To survive the summer heat and stuffiness helps climatic equipment and in particular split systems, which by habit are called air conditioners. Technique is not cheap, but the worst thing is that for its installation it is necessary to pay an amount a little less than for the equipment. That is why many people think about independent installation. Installation of air conditioner with your own hands is possible, but there are a lot of little things and peculiarities, ignorance of which leads to rapid wear of the equipment. Detailed step-by-step instructions will help you to do everything correctly.

A cikk tartalma

Choice of place

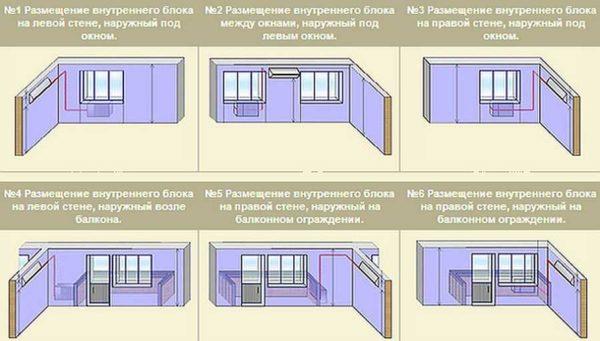

Installing an air conditioner with your own hands begins with determining the location of the equipment. Since split systems consist of two or more units, you will have to choose a place for both of them. It is necessary to take into account how the cold air will be distributed in the house or apartment, as well as to take into account the technical requirements.

Let’s start with the technical requirements. When choosing the location of the indoor unit, we take into account the following requirements:

- from the unit to the ceiling – at least 15 cm (some manufacturers have at least 20-30 cm);

- to the wall on the side – at least 30 cm;

- to the obstacle, against which the cold air flow will be broken – not less than 150 cm.

The outdoor unit is usually placed near a window or on an open balcony, if there is one. On a glazed balcony / loggia it is possible to install it on the fence (if it has sufficient bearing capacity) or next to it on the wall. If you live on the first or second floor of a multi-storey building, the outdoor unit try to put above the level of the window – away from passers-by. On higher floors can be located under the window or on the side.

If the installation of air conditioner with your own hands is planned in a private house, the place is usually chosen based on the load-bearing capacity of the walls. If there is a ventilated facade, you can apply a special fastener or hang the unit on the basement, if there is one.

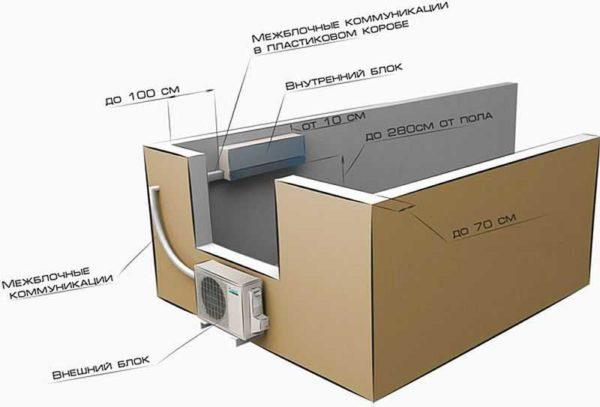

When choosing the location of split-system units, it is also necessary to remember that in most cases the minimum and maximum distance between the units is standardized. Specific figures depend on the manufacturer. For example, the minimum distance can be 1,5 m, 2,5 m (different models of Daikin) and even 3 meters (Panasonic). In some manufacturers, the minimum length is not regulated, that is, it can be any. In this case you can install the units “back to back”. Installers call this way of installation “sandwich”.

The situation with the maximum distance between two units is a bit simpler. It is usually 6 meters. It can be more, but then it will require additional refilling of the system with freon, and this is an additional expense, and not a small one. Therefore, try to invest in the required 6 meters.

What you need for self-installation

You probably know how much it costs to install an air conditioner by specialists. When you ask where such prices come from, because the work is only for 3 hours, they answer that the equipment is very expensive and its amortization is a significant part of the cost. It may be true, but most of this equipment may already be in the household. The exception is a vacuum pump, but many crews do without it, since it costs a normal one really a lot, and the bad one is of no use.

Berendezések

So, to install the air conditioner with your own hands, you will need the following equipment:

For an ideal installation, a vacuum pump is needed, but usually there is nowhere to take it and on routes up to 6 meters do without it.

Materials

To connect and install two split-system units, the following consumables will be needed:

- Cable for power connection and for connecting the blocks. Cable brand and parameters depend on manufacturers and are usually indicated in the passport in the installation manual. Usually it is a 4-core cable with a cross-section of 2 mm2 or 2.5 mm2. The cable length is equal to the length of the route with a small reserve.

