaster on top, you can not deepen it – a few millimeters will be easily covered.

- If there is a metal frame in the wall, it can not be cut categorically. We are usually talking about reinforced concrete structures. In them, the skeleton is a steel wire, which is located at a depth of 4-5 cm. So 2 cm is normal, but even when laying cables with a large diameter, you can not violate the metal

- If the wall has a large enough layer of plaster, the wires can be laid in the thickness of the mortar. This is easier than making a groove in the base material.

- When leading to a socket or switch, the depth of the groove can be slightly increased – so that the wire goes well into the mounting box. But even in this case, the metal frame must not be disturbed.

These are the general rules that relate to hollowing out the walls for wiring.

The tool for drilling and techniques of execution

There is a grandfatherly method – a chisel and a hammer, which does not require electricity, but takes a lot of time and effort. By striking the chisel, its tip is driven into the wall, unscrewing some of the material. Then the process is repeated many times. The speed of laying grooves in this way is very low. It can be used more or less successfully in plastering. With any other materials there will be big problems.

Faster work will go faster with power tools:

- The optimal option is a strobing cutter. This is a special tool with two saw disks, setting which set the parameters of the groove. That is, in one pass you get two parallel lines in the wall. Between them remains a certain amount of material, but it is then quite easily knocked out with a perforator with a special nozzle – a spatula. The advantage of working with shtroborezom – an even groove, the absence of dust, as it is possible to connect an industrial vacuum cleaner. The disadvantage – the equipment is very expensive, so for one-time work it is not worth buying. Exit – to rent in a specialized store.

- Manual circular saw, angle grinder (UShM) or Bulgarian. It is possible to make cuts in the wall with this tool, but it is very dangerous to work with it on a concrete or brick wall. Any inhomogeneity of the cut material – stone, metal, voids – can lead to the fact that the tool will snap. There is a very high probability of serious injury. When working with wooden surfaces, it is better to use a hand-held circular saw.

- Perforator. This tool is usually used at the final stage – between the two laid worms material is removed or chisel, or perforator with a spatula. It is possible, of course, immediately along the intended line to break off pieces of the wall, but the groove will turn out crooked. If you are not afraid of this, you can work like this.

- Drill. This is not the best way, but it is better than gouging manually with a chisel. Along the intended line, drill a number of holes of large diameter not far from each other. Great depth is not required here – no more than 20 mm, so it does not take much time. The resulting chain of holes with the help of a perforator or chisel and hammer turn into a groove.

These are all the methods that are used for screeding walls for wiring in concrete or brick walls. When it is necessary to make grooves in wood or foam concrete, there are certain differences.

What to make grooves in wood

In principle, you can work with all the tools described above, except for the perforator. The main difference is that instead of a chisel, chisels are used, but the essence of the work remains the same. First, two parallel cuts are made, and the wood between them is removed with a chisel. But in addition to these tools there are a few more specific ones:

So there are more possibilities for woodcutting in wood. In this case, if there is one of these tools, it is better to work with it – they are designed for wood and are the most convenient.

How to make grooves for wiring in aerated concrete

When laying walls of aerated concrete or foam concrete, they have to be reinforced. The reinforcement is placed in the cut grooves – shtrobes. For this purpose, there is a special shtrobroez for aerated concrete. It is a metal tube with a handle and a protrusion at the other end.

The process is very simple – you need to pull the tool, pressing it against the surface. Foam and aerated concrete is easy to process, so there are no difficulties. It is possible, of course, to use a circular saw or UShM, but the dust will be many times more, which is not happy in the room.

Grouting of brick walls

If it is a question of laying wiring in the house, where finishing work has not yet been carried out, then usually on brick walls shtroba is not made. On top of the wall fix a flat cable with cores of the desired cross-section, which is then closed with plaster. Usually it has a thickness of at least 3 cm, which is more than enough for laying cables 3*2,5 or 3*4. Larger ones are rarely used anyway.

If for some reason you are not satisfied with this option, or want to lay cables in corrugated hose, the hollowing of walls for wiring is done in the same way and with the same tools as for concrete. The only difference is that the brick is cut easier and faster.

Whether it is possible to cut through load-bearing walls

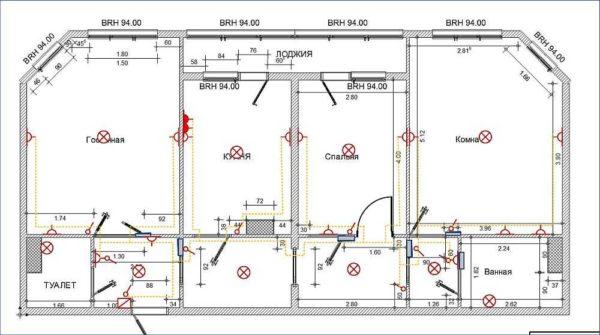

Ideally, when repairing the electrical wiring in the apartment, it is necessary to order a project. In its development, it takes into account the presence and location of load-bearing walls, and the possibility of laying in them punches. As a result, a plan is issued, on which it is precisely indicated where and what should be laid, what width and depth each groove should be. It remains only to fulfill everything exactly.

If you are worried about not damaging the load-bearing walls during the work, submit a request for permission to the MC. They should raise the documents and see how great the safety margin in your house. Most likely, they will give permission.

But so few people do. Mostly draw a plan (if they draw), then it is transferred to the walls, and begin work. If the drilling of walls for wiring is carried out in this order, in the load-bearing walls do not make grooves more than 20 mm depth and width and just hope that nothing will not damage.

Shtrobrovlenie walls for wiring: order and safety precautions

Since the laying of wiring should be carried out according to certain rules (described above), then first it is worth drawing a plan, think about the placement of all outlets, switches. It is desirable to draw the plan in scale, you can do it in special programs for drawing schemes, and you can – on paper. Then the walls are transferred to the points where sockets, switches, chandeliers, chandeliers, sconces, junction boxes are installed. After that, they are connected in a single system of lines, on which then lay the grooves. After that, with the help of a wiring detector check whether there is no under the laid traces of already existing wiring (if you do the repair), if necessary, make adjustments. Only after this actually begins the actual drilling of the walls for wiring.

First, you can use a drill and a special attachment – a crown of suitable diameter – to drill holes for the installation of subrozektriki and mounting boxes. Then you can start drilling.

But it is worth remembering that to make grooves for wiring in walls made of brick, concrete, wood – a dusty and noisy business. Therefore, you should work in the hours allotted for noisy work – in the daytime, on weekdays, with a break for lunch – small children can rest.

Before starting work in a particular room, it is desirable to cover the entrance with a wet cloth – less dust will fly. It is necessary to work in a respirator and goggles, or better – put on a protective shield that will cover the whole face (but do not give up the respirator). It is also worth putting on tight clothes that cover your hands and feet – when working, particles of wall material fly off, and the smallest ones are quite tangible split the skin, and the eyes can be seriously damaged.

These are the basic rules of safety when drilling walls for wiring, but you should not forget about the rules of working with power tools, especially such as a power tool and a hand-held circular saw.

One more tip: after you have laid out the wiring, carefully measure all the distances and put them on the plan. This will come in handy during repairs or if you need to nail/hang something where the wiring may run.

Cutting through walls for wiring can be tricky, but it’s totally doable! I once tackled this when rewiring my living room. Just remember to check for pipes and wires first. A good drywall saw makes it a breeze, and it’s super satisfying when everything lights up perfectly!