- Copper thick-walled seamless pipes (not water pipes, but special ones for cooling and air conditioning systems). Pipes will be required in two diameters – larger and smaller. Specific figures will be specified in the manual, the length of each section is equal to the length of the route plus 20-30 cm to spare. Once again, please note that copper pipes are not plumbing pipes, but for the refrigeration industry. They have a different copper – softer, which is well flared and can provide the required tightness. Copper tubes should be transported and stored with the edges plugged to avoid dust getting into them.

Copper pipes need special, thick-walled, seamless copper pipes made of soft copper - Insulation for pipes made of technical rubber. There are dark gray or black color. Color does not affect the quality, it is supplied in sections of two meters. The required length is equal to the length of the route. You need insulation for both pipe diameters – larger and smaller.

- Drainage tube. Specialists advise putting a special corrugated hose with a plastic spiral inside. When installing it independently, it is often replaced by a polypropylene pipe. The length of the drainage tube is the length of the route plus 80 cm.

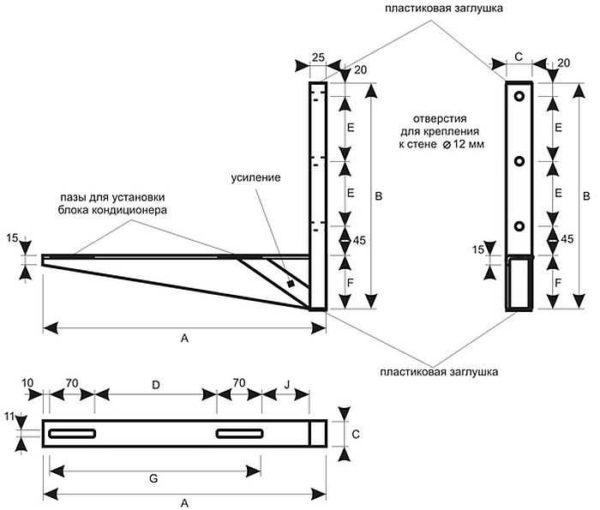

- Two L-shaped brackets for mounting the outdoor unit. Their size should correspond to the dimensions of the block, and the load-bearing capacity should exceed its mass in 4-5 times. This reserve is necessary to compensate for wind and snow loads. It is desirable to buy them in firms selling components for air conditioners. Ordinary brackets can be unreliable.

Brackets for air conditioners must withstand a heavy load – 3-4 times the weight of the outdoor unit - Bolts, anchors, dowels. Type, size and quantity depend on the type of brackets and mounting plate for the indoor unit, as well as on the type of walls on which the air conditioner is mounted.

- Plastic box 60*80 cm – to be able to cover the laid communications.

This is all that is necessary to install the air conditioner with your own hands.

Installation procedure and peculiarities of works

There is nothing super-complicated in independent installation of split-system, but there are a lot of nuances that can affect the durability and quality of work of the equipment. First of all, before starting works it is necessary to read carefully the instruction on installation and operation, which comes with the equipment. The time spent will be compensated by the fact that you will know exactly what and how to do exactly with your air conditioner, because there are some nuances.

Beginning – mounting the units

Before starting all the work, it is worth looking for hidden wiring or heating pipes in the proposed place of installation. It is not fun to get into them while working. Next comes the actual installation of the air conditioner with your own hands. It is necessary to start with installation of the internal block. At the chosen place we place a plate for its fastening. The unit should hang strictly horizontally without the slightest deviations. Therefore, the marking and fastening approach carefully.

Apply the plate, set it on a level, mark the places for fasteners. Drill holes, insert plastic plugs for dowels, hang the plate and fasten with dowels. Especially carefully fix the lower part of the plate – here are the latches that hold the block, so they must be rigidly fixed. No backlash. Then once again check the horizontality.

Having figured out where the route will be located (it should be inclined not less than 1 cm per meter – for normal laying of drainage), we start drilling a hole in the outer wall. The hole is also drilled with a slope – again, to normally go condensate (the angle can be greater than the route).

The minimum diameter of the hole is 5 cm. If you do not have a drill of this size, you can make a few holes of smaller diameter, to lead out not a common bundle of communications, but separately each tube / cable. In any case, it is better to drill two holes – one for copper and electric cable, the second – for the drainage pipe. It should be laid lower than the others – so that it does not drip on the communications in an emergency situation.

Then install the brackets for the outdoor unit. If it is a multi-storey building, you will need climbing equipment and skills to work at height. This unit must also hang strictly horizontal, so when marking the holes also use a level. When installing the brackets, the fasteners are installed in each hole, no matter how many there are – this is a must. Standard fasteners are anchors 10*100 mm. More is possible, less is highly undesirable.

After the brackets are fixed, the outdoor unit is put up. We fix the unit also in all the fasteners that are available. Only in this way you can guarantee that it will stand in place under any conditions.

Laying of communications

Two blocks are connected by an electric wire, two copper pipes. Also, a drainage pipe is led through the wall. All these communications must be properly selected, connected, laid and secured.

Copper pipes

We start with copper pipes. One of larger diameter, the other of smaller diameter. The sizes are specified in the air conditioner manual. Cut a piece of the required length with a pipe cutter, process the edges from burrs with a special tool, straightening and leveling the cut. It is undesirable to use an ordinary saw, as well as a file to remove burrs – there will be sawdust inside the pipe, which will get into the system and quickly destroy the compressor.

On the prepared pipes put on heat-insulating tubes. And the insulation should be solid and pass inside the wall including. The joints of pieces of insulation must be glued with metallized tape, achieving a very tight fit edges. The quality of thermal insulation is important, because condensation will form on the uninsulated parts of the tubes, and it can run down inside the wall, causing frozen sweat, destroying the wall.

The copper tubes wrapped in thermal insulation should be led through the hole in the wall. Before doing so, be sure to carefully seal the edge, which will be introduced into the wall, so that dust does not get inside the pipe (and it is better to plug securely both ends immediately after cutting and leave the plugs until the start of connection). This is a very important point, as dust will quickly put the compressor out of operation.

Cable and drainage

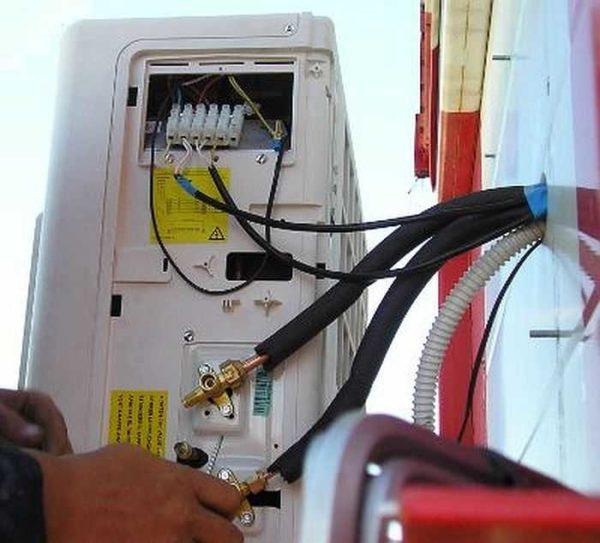

The case is simpler with an electric cable. Each wire is terminated with special lugs, installing them on the conductors cleaned of insulation and crimping with pliers. Prepared cable is connected according to the scheme, which is in the instructions.

On the indoor and outdoor unit above the ports for connecting copper pipes there is a removable plate, under which there are connectors for connecting the cable. Before you start self-installation of split system, remove the plates, consider what and where to connect – it will be easier to work later. Especially with the external unit.

Connection of the drainage tube is simple: it is connected to the appropriate terminal on the indoor unit and led through the wall. The length of this tube should be such that it ends at a distance of 60-80 cm from the wall. The laying of the drainage pipe should be made with a slope towards the exit to the street. The slope is not less than 1 cm per meter of length. More is possible, less is not.

The pipe must be fixed every meter so that there are no sags in it. Condensation accumulates in them, which can end up on your floor or furniture. When you run the pipe through a hole in the wall, it is also better to plug it with something.

Indoors, pipes and cables are usually wrapped with metallized tape in a single bundle. Then fixed to the wall in several places, over the top of the plastic box is fixed. Usually it is taken white or suitable for the finish color.

If you want, you can hide all the pipes in the wall – punch out the route in the wall, put there and after checking the performance of bricked up. But this is quite a risky option, as to repair something you will need to dismantle the wall.

Connecting blocks

Here, in general, there are no special secrets. Pulled through the hole in the wall communications, connect to the appropriate connectors. With the connection of the cable there are no problems – to the terminals you connect the wires of the same color that are already connected to them. In this case you will definitely not make a mistake.

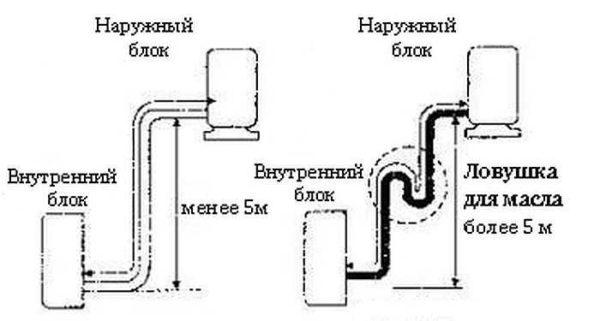

If the height difference in the installation of blocks exceeds 5 meters, it is necessary to make a loop to catch oil (we lay copper pipes in this way), dissolved in freon. If the difference in height is lower, no loops are made.

Drainage

There are two ways to drain the drainage from the split system – into the sewer system or just to the street, outside the window. The second way is more common, although it is not very correct.

Connection of the drainage pipe is also not complicated. On the drainage outlet of the indoor unit (a tube with a plastic tip at the bottom of the unit) is easily stretched corrugated hose. To keep it securely, you can tighten the connection with a clamp.

The same is the case with the drainage from the outdoor unit. Its outlet is at the bottom. Often leave everything as it is, and the water just drips down, but it is better, perhaps, also put on a drainage hose and drain the moisture away from the walls.

If a polymer pipe rather than a hose is used, it will be necessary to find an adapter to connect the air conditioner outlet and the pipe. You will have to look on the spot, because there are different situations.

When laying the drainage tube, it is better to avoid sharp turns and certainly not to allow sagging – condensate will accumulate in these places, which is not good at all. As has been said many times, the pipe is laid out with a slope. Optimal – 3 mm per 1 meter, the minimum – 1 mm per meter. Throughout it is fixed to the wall, at least every meter.

Freon circulation system

It is somewhat more complicated with the connection of copper tubes. They are carefully, without allowing kinks and creases are laid out on the walls. For bending, it is better to use a pipe bender, but you can do without a spring. In this case, too, sharp turns should be avoided, but in order not to bend the tubes.

First connect the tubes to the indoor unit. On it, we loosen the nuts on the ports. As you loosen the nuts, you’ll hear a hissing sound. That’s the nitrogen coming out. This is normal – nitrogen is pumped in at the factory to prevent oxidation of the insides. When the hissing stops, we remove the plugs, remove the nut, put it on the tube, and then start rolling.

Rolling

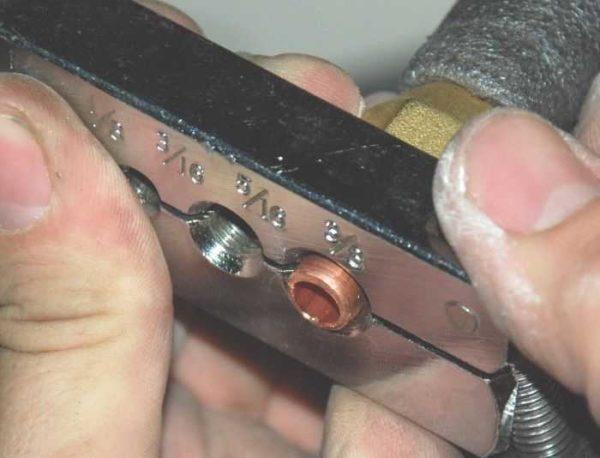

First, remove the plugs from the tubes and check the edge. It should be smooth, round, without burrs. If the cross section has become out of round when cutting, use a calibrator. This is a small device that can be found in any store. It is inserted into the tube, scrolled, equalizing the cross-section.

The edges of the tubes for 5 cm are carefully aligned, then the edges are flattened to be able to connect to the inlet / outlet of the blocks, creating a closed system. Correctness of this part of installation is very important, because the system of freon circulation should be airtight. Then the air conditioner will not need to be refilled for a long time.

When flattening, hold the pipe with the hole facing downward. Again, so that copper particles do not get inside, but spill out on the floor. In the holder it is clamped so that 2 mm stick out. Exactly like that, no more, no less. We clamp the tube, put the reaming cone, screw it in, applying considerable force (the tube is thick-walled). The reaming is finished when the cone does not go any further. Repeat the operation on the other side, then with another tube.

If you have not rolled pipes before, it is better to practice on unnecessary pieces. The edge should be even, with a clear, continuous border.

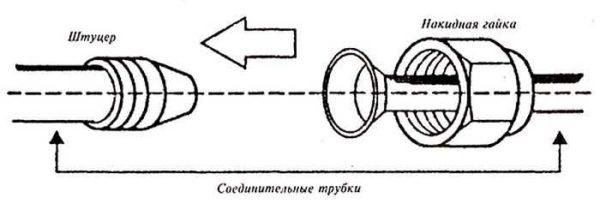

Connection to the port

The flared edge of the pipe is connected to the corresponding outlet, screw on the nut. No additional gaskets, sealants and the like should be used (prohibited). Special tubes made of high quality copper are taken for the same reason, so that they provide sealing without additional means.

It is necessary to apply serious force – about 60-70 kg. Only in this case the copper will be flattened, the connection will become almost monolithic and precisely hermetic.

The same operation is repeated with all four outlets.

Vacuuming – what for and how to do it

The last stage, which ends the installation of the air conditioner with their own hands is the removal of air and moisture, argon residues from the system. During installation, moist air from the room or from the street fills the copper tubes. If it is not removed, it will get into the system. As a result, the compressor will work with a greater load, will heat up more.

The presence of moisture also negatively affects the performance of the system. The matter is that freon, which is used for air conditioners, contains some amount of oil for lubrication of elements from inside. This oil is hygroscopic, but being saturated with water, it lubricates insides less effectively, and it leads to their premature wear.

It follows from all this that without removing air the system will work, but not for a very long time and with possible shutdown on overheating (if there is such automation).

You can remove air from the system in two ways: with the help of a vacuum pump or a certain amount of Freon released from the outdoor unit (it is filled at the factory and has some excess Freon – just in case).

The “blow-off” method

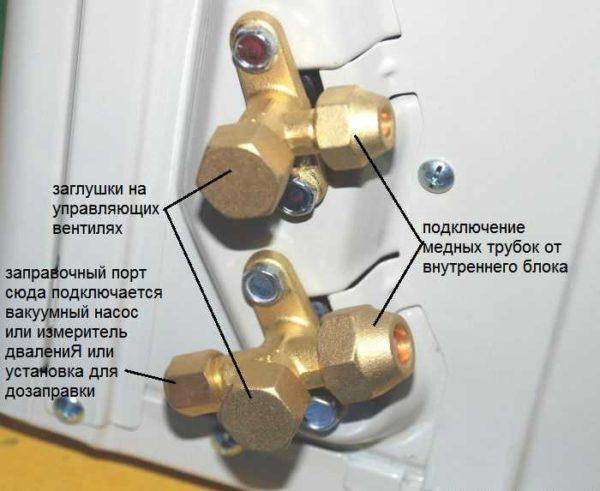

On the ports of the outdoor unit unscrew the valve caps (they are marked with arrows on the photo).

Operations will be carried out with the lower port (larger diameter), which sticks out perpendicular to the body. Under the cover there is a hexagon socket, select a wrench suitable in size.

Next, with this wrench, turn the valve 90° for one second and return it to its original position. We have let some freon into the system, there is an overpressure. We press with our finger on the spool, which is located on the same port. This releases the mixture of freon and gases in the system. We press it literally for seconds. Part of the mixture must remain, so as not to launch a new portion of air inside.

Repeat 2-3 times, no more, the second time you can turn the valve located above. If the route is 2-3 meters – you can 3 times, if the length of 4 meters – only two. There will not be enough freon reserves for more.

When the air is almost removed, on the outlet with a spool (filling) screw on the plug, control valves (under the hexagon) open fully, starting freon in the system. All joints are lubricated with soap foam to make sure they are tight. It is ready to start.

Vacuum pump

This operation requires a vacuum pump, a high-pressure tube, a group of two pressure gauges – high and low pressure.

Without opening the valves on the control valves, to the inlet with the spool connect the hose from the vacuum pump, turn on the equipment. It should work for 15-30 minutes. During this time all air, vapors, nitrogen residues are extracted.

Then the pump is switched off, the pump valve is closed but not disconnected and left for another 15-20 minutes. All this time it is necessary to observe the readings of pressure gauges. If the system is tight, there is no pressure change, the pressure gauge arrows are frozen in place. If the arrows change their position – somewhere there is a leak and it must be eliminated. Tighten the connections, usually the problem is at the point where the copper tubing is connected to the unit outlets.

If the leak remains, you can find it with the help of soap foam. To do this, you need to reverse pump air into the system.

If everything is normal, without disconnecting the pump hose, fully open the valve, which is located at the bottom. Inside the system you can hear some sounds – Freon is filling the system. Now, wearing gloves, quickly round off the vacuum pump hose – some ice-cold Freon may escape from the valve, and you don’t want to get frostbite. Now unscrew the valve completely at the top (where the thinner tube is connected).

Why in this order? Because when filling with Freon, the system is pressurized, which quickly locks up the fill port when the pump is disconnected. That’s all, installation of the air conditioner with your own hands is completed, you can turn it on.

For the sake of justice it is necessary to say that such operation – vacuumization – is carried out only in Russia and neighboring countries. In the same Israel, where air conditioners work all year round, they do nothing of the kind. Why, is a question for reflection.